1. Introduction

In recent years, reverse logistics has become a key component of any successful streamlined supply chain. Today’s global value chains require greater resilience and efficiencies in the flow of goods between and within countries. Sustainability in the supply chain has become a strategic intent for almost all businesses, and reverse logistics practice is key to the effort. In maximizing the value recovery and safe disposal of waste, reverse logistics expands products at the end of their life cycles through some activities such as resell, refurbish, remanufacture, and recycle, to name a few [

1]. Besides optimizing value and sustainability for businesses, the reverse logistics issue that directly impacts supply chains the most is to manage the return of products from the end consumer back to the manufacturer. With online shopping becoming increasingly prevalent, the reverse loop has never been so prominent in global supply chains. In an e-commerce-focused era in which customers are returning products at an increasing rate in various industry sectors, e-merchants and other retailers are at a critical juncture, as any continued lack of focus on reverse logistics will be unsustainable. Online purchases are being returned three times more often than store purchases [

2]. This statistic means reverse logistics supply chain management has become a necessity for online merchants to maintain a balanced inventory turn and operating expenses. Additionally, the unprecedented crisis by the Covid-19 pandemic has brought inexorable growth to the e-commerce sector, which is expected to lead to an even higher volume of returned goods. Undoubtedly, this trend will endure in a post-Covid-19 world. Accordingly, reverse logistics has a significant effect on customer relationships and, most significantly, leads to sustainability and long-term profitability of business operations.

Expected to reach 603.9 billion USD by 2025 [

3], reverse logistics, when optimized, can increase customer satisfaction and return on investment (ROI). Simply put, reverse logistics in e-commerce refers to the return process, which is the collection of all activities of goods that move in the reverse direction, i.e., from their point of consumption back to the business. The most critical processes are customer support, physical movement of goods, warehousing, triage, repairs, and after-sales support [

4]. An easy and hassle-free return process can gain customer engagement and loyalty. As a result, functional and efficient reverse logistics has become a pivotal element for e-commerce businesses. However, most companies are not able to manage their reverse logistics networks. Due to the complicated process and resource constraints, more and more businesses choose to outsource third-party companies to handle their reverse e-commerce services and optimize the return process. Third-party reverse logistics providers (3PRLP) are delegated to help companies productively manage returned currents of products at optimal cost. Hence, evaluating and selecting the best 3PRLP is an imperative and complicated task that must be undertaken prudently [

5] for businesses, especially e-commerce merchants and other retailers, to facilitate an effective reverse logistics process and retain customers.

Given the abovementioned importance of reverse logistics outsourcing to the industries, the relevant literature on potential sectors in developing countries is sparse, taking the e-commerce sector in Vietnam as a good example. This gap has formed our research motivation. The current study aims to address this gap by investigating reverse logistics outsourcing practices in Vietnam. According to Google, Vietnam is ranked the second-fastest-growing e-commerce market in Southeast Asia, following Indonesia [

6]. Vietnam’s e-commerce has been growing from about 28 percent in 2017 to nearly half of the population in 2020 [

7]. It is also forecast that the country’s e-commerce market will hit 15 billion USD by 2025 [

8]. While e-commerce giants in Vietnam such as Tiki, Lazada, and Grab have already developed their own logistics sector (warehousing, packing, shipping, and reverse logistics), most other online merchants (including some major players like Shopee and Sendo) are not able to operate an in-house logistics, therefore opt to delegate these activities to third-party logistics providers. Thus, it creates great opportunities and a promising market for e-commerce logistics. According to the 2017 logistics report of the Ministry of Industry and Trade, Vietnam has about 50 enterprises providing e-logistics services [

9]. With the need for fast, immediate, and on-demand delivery from customers who shop online, more and more e-logistics startups have entered this market. Providing the volume of e-commerce transactions increasing, logistics providers have to handle large volumes of returned goods. In Vietnam, wrong shipping addresses (especially in rural areas) and unsuccessful orders are daunting challenges faced by both e-commerce retailers and e-logistics businesses. Moreover, competition in terms of delivery speed and costs are factors that can distinguish the best third-party logistics providers.

Moreover, the literature on outsourcing 3PRLP is still limited because of its recent emergence and demand from stakeholders. This lack, therefore, attracted our attention. In this paper, the authors aim to efficiently assist the decision-makers in evaluating and selecting the most sustainable 3PRLP by proposing a robust hybrid multicriteria decision-making (MCDM) approach. Among MCDM methods, the analytic hierarchy process (AHP) and the technique for order preference by similarity to an ideal solution (TOPSIS) are two classical and most commonly used techniques. Conventional AHP and TOPSIS have been combined in different ways and investigated in many studies. In these methods, the criteria weights are often determined by AHP, and TOPSIS ranks the alternatives. Some exemplary studies are as follows. In the basic combination of the AHP-TOPSIS approach, the evaluations about criteria and alternatives are all supposed to be deterministic numbers [

10]. In the integration of AHP and the fuzzy TOPSIS method applied in [

11], the criteria weights determined by AHP are real numbers, and the evaluations of alternatives with respect to different criteria are in linguistic terms. Meanwhile, linguistic terms are adopted to evaluate criteria, and real numbers are used to assess alternatives in [

12]. As a further improvement to the existing literature of reverse logistics outsourcing in terms of methodologies, this paper combines fuzzy AHP (FAHP) and fuzzy TOPSIS (FTOPSIS), by which linguistic terms in evaluations of both criteria and alternatives are adopted. This adoption’s motive is that experts are often reluctant or unable to assign accurate values during the decision-making process. Thus, they prefer to provide their evaluations in linguistic terms, reflecting their uncertain, ambiguous, and vague judgment. In light of this, fuzzy set theory is a useful method for dealing with uncertainty. The decision model may include unknown, incomplete, and inaccessible information and partially ignorant data. During the whole evaluation process, the linguistic terms are converted into triangular fuzzy numbers.

The research procedure is described as follows. In the first stage, FAHP is applied for determining the fuzzy preference weights of the criteria. The evaluation process’s criteria concern economic factors (quality, cost, lead time, delivery and service, R&D capability), environmental factors (recycle, disposal, reproduction, and reuse, green technology, CO2 emissions), social factors (health and safety, customer’s voice, reputation), and risk factors (operation risk, financial risk). In the next stage, FTOPSIS is used to rank all alternatives, offering the optimized 3PRLPs. An application of selecting 3PRLPS for an e-commerce business in Vietnam is presented, simultaneously demonstrating the suggested method. In doing so, this study makes novel contributions to the field by providing a complete and robust evaluation process for 3PRLP selection in the e-commerce sector for a developing country in Asia which is almost neglected in the literature. As a result, this paper provides a holistic framework for businesses with theoretical and managerial implications as a robust decision support system in solving the reverse logistics outsourcing problem.

The paper unfolds as follows. In the next section, a literature review on reverse logistics outsourcing is reviewed.

Section 3 summarizes the materials and methods of FAHP and FTOPSIS used in the paper. Result analysis of a case study in Vietnam is shown in

Section 4. Finally,

Section 5 offers the managerial insights and conclusions of the paper.

2. Literature Review

Concerning the well-developed status of research on outsourcing 3PRLP, multiple criteria decision-making (MCDM) techniques that simultaneously consider various desired selection criteria in different dimensions have appeared to be promising for this task. Literature and practice show that economic, environmental, and social factors are dominant decision-making variables in selecting a sustainable provider of reverse logistics services [

13,

14,

15]. Sustainable development (economic, environmental, and social aspects) lead organizations to reverse logistics practices (

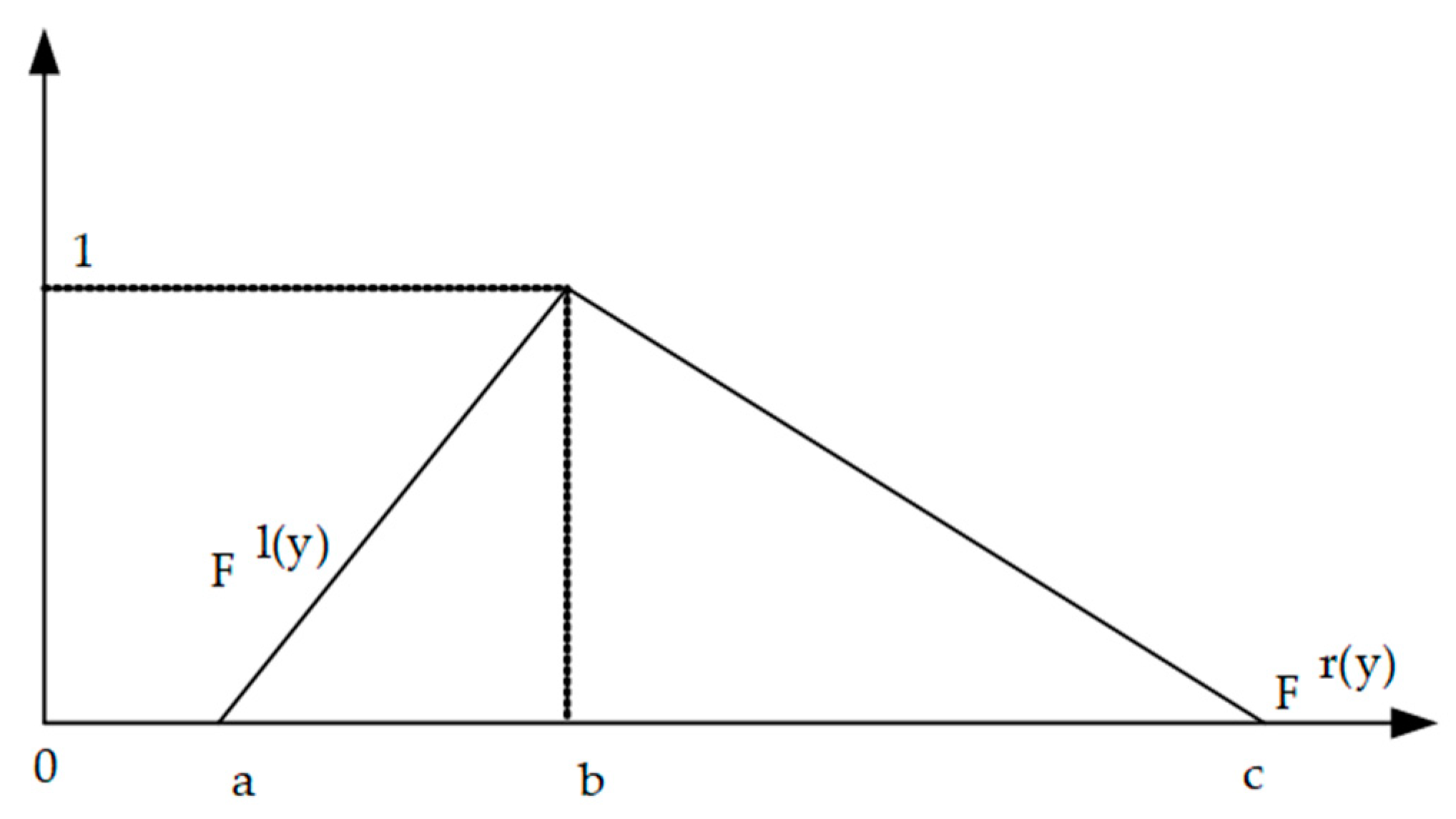

Figure 1) [

16]. To determine a qualified provider in the outsourcing process, the proposed evaluation approach and the set of criteria are two quintessential parts [

17]. Many notable studies have applied various MCDM techniques that consider different criteria to evaluate and select the best 3PRLP. For example, Tavana et al. [

18] proposed an integrated intuitionistic fuzzy AHP and SWOT method for solving the reverse logistics outsourcing problem faced by a company. Their findings indicated that when delegating reverse logistics activities to 3PRLPs, it is the most significant priority for a firm to focus on its core business; meanwhile, reducing costs constitutes one of its least important priorities. In the study of Zarbakhshnia et al. [

5], a multiple attribute decision making (MADM) model to rank and select the sustainable third-party reverse logistics providers in the presence of risk factors was proposed, and a realistic case study in the automotive industry was applied to demonstrate the model’s effectiveness. Bai and Sarkis [

19] first introduced the use of neighborhood rough set, TOPSIS, and VIKOR as a proper and realistic modeling approach for 3PRLPs evaluation and selection using economic/business, environmental, and social (sustainability) factors.

In the management science and decision-making literature, discussing reverse logistics outsourcing issues has become an increasingly important topic. Various criteria and approaches have been considered in the literature. In terms of criteria, businesses traditionally examine cost, quality, and flexibility [

19]. For organizations that seek long-term resilience of reverse supply chains, social and environmental concerns are considered sustainability factors [

20,

21,

22]. Regarding methodologies, numerous evaluation models based on MCDM techniques for outsourcing 3PRLP have been introduced ranging from analytical hierarchy process (AHP) [

23,

24,

25,

26,

27], fuzzy AHP [

28,

29], analytic network process (ANP) [

30,

31,

32], fuzzy ANP [

33], technique for order preference by similarity to ideal solution (TOPSIS) [

19,

27,

34,

35], fuzzy TOPSIS [

36], visekriterijumska optimizacija i kompromisno resenje (VIKOR) method [

19,

31,

33,

37], step-wise weight assessment ratio analysis (SWARA) [

38,

39], quality function deployment (QFD) model [

28,

40], data envelopment analysis (DEA) [

26,

35,

41,

42], other MCDM methods [

30,

31,

32,

33,

34,

38,

39,

43], exact methods (mathematical programming) [

26,

37,

43,

44,

45], and statistical approaches [

40,

46,

47,

48].

Table 1 presents a summary of the literature review on proposed approaches for 3PRLP selection and evaluation problems.

Given several methodologies used in the evaluation and selection of 3PRLPs, it can be observed that AHP and TOPSIS methods are the two typical and most commonly used due to their applicability. The foundation of the AHP is a set of axioms that carefully delimits the scope of the problem environment [

49]. Among mathematical weighting methods, the pairwise comparison method in the AHP is an effective procedure to determine the importance of different attributes to the objective. Its understandability in theory, simplicity in application, and robustness of its outcomes have been proven in practice and validated by a diverse range of decision-making problems. The TOPSIS method, first introduced in [

50], is one of the most well-known classical MCDM methods. Simply stated, in a geometrical sense, the TOPSIS method simultaneously considers the distance to the ideal solution and negative-ideal solution of each alternative and choosing the closest relative to the ideal solution as the best alternative [

27]. In this paper, the authors aim to solve the fuzzy information during the whole evaluation and selection process by considering linguistic terms in both criteria and alternatives, which thereby are converted into triangular fuzzy numbers using the fuzzy set theory. Thus, the gaps in the existing literature are addressed in this paper as follows: (1) methodologically, this is the first study to suggest a hybrid fuzzy decision support system that combines the fuzzy AHP (FAHP) and the fuzzy TOPSIS (FTOPSIS) for the field of reverse logistics outsourcing; (2) in terms of applications, the prescribed approach is used for a case study in Vietnam to support an e-commerce business determining their compatible and sustainable partners for reverse logistics among eight candidates; (3) the managerial implications of this paper provide a comprehensive insight that enables decision analysts to better understand the complete evaluation and selection process of 3PRLPs considering well-rounded aspects. From a broader standpoint, this study can assist e-commerce businesses or any organization to expedite their reverse logistics strategies in this era.

5. Discussion and Conclusions

As online shopping volumes grow, so do return volumes. Product return rates are rising in the e-commerce industry. The cost of doing e-commerce business is facilitating a simple and seamless return processes as part of the increase in customer expectations. This is where reverse logistics comes into its unique role, which is to handle many inevitable situations regarding e-commerce transactions, including deliveries of incorrect products, customer behaviors, damaged products, delays in order fulfillment, to name just a few [

66]. It cannot be failed to mention that reverse logistics systems, in essence, provide businesses with numerous opportunities to integrate the three drivers of sustainable development, such as remanufacturing, repair, recycle, and disposal. There is no question that proficient reverse logistics not only handles the e-commerce returns problem but also enables any business to gain customer retention, reduced costs, and higher achievement of sustainability goals. However, managing reverse logistics in-house means the supply chain of moving goods must be amplified, which leads companies to significant issues. For this reason, more and more e-commerce retailers consider reverse logistics outsourcing as an inevitable part of their business. Thus, the evaluation and selection problem of 3PRLP has never been so prominent in this era.

Methodologically, the authors elaborate that in using the proposed hybrid MCDM approach (combining FAHP and FTOPSIS), this has so far been the first study to fill the gap of the existing literature that lacks 3PRLP evaluation and selection practices for several industries within a developing countries context, and especially to address the increased demand of reverse logistics outsourcing in the e-commerce sector. The use of linguistic expressions for the whole evaluation process will mitigate the risk of fuzzy and uncertain judgment when weighing criteria, as well as improving the robustness of the ranking results and the overall computation efficiency. Proper transformations of linguistic terms also ensures that the approach has a broad range of applications.

E-commerce has been on the rise in Vietnam. By 2025, e-commerce purchases are projected to be used by over 70 percent of the 100 million population. Regarding the e-commerce logistics sector, it has contributed to approximately 20–25% of the GDP of Vietnam, according to Vietnam Logistics Business Association [

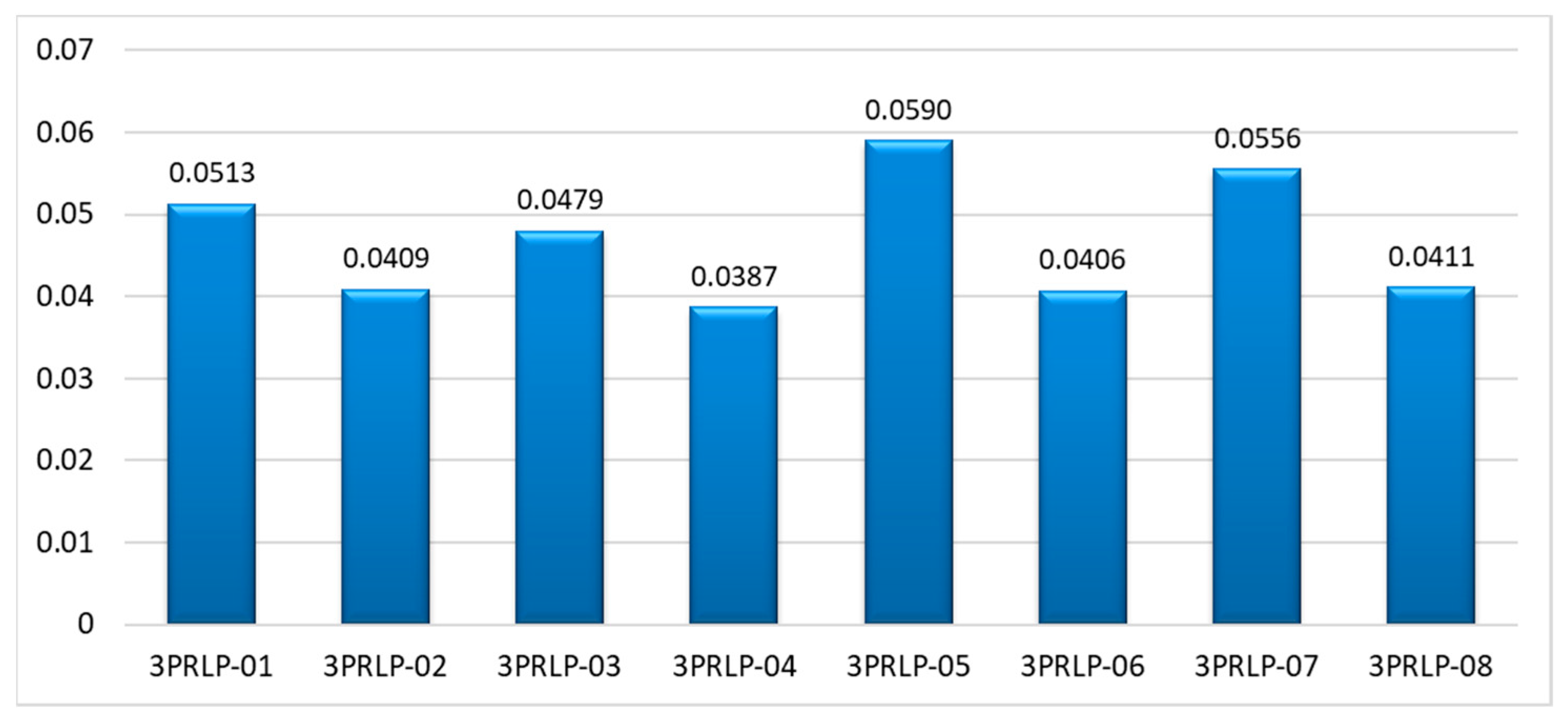

67]. This industry is also predicted to grow by roughly 12 percent every year. Thus, more and more logistics companies and investors are flooding into this untapped potential market. On the other hand, the dilemma of outsourcing logistics services and the decision to select a provider based on quality management and financial performance criteria are sure to be a headache facing e-commerce retailers. Within this context, our paper aims to provide significant insights for online merchants on the methods of evaluation and selection of 3PRLP. In doing so, the proposed approach is applied to illustrate a case study of the reverse logistics outsourcing problem in Vietnam. From the FAHP stage, results show that “lead time,” “cost,” “delivery and service,” and “quality” (economic factors) and “customer’s voice” (social factor) are the most impactful criteria according to expert evaluation. Environmental drivers such as “reproduction and reuse” and “green technology” were also ranked high, indicating the other aspect from the three pillars of sustainable development were noteworthy in reverse logistics outsourcing of e-commerce in Vietnam. In the next stage, FTOPSIS indicates that 3PRLP-05 was the optimized partner with the final ranking score of 0.059. For practical implications, these findings can help e-commerce businesses or any firms to gain a better understanding of the 3PRLP selection process. Thus, the companies can devise their strategies accordingly to better control their reverse logistics activities.

For future studies involving qualitative and quantitative criteria, new factors concerning today’s situation (i.e., post-Covid-19 world) should be upgraded to obtain well-rounded results. Regarding theoretical limitations, this paper calculated the consistency ratio using lower bound (pessimistic value) and upper bound (optimistic value) values of the fuzzy comparison matrix, hence, future studies should approach the procedure of defuzzification according to the derivate fuzzy AHP [

68]. Moreover, future studies should target other MCDM techniques (i.e., VIKOR, PROMETHEE II) for ranking alternatives and compare the results using ranking similarity reference coefficients [

69], and/or combine with the exact methods [

70]. In terms of applications, further studies might therefore investigate reverse logistics outsourcing practices in other countries than Vietnam to improve the findings’ external validity. Moreover, the procedure and criteria presented in this paper can also be considered in other related industries, such as supplier selection or any decision-making problems.