CERES Gimbal Performance on Terra

Abstract

:1. Introduction

1.1. Instrument and Gimbal Background

1.2. Space Lubricant

2. Materials and Methods

2.1. Lubricant Loss

- : vapor pressure

- : enthalpy of vaporization

- : universal gas constant

- : temperature

- : vapor pressure (torr)

- : weight loss (g)

- : temperature (K)

- : area of the orifice (cm2)

- : time (s)

- : Clausing factor

- : molecular weight (g/mol)

- : mass loss (gs−1)

- : fluid vapor pressure (torr)

- : diameter of annular seal (mm)

- : molecular weight (g/mol)

- : temperature (K)

- L: path length (mm)

- : gap width (mm)

2.2. Torque

- = Digital to Analog scale factor; V/count

- = controller forward gain; V/V

- = driver current closed loop gain; amp/V

- = motor torque constant; in-oz/amp

- = steady-state gain; in-oz/count

3. Results

3.1. Lubricant Loss

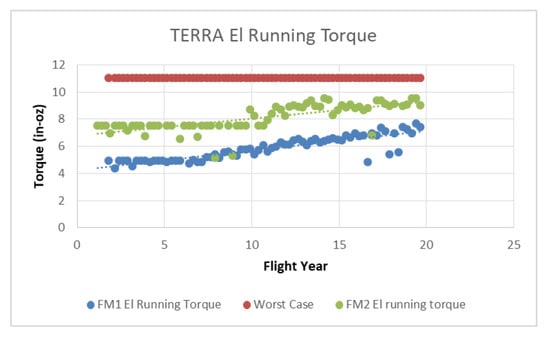

3.2. Torque

4. Discussion and Conclusions

Funding

Conflicts of Interest

References

- Gardos, M.N. Labyrinth sealing of aerospace mechanisms. ASLE Trans. 1974, 17, 237–250. [Google Scholar] [CrossRef]

- Salmon, W.A.; Apt, C.M. A lubrication system for space vehicles. SAE Trans. 1964, 72, 79–86. [Google Scholar]

- Krishnan, S.; Lee, S.H.; Hsu, H.Y.; Konchady, G. Lubrication of attitude control systems. In Advances in Spacecraft Technologies; InTech: Rijeka, Croatia, 2011; pp. 75–98. [Google Scholar]

- Fusaro, R.L. Lubrication of Space Systems. Available online: https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19970003296.pdf (accessed on 26 November 2018).

- Loewenthal, S.; Jones, W.; Grout, J.; Predmore, R.; Thorn, R. Instrument Bearing Life with Non-CFC Cleaners. Available online: https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20010071561.pdf (accessed on 16 January 2015).

- Sathyan, K.; Hsu, H.Y.; Lee, S.H.; Gopinath, K. Long-term lubrication of momentum wheels used in spacecrafts—An overview. Tribol. Int. 2010, 43, 259–267. [Google Scholar] [CrossRef]

- Brown, P.L.; Miller, J.B.; Jones, W.R., Jr.; Rasmussen, K.; Wheeler, D.R.; Rana, M.; Peri, F. The Clouds and the Earth’s Radiant Energy System Elevation Bearing Assembly Life Test. Available online: https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19990053852.pdf (accessed on 27 November 2018).

- Anderson, M.J.; Freeman, S.; Roberts, E.W. Evaporative losses of vacuum-compatible oils through labyrinth seals. In Proceedings of the 10th European Space Mechanisms and Tribology Symposium, San Sebastian, Spain, 24–26 September 2003. [Google Scholar]

- Jones, W.R., Jr.; Poslowski, A.K.; Shogrin, B.A.; Herrera-Fierro, P.; Jansen, M.J. Evaluation of several space lubricants using a vacuum four-ball tribometer. Tribol. Trans. 1999, 42, 317–323. [Google Scholar] [CrossRef] [Green Version]

- Loewenthal, S.; Jones, W.; Predmore, R. Life of Pennzane and 815Z-Lubricated Instrument Bearings Cleaned with Non-CFC Solvents. Available online: https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19990095611.pdf (accessed on 8 October 2014).

- Jansen, M.J.; Jones, W.R., Jr.; Predmore, R.E.; Loewenthal, S.L. Relative Lifetimes of Several Space Liquid Lubricants Using a Vacuum Spiral Orbit Tribometer (SOT). Available online: https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20010069634.pdf (accessed on 11 April 2019).

- Bazinet, D.G.; Espinosa, M.A.; Loewenthal, S.H.; Gschwender, L.; Jones, W.R., Jr.; Predmore, R.E. Life of scanner bearings with four space liquid lubricants. J. Synth. Lubr. 2006, 23, 81–90. [Google Scholar] [CrossRef]

- Buttery, M. An Evaluation of Liquid, Solid, and Grease Lubricants for Space Mechanisms Using a Spiral Orbit Tribometer. Available online: https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20100021923.pdf (accessed on 6 June 2018).

- Venier, C.; Casserly, E.W.; Jones, W.R., Jr.; Marchetti, M.; Jansen, M.J.; Predmore, R.E. Tribological Properties of a Pennzane (Registered Trademark)-Based Liquid Lubricant (Disubstituted Alkylated Cyclopentane) for Low Temperature Space Applications. Available online: https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20020050211.pdf (accessed on 16 September 2015).

- Peterangelo, S.C.; Gschwender, L.; Snyder, C.E., Jr.; Jones, W.R., Jr.; Nguyen, Q.; Jansen, M.J. Improved additives for multiply alkylated cyclopentane-based lubricants. J. Synth. Lubr. 2008, 25, 31–41. [Google Scholar] [CrossRef]

- Hilton, M.R.; Fleischauer, P.D. Lubricants for High-Vacuum Applications; The Aerospace Corporation: El Segundo, CA, USA, 1993. [Google Scholar]

- Aerospace Products: Oils. Available online: https://www.nyelubricants.com/stuff/contentmgr/files/0/8b17e8eb040695b7b90019c9cc9c65f5/en/aerospace_matrix_oil__brochure.pdf (accessed on 1 February 2020).

- Morales, W.; Street, K.W., Jr.; Koch, V.R.; Richard, R.M. Evaluation of vapor pressure and ultra-high vacuum tribological properties of ionic liquids (2) mixtures and additives. In Proceedings of the STLE/ASME International Tribology Conference, Miami, FL, USA, 20–22 October 2008. [Google Scholar]

- Carre, D.J.; Bertrand, P.A. Modeling and measurement of aryl phosphate ester vapor pressures at 50C. Tribol. Trans. 1999, 42, 777–782. [Google Scholar] [CrossRef]

- Carre, D.J.; Bertrand, P.A. A model to calculate evaporative oil loss in spacecraft mechanisms. Tribol. Trans. 1999, 42, 282–288. [Google Scholar] [CrossRef]

- Roberts, E.W. Space tribology: Its role in spacecraft mechanisms. J. Phys. Appl. Phys. 2012, 45, 503001. [Google Scholar] [CrossRef]

- Scialdone, J.J.; Miller, M.K.; Montoya, A.F. Methods of Measuring Vapor Pressures of Lubricants with Their Additives Using TGA and/or Microbalances. Available online: https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19960022382.pdf (accessed on 1 February 2020).

- Nguyen, Q.N.; Jones, W.R., Jr. Volatility and wear characteristics of a variety of liquid lubricants for space applications. Tribol. Trans. 2001, 44, 671–677. [Google Scholar] [CrossRef]

- Dushman, S. Scientific Foundations of Vacuum Technique; JW Wiley & Sons: New York, NY, USA, 1962. [Google Scholar]

- Bialke, B. Space-flight experience and life test performance of a synthetic hydrocarbon lubricant. In Proceedings of the 6th European Space Mechanisms and Tribology Symposium, Zurich, Switzerland, 4–6 October 1995. [Google Scholar]

- Prat, P.; Vergne, P.; Sicre, J. New results in high pressure and low temperature rheology of liquid lubricants for space applications. J. Tribol. 1994, 116, 629–634. [Google Scholar] [CrossRef]

- Palladino, M.; Murer, J.; Didierjean, S.; Gaillard, L. Life prediction of fluid lubricated space bearings: A case study. In Proceedings of the 14th European Space Mechanisms and Tribology Symposium, Constance, Germany, 28–30 September 2011. [Google Scholar]

- Mobley, J.; Robertson, M.; Hodges, C. Extended life testing of duplex ball bearings. In Proceedings of the 43rd Aerospace Mechanisms Symposium, Santa Clara, CA, USA, 4–6 May 2016. [Google Scholar]

- Kalogeras, C.G.; Didziulis, S.V. Bearing Tests of Lubricant Additive Formulation and Pretreatment Processes; Aerospace Corporation: El Segundo, CA, USA, 1995. [Google Scholar]

- Fleischauer, P. Performance of fluid and solid lubricants in spacecraft applications. J. Synth. Lubr. 1995, 12, 1–12. [Google Scholar] [CrossRef]

- Loewenthal, S.H. Two gimbal bearing case studies: Some lessons learned. In Proceedings of the 22nd Aerospace Mechanisms Symposium, Hampton, VA, USA, 4–6 May 1988. [Google Scholar]

- Bauer, R.; Fleischauer, P.D. Torque Characteristics of Solid Lubricated Precision Bearings during Oscillatory Motion; The Aerospace Corporation: El Segundo, CA, USA, 1994. [Google Scholar]

- Miller, J.; Langley Research Center, Hampton, VA, USA. Unpublished work. 2008.

- Todd, M.J. Investigation of Torque Anomaly in Oscillating PDM Bearings; ESA (ESTL) 49: Warrington, UK, 1981. [Google Scholar]

- Masuko, M.; Kishi, K.; Suzuki, A.; Obara, S. The lifetime of boundary lubrication performance of small-quantity applied liquid lubricants for space mechanisms evaluated with a vacuum reciprocating tribometer. Tribol. Trans. 2010, 53, 75–83. [Google Scholar] [CrossRef]

- Pellicciotti, J.; Loewenthal, S.; Jones, W.R., Jr.; Jumper, M. Hubble space telescope fine guidance sensor post-flight bearing inspection. In Proceedings of the 37th Aersospace Mecahnisms Symposium, Galveston, TX, USA, 19–21 May 2004. [Google Scholar]

| Parameter | Elevation Gimbal | Azimuth Gimbal |

|---|---|---|

| Motion | oscillatory | oscillatory |

| Lubrication | MT7-5-4 | MT7-5-4 |

| Temperature | 0 °C to 30 °C (operating) | −10 °C to 30 °C (operating) |

| Scan period | 6.6 s | Variable |

| Degree range | 17.7°–194.0°–17.7°/scan (EOS) | 90°–270°–90° (typ.) |

| Bearing material | AISI-440-C steel | AISI-440-C steel |

| Bearing | Angular contact pair | Angular spaced pair |

| Number of balls | 34/17 | 62 |

| Ball diameter | 0.125 | 0.25 |

| Pre-load | 10–20 lbs. | 300-350 lbs. |

| Starting torque | 1.0/0.75 in.-oz. | 46 in.-oz. |

| Angular travel/cycle | 352° (typ.) | 360° (typ.) |

| Pressure (in orbit) | <1 × 10−6 torr | <1 × 10−6 torr |

| Time (s) | 0.5 | 2.79 | 3.05 | 3.17 | 3.42 | 3.54 | 3.8 | 6.09 |

|---|---|---|---|---|---|---|---|---|

| Event | Delta 1 | Delta 2 | Delta 3 | Delta 4 | Delta 5 | Delta 6 | Delta 7 | Delta 8 |

| Position (deg) | 17.8 | 162.3 | 162.3 | 194 | 194 | 162.3 | 162.3 | 17.8 |

| Direction | CW | CW | CCW | CCW | ||||

| Angular Rate (deg/s) | 0 | 63.1 | 0 | 249.7 | 0 | 249.7 | 63.1 | 0 |

| Lubricant Loss Model | Operating Time (Flight Year) | Vapor Pressure (Torr) | Temp, T (K) | Clausing Factor, F | Molecular Weight, M (g/mol) | Lube Loss Rate (g/s) | Mass Loss (mg) | Modified Mass Loss (mg) Anderson | Initial Lubricant Mass (mg) (Reservoir) |

|---|---|---|---|---|---|---|---|---|---|

| Modified Langmuir | |||||||||

| Elevation | 20 | 2.47 × 10−10 | 303 | 0.077 | 900 | 1.04 × 10−12 | 0.657 | 65.7 | 367/409 |

| Elevation | 20 | 1.27 × 10−10 | 303 | 0.077 | 900 | 5.36 × 10−13 | 0.337 | 33.7 | 367/409j |

| Azimuth | 20 | 2.47 × 10−10 | 303 | 0.080 | 900 | 6.14 × 10−12 | 3.87 | 387 | 6882 |

| Azimuth | 20 | 1.27 × 10−10 | 303 | 0.080 | 900 | 3.157 × 10−12 | 1.99 | 199 | 6882 |

| Monte Carlo | |||||||||

| Elevation | 303 | 0.077 | 690 | 2.87 × 10−12 | 225 | ||||

| Azimuth | 303 | 0.080 | 690 | 1.689 × 10−11 | 6881 | ||||

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Butler, J.C. CERES Gimbal Performance on Terra. Lubricants 2020, 8, 79. https://0-doi-org.brum.beds.ac.uk/10.3390/lubricants8080079

Butler JC. CERES Gimbal Performance on Terra. Lubricants. 2020; 8(8):79. https://0-doi-org.brum.beds.ac.uk/10.3390/lubricants8080079

Chicago/Turabian StyleButler, John C. 2020. "CERES Gimbal Performance on Terra" Lubricants 8, no. 8: 79. https://0-doi-org.brum.beds.ac.uk/10.3390/lubricants8080079