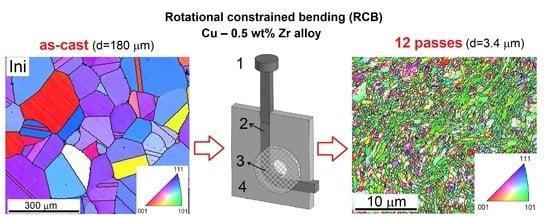

Microstructure Evolution in Cu–0.5 wt% Zr Alloy Processed by a Novel Severe Plastic Deformation Technique of Rotational Constrained Bending

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Microstructure of the Initial Sample and the Specimen Processed by One Pass

3.2. Evolution of the Microstructure with Increasing Number of Passes

3.3. Tensile Tests

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Langdon, T.G. Twenty-five years of ultrafine-grained materials: Achieving exceptional properties through grain refinement. Acta Mater. 2013, 61, 7035–7059. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Raab, G.J.; Valiev, R.Z.; Lowe, T.C.; Zhu, Y.T. Continuous processing of ultrafine grained Al by ECAP—Conform. Mater. Sci. Eng. A 2004, 382, 30–34. [Google Scholar] [CrossRef]

- Saito, Y.; Utsunomiya, H.; Tsuji, N.; Sakai, T. Novel ultra-high straining process for bulk materials—Development of the accumulative roll-bonding (ARB) process. Acta Mater. 1999, 47, 579–583. [Google Scholar] [CrossRef]

- Asano, M.; Yuasa, M.; Miyamoto, H.; Tanaka, T.; Erdogan, C.; Yalçinkaya, T. Potential of High Compressive Ductility of Ultrafine Grained Copper Fabricated by Severe Plastic Deformation. Metals 2020, 10, 1503. [Google Scholar] [CrossRef]

- Segal, V.M. Materials processing by simple shear. Mater. Sci. Eng. A 1995, 197, 157–164. [Google Scholar] [CrossRef]

- Krajňák, T.; Minárik, P.; Gubicza, J.; Máthis, K.; Kužel, R.; Janeček, M. Influence of equal channel angular pressing routes on texture, microstructure and mechanical properties of extruded AX41 magnesium alloy. Mater. Charact. 2017, 123, 282–293. [Google Scholar] [CrossRef]

- Minárik, P.; Veselý, J.; Čížek, J.; Zemková, M.; Vlasák, T.; Krajňák, T.; Kubásek, J.; Král, R.; Hofman, D.; Stráská, J. Effect of secondary phase particles on thermal stability of ultra-fine grained Mg-4Y-3RE alloy prepared by equal channel angular pressing. Mater. Charact. 2018, 140, 207–216. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Stráská, J.; Janeček, M.; Gubicza, J.; Krajňák, T.; Yoon, E.Y.; Kim, H.S. Evolution of microstructure and hardness in AZ31 alloy processed by high pressure torsion. Mater. Sci. Eng. A 2015, 625, 98–106. [Google Scholar] [CrossRef]

- Čížek, J.; Hruška, P.; Vlasák, T.; Vlček, M.; Janeček, M.; Minárik, P.; Krajňák, T.; Šlapáková, M.; Dopita, M.; Kužel, R.; et al. Microstructure development of ultra fine grained Mg-22 wt%Gd alloy prepared by high pressure torsion. Mater. Sci. Eng. A 2017, 704, 181–191. [Google Scholar] [CrossRef]

- Raab, G.I.; Utyashev, F.Z.; Asfandiyarov, R.N.; Raab, A.G.; Aksenov, D.A.; Kodirov, I.S.; Janeček, M.; Krajňák, T. Physical and Technical Foundations of the Use of Alternating Free Bending for Producing Long-length Semi-products from Metals and Alloys with Improved Mechanical Properties. Metals 2020, 10, 879. [Google Scholar] [CrossRef]

- Krajňák, T.; Janeček, M.; Minárik, P.; Veselý, J.; Cejpek, P.; Gubicza, J.; Hung, P.T.; Preisler, D.; Nový, F.; Raab, A.G.; et al. Microstructure evolution and mechanical properties of cp-Ti processed by a novel technique of rotational constrained bending. Metall. Mater. Trans. A. under review.

- Muramatsu, N.; Kimura, H.; Inoue, A. Development and Microstructure of Cu-Zr Alloy Wire with Ultimate Tensile Strength of 2.2 GPa. Mater. Trans. 2012, 53, 1062–1068. [Google Scholar] [CrossRef]

- Furukawa, M.; Horita, Z.; Nemoto, M.; Langdon, T.G. Review: Processing of metals by equal-channel angular pressing. J. Mater. Sci. 2001, 36, 2835–2843. [Google Scholar] [CrossRef]

- Raab, G.I.; Aksenov, D.A.; Asfandiyarov, R.N.; Raab, A.G.; Kodirov, I.S.; Janeček, M. Characteristics of the stress-strain state and structural changes in axisymmetric samples under sign-alternating deformation by free and constrained bending. Lett. Mater. 2019, 9, 494–498. [Google Scholar] [CrossRef] [Green Version]

- Ribárik, G.; Gubicza, J.; Ungár, T. Correlation between strength and microstructure of ball-milled Al–Mg alloys determined by X-ray diffraction. Mater. Sci. Eng. A 2004, 387–389, 343–347. [Google Scholar] [CrossRef]

- Muramatsu, N.; Kimura, H.; Inoue, A. Microstructures and Mechanical Properties of Highly Electrically Conductive Cu 0.5, Cu 1 and Cu 2 at% Zr Alloy Wires. Mater. Trans. 2013, 54, 176–183. [Google Scholar] [CrossRef] [Green Version]

- Raab, A.G.; Aksenov, D.A.; Asfandiyarov, R.N.; Kodirov, I.S.; Raab, G.I. Development of severe plastic deformation methods for the production of contact wires from a Cu-Zr alloy for high-speed railways. IOP Conf. Series: Mater. Sci. Eng. 2018, 447, 012088. [Google Scholar] [CrossRef]

- Chen, Y.J.; Li, Y.J.; Walmsley, J.C.; Dumoulin, S.; Skaret, P.C.; Roven, H.J. Microstructure evolution of commercial pure titanium during equal channel angular pressing. Mater. Sci. Eng. A 2010, 527, 789–796. [Google Scholar] [CrossRef] [Green Version]

- Frint, P.; Härtel, M.; Selbmann, R.; Dietrich, D.; Bergmann, M.; Lampke, T.; Landgrebe, D.; Wagner, M.F. Microstructural Evolution during Severe Plastic Deformation by Gradation Extrusion. Metals 2018, 8, 96. [Google Scholar] [CrossRef] [Green Version]

- Gubicza, J. Defect Structure and Properties of Nanomaterials; Woodhead Publishing: Duxford, UK, 2017. [Google Scholar]

- Li, S.; Beyerlein, I.J.; Bourke, M.A.M. Texture formation during equal channel angular extrusion of fcc and bcc materials: Comparison with simple shear. Mater. Sci. Eng. A 2005, 394, 66–77. [Google Scholar] [CrossRef]

- Klein, H.; Schwarzer, R.A. Texture Heterogeneity in ECAP Deformed Copper. Solid State Phenom. 2010, 160, 47–54. [Google Scholar] [CrossRef]

- Molodovaa, X.; Bhaumik, S.; Winning, M.; Gottstein, G. ECAP Processed Copper during Deformation and Subsequent Annealing. Mater. Sci. Forum 2006, 503–504, 469–474. [Google Scholar] [CrossRef]

- Suwas, S.; Massion, R.A.; Tóth, L.S.; Eberhardt, A.; Fundenberger, J.J.; Skrotzki, W. Evolution of crystallographic texture during equal channel angular extrusion of copper: The role of material variables. Metall. Mater. Trans. A 2006, 37, 739–753. [Google Scholar] [CrossRef]

| Number of Passes | ρ (1014 m−2) | <x> area (nm) | M |

|---|---|---|---|

| 0 | ˂0.1 | >1000 | n/a |

| 1 | 45 ± 5 | 59 ± 6 | 0.8 ± 0.1 |

| 2 | 27 ± 3 | 49 ± 5 | 1.5 ± 0.2 |

| 4 | 11 ± 1 | 54 ± 5 | 4.1 ± 0.4 |

| 8 | 13 ± 1 | 48 ± 5 | 3.0 ± 0.3 |

| 12 | 14 ± 1 | 45 ± 4 | 3.3 ± 0.3 |

| Component | Miller Indices | φ1 | Euler Angles (°) ϕ | φ2 | Fiber |

|---|---|---|---|---|---|

| ■ A*1 | (111) [−1–12] | 125.26 | 90 | 45 | A |

| ▼ A*2 | (111) [11–2] | 54.74/234.74 | 90 | 45 | A |

| ▶ A | (1−11) [110] | 0 | 35.26 | 45 | B |

| ◀ A- | (−11–1) [−1–10] | 180 | 35.26 | 45 | B |

| ◆ B | (1–12) [110] | 0/120/240 | 54.74 | 45 | B |

| ● B- | (−11–2) [−1–10] | 60/180 | 54.74 | 45 | B |

| 🟌 C | {001} <110> | 0/180 | 90 | 45 | B |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krajňák, T.; Janeček, M.; Minárik, P.; Gubicza, J.; Hung, P.T.; Nový, F.; Raab, A.; Raab, G.; Asfandiyarov, R. Microstructure Evolution in Cu–0.5 wt% Zr Alloy Processed by a Novel Severe Plastic Deformation Technique of Rotational Constrained Bending. Metals 2021, 11, 63. https://0-doi-org.brum.beds.ac.uk/10.3390/met11010063

Krajňák T, Janeček M, Minárik P, Gubicza J, Hung PT, Nový F, Raab A, Raab G, Asfandiyarov R. Microstructure Evolution in Cu–0.5 wt% Zr Alloy Processed by a Novel Severe Plastic Deformation Technique of Rotational Constrained Bending. Metals. 2021; 11(1):63. https://0-doi-org.brum.beds.ac.uk/10.3390/met11010063

Chicago/Turabian StyleKrajňák, Tomáš, Miloš Janeček, Peter Minárik, Jenő Gubicza, Pham Tran Hung, František Nový, Arseniy Raab, Georgy Raab, and Rashid Asfandiyarov. 2021. "Microstructure Evolution in Cu–0.5 wt% Zr Alloy Processed by a Novel Severe Plastic Deformation Technique of Rotational Constrained Bending" Metals 11, no. 1: 63. https://0-doi-org.brum.beds.ac.uk/10.3390/met11010063