Modelling Fungal Growth, Mycotoxin Production and Release in Grana Cheese

Abstract

:1. Introduction

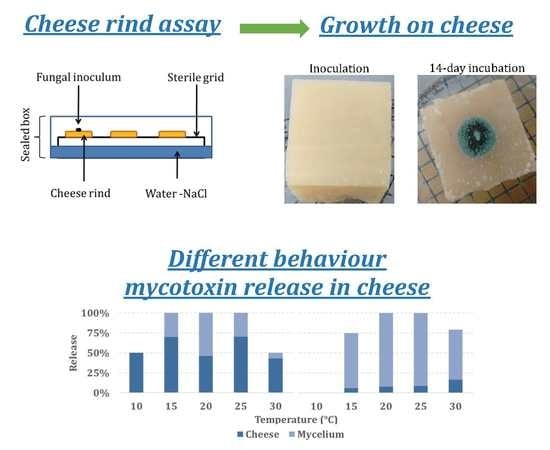

2. Materials and Methods

2.1. Cheese Blocks Sampling and Disinfection

2.2. Inoculum Preparation, Inoculation, and Incubation of the Cheese Blocks

2.3. Data Collection

2.4. Data Analysis

3. Results

3.1. Fungal Growth

3.2. Mycotoxin Producion

3.3. Modeling Fungal Growth

3.4. Modeling Mycotoxin Production

4. Discussion

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Camardo Leggieri, M.; Decontardi, S.; Bertuzzi, T.; Pietri, A.; Battilani, P. Modeling growth and toxin production of toxigenic fungi signaled in cheese under different temperature and water activity regimes. Toxins 2017, 9, 4. [Google Scholar] [CrossRef] [Green Version]

- Ministero Delle Politiche Agricole e Forestali. Available online: http://www.politicheagricole.it (accessed on 22 November 2019).

- Ropars, J.; Cruaud, C.; Lacoste, S.; Dupont, J. A taxonomic and ecological overwiew of cheese fungi. Int. J. Food Microbiol. 2012, 155, 199–210. [Google Scholar] [CrossRef]

- Lund, F.; Filtenborg, O.; Frisvad, J.C. Associated mycoflora of cheese. Food Microbiol. 1995, 12, 173–180. [Google Scholar] [CrossRef]

- Montagna, M.T.; Santacroce, M.P.; Spilotros, G.; Napoli, C.; Minervini, F.; Papa, A.; Dragoni, I. Investigation of fungal contamination in sheep and goat cheeses in southern italy. Mycopathologia 2004, 158, 245–249. [Google Scholar] [CrossRef]

- Creppy, E.E. Update of survey, regulation and toxic effects of mycotoxins in europe. Toxicol. Lett. 2002, 127, 19–28. [Google Scholar] [CrossRef]

- Erdogan, A.; Gurses, M.; Sert, S. Isolation of moulds capable of producing mycotoxins from blue mouldy tulum cheeses produced in turkey. Int. J. Food Microbiol. 2003, 85, 83–85. [Google Scholar] [CrossRef]

- Dall’Asta, C.; De Dea Lindner, J.; Galaverna, G.; Dossena, A.; Neviani, E.; Marchelli, R. The occurrence of ochratoxin a in blue cheese. Food Chem. 2008, 106, 729–734. [Google Scholar] [CrossRef]

- Fontaine, K.; Hymery, N.; Lacroix, M.Z.; Puel, S.; Puel, O.; Rigalma, K.; Gaydou, V.; Coton, E.; Mounier, J. Influence of intraspecific variability and abiotic factors on mycotoxin production in penicillium roqueforti. Int. J. Food Microbiol. 2015, 215, 187–193. [Google Scholar] [CrossRef]

- Decontardi, S.; Mauro, A.; Lima, N.; Battilani, P. Survey of penicillia associated with italian grana cheese. Int. J. Food Microbiol. 2017, 246, 25–31. [Google Scholar] [CrossRef] [Green Version]

- Kalinina, S.A.; Jagels, A.; Hickert, S.; Mauriz Marques, L.M.; Cramer, B.; Humpf, H.U. Detection of the cytotoxic penitrems a-f in cheese from the european single market by hplc-ms/ms. J. Agric. Food Chem. 2018, 66, 1264–1269. [Google Scholar] [CrossRef]

- Decontardi, S.; Soares, C.; Lima, N.; Battilani, P. Polyphasic identification of penicillia and aspergilli isolated from italian grana cheese. Food Microbiol. 2018, 73, 137–149. [Google Scholar] [CrossRef] [PubMed]

- Wu, F.; Mitchell, N.J. How climate change and regulations can affect the economics of mycotoxins. World Mycotoxin J. 2016, 9, 653–663. [Google Scholar] [CrossRef]

- Camardo Leggieri, M.; Decontardi, S.; Battilani, P. Modelling the sporulation of some fungi associated with cheese, at different temperature and water activity regimes. Int. J. Food Microbiol. 2018, 278, 52–60. [Google Scholar] [CrossRef] [PubMed]

- Battilani, P.; Pietri, A.; Giorni, P.; Formenti, S.; Bertuzzi, T.; Toscani, T.; Virgili, R.; Kozakiewicz, Z. Penicillium population in dry-cured ham manufacturing plants. J. Food Prot. 2007, 70, 975–980. [Google Scholar] [CrossRef] [PubMed]

- Pitt, J.I. The Genus Penicillium and Its Teleomorphic States Eupenicillium and Talaromyces; Academic Press Inc.: London, UK, 1979. [Google Scholar]

- Dallyn, H.; Fox, A. Spoilage of material of reduced water activity by xerophilic fungi. In Society of Applied Bacteriology Technical Series; Gould, G.H., Corry, J.E.L., Eds.; Academic Press: London, UK, 1980; Volume 15, pp. 129–139. [Google Scholar]

- Battilani, P.; Formenti, S.; Toscani, T.; Virgili, R. Influence of abiotic parameters on ochratoxin a production by a p. Nordicum strain in dry-cured meat model systems. Food Control 2010, 21, 1739–1744. [Google Scholar] [CrossRef]

- Analytis, S. Über die relation zwischen biologischer entwicklung und temperatur bei phytopathogenen pilzen. Phytopathol. Z. 1977, 90, 64–76. [Google Scholar] [CrossRef]

- Sengun, I.Y.; Yaman, D.B.; Gonul, S.A. Mycotoxins and mould contamination in cheese: A review. World Mycotoxin J. 2008, 1, 291–298. [Google Scholar] [CrossRef]

- Biancardi, A.; Piro, R.; Galaverna, G.; Dall’Asta, C. A simple and reliable liquid chromatography-tandem mass spectrometry method for determination of ochratoxin a in hard cheese. Int. J. Food Sci. Nutr. 2013, 64, 632–640. [Google Scholar] [CrossRef]

- Commission, E. Commission Regulation No 165/2010 of 26 February 2010 Amending Regulation (ec) No 1881/2006 Setting Maximum Levels for Certain Contaminants in Foodstuffs As Regards Aflatoxin; Official Journal of the European Union: Bruxelles, Belgium, 2010; pp. 8–12. [Google Scholar]

- Commission, E. Commission Regulation (ec) No 1881/2006 Setting Maximum Levels for Certain Contaminants in Foodstuffs; Official Journal of the European Union: Bruxelles, Belgium, 2006; pp. 4–24. [Google Scholar]

- Di Giuseppe, R.; Bertuzzi, T.; Rossi, F.; Rastelli, S.; Mulazzi, A.; Capraro, J.; De Curtis, A.; Iacoviello, L.; Pietri, A. Plasma ochratoxin a levels, food consumption, and risk biomarkers of a representative sample of men and women from the molise region in italy. Eur. J. Nutr. 2012, 51, 851–860. [Google Scholar] [CrossRef]

- Galvano, F.; Pietri, A.; Bertuzzi, T.; Gagliardi, L.; Ciotti, S.; Luisi, S.; Bognanno, M.; La Fauci, L.; Iacopino, A.M.; Nigro, F.; et al. Maternal dietary habits and mycotoxin occurrence in human mature milk. Mol. Nutr. Food Res. 2008, 52, 496–501. [Google Scholar] [CrossRef]

- Muñoz, K.; Blaszkewicz, M.; Campos, V.; Vega, M.; Degen, G.H. Exposure of infants to ochratoxin a with breast milk. Arch. Toxicol. 2014, 88, 837–846. [Google Scholar] [CrossRef] [PubMed]

- Soto, J.B.; Ruiz, M.J.; Manyes, L.; Juan-García, A. Blood, breast milk and urine: Potential biomarkers of exposure and estimated daily intake of ochratoxin a: A review. Food Addit. Contam. 2016, 33, 313–328. [Google Scholar] [CrossRef] [PubMed]

- Biasucci, G.; Calabrese, G.; Di Giuseppe, R.; Carrara, G.; Colombo, F.; Mandelli, B.; Maj, M.; Bertuzzi, T.; Pietri, A.; Rossi, F. The presence of ochratoxin a in cord serum and in human milk and its correspondence with maternal dietary habits. Eur. J. Nutr. 2011, 50, 211–218. [Google Scholar] [CrossRef] [PubMed]

- Alassane-Kpembi, I.; Schatzmayr, G.; Taranu, I.; Marin, D.; Puel, O.; Oswald, I.P. Mycotoxins co-contamination: Methodological aspects and biological relevance of combined toxicity studies. Crit. Rev. Food Sci. Nutr. 2017, 57, 3489–3507. [Google Scholar] [CrossRef]

- Grenier, B.; Oswald, I.P. Mycotoxin co-contamination of food and feed: Meta-analysis of publications describing toxicological interactions. World Mycotoxin J. 2011, 4, 285–313. [Google Scholar] [CrossRef]

- Lee, H.J.; Ryu, D. Worldwide occurrence of mycotoxins in cereals and cereal-derived food products: Public halth perspectives of their co-occurrence. J. Agric. Food Chem. 2017, 65, 7034–7051. [Google Scholar] [CrossRef]

- Yang, Y.; Yu, S.; Tan, Y.; Liu, N.; Wu, A. Individual and combined cytotoxic effects of co-occurring deoxynivalenol family mycotoxins on human gastric epithelial cells. Toxins 2017, 9, 96. [Google Scholar] [CrossRef] [Green Version]

- Sobral, M.M.C.; Faria, M.A.; Cunha, S.C.; Ferreira, I.M. Toxicological interactions between mycotoxins from ubiquitous fungi: Impact on hepatic and intestinal human epithelial cells. Chemosphere 2018, 202, 538–548. [Google Scholar] [CrossRef]

- McSweeney, P.L.H. (Ed.) Nutritional aspects of cheese. In Cheese Problems Solved; Woodhead Publishing: Sawston, UK, 2007; pp. 152–158. [Google Scholar]

- Summer, A.; Formaggioni, P.; Franceschi, P.; Di Frangia, F.; Righi, F.; Malacarne, M. Cheese as functional food: The example of parmigiano reggiano and grana padano. Food Technol. Biotechnol. 2017, 55, 277–289. [Google Scholar] [CrossRef]

- Frisvad, J.C.; Smedsgaard, J.; Larsen, T.O.; Samson, R.A. Mycotoxins, drugs and other extrolites produced by species in penicillium subgenus penicillium. Stud. Mycol. 2004, 49, 201–241. [Google Scholar]

- Manabe, M. Fermented foods and mycotoxins. Mycotoxins 2001, 51, 25–28. [Google Scholar] [CrossRef] [Green Version]

- Pardo, E.; Marín, S.; Ramos, A.J.; Sanchis, V. Ecophysiology of ochratoxigenic aspergillus ochraceus and penicillium verrucosum isolates. Predictive models for fungal spoilage prevention—A review. Food Addit. Contam. 2006, 23, 398–410. [Google Scholar] [CrossRef] [PubMed]

- Rodriguez, A.; Capela, D.; Medina, A.; Cordoba, J.J.; Magan, N. Relationship between ecophysiological factors, growth and ochratoxin a contamination of dry-cured sausage based matrices. Int. J. Food Microbiol. 2015, 194, 71–77. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-Montero, L.; Córdoba, J.J.; Peromingo, B.; Álvarez, M.; Núñez, F. Effects of environmental conditions and substrate on growth and ochratoxin a production by penicillium verrucosum and penicillium nordicum: Relative risk assessment of ota in dry-cured meat products. Food Res. Int. 2019, 121, 604–611. [Google Scholar] [CrossRef] [PubMed]

- Coton, M.; Auffret, A.; Poirier, E.; Debaets, S.; Coton, E.; Dantigny, P. Production and migration of ochratoxin a and citrinin in comté cheese by an isolate of penicillium verrucosum selected among penicillium spp. Mycotoxin producers in yes medium. Food Microbiol. 2019, 82, 551–559. [Google Scholar] [CrossRef]

- Kokkonen, M.; Jestoi, M.; Rizzo, A. The effect of substrate on mycotoxin production of selected penicillium strains. Int. J. Food Microbiol. 2005, 99, 207–214. [Google Scholar] [CrossRef]

- Hocking, A.D. Aspergillus and related teleomorphs. In Food Spoilage Microorganisms; Woodhead Publishing Limited: Abington, UK, 2006; pp. 451–487. [Google Scholar]

| Species | Strain Code a | Country of Isolation | Matrix of Isolation | Mycotoxin |

|---|---|---|---|---|

| A. versicolorb | CBS 108959 | Denmark | Sterigmatocystin (STC) | |

| P. crustosum | CBS 115503 | The Netherlands | Penitrem A (PA) Roquefortine C (ROQ-C) | |

| P. nordicum | BFE 856 | Italy | Ham | Ochratoxin A (OTA) |

| P. roqueforti | CBS 221.30 | USA | Roquefortine C (ROQ-C) Mycophenolic acid (MPA) Pr-Toxin (PR-Tox) | |

| P. verrucosum | MUM 16.76 | Italy | Cheese | Ochratoxin A (OTA) Citrinin (CIT) |

| Factors | Growth | |

|---|---|---|

| Temperature (°C) (A) | ** | |

| 10 | 3.4 | d§ |

| 15 | 11.5 | c |

| 20 | 22.1 | a |

| 25 | 16.3 | b |

| 30 | 3.1 | d |

| Fungi (B) | ** | |

| A. versicolor | 8.5 | b |

| P. crustosum | 13.1 | a |

| P. nordicum | 13.4 | a |

| P. roqueforti | 13.3 | a |

| P. verrucosum | 14.1 | a |

| (A × B) | ** | |

| Factors | A. versicolor | P. crustosum | P. nordicum | P. roqueforti | P. verrucosum | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| STC | PA | ROQ-C | OTA | ROQ-C | OTA | |||||||

| Temperature (°C) (A) | ** | ** | ** | ** | ** | ** | ||||||

| 10 | 409.3 | a § | <LOD | b | <LOD | c | <LOD | c | 3.8 | c | <LOD | c |

| (±1.84) | (±1.13) | |||||||||||

| 15 | 197.3 | ab | 92.6 | a | 151.8 | b | <LOD | c | 19.4 | bc | 43.2 | b |

| (±1.60) | (±12.45) | (±5.14) | (±2.03) | (±2.93) | ||||||||

| 20 | 64 | bc | 125.4 | a | 787.4 | a | 16.4 | ab | 91.7 | ab | 418.6 | a |

| (±2.25) | (±8.21) | (±3.75) | (±5.63) | (±2.48) | (±2.63) | |||||||

| 25 | 38.8 | bc | 160 | a | 4140.5 | a | 21.6 | a | 370.5 | a | 12.4 | bc |

| (±2.96) | (±14.71) | (±5.63) | (±3.75) | (±5.19) | (±4.49) | |||||||

| 30 | 122.2 | c | <LOD | b | 22.3 | b | 4.0 | bc | 14.7 | c | <LOD | c |

| (±2.67) | (±2.84) | (±3.35) | (±1.73) | |||||||||

| Partitioning (B) | ** | ** | ** | ** | ** | n.s. | ||||||

| Cheese rind | 186.8 | a | 1.5 | b | 101.9 | b | 3.0 | b | 19.0 | b | 113.5 | a |

| (±2.64) | (±2.31) | (±8.07) | (±3.00) | (±2.38) | (±11.25) | |||||||

| Mycelium | 76.1 | b | 204.4 | a | 2642 | a | 16.3 | a | 266.9 | a | 81.6 | b |

| (±3.39) | (±6.02) | (±6.03) | (±5.58) | (±3.81) | (±9.21) | |||||||

| A × B | n.s | ** | n.s. | ** | n.s. | n.s. | ||||||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Camardo Leggieri, M.; Pietri, A.; Battilani, P. Modelling Fungal Growth, Mycotoxin Production and Release in Grana Cheese. Microorganisms 2020, 8, 69. https://0-doi-org.brum.beds.ac.uk/10.3390/microorganisms8010069

Camardo Leggieri M, Pietri A, Battilani P. Modelling Fungal Growth, Mycotoxin Production and Release in Grana Cheese. Microorganisms. 2020; 8(1):69. https://0-doi-org.brum.beds.ac.uk/10.3390/microorganisms8010069

Chicago/Turabian StyleCamardo Leggieri, Marco, Amedeo Pietri, and Paola Battilani. 2020. "Modelling Fungal Growth, Mycotoxin Production and Release in Grana Cheese" Microorganisms 8, no. 1: 69. https://0-doi-org.brum.beds.ac.uk/10.3390/microorganisms8010069