Combined CFD-Stochastic Analysis of an Active Fluidic Injection System for Jet Noise Reduction

Abstract

:1. Introduction

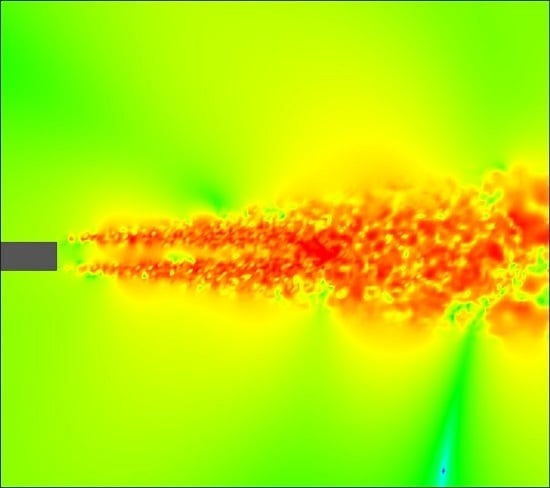

2. Model Description and Validation

2.1. Model Description

2.2. Model Validation

3. Active Fluidic Injection System

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| A | numerical constant |

| Ainj | injection section area |

| stochastic model parameters | |

| constant pressure and costant volume specific heat | |

| D | nozzle diameter |

| E | monodimensional turbulent kinetic energy spectrum |

| G | Green function |

| K | turbulent kinetic energy |

| k | acoustic wave number |

| k | turbulent wave vector |

| wave number of maximum E | |

| Kolmogorov wave number | |

| turbulence integral length scale | |

| M | Mach number |

| convective Mach number | |

| mass flow rate | |

| number of Fourier modes | |

| number of grid points per Fourier component | |

| p | acoustic pressure |

| probability density function | |

| jet pressure and temperature at the nozzle inlet section | |

| jet pressure and temperature at the nozzle outlet section | |

| ambient pressure and temperature | |

| pressure and temperature of the drained mass flow rate | |

| R | microphone radial distance |

| jet Reynolds number based on nozzle diameter | |

| St | Strouhal number |

| t | time |

| U | mean-flow velocity |

| jet centerline velocity and Mach number at nozzle outlet section | |

| fluctuating turbulent velocity and vorticity | |

| injection velocity | |

| magnitude, phase and direction of nth Fourier component of u′ | |

| turbulent wave vector random angles | |

| injection angle | |

| maximum distance between node i and its neighboring nodes j | |

| cubic cells dimension of 3D domain | |

| turbulent velocity difference | |

| turbulent dissipation rate | |

| kinematical viscosity | |

| vortex convection velocity ratio | |

| radian frequency or specific turbulent dissipation rate | |

| t | time |

| mean-flow velocity | |

| jet centerline velocity and Mach number at nozzle outlet section |

References

- Colonius, T.; Lele, S.K.; Moin, P. Sound generation in a mixing layer. J. Fluid Mech. 1997, 330, 375–409. [Google Scholar]

- Colonius, T.; Mohseni, K.; Freund, J.B.; Lele, S.K.; Moin, P. Evaluation of noise radiation mechanisms in a turbulent jet. In Proceedings of the Summer Program of Center for Turbulence Research, Stanford, CA, USA, 2 June 1998; pp. 159–167. [Google Scholar]

- Freund, J. Noise Sources in a Low-Reynolds-number Turbulent Jet at Mach 0.9. J. Fluid Mech. 2011, 438, 277–305. [Google Scholar] [CrossRef]

- Mitchell, B.; Lele, S.; Moin, P. Direct Computation of the Sound Generated by Vortex Pairing in an Axisymmetric Jet. J. Fluid Mech. 1999, 383, 113–142. [Google Scholar] [CrossRef]

- Bogey, C.; Bailly, C.; Juvè, D. Computation of the Sound Radiated by a 3-D Jet Using Large Eddy Simulation. In Proceedings of the 6th AIAA/CEAS Aeroacoustics Conference, Lahaina, HI, USA, 12–14 June 2000. [Google Scholar]

- Mankbadi, R.; Shih, S.; Hixon, R.; Povinelli, L. Direct Computation of Jet Noise Produced by Large-Scale Axisymmetric Structures. J. Propuls. Power 2000, 16, 207–215. [Google Scholar] [CrossRef]

- Andersson, N.; Eriksson, L.E.; Davidson, L. A Study of Mach 0.75 Jets and Their Radiated Sound Using Large-Eddy Simulation. In Proceedings of the 10th AIAA/CEAS Aeroacoustics Conference, Manchester, UK, 10–12 May 2004. [Google Scholar]

- Kraichnan, R.H. Diffusion by a Random Velocity Field. Phys. Fluids 1970, 13, 22–31. [Google Scholar] [CrossRef]

- Fung, J.C.H.; Hunt, J.C.R.; Malik, N.A.; Perkins, R.J. Kinematic Simulation of Homogeneous Turbulence by Unsteady Random Fourier Modes. J. Fluid Mech. 1992, 236, 281–318. [Google Scholar] [CrossRef]

- Béchara, W.; Bailly, C.; Lafon, P.; Candel, S. Stochastic Approach to Noise Modeling for Free Turbulent Flows. AIAA J. 1994, 32, 455–464. [Google Scholar] [CrossRef]

- Bailly, C.; Juvé, D. A Stochastic Approach to Compute Subsonic Noise Using Linearized Euler’s Equations. In Proceedings of the 5th AIAA/CEAS Aeroacoustics Conference, Seattle, WA, USA, 8–9 November 1999. [Google Scholar]

- Billson, M.; Eriksson, L.; Davidson, L. Jet Noise Modeling Using Synthetic Anisotropic Turbulence. In Proceedings of the 10th AIAA/CEAS Aeroacoustics Conference, Manchester, UK, 10–12 May 2004. [Google Scholar]

- Casalino, D.; Barbarino, M. Stochastic Method for Airfoil Self-Noise Computation in Frequency-Domain. AIAA J. 2011, 49, 2453–2469. [Google Scholar] [CrossRef]

- Di Francescantonio, P. Side Mirror Noise with Adaptive Spectral Reconstruction. In Proceedings of the SAE 2015 Noise and Vibration Conference and Exhibition, Grand Rapids, MI, USA, 22–25 June 2015. [Google Scholar]

- Lighthill, M.J. Jet Noise. AIAA J. 1963, 1, 1507–1517. [Google Scholar] [CrossRef]

- Bridges, J.; Brown, C.A. Parametric Testing of Chevrons on Single Flow Hot Jets: NASA TM 2004–213107. In Proceedings of the 10th AIAA/CEAS Aeroacoustics Conference, Manchester, UK, 10–12 May 2004. [Google Scholar]

- Engblom, W.A.; Kharavan, A.; Bridges, J. Numerical Prediction of Chevron Nozzle Noise Reduction Using WIND-MGBK Methodology. In Proceedings of the 10th AIAA/CEAS Aeroacoustics Conference, Manchester, UK, 10–12 May 2004. [Google Scholar]

- Birch, S.F.; Lyubimov, D.A.; Maslov, V.P.; Secundov, A.N. Noise Prediction for Chevron Nozzle Flows. In Proceedings of the 12nd AIAA/CEAS Aeroacoustics Conference, Cambridge, MA, USA, 8–10 May 2006. [Google Scholar]

- Massey, S.J.; Elmiligui, A.A.; Hunter, C.A.; Thomas, R.H.; Pao, S.P.; Mengle, V.G. Computational Analysis of a Chevron Nozzle Uniquely Tailored for Propulsion Airframe Aeroacoustics. In Proceedings of the 12nd AIAA/CEAS Aeroacoustics Conference, Cambridge, MA, USA, 8–10 May 2006. [Google Scholar]

- Shur, M.L.; Spalart, P.R.; Strelets, M.K. Noise Prediction for Increasingly Complex Jets, Part II: Applications. Int. J. Aeroacoustics 2005, 4, 247–266. [Google Scholar] [CrossRef]

- Shur, M.L.; Spalart, P.R.; Strelets, M.K.; Garbaruk, A.V. Further Steps in LES-Based Noise Prediction for Complex Jets. In Proceedings of the 44th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 9–12 January 2006. [Google Scholar]

- Henderson, B.S.; Kinzie, K.W.; Whitmire, J.; Abeysinghe, A. The impact of fluidic chevrons on jet noise. In Proceedings of the 11th AIAA/CEAS Aeroacoustics Conference, Monterey, CA, USA, 23–25 May 2005. [Google Scholar]

- Kinzie, K.W.; Henderson, B.S.; Whitmire, J.; Abeysinghe, A. Fluidic chevrons for jet noise reduction. In Proceedings of the 2004 International Symposium on Active Control of Sound and Vibration (ACTIVE 2004), Williamsburg, VA, USA, 20–22 September 2004. [Google Scholar]

- Henderson, B.S.; Kinzie, K.W.; Whitmire, J.; Abeysinghe, A. Aeroacoustic Improvements to Fluidic Chevron Nozzles. In Proceedings of the 12th AIAA/CEAS Aeroacoustics Conference, Cambridge, MA, USA, 8–10 May 2006. [Google Scholar]

| TEST | Injection Mass Flow Rate/Nozzle Mass Flow Rate | Injection Section Area/Nozzle Outlet Area | Injection Direction [deg] | Injection Velocity [m/s] |

|---|---|---|---|---|

| 1 | 13.0% | 10.2% | 45 | 350 |

| 2 | 13.0% | 10.2% | 60 | 450 |

| 3 | 13.0% | 10.2% | 80 | 690 |

| 4 | 6.5% | 4.08% | 80 | 720 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barbarino, M.; Ilsami, M.; Tuccillo, R.; Federico, L. Combined CFD-Stochastic Analysis of an Active Fluidic Injection System for Jet Noise Reduction. Appl. Sci. 2017, 7, 623. https://0-doi-org.brum.beds.ac.uk/10.3390/app7060623

Barbarino M, Ilsami M, Tuccillo R, Federico L. Combined CFD-Stochastic Analysis of an Active Fluidic Injection System for Jet Noise Reduction. Applied Sciences. 2017; 7(6):623. https://0-doi-org.brum.beds.ac.uk/10.3390/app7060623

Chicago/Turabian StyleBarbarino, Mattia, Mario Ilsami, Raffaele Tuccillo, and Luigi Federico. 2017. "Combined CFD-Stochastic Analysis of an Active Fluidic Injection System for Jet Noise Reduction" Applied Sciences 7, no. 6: 623. https://0-doi-org.brum.beds.ac.uk/10.3390/app7060623