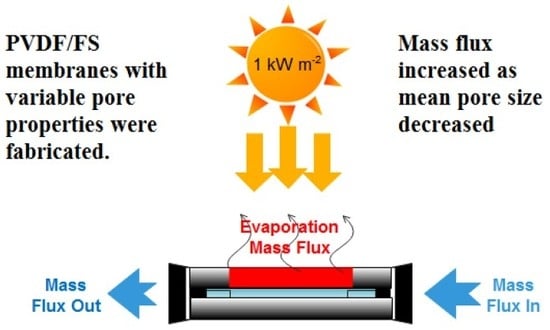

Effect of Pore Characteristics in Polyvinylidene Fluoride/Fumed Silica Membranes on Mass Flux in Solar-Assisted Evaporation Applications

Abstract

:Featured Application

Abstract

1. Introduction

2. Methodology

2.1. Materials

2.2. Fabrication of PVDF-FS Membranes

2.3. Characterization of PVDF-FS Membranes

2.4. Solar-Assisted Evaporation Experiments

3. Results and Discussion

3.1. The Impact of FS Blending on the Membrane Properties

3.2. Performance of the PVDF-FS Membranes in the Solar-Assisted Evaporation of Saltwater

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Global Engagement. Available online: https://www.iea.org/countries/United Arab Emirates/ (accessed on 20 March 2019).

- Jiang, S.; Li, Y.; Ladewig, B.P. Science of the Total Environment A review of reverse osmosis membrane fouling and control strategies. Sci. Total Environ. 2017, 595, 567–583. [Google Scholar] [CrossRef] [PubMed]

- Ashoor, B.B.; Mansour, S.; Giwa, A.; Dufour, V.; Hasan, S.W. Principles and applications of direct contact membrane distillation (DCMD): A comprehensive review. Desalination 2016, 398, 222–246. [Google Scholar] [CrossRef]

- Khawaji, A.D.; Kutubkhanah, I.K.; Wie, J. Advances in seawater desalination technologies. Desalination 2008, 221, 47–69. [Google Scholar] [CrossRef]

- Matsuura, T. Progress in membrane science and technology for seawater desalination a review. Desalination 2001, 134, 47–54. [Google Scholar] [CrossRef]

- Mei, Y.; Tang, C.Y. Recent developments and future perspectives of reverse electrodialysis technology: A review. Desalination 2018, 425, 156–174. [Google Scholar] [CrossRef]

- Jani, H.K.; Modi, K.V. A review on numerous means of enhancing heat transfer rate in solar-thermal based desalination devices. Renew. Sustain. Energy Rev. 2018, 93, 302–317. [Google Scholar] [CrossRef]

- Hanks, D.F.; Lu, Z.; Sircar, J.; Salamon, T.R.; Antao, D.S.; Bagnall, K.R.; Barabadi, B.; Wang, E.N. Nanoporous membrane device for ultra high heat flux thermal management. Microsyst. Nanoeng. 2018, 4, 1–10. [Google Scholar] [CrossRef]

- Sharon, H.; Reddy, K.S. A review of solar energy driven desalination technologies. Renew. Sustain. Energy Rev. 2015, 41, 1080–1118. [Google Scholar] [CrossRef]

- Plawsky, J.L.; Fedorov, A.G.; Garimella, S.; Ma, H.B.; Maroo, S.C.; Li, C.; Nam, Y. Nano-and Microstructures for Thin-Film Evaporation—A Review. Nanoscale Microscale Thermophys. Eng. 2017, 7265, 251–269. [Google Scholar] [CrossRef]

- Lu, Z.; Narayanan, S.; Wang, E.N. Modeling of evaporation from nanopores with non-equilibrium and non-local effects. Langmuir 2018, 31, 9817–9824. [Google Scholar] [CrossRef]

- Ibrahem, K.; Abd Rabbo, M.F.; Gambaryan-Roisman, T.; Stephan, P. Experimental Investigation of Evaporative Heat Transfer Characteristics at the 3-Phase Contact Line. Exp. Therm. Fluid Sci. 2010, 34, 1036–1041. [Google Scholar] [CrossRef]

- Raj, R.; Kunkelmann, C.; Stephan, P.; Plawsky, J.; Kim, J. Contact Line Behavior for a Highly Wetting Fluid under Superheated Conditions. Int. J. Heat Mass Transf. 2012, 55, 2664–2675. [Google Scholar] [CrossRef]

- Xiao, R.; Maroo, S.C.; Wang, E.N. Negative pressures in nanoporous membranes for thin film evaporation. Appl. Phys. Lett. 2013, 102, 123103. [Google Scholar] [CrossRef]

- Wilke, K.L.; Barabadi, B.; Lu, Z.; Zhang, T.; Wang, E.N. Parametric study of thin film evaporation from nanoporous membranes. Appl. Phys. Lett. 2017, 171603, 111. [Google Scholar] [CrossRef]

- Kim, S.S.; Weibel, J.A.; Fisher, T.S.; Garimella, S. Thermal Performance of Carbon Nanotube Enhanced Vapor Chamber Wicks. ASME Conf. Proc. 2010, 2010, 417–424. [Google Scholar]

- Ding, C.; Soni, G.; Bozorgi, P.; Piorek, B.D.; Meinhart, C.D.; MacDonald, N.C. A Flat Heat Pipe Architecture Based on Nanostructured Titania. J. Microelectromech. Syst. 2010, 19, 878–884. [Google Scholar] [CrossRef]

- Shou-Shing, H.; Chih-Yi, L. Subcooled convective boiling in structured surface microchannels. J. Micromechan. Microeng. 2010, 20, 015027. [Google Scholar]

- Mavukkandy, M.O.; Bilad, M.R.; Kujawa, J.; Al-Gharabli, S.; Arafat, H.A. On the effect of fumed silica particles on the structure, properties and application of PVDF membranes. Sep. Purif. Technol. 2017, 187, 365–373. [Google Scholar] [CrossRef]

- AlMarzooqi, F.A.; Bilad, M.R.; Arafat, H.A. Improving Liquid Entry Pressure of Polyvinylidene Fluoride (PVDF) Membranes by Exploiting the Role of Fabrication Parameters in Vapor-Induced Phase Separation VIPS and Non-Solvent-Induced Phase Separation (NIPS) Processes. Appl. Sci. 2017, 7, 181. [Google Scholar] [CrossRef]

- Li, J.; Liu, C.; Xu, Z.; Zhang, K.; Ke, X.; Li, C.; Wang, L. A bio-inspired micropump based on stomatal transpiration in plants. Lab Chip 2011, 11, 2785–2789. [Google Scholar] [CrossRef]

- Finnerty, C.; Zhang, L.; Sedlak, D.L.; Nelson, K.L.; Mi, B. Synthetic graphene oxide leaf for solar desalination with zero liquid discharge. Environ. Sci. Technol. 2017, 51, 11701–11709. [Google Scholar] [CrossRef]

- Ahmed, F.E.; Hashaikeh, R.; Hilal, N. Solar powered desalination–Technology, energy and future outlook. Desalination 2019, 453, 54–76. [Google Scholar] [CrossRef]

- Kim, K.; Yu, S.; An, C.; Kim, S.W.; Jang, J.H. Mesoporous three-dimensional graphene networks for highly efficient solar desalination under 1 sun illumination. ACS Appl. Mater. Interfaces 2018, 10, 15602–15608. [Google Scholar] [CrossRef]

- Yin, X.; Zhang, Y.; Guo, Q.; Cai, X.; Xiao, J.; Ding, Z.; Yang, J. Macroporous double-network hydrogel for high-efficiency solar steam generation under 1 sun illumination. ACS Appl. Mater. Interfaces 2018, 10, 10998–11007. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, Z.; Huang, X.; Xuan, C.; Xie, J.; Fu, H.; Wu, Q.; Zhang, J.; Zhou, X.; Liu, Y. High-absorption recyclable photothermal membranes used in a bionic system for high-efficiency solar desalination via enhanced localized heating. J. Mater. Chem. A 2017, 5, 20044–20052. [Google Scholar] [CrossRef]

- Liu, K.K.; Jiang, Q.; Tadepalli, S.; Raliya, R.; Biswas, P.; Naik, R.R.; Singamaneni, S. Wood–graphene oxide composite for highly efficient solar steam generation and desalination. ACS Appl. Mater. Interfaces 2017, 9, 7675–7681. [Google Scholar] [CrossRef]

- Zhu, G.; Xu, J.; Zhao, W.; Huang, F. Constructing black titania with unique nanocage structure for solar desalination. ACS Appl. Mater. Interfaces 2016, 8, 31716–31721. [Google Scholar] [CrossRef]

- Shang, M.; Li, N.; Zhang, S.; Zhao, T.; Zhang, C.; Liu, C.; Li, H.; Wang, Z. Full-spectrum solar-to-heat conversion membrane with interfacial plasmonic heating ability for high-efficiency desalination of seawater. ACS Appl. Energy Mater. 2017, 1, 56–61. [Google Scholar] [CrossRef]

- Liu, X.; Hou, B.; Wang, G.; Cui, Z.; Zhu, X.; Wang, X. Black titania/graphene oxide nanocomposite films with excellent photothermal property for solar steam generation. J. Mater. Res. 2018, 33, 674–684. [Google Scholar] [CrossRef]

- Canbazoglu, F.; Fan, B.; Kargar, A.; Vemuri, K.; Bandaru, P. Enhanced solar evaporation of water from porous media, through capillary mediated forces and surface treatment. AIP Adv. 2016, 6, 085218. [Google Scholar] [CrossRef]

| Mass Ratios (%) | ||

|---|---|---|

| Membrane | FS | DMAc |

| PVDF | 0 | 88 |

| PVDF-FS3 | 3 | 85 |

| PVDF-FS4 | 4 | 84 |

| PVDF-FS5 | 5 | 83 |

| PVDF-FS7 | 7 | 81 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bahman, M.; AlNahyan, M.; Mustafa, I.; AlMarzooqi, F. Effect of Pore Characteristics in Polyvinylidene Fluoride/Fumed Silica Membranes on Mass Flux in Solar-Assisted Evaporation Applications. Appl. Sci. 2019, 9, 3186. https://0-doi-org.brum.beds.ac.uk/10.3390/app9153186

Bahman M, AlNahyan M, Mustafa I, AlMarzooqi F. Effect of Pore Characteristics in Polyvinylidene Fluoride/Fumed Silica Membranes on Mass Flux in Solar-Assisted Evaporation Applications. Applied Sciences. 2019; 9(15):3186. https://0-doi-org.brum.beds.ac.uk/10.3390/app9153186

Chicago/Turabian StyleBahman, Mona, Maryam AlNahyan, Ibrahim Mustafa, and Faisal AlMarzooqi. 2019. "Effect of Pore Characteristics in Polyvinylidene Fluoride/Fumed Silica Membranes on Mass Flux in Solar-Assisted Evaporation Applications" Applied Sciences 9, no. 15: 3186. https://0-doi-org.brum.beds.ac.uk/10.3390/app9153186