Classification of Grain Storage Inventory Modes Based on Temperature Contour Map of Grain Bulk Using Back Propagation Neural Network

Abstract

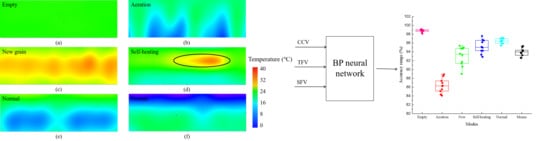

:1. Introduction

2. Methodology

2.1. Virtual Coordinate System of Temperature Sensors and Preprocessing of Temperature Data

2.2. Generation of RGB Temperature Contour Maps

2.3. Classification of Storage Conditions

2.4. Datasets for Training and Validation

2.5. Features Extraction of Temperature Contour Maps

2.5.1. Color Coherence Vector Extraction

2.5.2. Texture Feature Extraction

2.5.3. Smoothness Feature Extraction

2.6. Construction of BP Neural Network

2.7. Experiments Method

2.7.1. Optimization Experiments of Neural Network Input

2.7.2. Classification Experiments of Neural Network

2.7.3. Comparative Experiment

3. Results and Discussion

3.1. Optimization Experiments Results of Neural Network Input

3.1.1. Effect of Color Quantification on Classification Accuracy

3.1.2. Effect of Training Features on Classification Accuracy

3.2. Classification Accuracy

3.3. Comparative Experimental Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, C.; Tian, X.G.; He, R.; Ju, X.R.; Yuan, J.; Song, X.Y. Causes and research progress of condensation in grain heap. Grain Storage 2018, 47, 1–5. [Google Scholar]

- Xue, F.; Qu, C.; Wang, R.W.; Li, H.L. Progress on the fever and moldy of paddy during storage. Sci. Technol. Food Ind. 2016, 38, 338–340. [Google Scholar]

- Yang, S.; Cao, Y.; Zhao, H.; Fei, M. Research progress of rapid detection technology in grain mildew. Grain Oil 2018, 31, 21–23. [Google Scholar]

- Zhang, Y.Y.; Cai, J.P.; Jiang, P. Detection techniques for mold harm activities in stored-grain. Food Mach. 2013, 29, 267–272. [Google Scholar]

- Geng, Z.F.; Liu, Z.L.; Wang, C.F.; Liu, Q.Z.; Shen, S.M.; Liu, Z.M.; Du, S.S.; Deng, Z.W. Feeding Deterrents against Two Grain Storage Insects from Euphorbia fischeriana. Molecules 2011, 16, 466–476. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.S.; Arthur, F.H.; VanGundy, D.; Phillips, T.W. Combination of Methoprene and Controlled Aeration to Manage Insects in Stored Wheat. Insects 2016, 7, 25. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Wu, T.; Shao, T.; Peng, Z. Integrated model of BP neural network and CNN algorithm for automatic wear debris classification. Wear 2019, 426, 1761–1770. [Google Scholar] [CrossRef]

- Manandhar, A.; Milindi, P.; Shah, A. An Overview of the Post-Harvest Grain Storage Practices of Smallholder Farmers in Developing Countries. Agriculture 2018, 8, 57. [Google Scholar] [CrossRef] [Green Version]

- China National Standards Management Committee. Technical criterion for grain and oil-seeds storage-GB/T 29890-2013; China Standards Press: Beijing, China, 2013. [Google Scholar]

- Nie, Z.B. Director of the State Administration of Grain, Answers Questions about the “Interim Measures for the Inspection of Grain Stocks” on the Chinese Government Website. 2006. Available online: http://www.gov.cn/ztzl/yzn/content_479484.htm (accessed on 26 October 2020).

- Xiao, Q. Research on the Strategies and Methods of Storing Grain Digital Supervision Based on the Grain Monitoring; Jilin University: Changchun, China, 2018. [Google Scholar]

- Cui, H.; Wu, W.; Wu, Z.; Han, F.; Zhu, H.; Qin, X. Reserves monitoring method for grain storage based on temporal and spatial correlation of grain temperature. Trans. Chin. Soc. Agric. Mach. 2019, 50, 321–330. [Google Scholar]

- Cui, H.W.; Wu, W.F.; Wu, Z.D.; Han, F. A Method for Detecting Abnormal Changes in the Temperature Field of Grain Bulk Based on HSV Features of Cloud Maps. Trans. ASABE 2020, 63, 1181–1191. [Google Scholar]

- Zheng, Y.; Li, G.; Li, Y. Survey of application of deep learning in image Recognition. Comput. Eng. Appl. 2019, 55, 20–36. [Google Scholar]

- Chen, Y.; Huang, L.; Zhu, L.; Yokoya, N.; Jia, X. Fine-grained classification of hyperspectral imagery based on deep learning. Remote Sens. 2019, 11, 2690. [Google Scholar] [CrossRef]

- Yin, C.; Chen, Z. Developing sustainable classification of diseases via deep learning and semi-supervised learning. Healthcare 2020, 8, 291. [Google Scholar] [CrossRef] [PubMed]

- Ragab, D.A.; Sharkas, M.; Marshall, S.; Ren, J. Breast cancer detection using deep convolutional neural networks and support vector machines. PeerJ 2019, 7, e6201. [Google Scholar] [CrossRef] [PubMed]

- Costa, N.L.; Llobodanin, L.A.G.; Castro, I.A.; Barbosa, R. Geographical classification of tannat wines based on support vector machines and feature selection. Beverages 2018, 4, 97. [Google Scholar] [CrossRef] [Green Version]

- Fan, Y.; Wang, B.; Wang, W.; Tang, Y. A Summary of Research on Deep Learning in China. Distance Educ. China 2015, 6, 27–33+79. [Google Scholar]

- Li, J.; Pan, Z. Network Traffic Classification Based on Deep Learning. KSII Trans. Internet Inf. Syst. 2020, 14, 4246–4267. [Google Scholar]

- Chen, Y.; Wang, Y.; Gu, Y.; He, X.; Ghamisi, P.; Jia, X. Deep Learning Ensemble for Hyperspectral Image Classification. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2019, 12, 1882–1897. [Google Scholar] [CrossRef]

- Liu, P.; Zhang, H.; Eom, K.B. Active Deep Learning for Classification of Hyperspectral Images. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2017, 10, 712–724. [Google Scholar] [CrossRef] [Green Version]

- Cervantes, J.; Garcia-Lamont, F.; Rodríguez-Mazahua, L.; Lopez, A. A comprehensive survey on support vector machine classification: Applications, challenges and trends. Neurocomputing 2020, 408, 189–215. [Google Scholar] [CrossRef]

- Zhang, Y. Support Vector Machine Classification Algorithm and Its Application. In Information Computing and Applications; Pt II; Liu, C.F., Wang, L.Z., Yang, A.M., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 179–186. [Google Scholar]

- Wang, Y.; Wang, J.; Chang, S.; Sun, L.; An, L.; Chen, Y.; Xu, J. Classification of Street Tree Species Using UAV Tilt Photogrammetry. Remote Sens. 2021, 13, 216. [Google Scholar] [CrossRef]

- Zhou, F.; Su, Z.; Chai, X.; Chen, L. Detection of Foreign Matter in Transfusion Solution Based on Gaussian Background Modeling and an Optimized BP Neural Network. Sensors 2014, 14, 19945–19962. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, S.; Liu, J.; Yu, Y. Prediction of cut size for pneumatic classification based on a back propagation (BP) neural network. ZKG Int. 2016, 69, 64–71. [Google Scholar]

- Huang, Y.; Meng, S.; Hwang, S.; Kobayashi, K.; Sugiyama, J. Neural Network for Classification of Chinese Zither Panel Wood via Near-infrared Spectroscopy. BioResources 2020, 15, 130–141. [Google Scholar]

- Yuan, C.; Sun, X.; Wu, Q.J. Difference co-occurrence matrix using BP neural network for fingerprint liveness detection. Soft Comput. 2019, 23, 5157–5169. [Google Scholar] [CrossRef]

- Cui, H.W.; Wu, W.F.; Wu, Z.D.; Han, F. Monitoring method of stored grain quantity based on temperature field cloud maps. Trans. Chin. Soc. Agric. Eng. 2019, 35, 290–298. [Google Scholar]

- Duan, S.; Yang, W.; Wang, X.; Mao, S.; Zhang, Y. Grain pile temperature forecasting from weather factors: A support vector regression approach. In Proceedings of the 2019 IEEE/CIC International Conference on Communications in China (ICCC), Changchun, China, 11–13 August 2019. [Google Scholar]

- Gholami, V.; Chau, K.; Fadaee, F.; Torkaman, J.; Ghaffari, A. Modeling of groundwater level fluctuations using dendrochronology in alluvial aquifers. J. Hydrol. 2015, 529, 1060–1069. [Google Scholar] [CrossRef]

- Alqahtani, A.; Whyte, A. Artificial neural networks incorporating cost significant items towards enhancing estimation for (life-cycle) costing of construction projects. Constr. Econ. Build. 2013, 13, 51–64. [Google Scholar] [CrossRef] [Green Version]

- Pass, G.; Zabih, R.; Miller, J. Comparing images using color coherence vectors. In Proceedings of the Fourth ACM International Multimedia Conference, Boston, MA, USA, 1 February 1997. [Google Scholar]

- Moslehi, M.; de Barros, F.P. Using color coherence vectors to evaluate the performance of hydrologic data assimilation. Water Resour. Res. 2019, 55, 1717–1729. [Google Scholar] [CrossRef]

- Ramella, G.; Di Baja, G.S. A new method for color quantization. In Proceedings of the 2016 12th International Conference on Signal-Image Technology & Internet-Based Systems (SITIS), Naples, Italy, 28 November–1 December 2016. [Google Scholar]

- Djemal, R.; AlSharabi, K.; Ibrahim, S.; Alsuwailem, A. EEG-based computer aided diagnosis of autism spectrum disorder using wavelet, entropy, and ANN. BioMed Res. Int. 2017, 2017, 9816591. [Google Scholar] [CrossRef] [Green Version]

- Vécsei, A.; Fuhrmann, T.; Uhl, A. Towards automated diagnosis of celiac disease by computer-assisted classification of duodenal imagery. In Proceedings of the 4th IET International Conference on Advances in Medical, Signal and Information Processing (MEDSIP 2008), Santa Margherita Ligure, Italy, 14–16 July 2008. [Google Scholar]

- Navarro, C.F.; Perez, C.A. Color—Texture pattern classification using global—Local feature extraction, an SVM classifier, with bagging ensemble post-processing. Appl. Sci. 2019, 9, 3130. [Google Scholar] [CrossRef] [Green Version]

- Sinaga, A.S. Texture Features Extraction of Human Leather Ports Based on Histogram. Indones. J. Artif. Intell. Data Min. 2018, 1, 92–98. [Google Scholar] [CrossRef] [Green Version]

- Deutsch, C.V. Constrained smoothing of histograms and scatterplots with simulated annealing. Technometrics 1996, 38, 266–274. [Google Scholar] [CrossRef]

- Liu, P.; Zhang, W. A fault diagnosis intelligent algorithm based on improved bp neural network. Int. J. Pattern Recognit. Artif. Intell. 2019, 33, 1959028. [Google Scholar] [CrossRef]

- Cao, J.; Chen, L.; Wang, M.; Shi, H.; Tian, Y. A Parallel Adaboost-Backpropagation Neural Network for Massive Image Dataset Classification. Sci. Rep. 2016, 6, 38201. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.W.; Chen, S.R.; Gao, H.B.; Xu, K.J.; Yang, M.Y. State of Charge Estimation of Power Battery Using Improved Back Propagation Neural Network. Batteries 2018, 4, 69. [Google Scholar] [CrossRef] [Green Version]

- Liang, P.; Shi, W.; Zhang, X. Remote Sensing Image Classification Based on Stacked Denoising Autoencoder. Remote Sens. 2017, 10, 16. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Wang, P.; Liang, S.; Qi, X.; Li, L.; Xu, L. Monitoring maize growth conditions by training a BP neural network with remotely sensed vegetation temperature condition index and leaf area index. Comput. Electron. Agric. 2019, 160, 82–90. [Google Scholar] [CrossRef]

- Heaton, J. The Number of Hidden Layers. 2017. Available online: https://www.heatonresearch.com/2017/06/01/hidden-layers.html (accessed on 26 October 2020).

- Zhao, Z.; Xin, H.; Ren, Y.; Guo, X. Application and comparison of BP neural network algorithm in MATLAB. In Proceedings of the 2010 International Conference on Measuring Technology and Mechatronics Automation, Changsha, China, 13–14 March 2010. [Google Scholar]

- Qu, S.L.; Sun, Z.F.; Fan, H.F.; Li, K. BP neural network for the prediction of urban building energy consumption based on Matlab and its application. In Proceedings of the 2010 Second International Conference on Computer Modeling and Simulation, Sanya, China, 22–24 January 2010. [Google Scholar]

- Pan, R.; Gao, W.; Liu, J.; Wang, H. Automatic recognition of woven fabric pattern based on image processing and BP neural network. J. Text. Inst. 2011, 102, 19–30. [Google Scholar] [CrossRef]

- Wei, Y.; Xia, L.; Pan, S.; Wu, J.; Zhang, X.; Han, M.; Zhang, W.; Xie, J.; Li, Q. Prediction of occupancy level and energy consumption in office building using blind system identification and neural networks. Appl. Energy 2019, 240, 276–294. [Google Scholar] [CrossRef]

- Huang, Y.; Zhao, L. Review on landslide susceptibility mapping using support vector machines. Catena 2018, 165, 520–529. [Google Scholar] [CrossRef]

- Zhu, X.; Li, N.; Pan, Y. Optimization Performance Comparison of Three Different Group Intelligence Algorithms on a SVM for Hyperspectral Imagery Classification. Remote Sens. 2019, 11, 734. [Google Scholar] [CrossRef] [Green Version]

- Chang, C.; Lin, C. LIBSVM: A library for support vector machines. ACM Trans. Intell. Syst. Technol. Cereals Oils Foods 2011, 2, 1–27. [Google Scholar] [CrossRef]

- Mehdipour, V.; Memarianfard, M. Ground-level O3 sensitivity analysis using support vector machine with radial basis function. Int. J. Environ. Sci. Technol. 2018, 16, 2745–2754. [Google Scholar] [CrossRef]

| Constant a | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Accuracy (%) | 92.61 | 92.66 | 93.22 | 94.26 | 94.36 | 93.67 | 95.32 | 95.07 | 94.17 | 93.81 |

| SD (%) | 4.32 | 4.56 | 4.23 | 3.76 | 3.94 | 4.51 | 3.42 | 4.28 | 5.09 | 5.14 |

| Kernel Function | Empty (%) | Aeration (%) | New (%) | Self-Heating (%) | Normal (%) | Overall (%) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean | SD | Mean | SD | Mean | SD | Mean | SD | Mean | SD | Mean | SD | |

| Linear | 88.6 | 1.2 | 76.0 | 2.0 | 68.4 | 2.8 | 80.9 | 3.0 | 78.6 | 0.6 | 80.2 | 0.8 |

| Radial basis | 94.0 | 1.1 | 91.3 | 0.8 | 87.2 | 1.5 | 92.3 | 1.6 | 91.1 | 0.6 | 91.6 | 0.6 |

| Polynomial | 93.1 | 1.4 | 92.3 | 1.8 | 87.7 | 2.7 | 92.5 | 1.9 | 93.4 | 0.4 | 92.6 | 0.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, H.; Zhang, Q.; Zhang, J.; Wu, Z.; Wu, W. Classification of Grain Storage Inventory Modes Based on Temperature Contour Map of Grain Bulk Using Back Propagation Neural Network. Agriculture 2021, 11, 451. https://0-doi-org.brum.beds.ac.uk/10.3390/agriculture11050451

Cui H, Zhang Q, Zhang J, Wu Z, Wu W. Classification of Grain Storage Inventory Modes Based on Temperature Contour Map of Grain Bulk Using Back Propagation Neural Network. Agriculture. 2021; 11(5):451. https://0-doi-org.brum.beds.ac.uk/10.3390/agriculture11050451

Chicago/Turabian StyleCui, Hongwei, Qiang Zhang, Jinsong Zhang, Zidan Wu, and Wenfu Wu. 2021. "Classification of Grain Storage Inventory Modes Based on Temperature Contour Map of Grain Bulk Using Back Propagation Neural Network" Agriculture 11, no. 5: 451. https://0-doi-org.brum.beds.ac.uk/10.3390/agriculture11050451