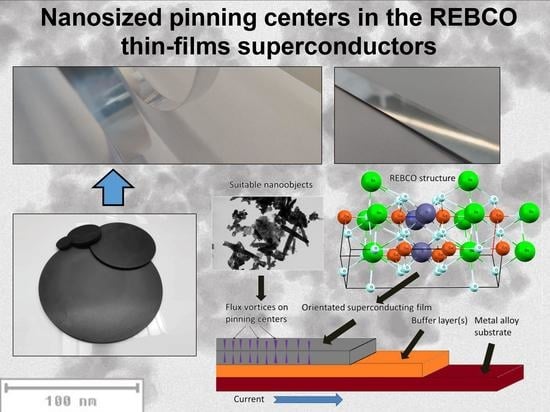

Nanosized Pinning Centers in the Rare Earth-Barium-Copper-Oxide Thin-Film Superconductors

Abstract

:1. Introduction

2. Vortex Pinning in the Type II Superconductors

3. Methods of the Pinning Center Introduction into the Superconducting Thin-Films

4. Artificial Pinning Centers in RECBO Thin-Film Superconductors

5. Synthesis and Viability of Material for Artificial Pinning Centers for the REBCO Coated Superconductors

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bardeen, J.; Cooper, L.N.; Schrieffer, J.R. Theory of superconductivity. Phys. Rev. 1957, 108, 1175. [Google Scholar] [CrossRef] [Green Version]

- Bednorz, J.G.; Müller, K.A. Possible high Tc superconductivity in the Ba-La-Cu-O system. Z. Phys. B Condens. Matter 1986, 64, 189–193. [Google Scholar] [CrossRef]

- Yildiz, Y.; Nalbant, M. A review of cryogenic cooling in machining processes. Int. J. Mach. Tools Manuf. 2008, 48, 947–964. [Google Scholar] [CrossRef]

- Natsume, K.; Mito, T.; Yanagi, N.; Tamura, H.; Tamada, T.; Shikimachi, K.; Hirano, N.; Nagaya, S. Heat transfer performance of cryogenic oscillating heat pipes for effective cooling of superconducting magnets. Cryogenics 2011, 51, 309–314. [Google Scholar] [CrossRef]

- Watanabe, K.; Awaji, S.; Sakuraba, J.; Watazawa, K.; Hasebe, T.; Jikihara, K.; Yamada, Y.; Ishihara, M. 11 T liquid helium-free superconducting magnet. Cryogenics 1996, 36, 1019–1025. [Google Scholar] [CrossRef]

- Timmerhaus, K.D.; Reed, R.P. Cryogenic Engineering: Fifty Years of Progress; Springer Science & Business Media: Berlin, Germany, 2007. [Google Scholar]

- Van Sciver, S. Forced flow He II cooling for superconducting magnets—Design considerations. Cryogenics 1998, 38, 503–512. [Google Scholar] [CrossRef]

- Dustmann, C.-H. Cooling System for Indirectly Cooled Superconducting Magnets. Patent EP0144873A2, 19 June 1985. [Google Scholar]

- Larkin, A.; Ovchinnikov, Y. Nonlinear conductivity of superconductors in the mixed state. Sov. Phys. JETP 1975, 41, 960–965. [Google Scholar]

- Kim, Y.; Hempstead, C.; Strnad, A. Flux-Flow resistance in type-II superconductors. Phys. Rev. 1965, 139, A1163. [Google Scholar] [CrossRef]

- Hao, Z.; Clem, J.R.; McElfresh, M.; Civale, L.; Malozemoff, A.; Holtzberg, F. Model for the reversible magnetization of high-κ type-II superconductors: Application to high-Tc superconductors. Phys. Rev. B 1991, 43, 2844. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; MacDonald, A.H. Mixed-State quasiparticle spectrum for d-wave superconductors. Phys. Rev. B 1995, 52, R3876. [Google Scholar] [CrossRef] [Green Version]

- Tachiki, M.; Matsumoto, H.; Umezawa, H. Mixed state in magnetic superconductors. Phys. Rev. B 1979, 20, 1915. [Google Scholar] [CrossRef]

- Stephens, G.; Bettencourt, L.M.; Zurek, W. Critical dynamics of gauge systems: Spontaneous vortex formation in 2D superconductors. Phys. Rev. Lett. 2002, 88, 137004. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Grigorieva, I.; Escoffier, W.; Misko, V.; Baelus, B.; Peeters, F.; Vinnikov, L.Y.; Dubonos, S. Pinning-Induced formation of vortex clusters and giant vortices in mesoscopic superconducting disks. Phys. Rev. Lett. 2007, 99, 147003. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Llordes, A.; Palau, A.; Gázquez, J.; Coll, M.; Vlad, R.; Pomar, A.; Arbiol, J.; Guzman, R.; Ye, S.; Rouco, V. Nanoscale strain-induced pair suppression as a vortex-pinning mechanism in high-temperature superconductors. Nat. Mater. 2012, 11, 329–336. [Google Scholar] [CrossRef] [PubMed]

- Chibotaru, L.F.; Ceulemans, A.; Bruyndoncx, V.; Moshchalkov, V.V. Symmetry-Induced formation of antivortices in mesoscopic superconductors. Nature 2000, 408, 833–835. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Maniv, A.; Polturak, E.; Koren, G. Observation of magnetic flux generated spontaneously during a rapid quench of superconducting films. Phys. Rev. Lett. 2003, 91, 197001. [Google Scholar] [CrossRef] [Green Version]

- Kibble, T.; Rajantie, A. Estimation of vortex density after superconducting film quench. Phys. Rev. B 2003, 68, 174512. [Google Scholar] [CrossRef] [Green Version]

- Horide, T.; Kawamura, T.; Matsumoto, K.; Ichinose, A.; Yoshizumi, M.; Izumi, T.; Shiohara, Y. Jc improvement by double artificial pinning centers of BaSnO3 nanorods and Y2O3 nanoparticles in YBa2Cu3O7 coated conductors. Supercond. Sci. Technol. 2013, 26, 075019. [Google Scholar] [CrossRef]

- Watanabe, K.; Matsushita, T.; Kobayashi, N.; Kawabe, H.; Aoyagi, E.; Hiraga, K.; Yamane, H.; Kurosawa, H.; Hirai, T.; Muto, Y. Strong flux pinning centers in Y-Ba-Cu-O films prepared by chemical vapor deposition. Appl. Phys. Lett. 1990, 56, 1490–1492. [Google Scholar] [CrossRef]

- Tanaka, Y.; Ishizuka, M.; He, L.; Horiuchi, S.; Maeda, H. Jc property and microstructure of Bi2223 tapes made using AgCu alloy sheaths doped with Ti, Zr or Hf. Phys. C Supercond. 1996, 268, 133–142. [Google Scholar] [CrossRef]

- Godeke, A. A review of the properties of Nb3Sn and their variation with A15 composition, morphology and strain state. Supercond. Sci. Technol. 2006, 19, R68. [Google Scholar] [CrossRef] [Green Version]

- Eisterer, M. Magnetic properties and critical currents of MgB2. Supercond. Sci. Technol. 2007, 20, R47. [Google Scholar] [CrossRef]

- Matsumoto, K.; Horide, T.; Osamura, K.; Mukaida, M.; Yoshida, Y.; Ichinose, A.; Horii, S. Enhancement of critical current density of YBCO films by introduction of artificial pinning centers due to the distributed nano-scaled Y2O3 islands on substrates. Phys. C Supercond. 2004, 412, 1267–1271. [Google Scholar] [CrossRef]

- Parrell, J.; Dorris, S.; Larbalestier, D. On the role of Vickers and Knoop microhardness as a guide to developing high critical current density Ag-clad BSCCO-2223 tapes. Phys. C Supercond. 1994, 231, 137–146. [Google Scholar] [CrossRef]

- Ren, Z.; Che, G.; Dong, X.; Yang, J.; Lu, W.; Yi, W.; Shen, X.; Li, Z.; Sun, L.; Zhou, F. Superconductivity and phase diagram in iron-based arsenic-oxides ReFeAsO1−δ (Re = rare-earth metal) without fluorine doping. Europhys. Lett. 2008, 83, 17002. [Google Scholar]

- Gao, M.M.; Suo, H.L.; Zhao, Y.; Grivel, J.C.; Cheng, Y.L.; Ma, L.; Wang, R.; Gao, P.K.; Wang, J.H.; Liu, M.; et al. Characterization and properties of an advanced composite substrate for YBCO-coated conductors. Acta Mater. 2010, 58, 1299–1308. [Google Scholar] [CrossRef]

- Zhao, Y.; Grivel, J.C.; Napari, M.; Pavlopoulos, D.; Bednarcik, J.; von Zimmermann, M. Highly textured Gd2Zr2O7 films grown on textured Ni-5 at.%W substrates by solution deposition route: Growth, texture evolution, and microstructure dependency. Thin Solid Films 2012, 520, 1965–1972. [Google Scholar] [CrossRef]

- Li, Z.Y.; Li, J.; Wang, Y.; Yao, Z.; Kang, Z.R.; Yuan, B.; Yang, Z.D.; Jin, Z.; Hong, Z. A study on critical current and AC loss characteristics of novel 2G HTS narrow wires. IEEE Trans. Appl. Supercond. 2016, 26. [Google Scholar] [CrossRef]

- Sung, H.J.; Park, M.; Go, B.S.; Yu, I.K. A study on the required performance of a 2G HTS wire for HTS wind power generators. Supercond. Sci. Technol. 2016, 29, 054001. [Google Scholar] [CrossRef]

- Vetrella, U.B.; Celentano, G.; Marchetti, M.; Messina, G.; Morici, L.; Sabatino, P.; Viola, R.; della Corte, A. HTS coils fabrication from commercial 2G YBCO tapes: Measurements and simulation. IEEE Trans. Appl. Supercond. 2014, 24, 4600204. [Google Scholar] [CrossRef]

- Lim, C.S.; Wang, L.; Chua, C.K.; Sofer, Z.; Jankovský, O.; Pumera, M. High temperature superconducting materials as bi-functional catalysts for hydrogen evolution and oxygen reduction. J. Mater. Chem. A 2015, 3, 8346–8352. [Google Scholar] [CrossRef]

- Yang, W.M.; Chao, X.X.; Guo, F.X.; Li, J.W.; Chen, S.L. Magnetic levitation and its application for education devices based on YBCO bulk superconductors. Phys. C-Supercond. Appl. 2013, 493, 71–74. [Google Scholar] [CrossRef]

- Durrell, J.H.; Ainslie, M.D.; Zhou, D.; Vanderbemden, P.; Bradshaw, T.; Speller, S.; Filipenko, M.; Cardwell, D.A. Bulk superconductors: A roadmap to applications. Supercond. Sci. Technol. 2018, 31, 103501. [Google Scholar] [CrossRef]

- Valiente-Blanco, I.; Diez-Jimenez, E.; Perez-Diaz, J.L. Engineering and performance of a contactless linear slider based on superconducting magnetic levitation for precision positioning. Mechatronics 2013, 23, 1051–1060. [Google Scholar] [CrossRef]

- Sass, F.; Dias, D.H.N.; Sotelo, G.G.; de Andrade, R. Lateral displacement influence on the levitation force of YBCO coated conductor linear bearings. IEEE Trans. Appl. Supercond. 2014, 24, 3600405. [Google Scholar] [CrossRef]

- Iijima, Y.; Matsumoto, K. High-Temperature-Superconductor coated conductors: Technical progress in Japan. Supercond. Sci. Technol. 2000, 13, 68. [Google Scholar] [CrossRef]

- Malozemoff, A.; Fleshler, S.; Rupich, M.; Thieme, C.; Li, X.; Zhang, W.; Otto, A.; Maguire, J.; Folts, D.; Yuan, J. Progress in high temperature superconductor coated conductors and their applications. Supercond. Sci. Technol. 2008, 21, 034005. [Google Scholar] [CrossRef]

- Obradors, X.; Puig, T.; Pomar, A.; Sandiumenge, F.; Mestres, N.; Coll, M.; Cavallaro, A.; Roma, N.; Gazquez, J.; Gonzalez, J. Progress towards all-chemical superconducting YBa2Cu3O7-coated conductors. Supercond. Sci. Technol. 2006, 19, S13. [Google Scholar] [CrossRef]

- Finnemore, D.; Gray, K.; Maley, M.; Welch, D.; Christen, D.; Kroeger, D. Coated conductor development: An assessment. Phys. C Supercond. 1999, 320, 1–8. [Google Scholar] [CrossRef]

- Malozemoff, A.; Annavarapu, S.; Fritzemeier, L.; Li, Q.; Prunier, V.; Rupich, M.; Thieme, C.; Zhang, W.; Goyal, A.; Paranthaman, M. Low-Cost YBCO coated conductor technology. Supercond. Sci. Technol. 2000, 13, 473. [Google Scholar] [CrossRef]

- Senatore, C.; Alessandrini, M.; Lucarelli, A.; Tediosi, R.; Uglietti, D.; Iwasa, Y. Progresses and challenges in the development of high-field solenoidal magnets based on RE123 coated conductors. Supercond. Sci. Technol. 2014, 27, 103001. [Google Scholar] [CrossRef] [Green Version]

- Graser, S.; Hirschfeld, P.J.; Kopp, T.; Gutser, R.; Andersen, B.M.; Mannhart, J. How grain boundaries limit supercurrents in high-temperature superconductors. Nat. Phys. 2010, 6, 609–614. [Google Scholar] [CrossRef] [Green Version]

- Durrell, J.H.; Rutter, N.A. Importance of low-angle grain boundaries in YBa2Cu3O7-δ coated conductors. Supercond. Sci. Technol. 2008, 22, 013001. [Google Scholar] [CrossRef] [Green Version]

- Chikumoto, N.; Lee, S.; Nakao, K.; Tanabe, K. Development of inside-plume PLD process for the fabrication of large Ic (B) REBCO tapes. Phys. C Supercond. 2009, 469, 1303–1306. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhu, J.; Jiang, G.; Chen, C.; Wu, W.; Zhang, Z.; Chen, S.; Hong, Y.; Hong, Z.; Jin, Z. Progress in fabrication of second generation high temperature superconducting tape at Shanghai superconductor technology. Supercond. Sci. Technol. 2019, 32, 044004. [Google Scholar] [CrossRef]

- Prusseit, W.; Nemetschek, R.; Hoffmann, C.; Sigl, G.; Lümkemann, A.; Kinder, H. ISD process development for coated conductors. Phys. C Supercond. Appl. 2005, 426, 866–871. [Google Scholar] [CrossRef]

- Feys, J.; Vermeir, P.; Lommens, P.; Hopkins, S.C.; Granados, X.; Glowacki, B.A.; Baecker, M.; Reich, E.; Ricard, S.; Holzapfel, B. Ink-Jet printing of YBa2Cu3O7 superconducting coatings and patterns from aqueous solutions. J. Mater. Chem. 2012, 22, 3717–3726. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Zdun, K.; Hope, L.; Xie, J.; Corcoran, S.; Qiao, Y.; Reeves, J.; Lenseth, K.; Selvamanickam, V. Texture development and superconducting properties of YBCO thick films deposited on buffered metal substrates at various deposition rates. IEEE Trans. Appl. Supercond. 2003, 13, 2758–2761. [Google Scholar]

- Schindl, M.; Genoud, J.-Y.; Suo, H.; Dhalle, M.; Walker, E.; Flukiger, R. Epitaxial growth of biaxially aligned Y-Ba-Cu-O superconductors by spray pyrolysis on textured Ag ribbons and single crystal substrates. IEEE Trans. Appl. Supercond. 2001, 11, 3313–3316. [Google Scholar] [CrossRef]

- Kim, H.-S.; Oh, S.-S.; Ha, H.-S.; Youm, D.; Moon, S.-H.; Kim, J.H.; Dou, S.X.; Heo, Y.-U.; Wee, S.-H.; Goyal, A. Ultra-High performance, high-temperature superconducting wires via cost-effective, scalable, co-evaporation process. Sci. Rep. 2014, 4, 4744. [Google Scholar] [CrossRef]

- Hari Babu, N.; Reddy, E.; Cardwell, D.; Campbell, A.; Tarrant, C.; Schneider, K. Artificial flux pinning centers in large, single-grain (RE)-Ba-Cu-O superconductors. Appl. Phys. Lett. 2003, 83, 4806–4808. [Google Scholar] [CrossRef]

- Bondarenko, S.I.; Koverya, V.P.; Krevsun, A.V.; Link, S.I. High-Temperature superconductors of the family (RE)Ba2Cu3O7-delta and their application. Low Temp. Phys. 2017, 43, 1125–1151. [Google Scholar] [CrossRef] [Green Version]

- Foltyn, S.; Civale, L.; MacManus-Driscoll, J.; Jia, Q.; Maiorov, B.; Wang, H.; Maley, M. Materials science challenges for high-temperature superconducting wire. Nat. Mater. 2007, 6, 631–642. [Google Scholar] [CrossRef]

- Shiohara, Y.; Yoshizumi, M.; Takagi, Y.; Izumi, T. Future prospects of high Tc superconductors-coated conductors and their applications. Phys. C Supercond. 2013, 484, 1–5. [Google Scholar] [CrossRef]

- Selvamanickam, V.; Chen, Y.; Xiong, X.; Xie, Y.Y.; Martchevski, M.; Rar, A.; Qiao, Y.; Schmidt, R.M.; Knoll, A.; Lenseth, K.P. High performance 2G wires: From R&D to pilot-scale manufacturing. IEEE Trans. Appl. Supercond. 2009, 19, 3225–3230. [Google Scholar]

- Bartůněk, V.; Luxa, J.; Sedmidubský, D.; Hlásek, T.; Jankovský, O. Microscale and nanoscale pinning centres in single-domain REBCO superconductors. J. Mater. Chem. C. 2019, 7, 13010–13019. [Google Scholar] [CrossRef]

- Uglietti, D. A review of commercial high temperature superconducting materials for large magnets: From wires and tapes to cables and conductors. Supercond. Sci. Technol. 2019, 32, 29. [Google Scholar] [CrossRef]

- Barth, C.; Mondonico, G.; Senatore, C. Electro-Mechanical properties of REBCO coated conductors from various industrial manufacturers at 77 K, self-field and 4.2 K, 19 T. Supercond. Sci. Technol. 2015, 28, 045011. [Google Scholar] [CrossRef] [Green Version]

- Wolf, M.J.; Fietz, W.H.; Bayer, C.M.; Schlachter, S.I.; Heller, R.; Weiss, K.-P. HTS CroCo: A stacked HTS conductor optimized for high currents and long-length production. IEEE Trans. Appl. Supercond. 2016, 26, 19–24. [Google Scholar] [CrossRef]

- Allen, N.; Chiesa, L.; Takayasu, M. Structural modeling of HTS tapes and cables. Cryogenics 2016, 80, 405–418. [Google Scholar] [CrossRef]

- Takayasu, M.; Chiesa, L.; Allen, N.C.; Minervini, J.V. Present status and recent developments of the twisted stacked-tape cable conductor. IEEE Trans. Appl. Supercond. 2016, 26, 25–34. [Google Scholar] [CrossRef] [Green Version]

- Wördenweber, R. Growth of high-Tcthin films. Supercond. Sci. Technol. 1999, 12, R86–R102. [Google Scholar] [CrossRef]

- Singh, R.K.; Kumar, D. Pulsed laser deposition and characterization of high-Tc YBa2Cu3O7-x superconducting thin films. Mater. Sci. Eng. R-Rep. 1998, 22, 113–185. [Google Scholar] [CrossRef]

- Tasaki, Y.; Yoshizawa, S.; Koyama, K.; Fujino, Y. Preparation of YBCO thin film by MOCVD method using new liquid metal organic precursors. IEEE Trans. Appl. Supercond. 1999, 9, 2367–2370. [Google Scholar] [CrossRef]

- Watson, I.M. Metal-Organic CVD of the high-T-c superconductor YBa2Cu3O7-delta. Chem. Vap. Depos. 1997, 3, 9–26. [Google Scholar] [CrossRef]

- Selvamanickam, V.; Xie, Y.; Reeves, J.; Chen, Y. MOCVD-Based YBCO-coated conductors. MRS Bull. 2004, 29, 579–582. [Google Scholar] [CrossRef]

- Obradors, X.; Puig, T.; Ricart, S.; Coll, M.; Gazquez, J.; Palau, A.; Granados, X. Growth, nanostructure and vortex pinning in superconducting YBa2Cu3O7 thin films based on trifluoroacetate solutions. Supercond. Sci. Technol. 2012, 25, 32. [Google Scholar] [CrossRef]

- Araki, T.; Hirabayashi, I. Review of a chemical approach to YBa2Cu3O7-x coated superconductors—Metalorganic deposition using trifluoroacetates. Supercond. Sci. Technol. 2003, 16, R71–R94. [Google Scholar] [CrossRef]

- Degardin, A.; Caristan, E.; Pech, T.; Kreisler, A. Model for reactive sputtering Optimisation results for YBaCuO thin films deposited on polycrystalline zirconia substrates. J. Alloys Compd. 1997, 251, 107–110. [Google Scholar] [CrossRef]

- Kim, H.S.; Chung, K.C.; Lee, B.S.; Lim, S.M.; Youm, D. Effects of plasma on the growth conditions of Y1Ba2Cu3O7-delta thin films in dc sputtering. Supercond. Sci. Technol. 2003, 16, 760–767. [Google Scholar] [CrossRef]

- Maniv, T.; Zhuravlev, V.; Vagner, I.; Wyder, P. Vortex states and quantum magnetic oscillations in conventional type-II superconductors. Rev. Mod. Phys. 2001, 73, 867. [Google Scholar] [CrossRef]

- Abrikosov, A.A. On the magnetic properties of superconductors of the second group. Sov. Phys. JETP 1957, 5, 1174–1182. [Google Scholar]

- Bardeen, J.; Stephen, M.J. Theory of motion of vortices in superconductors. Phys. Rev. 1965, 140, A1197. [Google Scholar] [CrossRef]

- Cooley, L.D.; Grishin, A.M. Pinch effect in commensurate vortex-pin lattices. Phys. Rev. Lett. 1995, 74, 2788–2791. [Google Scholar] [CrossRef]

- Mawatari, Y. Dynamics of vortices in planar pinning centers and anisotropic conductivity in type-II superconductors. Phys. Rev. B 1997, 56, 3433. [Google Scholar] [CrossRef]

- Silhanek, A.; Van Look, L.; Raedts, S.; Jonckheere, R.; Moshchalkov, V. Guided vortex motion in superconductors with a square antidot array. Phys. Rev. B 2003, 68, 214504. [Google Scholar] [CrossRef] [Green Version]

- Vélez, M.; Martin, J.; Villegas, J.; Hoffmann, A.; González, E.; Vicent, J.; Schuller, I.K. Superconducting vortex pinning with artificial magnetic nanostructures. J. Magn. Magn. Mater. 2008, 320, 2547–2562. [Google Scholar] [CrossRef]

- Matsuda, T.; Harada, K.; Kasai, H.; Kamimura, O.; Tonomura, A. Observation of dynamic interaction of vortices with pinning centers by Lorentz microscopy. Science 1996, 271, 1393–1395. [Google Scholar] [CrossRef]

- Cheng, C.H.; Zhao, Y.; Feng, Y.; Zhang, H.; Nishiyama, M.; Koshizuka, N.; Murakami, M. Superconductors with nanoscale pinning centers. In Frontiers in Superconducting Materials; Narlikar, A.V., Ed.; Springer: Berlin, Germany, 2005; pp. 619–647. [Google Scholar]

- Horvat, J. Nanopinning in high-temperature superconductors. In Encyclopedia of Nanoscience and Nanotechnology; American Scientific Publishers: Valencia, CA, USA, 2004; Volume 7, pp. 207–218. [Google Scholar]

- Kummeth, P.; Neumuller, H.W.; Ries, G.; Kraus, M.; Klaumunzer, S.; Saemannischenko, G. Enhancement of critical current-density Jcm and pinning energy-U in melt-textured Bi2Sr2CaCu2O8+delta on Ag-tape by heavy-ion irradiation. J. Alloys Compd. 1993, 195, 403–406. [Google Scholar] [CrossRef]

- Yang, P.; Lieber, C.M. Nanostructured high-temperature superconductors: Creation of strong-pinning columnar defects in nanorod/superconductor composites. J. Mater. Res. 1997, 12, 2981–2996. [Google Scholar] [CrossRef] [Green Version]

- Matsumoto, K.; Mele, P. Artificial pinning center technology to enhance vortex pinning in YBCO coated conductors. Supercond. Sci. Technol. 2009, 23, 014001. [Google Scholar] [CrossRef]

- Strickland, N.; Long, N.; Talantsev, E.; Hoefakker, P.; Xia, J.; Rupich, M.; Zhang, W.; Li, X.; Kodenkandath, T.; Huang, Y. Nanoparticle additions for enhanced flux pinning in YBCO HTS films. Curr. Appl. Phys. 2008, 8, 372–375. [Google Scholar] [CrossRef]

- Terai, T.; Masegi, T.; Kusagaya, K.; Takahashi, Y.; Kishio, K.; Motohira, N.; Nakatani, K. Enhancement on Jc of Bi2Sr2CaCu2Oy by electron-irradiation. Phys. C 1991, 185, 2383–2384. [Google Scholar] [CrossRef]

- Day, A.C.; Hull, J.R.; Strasik, M.; Johnson, P.E.; McCrary, K.E.; Edwards, J.; Mittleider, J.A.; Schindler, J.R.; Hawkins, R.A.; Yoder, M.L. Temperature and frequency effects in a high-performance superconducting bearing. IEEE Trans. Appl. Supercond. 2003, 13, 2179–2184. [Google Scholar] [CrossRef]

- Hazelton, D.; Selvamanickam, V. Superpower′s YBCO coated high-temperature superconducting (HTS) wire and magnet applications. Proc. IEEE 2009, 97, 1831–1836. [Google Scholar] [CrossRef]

- Lee, Y.; Yamasaki, H.; Furuse, M. Magnetic-Field angle dependent critical current densities and flux pinning in commercial YBCO tapes below liquid nitrogen temperatures. Phys. C Supercond. Appl. 2011, 471, 1017–1020. [Google Scholar] [CrossRef]

- Wahl, A.; Hervieu, M.; Vantendeloo, G.; Hardy, V.; Provost, J.; Groult, D.; Simon, C.; Raveau, B. Columnar defects and irreversibility lines in tl-based superconductors. Radiat Eff. Defects Solids 1995, 133, 293–310. [Google Scholar] [CrossRef]

- Weber, H.W.; Wiesinger, H.P.; Kritscha, W.; Sauerzopf, F.M.; Crabtree, G.W.; Liu, J.Z.; Chang, Y.C.; Jiang, P.Z. Critical Currents in Neutron-Irradiated Ybco and Biscco Single-Crystals; Adam Hilger Ltd.: Bristol, UK, 1991; pp. S103–S105. [Google Scholar]

- Safar, H.; Cho, J.H.; Fleshler, S.; Maley, M.P.; Willis, J.O.; Coulter, J.Y.; Ullmann, J.L.; Lisowski, P.W.; Riley, G.N.; Rupich, M.W.; et al. Enhancement of transport critical-current densities at 75 K in (Bi,Pb)2Sr2Ca2Cu3Oy/Ag tapes by means of fission tracks from irradiation by 0.8 Gev protons. Appl. Phys. Lett. 1995, 67, 130–132. [Google Scholar] [CrossRef]

- Giapintzakis, J.; Lee, W.C.; Rice, J.P.; Ginsberg, D.M.; Robertson, I.M.; Wheeler, R.; Kirk, M.A.; Ruault, M.O. Production and identification of flux-pinning defects by electron-irradiation in YBa2Cu3O7-X single-crystals. Phys. Rev. B 1992, 45, 10677–10683. [Google Scholar] [CrossRef]

- Hart, H.R.; Luborsky, F.E.; Arendt, R.H.; Fleischer, R.L.; Tkaczyk, J.E.; Orsini, D.A. Flux pinning and flux creep in uranium-doped (Bi,Pb)-Sr-Ca-Cu-O superconducting powders after thermal-neutron irradiation. IEEE Trans. Magn. 1991, 27, 1375–1378. [Google Scholar] [CrossRef]

- Thompson, J.R.; Paul, D.; Wang, Z.L.; Kroeger, D.M.; Christen, D.K. Thermal-Stability and annealing of columnar defects in Bi2Sr2Ca1Cu2O8/Ag superconductor. Appl. Phys. Lett. 1995, 67, 1007–1009. [Google Scholar] [CrossRef]

- Weinstein, R.; Sawh, R.-P. A class of chemical pinning centers including two elements foreign to HTS. Phys. C Supercond. 2003, 383, 438–444. [Google Scholar] [CrossRef]

- Dou, S.X.; Wang, X.L.; Guo, Y.C.; Hu, Q.Y.; Mikheenko, P.; Horvat, J.; Ionescu, M.; Liu, H.K. Introduction of pinning centres into Bi-(Pb)-Sr-Ca-Cu-O superconductors. Supercond. Sci. Technol. 1997, 10, A52–A67. [Google Scholar] [CrossRef]

- Diko, P.; Antal, V.; Kanuchova, M.; Sefcikova, M.; Kovac, J. Pinning behavior of Al, Mn and Ag substitutions in YBCO TSMG bulk superconductors. In International Conference on Superconductivity and Magnetism; Gencer, A., Grasso, G., Eds.; Iop Publishing Ltd.: Bristol, UK, 2009; Volume 153. [Google Scholar]

- Ren, Y.R.; Weinstein, R.; Sawh, R.P. New chemical pinning center from uranium compound in melt-textured YBCO. Phys. C 1997, 282, 2275–2276. [Google Scholar] [CrossRef]

- Sawh, R.P.; Weinstein, R.; Ren, Y.; Obot, V.; Weber, H. Uranium fission fragment pinning centers in melt-textured YBCO. Phys. C 2000, 341, 2441–2442. [Google Scholar] [CrossRef]

- Zmorayova, K.; Sefcikova, M.; Diko, P.; Babu, N.H.; Cardwell, D.A. New pinning centres in YBCO bulk supreconductors with depleted uranium addition. Czech. J. Phys. 2004, 54, D469–D472. [Google Scholar] [CrossRef]

- Latha, B.; Ikuta, H.; Mizutani, U. Enhancement of critical currents and trapped fields of melt textured ZnO doped Dy-Ba-Cu-O bulk superconductors. Phys. C-Supercond. Appl. 2004, 412, 566–570. [Google Scholar] [CrossRef]

- Sawh, R.P.; Weinstein, R.; Obot, V.; Parks, D.; Gandini, A.; Skorpenske, H. Self-Assembling nano-diameter needlelike pinning centers in YBCO, utilizing a foreign element dopant. In Proceedings of the 7th European Conference on Applied Superconductivity, Vienna, Austria, 11–15 September 2005; Weber, H.W., Sauerzopf, F.M., Eds.; Iop Publishing Ltd.: Bristol, UK, 2006; Volume 43, pp. 239–242. [Google Scholar]

- Li, B.Z.; Zhou, D.F.; Xu, K.; Tsuzuki, K.; Zhang, J.C.; Izumi, M. Flux pinning behaviors of a textured Gd-Ba-Cu-O superconductor mediated by the addition of BaTiO3, TiO2 and BaO2. Phys. C-Supercond. Appl. 2014, 496, 28–34. [Google Scholar] [CrossRef]

- Rejith, P.P.; Vidya, S.; Thomas, J.K. Improvement of critical current density in YBa2Cu3O7-delta superconductor with nano TiO2 addition. Mater. Today-Proc. 2015, 2, 997–1001. [Google Scholar] [CrossRef]

- Yang, C.M.; Chen, P.W.; Liu, C.J.; Chen, S.Y.; Kuo, C.S.; Chen, I.G.; Wu, M.K. Effect of ZnO/TiO2 nanorods fabricated using the electrospinning method in Y-Ba-Cu-O single grain bulk superconductors. IEEE Trans. Appl. Supercond. 2017, 27. [Google Scholar] [CrossRef]

- Li, G.Z.; Wang, S.Y.; Li, J.W.; Yang, W.M. Introducing multi-source pinning centers into Y-Ba-Cu-O superconductor through addition of BiFeO3 nano-particles. Scr. Mater. 2017, 132, 22–24. [Google Scholar] [CrossRef]

- Leitner, J.; Bartůněk, V.; Sedmidubský, D.; Jankovský, O. Thermodynamic properties of nanostructured ZnO. Appl. Mater. Today 2018, 10, 1–11. [Google Scholar] [CrossRef]

- Bartůněk, V.; Smrčková, O. Nanoparticles and superconductors. Ceram. Silik. 2010, 54, 133–138. [Google Scholar]

- Bale, C.W.; Belisle, E.; Chartrand, P.; Decterov, S.A.; Eriksson, G.; Gheribi, A.E.; Hack, K.; Jung, I.H.; Kang, Y.B.; Melancon, J.; et al. FactSage thermochemical software and databases, 2010–2016. Calphad-Comput. Coupling Phase Diagr. Thermochem. 2016, 55, 1–19. [Google Scholar] [CrossRef]

- Kobayashi, H.; Ishida, S.; Takahashi, K.; Konishi, M.; Ibi, A.; Miyata, S.; Yamada, Y.; Shiohara, Y.; Kato, T.; Hirayama, T. Investigation of magnetic properties of YBCO film with artificial pinning centers on PLD/IBAD metal substrate. Phys. C-Supercond. Appl. 2006, 445, 625–627. [Google Scholar] [CrossRef]

- Peurla, M.; Huhtinen, H.; Paturi, P.; Stepanov, Y.P.; Raittila, J.; Laiho, R. YBCO films prepared by PLD using nanocrystalline targets doped with BaZrO3 or Y211. IEEE Trans. Appl. Supercond. 2005, 15, 3050–3053. [Google Scholar] [CrossRef]

- Polat, Ö.; Ertuğrul, M.; Thompson, J.R.; Leonard, K.J.; Sinclair, J.W.; Paranthaman, M.P.; Wee, S.H.; Zuev, Y.L.; Xiong, X.; Selvamanickam, V.; et al. Superconducting properties of YBa2Cu3O7−δ films deposited on commercial tape substrates, decorated with Pd or Ta nano-islands. Supercond. Sci. Technol. 2012, 25, 025018. [Google Scholar] [CrossRef]

- Jin, Z.; Park, C.; Song, K.J.; Kang, S.; Ko, K.E.; Park, C.; Ko, R.K.; Han, S.W. Micro-Structural properties of YBa2Cu3O7-x/ZnO nanorods on SrTiO3. J. Nanosci. Nanotechnol. 2015, 15, 642–646. [Google Scholar] [CrossRef]

- Teranishi, R.; Konya, K.; Inoue, M.; Sato, Y.; Kaneko, K.; Izumi, T.; Awaji, S. Study of growth process for YBa2Cu3Oy coated conductors with BaZrO3 flux pinning centers by monitoring electrical conductivity. IEEE Trans. Appl. Supercond. 2018, 28, 5. [Google Scholar] [CrossRef]

- Choi, S.M.; Shin, G.M.; Yoo, S.I. Flux pinning characteristics of Sn-doped YBCO film by the MOD process. Phys. C-Supercond. Appl. 2013, 485, 154–159. [Google Scholar] [CrossRef]

- Menushenkov, A.P.; Ivanov, V.G.; Chepikov, V.N.; Nygaard, R.R.; Soldatenko, A.V.; Rudnev, I.A.; Osipov, M.A.; Mineev, N.A.; Kaul, A.R.; Mathon, O.; et al. Correlation of local structure peculiarities and critical current density of 2G MOCVD YBCO tapes with BaZrO3 nanoinclusions. Supercond. Sci. Technol. 2017, 30, 8. [Google Scholar] [CrossRef]

- Ichino, Y.; Yoshida, Y. Numerical simulation of nanorod growth in REBa2Cu3Oy superconducting thin films. IEEE Trans. Appl. Supercond. 2017, 27. [Google Scholar] [CrossRef]

- Gutierrez, J.; Llordes, A.; Gazquez, J.; Gibert, M.; Roma, N.; Ricart, S.; Pomar, A.; Sandiumenge, F.; Mestres, N.; Puig, T. Strong isotropic flux pinning in solution-derived YBa2Cu3O7-x nanocomposite superconductor films. Nat. Mater. 2007, 6, 367–373. [Google Scholar] [CrossRef] [PubMed]

- Solovyov, V.; Wiesmann, H.; Wu, L.; Li, Q.; Cooley, L.; Suenaga, M.; Maiorov, B.; Civale, L. High critical currents by isotropic magnetic-flux-pinning centres in a 3 µm-thick YBa2Cu3O7 superconducting coated conductor. Supercond. Sci. Technol. 2007, 20, L20. [Google Scholar] [CrossRef]

- Talantsev, E.; Strickland, N.; Hoefakker, P.; Xia, J.; Long, N. Critical current anisotropy for second generation HTS wires. Curr. Appl. Phys. 2008, 8, 388–390. [Google Scholar] [CrossRef]

- Blatter, G.; Geshkenbein, V.B.; Larkin, A. From isotropic to anisotropic superconductors: A scaling approach. Phys. Rev. Lett. 1992, 68, 875. [Google Scholar] [CrossRef]

- Wimbush, S.C.; Strickland, N.M.; Long, N.J. Low-Temperature scaling of the critical current in 1 G HTS wires. IEEE Trans. Appl. Supercond. 2014, 25, 1–5. [Google Scholar] [CrossRef]

- Iida, K.; Hänisch, J.; Thersleff, T.; Kurth, F.; Kidszun, M.; Haindl, S.; Hühne, R.; Schultz, L.; Holzapfel, B. Scaling behavior of the critical current in clean epitaxial Ba(Fe1−xCox)2As2 thin films. Phys. Rev. B 2010, 81, 100507. [Google Scholar] [CrossRef] [Green Version]

- Bartůněk, V.; Smrčková, O. Preparation of the silver-superconductor composite by deposition of the silver nanoparticles in the bismuth cuprate superconductor. J. Supercond. Nov. Magn. 2011, 24, 1241–1244. [Google Scholar] [CrossRef]

- Sung, H.H.; Yang, H.C.; Horng, H.E. Enhanced flux pinning in ybco films with Ag impurities. Chin. J. Phys. 1992, 30, 681–689. [Google Scholar]

- Yang, H.C.; Sung, H.H.; Lu, J.H.; Wang, L.M.; Horng, H.E. Flux-Pinning in ybco and bscco films with Ag impurities. Phys. C Supercond. Appl. 1993, 273, 189–204. [Google Scholar]

- Farbod, M.; Batvandi, M.R. Doping effect of Ag nanoparticles on critical current of YBa2Cu3O7−δ bulk superconductor. Phys. C Supercond. 2011, 471, 112–117. [Google Scholar] [CrossRef]

- Dadras, S.; Gharehgazloo, Z. Effect of Au nano-particles doping on polycrystalline YBCO high temperature superconductor. Phys. B-Condens. Matter 2016, 492, 45–49. [Google Scholar] [CrossRef]

- Katzer, C.; Stahl, C.; Michalowski, P.; Treiber, S.; Schmidl, F.; Seidel, P.; Albrecht, J.; Schutz, G. Gold nanocrystals in high-temperature superconducting films: Creation of pinning patterns of choice. New J. Phys. 2013, 15, 113029. [Google Scholar] [CrossRef] [Green Version]

- Katzer, C.; Schmidt, M.; Michalowski, P.; Kuhwald, D.; Schmidl, F.; Grosse, V.; Treiber, S.; Stahl, C.; Albrecht, J.; Hubner, U.; et al. Increased flux pinning in YBa2Cu3O7-delta thin-film devices through embedding of Au nano crystals. Epl 2011, 95, 6. [Google Scholar] [CrossRef]

- Shlyk, L.; Krabbes, G.; Fuchs, G.; Stover, G.; Gruss, S.; Nenkov, K. Pinning behavior and magnetic relaxation in melt-processed YBCO doped with Li, Ni and Pd. Phys. C-Supercond. Appl. 2002, 377, 437–444. [Google Scholar] [CrossRef]

- Shlyk, L.; Nenkov, K.; Krabbes, G.; Fuchs, G. Melt-processed YBCO with Pt or Ce additions: Comparison of pinning behavior. Phys. C-Supercond. Appl. 2005, 423, 22–28. [Google Scholar] [CrossRef]

- Zhou, L.; Chen, S.K.; Wang, K.G.; Wu, X.Z.; Zhang, P.X.; Feng, Y.; Wen, H.H.; Li, S.L. Preparation of enhanced Jc YBCO bulks by powder melting process with a combination of submicron 211 precursor and Pt addition. Phys. C-Supercond. Appl. 2002, 371, 62–68. [Google Scholar] [CrossRef]

- Babu, N.H.; Iida, K.; Matthews, L.S.; Shi, Y.; Cardwell, D.A. Influence of Sm2Ba4CuBiOy phase content on J(c) of SmBa2Cu3O7/Sm2Ba4CuBiOy nano-composites. Mater. Sci. Eng. B-Adv. Funct. Solid-State Mater. 2008, 151, 21–24. [Google Scholar] [CrossRef]

- Bodea, M.A.; Pedarnig, J.D.; Withnell, T.D.; Weber, H.W.; Cardwell, D.A.; Babu, N.H.; Koblischka-Veneva, A. Iop. characterization of nano-composite M-2411/Y-123 thin films by electron backscatter diffraction and in-field critical current measurements. In Proceedings of the 9th European Conference on Applied Superconductivity, Dresden, Germany, 13–17 September 2009; Iop Publishing Ltd.: Bristol, UK, 2010; Volume 234. [Google Scholar]

- Koblischka-Veneva, A.; Koblischka, M.R. EBSD analysis of melt-textured YBCO with embedded Ag-2411 nanoparticles. Mater. Sci. Eng. B-Adv. Funct. Solid-State Mater. 2008, 151, 65–68. [Google Scholar] [CrossRef]

- Shi, Y.; Babu, N.H.; Iida, K.; Yeoh, W.K.; Dennis, A.R.; Cardwell, D.A. The influence of Gd-2411(Nb) on the superconducting properties of GdBCO/Ag single grains. Supercond. Sci. Technol. 2009, 22, 075025. [Google Scholar] [CrossRef]

- Shi, Y.H.; Yoeh, W.; Dennis, A.R.; Babu, N.H.; Pathak, S.; Xu, Z.; Cardwell, D.A. Iop. growth rate of YBCO single grains containing Y-2411(M). In Proceedings of the 9th European Conference on Applied Superconductivity, Dresden, Germany, 13–17 September 2009; Iop Publishing Ltd.: Bristol, UK, 2010; Volume 234. [Google Scholar]

- Jankovský, O.; Antončík, F.; Hlásek, T.; Plecháček, V.; Sedmidubský, D.; Huber, Š.; Lojka, M.; Bartůněk, V. Synthesis and properties of YBa2Cu3O7-δ—Y2Ba4CuWO10.8 superconducting composites. J. Eur. Ceram. Soc. 2018, 38, 2541–2546. [Google Scholar] [CrossRef]

- Antončík, F.; Hlásek, T.; Sedmidubský, D.; Bartůněk, V.; Jankovský, O. Synthesis of YBCO—Y-2411-M (M=Bi, Mo, Nb, Ta, Ti and Zr) superconducting composites by TSMG. AIP Conf. Proc. 2018, 1988, 020002. [Google Scholar] [CrossRef]

- MacManus-Driscoll, J.L.; Foltyn, S.R.; Jia, Q.X.; Wang, H.; Serquis, A.; Civale, L.; Maiorov, B.; Hawley, M.E.; Maley, M.P.; Peterson, D.E. Strongly enhanced current densities in superconducting coated conductors of YBa2Cu3O7−x + BaZrO3. Nat. Mater. 2004, 3, 439. [Google Scholar] [CrossRef] [PubMed]

- Wee, S.H.; Goyal, A.; Specht, E.D.; Cantoni, C.; Zuev, Y.L.; Selvamanickam, V.; Cook, S. Enhanced flux pinning and critical current density via incorporation of self-assembled rare-earth barium tantalate nanocolumns within YBa2Cu3O7-delta films. Phys. Rev. B 2010, 81, 140503. [Google Scholar] [CrossRef]

- Rizzo, F.; Augieri, A.; Kursumovic, A.; Bianchetti, M.; Opherden, L.; Sieger, M.; Huhne, R.; Hanisch, J.; Meledin, A.; Van Tendeloo, G.; et al. Pushing the limits of applicability of REBCO coated conductor films through fine chemical tuning and nanoengineering of inclusions. Nanoscale 2018, 10, 8187–8195. [Google Scholar] [CrossRef]

- Bian, W.B.; Chen, Y.Q.; Yin, X.R.; Tang, X.N.; Feng, Y.; Zhang, K.X.; Wu, H.M.; Li, L.W.; Hong, F.; Zhao, G.Y.; et al. Manipulation of YBCO film properties by the introduction of perovskite BaTiO3 nanodots as substrate decorations. J. Eur. Ceram. Soc. 2016, 36, 3417–3422. [Google Scholar] [CrossRef]

- Zhou, H.; Maiorov, B.; Baily, S.A.; Dowden, P.C.; Kennison, J.A.; Stan, L.; Holesinger, T.G.; Jia, Q.X.; Foltyn, S.R.; Civale, L. Thickness dependence of critical current density in YBa2Cu3O7-delta films with BaZrO3 and Y2O3 addition. Supercond. Sci. Technol. 2009, 22, 085013. [Google Scholar] [CrossRef]

- Wimbush, S.C.; Walsh, D.; Hall, S.R. Synthesis and characterization of BaZrO3-doped YBa2Cu3O7-delta microtapes with improved critical current densities. Phys. C-Supercond. Appl. 2010, 470, 373–377. [Google Scholar] [CrossRef]

- Matsumoto, K.; Nishihara, M.; Kimoto, T.; Horide, T.; Jha, A.K.; Yoshida, Y.; Awaji, S.; Ichinose, A. Temperature dependence of critical currents in REBCO thin films with artificial pinning centers. Supercond. Sci. Technol. 2017, 30, 8. [Google Scholar] [CrossRef] [Green Version]

- Sierra, J.; López-Domínguez, P.; Rijckaert, H.; Rikel, M.; Hänisch, J.; Khan, M.; Falter, M.; Bennewitz, J.; Huhtinen, H.; Schäfer, S.; et al. High critical current density and enhanced pinning in superconducting films of YBa2Cu3O7-δ nanocomposites with embedded BaZrO3, BaHfO3, BaTiO3 and SrZrO3 nanocrystals. ACS Appl. Nano Mater. 2020, 3, 5542–5553. [Google Scholar] [CrossRef]

- Mele, P.; Matsumoto, K.; Horide, T.; Ichinose, A.; Mukaida, M.; Yoshida, Y.; Horii, S. Insertion of nanoparticulate artificial pinning centres in YBa2Cu3O7-x films by laser ablation of a Y2O3-surface modified target. Supercond. Sci. Technol. 2007, 20, 616–620. [Google Scholar] [CrossRef]

- Shiohara, Y.; Taneda, T.; Yoshizumi, M. Overview of materials and power applications of coated conductors project. Jpn. J. Appl. Phys. 2011, 51, 010007. [Google Scholar] [CrossRef]

- Roma, N.; Morlens, S.; Ricart, S.; Zalamova, K.; Moreto, J.; Pomar, A.; Puig, T.; Obradors, X. Acid anhydrides: A simple route to highly pure organometallic solutions for superconducting films. Supercond. Sci. Technol. 2006, 19, 521. [Google Scholar] [CrossRef]

- Holesinger, T.G.; Civale, L.; Maiorov, B.; Feldmann, D.M.; Coulter, J.Y.; Miller, D.J.; Maroni, V.A.; Chen, Z.; Larbalestier, D.C.; Feenstra, R. Progress in nanoengineered microstructures for tunable high-current, high-temperature superconducting wires. Adv. Mater. 2008, 20, 391–407. [Google Scholar] [CrossRef]

- Maiorov, B.; Baily, S.; Zhou, H.; Ugurlu, O.; Kennison, J.; Dowden, P.; Holesinger, T.; Foltyn, S.; Civale, L. Synergetic combination of different types of defect to optimize pinning landscape using BaZrO3-doped YBa2Cu3O7. Nat. Mater. 2009, 8, 398–404. [Google Scholar] [CrossRef]

- Ding, F.; Gu, H.; Zhang, T.; Wang, H.; Qu, F.; Dai, S.; Peng, X.; Cao, J. Enhanced flux pinning in MOD-YBCO films with co-doping of BaZrO3 and Y2O3 nanoparticles. J. Alloys Compd. 2012, 513, 277–281. [Google Scholar] [CrossRef]

- Sebastian, M.; Ebbing, C.; Zhang, W.; Huang, J.; Wang, H.; Chen, S.; Gautum, B.; Wu, J.; Haugan, T. Comparison study of the flux pinning enhancement of YBCO superconductor with BZO and BZO + Y2O3 mixed phase additions. In Proceedings of the International Cryogenic Materials Conference (ICMC 2017), Madison, WI, USA, 9–13 July 2017; p. 012031. Available online: https://0-iopscience-iop-org.brum.beds.ac.uk/issue/1757-899X/279/1 (accessed on 22 July 2020).

- Pižl, M.; Jankovský, O.; Ulbrich, P.; Szabó, N.; Hoskovcová, I.; Sedmidubský, D.; Bartůněk, V. Facile preparation of nanosized yttrium oxide by the thermal decomposition of amorphous Schiff base yttrium complex precursor. J. Organomet. Chem. 2017, 830, 146–149. [Google Scholar] [CrossRef]

- Chepikov, V.; Mineev, N.; Degtyarenko, P.; Lee, S.; Petrykin, V.; Ovcharov, A.; Vasiliev, A.; Kaul, A.; Amelichev, V.; Kamenev, A. Introduction of BaSnO3 and BaZrO3 artificial pinning centres into 2G HTS wires based on PLD-GdBCO films. Phase I of the industrial R&D programme at SuperOx. Supercond. Sci. Technol. 2017, 30, 124001. [Google Scholar]

- Gautam, B.; Sebastian, M.A.; Chen, S.; Haugan, T.; Zhang, W.; Huang, J.; Wang, H.; Wu, J.Z. Microscopic adaptation of BaHfO3 and Y2O3 artificial pinning centers for strong and isotropic pinning landscape in YBa2Cu3O7-x thin films. Supercond. Sci. Technol. 2018, 31, 025008. [Google Scholar] [CrossRef]

- Kochat, M.; Pratap, R.; Galstyan, E.; Majkic, G.; Selvamanickam, V. Electromagnetic properties of thick film REBCO tapes. IEEE Trans. Appl. Supercond. 2019, 29, 4. [Google Scholar] [CrossRef]

- Geng, H.; Cui, X.Y.; Weng, J.H.; She, H.L.; Wang, W.Q. Review of experimental research on Joule-Thomson cryogenic refrigeration system. Appl. Therm. Eng. 2019, 157, 113640. [Google Scholar] [CrossRef]

- Liang, K. A review of linear compressors for refrigeration. Int. J. Refrig.-Rev. Int. Du Froid 2017, 84, 253–273. [Google Scholar] [CrossRef]

- Liu, G.Q.; Ke, Y.J.; Zhang, K.B.; He, X.; Luo, F.; He, B.; Sun, Z.G. Research progress of physical model of full-solid-state magnetic refrigeration system. Acta Phys. Sin. 2019, 68, 217501. [Google Scholar] [CrossRef]

- Qian, S.X.; Yu, J.L.; Yan, G. A review of regenerative heat exchange methods for various cooling technologies. Renew. Sustain. Energy Rev. 2017, 69, 535–550. [Google Scholar] [CrossRef]

- Rizzo, F. The importance of understanding how nanorods in REBCO films affect the angular dependence of the critical current density at low temperature for high field applications. Supercond. Sci. Technol. 2020, 33, 2. [Google Scholar] [CrossRef]

- Manju, P.; Ajith, M.R.; Jaiswal-Nagar, D. Synthesis and characterization of BaZrO3 nanoparticles by citrate-nitrate sol-gel auto-combustion technique: Systematic study for the formation of dense BaZrO3 ceramics. J. Eur. Ceram. Soc. 2019, 39, 3756–3767. [Google Scholar] [CrossRef]

- Watanabe, K.; Awaji, S.; Nishijima, G.; Hamajima, T.; Kiyoshi, T.; Kumakura, H.; Hanai, S.; Koyanagi, K.; Ono, M. 20 T compact superconducting outsert employing Y123 coated conductors for a 45 T Hybrid magnet. IEEE Trans. Appl. Supercond. 2009, 19, 1592–1595. [Google Scholar] [CrossRef]

- Parashar, M.; Shukla, V.K.; Singh, R. Metal oxides nanoparticles via sol-gel method: A review on synthesis, characterization and applications. J. Mater. Sci.-Mater. Electron. 2020, 31, 3729–3749. [Google Scholar] [CrossRef]

- Nikam, A.V.; Prasad, B.L.V.; Kulkarni, A.A. Wet chemical synthesis of metal oxide nanoparticles: A review. Crystengcomm 2018, 20, 5091–5107. [Google Scholar] [CrossRef]

- Bartunek, V.; Sedmidubsky, D.; Hlasek, T.; Pinc, J.; Jankovsky, O. Thermal decomposition of lactates: Towards ultrafine nanostrucured oxides. AIP Conf. Proc. 2018, 1988, 020004. Available online: https://aip.scitation.org/doi/10.1063/1.5047598 (accessed on 22 July 2020).

- Bartunek, V.; Sedmidubsky, D.; Huber, S.; Svecova, M.; Ulbrich, P.; Jankovsky, O. Synthesis and properties of nanosized stoichiometric cobalt ferrite spinel. Materials 2018, 11, 1241. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jankovsky, O.; Rach, V.; Sedmidubsky, D.; Huber, S.; Ulbrich, P.; Svecova, M.; Bartunek, V. Simple synthesis of free surface nanostructured spinel NiFe2O4 with a tunable particle size. J. Alloys Compd. 2017, 723, 58–63. [Google Scholar] [CrossRef]

- Manimaran, M.; Kannabiran, K. Actinomycetes-Mediated biogenic synthesis of metal and metal oxide nanoparticles: progress and challenges. Lett. Appl. Microbiol. 2017, 64, 401–408. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Niederberger, M.; Pinna, N.; Polleux, J.; Antonietti, M. A general soft-chemistry route to perovskites and related materials: Synthesis of BaTiO3, BaZrO3, and LiNbO3 nanoparticles. Angew. Chem.-Int. Edit. 2004, 43, 2270–2273. [Google Scholar] [CrossRef]

- De Keukeleere, K.; Feys, J.; Meire, M.; De Roo, J.; De Buysser, K.; Lommens, P.; Van Driessche, I. Solution-Based synthesis of BaZrO3 nanoparticles: Conventional versus microwave synthesis. J. Nanopart. Res. 2013, 15, 12. [Google Scholar] [CrossRef]

- Leonard, K.J.; Sathyamurthy, S.; Paranthaman, M.P. Characterization of BaZrO3 nanoparticles prepared by reverse micelle synthesis. Chem. Mater. 2005, 17, 4010–4017. [Google Scholar] [CrossRef]

| Superconductor | Typical Forms/Application | Usual Critical Parameters |

|---|---|---|

| Low-temperature Nb3Sn superconductor | Composite wire-magnets | Tc = 18.3 K, upper critical magnetic field (Hc2) up to 35 T, [23] |

| MgB2 | Silver/steel sheeted wires-magnets, current lead | Tc = 39 K, 109 A/m2 at 5 T, Hc2 up to 74 T in thin films, [24] |

| YBaCuO | Tapes, films, bulk-magnets, levitation bulks, current lead | 123 phase: Tc = 92 K, Jc 2.8 MA/cm2 self-field, 77K, [25] |

| Bi(Pb)SrCaCuO | Tapes, bulk-current lead, levitation bulks, magnetic screens | 2223 phase: Tc = 108, Jc = 5 kA/mm2 self-field,77 K, [26] |

| REFeAsO | Experimental samples | Tc = 55 K for SmFeAsO–metallic behavior form Tc to 300 K, [27] |

| Method (Abbreviation) | Method Principle | Ref. |

|---|---|---|

| Pulsed laser ablation (PLA)/Pulsed laser deposition (PLD) | Film deposition by PLD by irradiation of a target by a laser beam. The laser beam removes material from the target and material is moved to the substrate. | [64,65] |

| Metalorganic chemical vapor deposition (MOCVD)/Metalorganic vapor-phase epitaxy (MOVPE) | Organometallic precursors are injected together with carrier gasses and thin-film grows due to chemical reactions on the substrate | [66,67,68] |

| Chemical solution deposition (CSD)/Metal-organic deposition (MOD) | Deposition of chemical precursors, usually trifluoroacetate (TFA; MOD-TFA method) on the substrate, e.g., By dip-coating, followed by pyrolysis, heating, film growth and oxidation processes | [69,70] |

| Ion plasma sputtering (no abbreviation common) | Argon and oxygen plasma, in the magnetic field, is used for sputtering of target form REBCO material onto the layer | [71,72] |

| Pinning Material | Type of Superconducting Material | Improvement in Jc (if Applicable) or Maximal Jc at the Respective Conditions | Reference |

|---|---|---|---|

| BaZrO3 | YBCO film | 5 Jc-self field | [143] |

| Ba2RETaO6 | YBCO film | 6 Jc-self field | [144] |

| Ba2Y(Nb,Ta)O6 | YBCO film | 10 MA cm−2, 30 K, 5 T | [145] |

| BaTiO3 | YBCO film | 8.42 MA cm−2-self field | [146] |

| BaZrO3 and Y2O3 | YBCO delta film | 2.3 MA cm−2 (6.4 µm thickness) | [147] |

| BaZrO3 | YBCO delta microtapes | Jc at 1 T of 3 MA cm−2 | [148] |

| BaHfO3 | GdBCO thin film | 6 Jc-self field, 10 K, 6T | [149] |

| BaHfO3 | YBCO delta film | 3.5 Jc 77 K, 1T | [150] |

| Y2O3 | YBCO film | 2.25 Jc, 77 K, 5T | [151] |

| Ag | YBCO delta film | 2.5∙Jc self field | [129] |

| Au | YBCO delta film | 1.7 Jc self field | [132] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Antončík, F.; Jankovský, O.; Hlásek, T.; Bartůněk, V. Nanosized Pinning Centers in the Rare Earth-Barium-Copper-Oxide Thin-Film Superconductors. Nanomaterials 2020, 10, 1429. https://0-doi-org.brum.beds.ac.uk/10.3390/nano10081429

Antončík F, Jankovský O, Hlásek T, Bartůněk V. Nanosized Pinning Centers in the Rare Earth-Barium-Copper-Oxide Thin-Film Superconductors. Nanomaterials. 2020; 10(8):1429. https://0-doi-org.brum.beds.ac.uk/10.3390/nano10081429

Chicago/Turabian StyleAntončík, Filip, Ondřej Jankovský, Tomáš Hlásek, and Vilém Bartůněk. 2020. "Nanosized Pinning Centers in the Rare Earth-Barium-Copper-Oxide Thin-Film Superconductors" Nanomaterials 10, no. 8: 1429. https://0-doi-org.brum.beds.ac.uk/10.3390/nano10081429