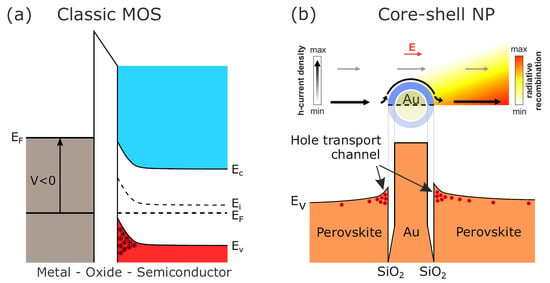

Giant Enhancement of Radiative Recombination in Perovskite Light-Emitting Diodes with Plasmonic Core-Shell Nanoparticles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental

2.2. Numerical

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| PeLED | perovskite light-emitting diode |

| LESC | light-emitting solar cell |

| MOS | metal-oxide-semiuconductor |

| SC | solar cell |

| EQE | external quantum efficiency |

| IQE | internal quantum efficiency |

| NP | nanoparticle |

References

- Stranks, S.D.; Snaith, H.J. Metal-halide perovskites for photovoltaic and light-emitting devices. Nat. Nanotechnol. 2015, 10, 391–402. [Google Scholar] [CrossRef]

- Nedelcu, G.; Protesescu, L.; Yakunin, S.; Bodnarchuk, M.I.; Grotevent, M.J.; Kovalenko, M.V. Fast anion-exchange in highly luminescent nanocrystals of cesium lead halide perovskites (CsPbX3, X = Cl, Br, I). Nano Lett. 2015, 15, 5635–5640. [Google Scholar] [CrossRef] [PubMed]

- Herz, L.M. Charge-carrier mobilities in metal halide perovskites: Fundamental mechanisms and limits. ACS Energy Lett. 2017, 2, 1539–1548. [Google Scholar] [CrossRef]

- Huang, H.; Bodnarchuk, M.I.; Kershaw, S.V.; Kovalenko, M.V.; Rogach, A.L. Lead halide perovskite nanocrystals in the research spotlight: Stability and defect tolerance. ACS Energy Lett. 2017, 2, 2071–2083. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mak, C.H.; Huang, X.; Liu, R.; Tang, Y.; Han, X.; Ji, L.; Zou, X.; Zou, G.; Hsu, H.Y. Recent progress in surface modification and interfacial engineering for high-performance perovskite light-emitting diodes. Nano Energy 2020, 73, 104752. [Google Scholar] [CrossRef]

- Berestennikov, A.S.; Voroshilov, P.M.; Makarov, S.V.; Kivshar, Y.S. Active meta-optics and nanophotonics with halide perovskites. Appl. Phys. Rev. 2019, 6, 031307. [Google Scholar] [CrossRef]

- Yang, J.; Bao, Q.; Shen, L.; Ding, L. Potential applications for perovskite solar cells in space. Nano Energy 2020, 76, 105019. [Google Scholar] [CrossRef]

- Wang, H.; Wang, X.; Zhang, H.; Ma, W.; Wang, L.; Zong, X. Organic-Inorganic Hybrid Perovskites: Game-Changing Candidates for Solar Fuel Production. Nano Energy 2020, 71, 104647. [Google Scholar] [CrossRef]

- Kim, G.; Min, H.; Lee, K.S.; Yoon, S.M.; Seok, S.I. Impact of strain relaxation on performance of α-formamidinium lead iodide perovskite solar cells. Science 2020, 370, 108–112. [Google Scholar] [CrossRef]

- Lin, K.; Xing, J.; Quan, L.N.; de Arquer, F.P.G.; Gong, X.; Lu, J.; Xie, L.; Zhao, W.; Zhang, D.; Yan, C.; et al. Perovskite light-emitting diodes with external quantum efficiency exceeding 20 per cent. Nature 2018, 562, 245–248. [Google Scholar] [CrossRef]

- Lu, M.; Zhang, Y.; Wang, S.; Guo, J.; Yu, W.W.; Rogach, A.L. Metal halide perovskite light-emitting devices: Promising technology for next-generation displays. Adv. Funct. Mater. 2019, 29, 1902008. [Google Scholar] [CrossRef]

- Gil-Escrig, L.; Longo, G.; Pertegás, A.; Roldán-Carmona, C.; Soriano, A.; Sessolo, M.; Bolink, H.J. Efficient photovoltaic and electroluminescent perovskite devices. Chem. Commun. 2015, 51, 569–571. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.B.; Yoon, Y.J.; Jeong, J.; Heo, J.; Jang, H.; Seo, J.H.; Walker, B.; Kim, J.Y. Peroptronic devices: Perovskite-based light-emitting solar cells. Energy Environ. Sci. 2017, 10, 1950–1957. [Google Scholar] [CrossRef]

- Gets, D.; Saranin, D.; Ishteev, A.; Haroldson, R.; Danilovskiy, E.; Makarov, S.; Zakhidov, A. Light-emitting perovskite solar cell with segregation enhanced self doping. Appl. Surf. Sci. 2019, 476, 486–492. [Google Scholar] [CrossRef]

- Gets, D.; Verkhogliadov, G.; Danilovskiy, E.; Baranov, A.; Makarov, S.; Zakhidov, A. Dipolar cation accumulation at the interfaces of perovskite light-emitting solar cells. J. Mater. Chem. C 2020, 8, 16992–16999. [Google Scholar] [CrossRef]

- Stranks, S.D.; Hoye, R.L.; Di, D.; Friend, R.H.; Deschler, F. The physics of light emission in halide perovskite devices. Adv. Mater. 2019, 31, 1803336. [Google Scholar] [CrossRef] [Green Version]

- Makarov, S.; Furasova, A.; Tiguntseva, E.; Hemmetter, A.; Berestennikov, A.; Pushkarev, A.; Zakhidov, A.; Kivshar, Y. Halide-Perovskite Resonant Nanophotonics. Adv. Opt. Mater. 2019, 7, 1800784. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, D.; Fu, Y.; Poddar, S.; Shu, L.; Mo, X.; Fan, Z. Light Out-Coupling Management in Perovskite LEDs—What Can We Learn from the Past? Adv. Funct. Mater. 2020, 30, 2002570. [Google Scholar] [CrossRef]

- Wang, H.; Haroldson, R.; Balachandran, B.; Zakhidov, A.; Sohal, S.; Chan, J.Y.; Zakhidov, A.; Hu, W. Nanoimprinted perovskite nanograting photodetector with improved efficiency. ACS Nano 2016, 10, 10921–10928. [Google Scholar] [CrossRef]

- Makarov, S.V.; Milichko, V.; Ushakova, E.V.; Omelyanovich, M.; Cerdan Pasaran, A.; Haroldson, R.; Balachandran, B.; Wang, H.; Hu, W.; Kivshar, Y.S.; et al. Multifold emission enhancement in nanoimprinted hybrid perovskite metasurfaces. ACS Photonics 2017, 4, 728–735. [Google Scholar] [CrossRef]

- Tiguntseva, E.; Chebykin, A.; Ishteev, A.; Haroldson, R.; Balachandran, B.; Ushakova, E.; Komissarenko, F.; Wang, H.; Milichko, V.; Tsypkin, A.; et al. Resonant silicon nanoparticles for enhancement of light absorption and photoluminescence from hybrid perovskite films and metasurfaces. Nanoscale 2017, 9, 12486–12493. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, C.; Xiao, S.; Wang, Y.; Gao, Y.; Fan, Y.; Huang, C.; Zhang, N.; Yang, W.; Song, Q. Lead Halide Perovskite-Based Dynamic Metasurfaces. Laser Photonics Rev. 2019, 13, 1900079. [Google Scholar] [CrossRef] [Green Version]

- Baryshnikova, K.; Gets, D.; Liashenko, T.; Pushkarev, A.; Mukhin, I.; Kivshar, Y.; Makarov, S. Broadband Antireflection with Halide Perovskite Metasurfaces. Laser Photonics Rev. 2020, 14, 2000338. [Google Scholar] [CrossRef]

- Chen, P.; Xiong, Z.; Wu, X.; Shao, M.; Meng, Y.; Xiong, Z.H.; Gao, C. Nearly 100% efficiency enhancement of CH3NH3PbBr3 perovskite light-emitting diodes by utilizing plasmonic Au nanoparticles. J. Phys. Chem. Lett. 2017, 8, 3961–3969. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, B.; Wang, W.; Liu, S.; Zheng, Y.; Chen, S.; Wang, K.; Sun, X.W. Plasmonic perovskite light-emitting diodes based on the Ag–CsPbBr3 system. ACS Appl. Mater. Interfaces 2017, 9, 4926–4931. [Google Scholar] [CrossRef]

- Set, Y.T.; Zhang, T.; Birgersson, E.; Luther, J. What parameters can be reliably deduced from the current-voltage characteristics of an organic bulk-heterojunction solar cell? J. Appl. Phys. 2015, 117, 084503. [Google Scholar] [CrossRef]

- Neukom, M.T.; Schiller, A.; Züfle, S.; Knapp, E.; Ávila, J.; Pérez-del Rey, D.; Dreessen, C.; Zanoni, K.P.; Sessolo, M.; Bolink, H.J.; et al. Consistent device simulation model describing perovskite solar cells in steady-state, transient, and frequency domain. ACS Appl. Mater. Interfaces 2019, 11, 23320–23328. [Google Scholar] [CrossRef]

- Auf der Maur, M.; Penazzi, G.; Romano, G.; Sacconi, F.; Pecchia, A.; Di Carlo, A. The multiscale paradigm in electronic device simulation. IEEE Trans. Electron. Devices 2011, 58, 1425–1432. [Google Scholar] [CrossRef]

- Barettin, D.; Platonov, A.V.; Pecchia, A.; Kats, V.N.; Cirlin, G.E.; Soshnikov, I.P.; Bouravleuv, A.D.; Besombes, L.; Mariette, H.; Auf der Maur, M.; et al. Model of a GaAs quantum dot embedded in a polymorph AlGaAs nanowire. IEEE J. Sel. Top. Quantum Electron. 2013, 19, 1901209. [Google Scholar] [CrossRef] [Green Version]

- Barettin, D.; Auf der Maur, M.; De Angelis, R.; Prosposito, P.; Casalboni, M.; Pecchia, A. Inter-dot strain field effect on the optoelectronic properties of realistic InP lateral quantum-dot molecules. J. Appl. Phys. 2015, 117, 094306. [Google Scholar] [CrossRef]

- Pecchia, A.; Gentilini, D.; Rossi, D.; Auf der Maur, M.; Di Carlo, A. Role of ferroelectric nanodomains in the transport properties of perovskite solar cells. Nano Lett. 2016, 16, 988–992. [Google Scholar] [CrossRef] [PubMed]

- Rossi, D.; Pecchia, A.; der Maur, M.A.; Leonhard, T.; Röhm, H.; Hoffmann, M.J.; Colsmann, A.; Di Carlo, A. On the importance of ferroelectric domains for the performance of perovskite solar cells. Nano Energy 2018, 48, 20–26. [Google Scholar] [CrossRef]

- Ndione, P.F.; Li, Z.; Zhu, K. Effects of alloying on the optical properties of organic–inorganic lead halide perovskite thin films. J. Mater. Chem. C 2016, 4, 7775–7782. [Google Scholar] [CrossRef]

- Rehman, W.; Milot, R.L.; Eperon, G.E.; Wehrenfennig, C.; Boland, J.L.; Snaith, H.J.; Johnston, M.B.; Herz, L.M. Charge-carrier dynamics and mobilities in formamidinium lead mixed-halide perovskites. Adv. Mater. 2015, 27, 7938–7944. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Eperon, G.E.; Stranks, S.D.; Menelaou, C.; Johnston, M.B.; Herz, L.M.; Snaith, H.J. Formamidinium lead trihalide: A broadly tunable perovskite for efficient planar heterojunction solar cells. Energy Environ. Sci. 2014, 7, 982–988. [Google Scholar] [CrossRef]

- Liu, X.; Yu, H.; Yan, L.; Dong, Q.; Wan, Q.; Zhou, Y.; Song, B.; Li, Y. Triple cathode buffer layers composed of PCBM, C60, and LiF for high-performance planar perovskite solar cells. ACS Appl. Mater. Interfaces 2015, 7, 6230–6237. [Google Scholar] [CrossRef] [PubMed]

- Seo, J.; Park, S.; Kim, Y.C.; Jeon, N.J.; Noh, J.H.; Yoon, S.C.; Seok, S.I. Benefits of very thin PCBM and LiF layers for solution-processed p–i–n perovskite solar cells. Energy Environ. Sci. 2014, 7, 2642–2646. [Google Scholar] [CrossRef]

| Parameter | PEDOT:PSS | FAPbBrI | C | Unit |

|---|---|---|---|---|

| Thickness, d | 10 | 400/600 | 30 | nm |

| Valence (HOMO) Energy, Ev | −5.2 | −5.7 | −6 | eV |

| Bandgap Energy, Eg | 1.6 | 1.95 | 2.15 | eV |

| Hole Mobility, | 1.1 | 2 | 1.6 | cm/(V·s) |

| Electron Mobility, | 0.45 | 2 | 0.1 | cm/(V·s) |

| Doping concentration | 10 | - | 10 | cm |

| SRH recombination (bulk/surface), | 10 | 2× 10/10 | 10 | s |

| Direct recombination (bulk/surface), | – | 2 × 10/2 × 10 | – | s |

| ITO work function | −4.85 | – | – | eV |

| Ag work function | – | – | −4.6 | eV |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Masharin, M.A.; Berestennikov, A.S.; Barettin, D.; Voroshilov, P.M.; Ladutenko, K.S.; Di Carlo, A.; Makarov, S.V. Giant Enhancement of Radiative Recombination in Perovskite Light-Emitting Diodes with Plasmonic Core-Shell Nanoparticles. Nanomaterials 2021, 11, 45. https://0-doi-org.brum.beds.ac.uk/10.3390/nano11010045

Masharin MA, Berestennikov AS, Barettin D, Voroshilov PM, Ladutenko KS, Di Carlo A, Makarov SV. Giant Enhancement of Radiative Recombination in Perovskite Light-Emitting Diodes with Plasmonic Core-Shell Nanoparticles. Nanomaterials. 2021; 11(1):45. https://0-doi-org.brum.beds.ac.uk/10.3390/nano11010045

Chicago/Turabian StyleMasharin, Mikhail A., Alexander S. Berestennikov, Daniele Barettin, Pavel M. Voroshilov, Konstantin S. Ladutenko, Aldo Di Carlo, and Sergey V. Makarov. 2021. "Giant Enhancement of Radiative Recombination in Perovskite Light-Emitting Diodes with Plasmonic Core-Shell Nanoparticles" Nanomaterials 11, no. 1: 45. https://0-doi-org.brum.beds.ac.uk/10.3390/nano11010045