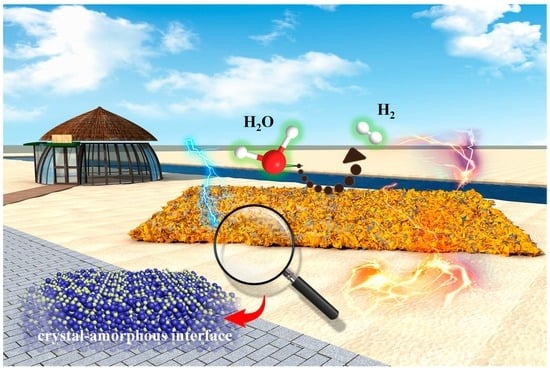

Plasma-Wind-Assisted In2S3 Preparation with an Amorphous Surface Structure for Enhanced Photocatalytic Hydrogen Production

Abstract

:1. Introduction

2. Materials and Methods

2.1. Synthesis of the In2S3

2.2. Synthesis of the P-In2S3

2.3. Characterization of the Photocatalysts

2.4. Photocatalytic Activity

2.5. Computational Details

3. Results and Discussion

3.1. The Synthesis Process and Related Morphological, Spectroscopic Characterization

3.2. The Photocatalytic Hydrogen Production Performance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, R.; Wang, Y.; Ma, Y.; Mal, A.; Gao, X.Y.; Gao, L.; Qiao, L.; Li, X.B.; Wu, L.Z.; Wang, C. Rational design of isostructural 2D porphyrin-based covalent organic frameworks for tunable photocatalytic hydrogen evolution. Nat. Commun. 2021, 12, 1354. [Google Scholar] [CrossRef] [PubMed]

- Kosco, J.; Bidwell, M.; Cha, H.; Martin, T.; Howells, C.T.; Sachs, M.; Anjum, D.H.; Gonzalez Lopez, S.; Zou, L.; Wadsworth, A.; et al. Enhanced photocatalytic hydrogen evolution from organic semiconductor heterojunction nanoparticles. Nat. Mater. 2020, 19, 559–565. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.J.; Jang, H.; Liu, H.H.; Kim, M.G.; Yang, D.J.; Liu, S.G.; Liu, X.E.; Cho, J. Sodium-decorated amorphous/crystalline RuO2 with rich oxygen vacancies: A robust pH-universal oxygen evolution electrocatalyst. Angew. Chem. Int. Ed. 2021, 60, 18821–18829. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Q.H.; Xu, Z.H.; Qiu, B.C.; Xing, M.Y.; Zhang, J.L. Emerging cocatalysts on g-C3N4 for photocatalytic hydrogen evolution. Small 2021, 17, 2101070. [Google Scholar] [CrossRef] [PubMed]

- Guo, S.H.; Li, X.H.; Li, J.; Wei, B.Q. Boosting photocatalytic hydrogen production from water by photothermally induced biphase systems. Nat. Commun. 2021, 12, 1343. [Google Scholar] [CrossRef]

- Xiao, R.; Zhao, C.; Zou, Z.; Chen, Z.; Tian, L.; Xu, H.; Tang, H.; Liu, Q.; Lin, Z.; Yang, X. In situ fabrication of 1D CdS nanorod/2D Ti3C2 MXene nanosheet Schottky heterojunction toward enhanced photocatalytic hydrogen evolution. Appl. Catal. B Environ. 2020, 268, 118382. [Google Scholar] [CrossRef]

- Cai, C.; Teng, Y.; Wu, J.H.; Li, J.Y.; Chen, H.Y.; Chen, J.H.; Kuang, D.B. In situ photosynthesis of an MAPbI3/CoP hybrid heterojunction for efficient photocatalytic hydrogen evolution. Adv. Funct. Mater. 2020, 30, 2001478. [Google Scholar] [CrossRef]

- Yang, J.L.; He, Y.L.; Ren, H.; Zhong, H.L.; Lin, J.S.; Yang, W.M.; Li, M.D.; Yang, Z.L.; Zhang, H.; Tian, Z.Q.; et al. Boosting photocatalytic hydrogen evolution reaction using dual plasmonic antennas. ACS Catal. 2021, 11, 5047–5053. [Google Scholar] [CrossRef]

- Mo, J.; Barbosa, E.C.M.; Wu, S.; Li, Y.Y.; Sun, Y.C.; Xiang, W.K.; Li, T.; Pu, S.D.; Robertson, A.; Wu, T.S.; et al. Atomic-Precision Tailoring of Au-Ag Core-Shell Composite Nanoparticles for Direct Electrochemical-Plasmonic Hydrogen Evolution in Water Splitting. Adv. Funct. Mater. 2021, 31, 2102517. [Google Scholar] [CrossRef]

- Li, S.; Miao, P.; Zhang, Y.; Wu, J.; Zhang, B.; Du, Y.; Han, X.; Sun, J.; Xu, P. Recent advances in plasmonic nanostructures for enhanced photocatalysis and electrocatalysis. Adv. Mater. 2021, 33, 2000086. [Google Scholar] [CrossRef]

- Wang, X.; Wang, X.; Huang, J.; Li, S.; Meng, A.; Li, Z. Interfacial chemical bond and internal electric field modulated Z-scheme Sv-ZnIn2S4/MoSe2 photocatalyst for efficient hydrogen evolution. Nat. Commun. 2021, 12, 4112. [Google Scholar] [CrossRef] [PubMed]

- Luo, M.L.; Yang, Q.; Yang, W.B.; Wang, J.H.; He, F.F.; Liu, K.W.; Cao, H.M.; Yan, H.J. Defects engineering leads to enhanced photocatalytic H2 evolution on graphitic carbon nitride-covalent organic framework nanosheet composite. Small 2020, 16, 2001100. [Google Scholar] [CrossRef] [PubMed]

- Zhu, C.; Xian, Q.; He, Q.; Chen, C.; Zou, W.; Sun, C.; Wang, S.; Duan, X. Edge-rich bicrystalline 1T/2H-MoS2 cocatalyst-decorated {110} terminated CeO2 nanorods for photocatalytic hydrogen evolution. ACS Appl. Mater. Interfaces 2021, 13, 35818–35827. [Google Scholar] [CrossRef] [PubMed]

- Liang, Z.; Xue, Y.; Guo, Y.; Zhang, G.; Cui, H.; Tian, J. Rationalizing and controlling the phase transformation of semi-metallic 1T′-phase and semi-conductive 2H-phase MoS2 as cocatalysts for photocatalytic hydrogen evolution. Chem. Eng. J. 2020, 396, 125344. [Google Scholar] [CrossRef]

- Jin, X.X.; Wang, R.Y.; Zhang, L.X.; Si, R.; Shen, M.; Wang, M.; Tian, J.J.; Shi, J.L. Electron configuration modulation of nickel single atoms for elevated photocatalytic hydrogen evolution. Angew. Chem. Int. Ed. 2020, 59, 6827–6831. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.H.; Zhang, L.S.; Liu, H.Y.; Wu, D.S.; Wu, F.Y.; Tian, L.; Liu, L.L.; Zou, J.P.; Luo, S.L.; Chen, B.B. Silver single atom in carbon nitride catalyst for highly efficient photocatalytic hydrogen evolution. Angew. Chem. Int. Ed. 2020, 59, 23112–23116. [Google Scholar] [CrossRef]

- Chen, Y.; Ji, S.; Sun, W.; Lei, Y.; Wang, Q.; Li, A.; Chen, W.; Zhou, G.; Zhang, Z.; Wang, Y.; et al. Engineering the atomic interface with single platinum atoms for enhanced photocatalytic hydrogen production. Angew. Chem. Int. Ed. 2020, 59, 1295–1301. [Google Scholar] [CrossRef]

- Wang, D.; Gong, X.Q. Function-oriented design of robust metal cocatalyst for photocatalytic hydrogen evolution on metal/titania composites. Nat. Commun. 2021, 12, 158. [Google Scholar] [CrossRef]

- Li, J.; Liu, X.; Che, H.; Liu, C.; Li, C. Facile construction of O-doped crystalline/non-crystalline g-C3N4 embedded nano-homojunction for efficiently photocatalytic H2 evolution. Carbon 2021, 172, 602–612. [Google Scholar] [CrossRef]

- Li, Y.; Je, M.; Kim, J.; Xia, C.; Roh, S.H.; So, W.; Lee, H.; Kim, D.; Cho, S.M.; Bae, J.W.; et al. Rational nanopositioning of homogeneous amorphous phase on crystalline tungsten oxide for boosting solar water oxidation. Chem. Eng. J. 2022, 438, 135532. [Google Scholar] [CrossRef]

- Zhou, D.; Fan, K.; Zhuo, Q.; Zhao, Y.; Sun, L. In situ induced crystalline−amorphous heterophase junction by K+ to improve photoelectrochemical water oxidation of BiVO4. ACS Appl. Mater. Interfaces 2021, 13, 2723–2733. [Google Scholar] [CrossRef] [PubMed]

- Heng, H.; Gan, Q.; Meng, P.; Liu, X. The visible-light-driven type III heterojunction H3PW12O40/TiO2-In2S3: A photocatalysis composite with enhanced photocatalytic activity. J. Alloys Compd. 2017, 696, 51–59. [Google Scholar] [CrossRef]

- Hou, J.; Cao, S.; Sun, Y.; Wu, Y.; Liang, F.; Lin, Z.; Sun, L. Atomically thin mesoporous In2O3–x/In2S3 lateral heterostructures enabling robust broadband-light photo-electrochemical water splitting. Adv. Energy Mater. 2018, 8, 1701114. [Google Scholar] [CrossRef]

- Li, Y.; Han, P.; Hou, Y.; Peng, S.; Kuang, X. Oriented ZnmIn2Sm+3@In2S3 heterojunction with hierarchical structure for efficient photocatalytic hydrogen evolution. Appl. Catal. B Environ. 2019, 244, 604–611. [Google Scholar] [CrossRef]

- Wang, Y.; Xing, Z.; Zhao, H.; Song, S.; Liu, M.; Li, Z.; Zhou, W. MoS2@In2S3/Bi2S3 Core-shell dual Z-scheme tandem heterojunctions with Broad-spectrum response and enhanced Photothermal-photocatalytic performance. Chem. Eng. J. 2022, 431, 133355. [Google Scholar] [CrossRef]

- Kresse, G.; Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 1991, 59, 1758–1775. [Google Scholar] [CrossRef]

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Generalized gradient approximation made simple. Phys. Rev. Lett. 1996, 77, 3865–3868. [Google Scholar] [CrossRef] [Green Version]

- Grimme, S.; Antony, J.; Ehrlich, S.; Krieg, H. A consistent and accurate ab initio parametrization of density functional dispersion correction (DFT-D) for the 94 elements H-Pu. J. Chem. Phys. 2010, 132, 154104. [Google Scholar] [CrossRef] [Green Version]

- Sakuda, A.; Ohara, K.; Fukuda, K.; Nakanishi, K.; Kawaguchi, T.; Arai, H.; Uchimoto, Y.; Ohta, T.; Matsubara, E.; Ogumi, Z.; et al. Amorphous metal polysulfides: Electrode materials with unique insertion/extraction reactions. J. Am. Chem. Soc. 2017, 139, 8796–8799. [Google Scholar] [CrossRef]

- Zhao, Y.; Yu, D.; Lu, J.; Tao, L.; Chen, Z.; Yang, Y.; Wei, A.; Tao, L.; Liu, J.; Zheng, Z.; et al. Thickness-dependent optical properties and in-plane anisotropic Raman response of the 2D β-In2S3. Adv. Opt. Mater. 2019, 7, 1901085. [Google Scholar] [CrossRef]

- Kärber, E.; Otto, K.; Katerski, A.; Mere, A.; Krunks, M. Raman spectroscopic study of In2S3 films prepared by spray pyrolysis. Mater. Sci. Semicon. Proc. 2014, 25, 137–142. [Google Scholar] [CrossRef]

- Rengaraj, S.; Venkataraj, S.; Tai, C.W.; Kim, Y.; Repo, E.; Sillanpaa, M. Self-assembled mesoporous hierarchical-like In2S3 hollow microspheres composed of nanofibers and nanosheets and their photocatalytic activity. Langmuir 2011, 27, 5534–5541. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Z.; Wang, B.; Yu, J.C.; Wang, J.; An, T.; Zhao, H.; Li, H.; Yuan, S.; Wong, P.K. AglnS2/In2S3 heterostructure sensitization of Escherichia coli for sustainable hydrogen production. Nano Energy 2018, 46, 234–240. [Google Scholar] [CrossRef] [Green Version]

- Zhang, K.; Wang, L.; Kim, J.K.; Ma, M.; Veerappan, G.; Lee, C.L.; Kong, K.J.; Lee, H.; Park, J.H. An order/disorder/water junction system for highly efficient co-catalyst-free photocatalytic hydrogen generation. Energy Environ. Sci. 2016, 9, 499–503. [Google Scholar] [CrossRef]

- Guo, S.; Li, X.; Ren, X.; Yang, L.; Zhu, J.; Wei, B. Optical and electrical enhancement of hydrogen evolution by MoS2@MoO3 core-shell nanowires with designed tunable plasmon resonance. Adv. Funct. Mater. 2018, 28, 1802567. [Google Scholar] [CrossRef]

- Sun, H.; Hua, W.; Li, Y.; Wang, J.G. Promoting photoelectrochemical activity and stability of WO3/BiVO4 heterojunctions by coating a tannin Nickel iron complex. ACS Sustain. Chem. Eng. 2020, 8, 12637–12645. [Google Scholar] [CrossRef]

- Ma, Y.M.; Pendlebury, S.R.; Reynal, A.; le Formal, F.; Durrant, J.R. Dynamics of photogenerated holes in undoped BiVO4 photoanodes for solar water oxidation. Chem. Sci. 2014, 5, 2964–2973. [Google Scholar] [CrossRef] [Green Version]

- Guo, S.H.; Li, Y.H.; Tang, S.W.; Zhang, Y.Y.; Li, X.H.; Sobrido, A.J.; Titirici, M.M.; Wei, B.Q. Monitoring hydrogen evolution reaction intermediates of transition metal dichalcogenides via operando Raman spectroscopy. Adv. Funct. Mater. 2020, 30, 2003035. [Google Scholar] [CrossRef]

- Chen, H.D.; Chen, Z.; Zhang, X.; Lu, Z.; Xiao, S.; Xiao, B.; Singh, C.V. Exploring single atom catalysts of transition-metal doped phosphorus carbide monolayer for HER: A first-principles study. J. Energy Chem. 2021, 52, 155. [Google Scholar] [CrossRef]

- Liang, H.F.; Ming, F.W.; Alshareef, H.N. Applications of plasma in energy conversion and storage materials. Adv. Energy Mater. 2018, 8, 1801804. [Google Scholar] [CrossRef]

- Hefny, M.M.; Necas, D.; Zajickova, L.; Benedikt, J. The transport and surface reactivity of O atoms during the atmospheric plasma etching of hydrogenated amorphous carbon films. Plasma Sources Sci. Technol. 2019, 28, 035010. [Google Scholar] [CrossRef]

- Sun, Z.G.; Li, X.S.; Liu, J.L.; Zhu, B.; Li, X.G.; Zhu, A.M. Effect of ammonia-derived species on visible-light photocatalytic activity of Au supported on amorphous TiO2 activated by plasma. Plasma Process. Polym. 2018, 15, 1800095. [Google Scholar] [CrossRef]

- Ma, X.; Li, W.; Li, H.; Dong, M.; Li, X.; Geng, L.; Fan, H.; Li, Y.; Qiu, H.; Wang, T. Fabrication of novel and noble-metal-free MoP/In2S3 Schottky heterojunction photocatalyst with efficient charge separation for enhanced photocatalytic H2 evolution under visible light. J. Colloid Interface Sci. 2022, 617, 284–292. [Google Scholar] [CrossRef] [PubMed]

- Ma, X.; Ren, C.; Li, H.; Liu, X.; Li, X.; Han, K.; Li, W.; Zhan, Y.; Khan, A.; Chang, Z.; et al. A novel noble-metal-free Mo2C-In2S3 heterojunction photocatalyst with efficient charge separation for enhanced photocatalytic H2 evolution under visible light. J. Colloid Interface Sci. 2020, 582, 488–495. [Google Scholar] [CrossRef]

- Ma, X.; Li, W.; Ren, C.; Li, H.; Liu, X.; Li, X.; Wang, T.; Dong, M.; Liu, S.; Chen, S. A novel noble-metal-free binary and ter-nary In2S3 photocatalyst with WC and “W-Mo auxiliary pairs” for highly-efficient visible-light hydrogen evolution. J. Alloys Compd. 2021, 875, 160058. [Google Scholar] [CrossRef]

- Li, X.; Lyu, X.; Zhao, X.; Zhang, Y.; Akanyange, S.N.; Crittenden, J.C.; Zhao, H.; Jiang, T. Enhanced photocatalytic H2 evolu-tion over In2S3 via decoration with GO and Fe2P co-catalysts. Int. J. Hydrogen Energy 2021, 46, 18376–18390. [Google Scholar] [CrossRef]

- Geng, H.; Ying, P.; Li, K.; Zhao, Y.; Gu, X. Epitaxial In2S3/ZnIn2S4 heterojunction nanosheet arrays on FTO substrates for photoelectrochemical water splitting. Appl. Surf. Sci. 2021, 563, 150289. [Google Scholar] [CrossRef]

- Song, H.; Zhang, Q.; Hu, D.; Sun, Z.; Han, Y.; Meng, H.; Sun, T.; Zhang, X. In-situ partial cation exchange-derived ZnIn2S4 nanoparticles hybridized 1D MIL-68/In2S3 microtubes for highly efficient visible-light induced photocatalytic H2 production. Sep. Purif. Technol. 2022, 287, 120585. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, S.; Luo, H.; Duan, X.; Wei, B.; Zhang, X. Plasma-Wind-Assisted In2S3 Preparation with an Amorphous Surface Structure for Enhanced Photocatalytic Hydrogen Production. Nanomaterials 2022, 12, 1761. https://0-doi-org.brum.beds.ac.uk/10.3390/nano12101761

Guo S, Luo H, Duan X, Wei B, Zhang X. Plasma-Wind-Assisted In2S3 Preparation with an Amorphous Surface Structure for Enhanced Photocatalytic Hydrogen Production. Nanomaterials. 2022; 12(10):1761. https://0-doi-org.brum.beds.ac.uk/10.3390/nano12101761

Chicago/Turabian StyleGuo, Shaohui, Hui Luo, Xiaochuan Duan, Bingqing Wei, and Xianming Zhang. 2022. "Plasma-Wind-Assisted In2S3 Preparation with an Amorphous Surface Structure for Enhanced Photocatalytic Hydrogen Production" Nanomaterials 12, no. 10: 1761. https://0-doi-org.brum.beds.ac.uk/10.3390/nano12101761