Crosslinked Carbon Nanotubes/Polyaniline Composites as a Pseudocapacitive Material with High Cycling Stability

Abstract

:1. Introduction

2. Results and Discussion

2.1. C-CNTs

2.2. C-CNTs/PANI Composites

2.3. Electrochemical Performances

3. Experimental Section

3.1. Materials and Reagents

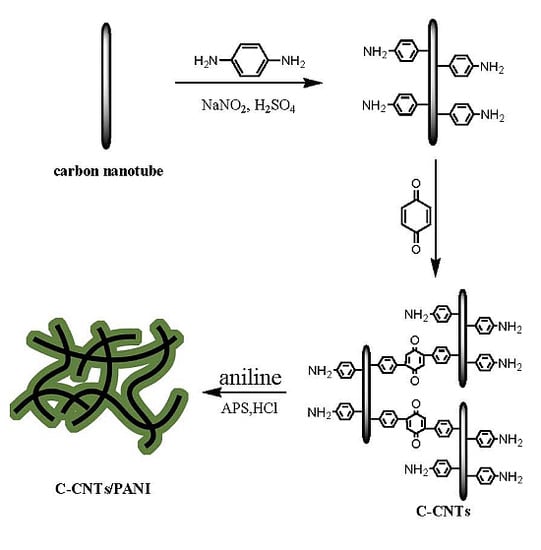

3.2. Synthesis of C-CNTs

3.3. Synthesis of C-CNTs/PANI

3.4. Characterizations and Testing

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhang, J.; Zhao, X. On the configuration of supercapacitors for maximizing electrochemical performance. ChemSusChem 2012, 5, 818–841. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.X.; Xiao, S.Y.; Hou, Y.Y.; Hu, C.L.; Liu, L.L.; Wu, Y.P. Electrode materials for aqueous asymmetric supercapacitors. RSC Adv. 2013, 3, 13059–13084. [Google Scholar] [CrossRef]

- Simon, P.; Gogotsi, Y. Materials for electrochemical capacitors. Nat. Mater. 2008, 7, 845–854. [Google Scholar] [CrossRef] [PubMed]

- Wang, G.P.; Zhang, L.; Zhang, J.J. A review of electrode materials for electrochemical supercapacitors. Chem. Soc. Rev. 2012, 41, 797–828. [Google Scholar] [CrossRef] [PubMed]

- Deng, W.T.; Ji, X.B.; Chen, Q.Y.; Banks, C.E. Electrochemical capacitors utilising transition metal oxides: An update of recent developments. RSC Adv. 2011, 1, 1171–1178. [Google Scholar] [CrossRef]

- Holze, R.; Wu, Y.P. Intrinsically conducting polymers in electrochemical energy technology: Trends and progress. Electrochim. Acta 2014, 122, 93–107. [Google Scholar] [CrossRef]

- Zhong, J.; Yang, Z.Y.; Mukherjee, R.; Thomas, A.V.; Zhu, K.; Sun, P.Z.; Lian, J.; Zhu, H.W.; Koratkar, N. Carbon nanotubes sponges as conductive networks for supercapacitor devices. Nano Energy 2013, 2, 1025–1030. [Google Scholar] [CrossRef]

- Ciric-Marjanovic, G. Recent advances in polyaniline research: Polymerization mechanisms, structural aspects, properties and applications. Synth. Met. 2013, 177, 1–47. [Google Scholar] [CrossRef]

- Nyholm, L.; Nystrom, G.; Mihranyan, A.; Strømme, M. Toward flexible polymer and paper-based energy storage devices. Adv. Mater. 2011, 23, 3751–3769. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Deng, J.X.; Duan, X.J.; Liu, D.; Guo, J.S.; Liu, P. Crosslinked polyaniline nanorods with improved electrochemical performance as electrode material for supercapacitors. J. Mater. Chem. A 2014, 2, 12323–12329. [Google Scholar] [CrossRef]

- Li, X.L.; Liu, Y.F.; Guo, W.; Chen, J.J.; He, W.X.; Peng, F.F. Synthesis of spherical PANI particles via chemical polymerization in ionic liquid for high-performance supercapacitors. Electrochim. Acta 2014, 135, 550–557. [Google Scholar] [CrossRef]

- Liu, P. Core-shell nanocomposites with conducting polymer shells. In Recent Research Developments in Applied Polymer Science; Pandalai, S.G., Ed.; Research Signpost: Kerala, India, 2010; Volume 4, pp. 351–372. [Google Scholar]

- Zhou, Y.; Qin, Z.Y.; Li, L.; Zhang, Y.; Wei, Y.L.; Wang, L.F.; Zhu, M.F. Polyaniline/multi-walled carbon nanotube composites with core-shell structures as supercapacitor electrode materials. Electrochim. Acta 2010, 55, 3904–3908. [Google Scholar] [CrossRef]

- Ramana, G.V.; Srikanth, V.V.S.S.; Padya, B.; Jain, P.K. Carbon nanotube-polyaniline nanotube core-shell structures for electrochemical applications. Eur. Polym. J. 2014, 57, 137–142. [Google Scholar] [CrossRef]

- Mi, H.Y.; Zhang, X.G.; An, S.Y.; Ye, X.G.; Yang, S.D. Microwave-assisted synthesis and electrochemical capacitance of polyaniline/multi-wall carbon nanotubes composite. Electrochem. Commun. 2007, 9, 2859–2862. [Google Scholar] [CrossRef]

- Otrokhov, G.; Pankratov, D.; Shumakovich, G.; Khlupova, M.; Zeifman, Y.; Vasil’eva, I.; Morozova, O.; Yaropolov, A. Enzymatic synthesis of polyaniline/multi-walled carbon nanotube composite with core shell structure and its electrochemical characterization for supercapacitor application. Electrochim. Acta 2014, 123, 151–157. [Google Scholar] [CrossRef]

- Hyder, M.N.; Lee, S.W.; Cebeci, F.C.; Schmidt, D.J.; Yang, S.H.; Hammond, P.T. Layer-by-layer assembled polyaniline nanofiber/multiwall carbon nanotube thin film electrodes for high-power and high-energy storage applications. ACS Nano 2011, 11, 8552–8561. [Google Scholar] [CrossRef] [PubMed]

- He, X.P.; Gao, B.; Wang, G.B.; Wei, J.T.; Zhao, C. A new nanocomposite: Carbon cloth based polyaniline for an electrochemical supercapacitor. Electrochim. Acta 2013, 111, 210–215. [Google Scholar]

- Hu, H.; Liu, S.W.; Hanif, M.; Chen, S.L.; Hou, H.Q. Three-dimensional cross-linked carbon network wrapped with ordered polyaniline nanowires for high-performance pseudo-supercapacitors. J. Power Sources 2014, 268, 451–458. [Google Scholar] [CrossRef]

- Liu, H.L.; Wang, Y.; Gou, X.L.; Qi, T.; Yang, J.; Ding, Y.L. Three-dimensional graphene/polyaniline composite material for high-performance supercapacitor applications. Mater. Sci. Eng. B 2013, 178, 293–298. [Google Scholar] [CrossRef]

- Kulkarni, S.B.; Patil, U.M.; Shackery, I.; Sohn, J.S.; Lee, S.; Park, B.; Jun, S. High-performance supercapacitor electrode based on a polyaniline nanofibers/3D graphene framework as an efficient charge transporter. J. Mater. Chem. A 2014, 2, 4989–4998. [Google Scholar] [CrossRef]

- Zhang, J.W.; Jiang, D.Z.; Peng, H.X.; Qin, F.X. Enhanced mechanical and electrical properties of carbon nanotube buckypaper by in situ cross-linking. Carbon 2013, 63, 125–132. [Google Scholar] [CrossRef]

- Dyke, C.A.; Tour, J.M. Solvent-free functionalization of carbon nanotubes. J. Am. Chem. Soc. 2003, 125, 1156–1157. [Google Scholar] [CrossRef] [PubMed]

- Kuan, H.C.; Ma, C.C.M.; Chang, W.P.; Yuen, S.M.; Wu, H.H.; Lee, T.M. Synthesis, thermal, mechanical and rheological properties of multiwall carbon nanotube/waterborne polyurethane nanocomposite. Compos. Sci. Technol. 2005, 65, 1703–1710. [Google Scholar] [CrossRef]

- Wu, T.M.; Lin, Y.W. Doped polyaniline/multi-walled carbon nanotube composites: Preparation, characterization and properties. Polymer 2006, 47, 3576–3582. [Google Scholar] [CrossRef]

- Choi, H.J.; Jeon, I.Y.; Kang, S.W.; Baek, J.B. Electrochemical activity of a polyaniline/polyaniline-grafted multiwalled carbon nanotube mixture produced by a simple suspension polymerization. Electrochim. Acta 2011, 56, 10023–10031. [Google Scholar] [CrossRef]

- Gao, Z.Y.; Wang, F.; Chang, J.L.; Wu, D.P.; Wang, X.R.; Wang, X.; Xu, F.; Gao, S.Y.; Jiang, K. Chemically grafted graphene-polyaniline composite for application in supercapacitor. Electrochim. Acta 2014, 133, 325–334. [Google Scholar] [CrossRef]

- Mekki, A.; Samanta, S.; Singh, A.; Salmi, Z.; Mahmoud, R.; Chehimi, M.M.; Aswal, D.K. Core/shell, protuberance-free multiwalled carbon nanotube/polyaniline nanocomposites via interfacial chemistry of aryl diazonium salts. J. Colloid Interface Sci. 2014, 418, 185–192. [Google Scholar] [CrossRef] [PubMed]

- Patil, D.S.; Shaikh, J.S.; Dalavi, D.S.; Kalagi, S.S.; Patil, P.S. Chemical synthesis of highly stable PVA/PANI films for supercapacitor application. Mater. Chem. Phys. 2011, 128, 449–455. [Google Scholar] [CrossRef]

- Niu, Z.Q.; Luan, P.S.; Shao, Q.; Dong, H.B.; Li, J.Z.; Chen, J.; Zhao, D.; Cai, L.; Zhou, W.Y.; Chen, X.D.; et al. A “skeleton/skin” strategy for preparing ultrathin free-standing single-walled carbon nanotube/polyaniline films for high performance supercapacitor electrodes. Energy Environ. Sci. 2012, 5, 8726–8733. [Google Scholar] [CrossRef]

- Feng, W.; Bai, X.D.; Lian, Y.Q.; Liang, J.; Wang, X.G.; Yoshino, K. Well-aligned polyaniline/carbon-nanotube composite films grown by in-situ aniline polymerization. Carbon 2003, 41, 1551–1557. [Google Scholar] [CrossRef]

- Wu, J.S.; Rui, X.H.; Long, G.K.; Chen, W.Q.; Yan, Q.Y.; Zhang, Q.C. Pushing up lithium storage through nanostructured polyazaacene analogues as anode. Angew. Chem. Int. Ed. 2015. [Google Scholar] [CrossRef]

- Wang, Q.G.; Qian, X.; Wang, S.M.; Zhou, W.; Guo, H.; Wu, X.M.; Li, J.P.; Wang, X.H. Conductive polyaniline composite films from aqueous dispersion: Performance enhancement by multi-walled carbon nanotube. Synth. Met. 2015, 199, 1–7. [Google Scholar] [CrossRef]

- Chen, H.Y.; Di, J.T.; Jin, Y.; Chen, M.H.; Tian, J.; Li, Q.W. Active carbon wrapped carbon nanotube buckypaper for the electrode of electrochemical supercapacitors. J. Power Sources 2013, 237, 325–331. [Google Scholar] [CrossRef]

- Yu, P.P.; Li, Y.Z.; Zhao, X.; Wu, L.H.; Zhang, Q.H. Graphene-wrapped polyaniline nanowire arrays on nitrogen-doped carbon fabric as novel flexible hybrid electrode materials for high-performance supercapacitor. Langmuir 2014, 30, 5306–5313. [Google Scholar] [CrossRef] [PubMed]

- Trchová, M.; Morávková, Z.; Šeděnková, I.; Stejskal, J. Spectroscopy of thin polyaniline films deposited during chemical oxidation of aniline. Chem. Paper 2012, 66, 415–445. [Google Scholar] [CrossRef]

- Wu, J.S.; Rui, X.H.; Wang, C.Y.; Pei, W.B.; Lau, R.; Yan, Q.Y.; Zhang, Q.C. Nanostructured conjugated ladder polymers for stable and fast Lithium storage anodes with high-capacity. Adv. Energy Mater. 2015, 5. [Google Scholar] [CrossRef]

- Remyamol, T.; Gopinath, P.; John, H. Core-shell nanostructures of covalently grafted polyaniline multi-walled carbon nanotube hybrids for improved optical limiting. Org. Lett. 2015, 40, 21–24. [Google Scholar] [CrossRef] [PubMed]

- Ellison, M.D.; Gasda, P.J. Functionalization of single-walled carbon nanotubes with 1,4-benzenediamine using a diazonium reaction. J. Phys. Chem. C 2008, 112, 738–740. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, D.; Wang, X.; Deng, J.; Zhou, C.; Guo, J.; Liu, P. Crosslinked Carbon Nanotubes/Polyaniline Composites as a Pseudocapacitive Material with High Cycling Stability. Nanomaterials 2015, 5, 1034-1047. https://0-doi-org.brum.beds.ac.uk/10.3390/nano5021034

Liu D, Wang X, Deng J, Zhou C, Guo J, Liu P. Crosslinked Carbon Nanotubes/Polyaniline Composites as a Pseudocapacitive Material with High Cycling Stability. Nanomaterials. 2015; 5(2):1034-1047. https://0-doi-org.brum.beds.ac.uk/10.3390/nano5021034

Chicago/Turabian StyleLiu, Dong, Xue Wang, Jinxing Deng, Chenglong Zhou, Jinshan Guo, and Peng Liu. 2015. "Crosslinked Carbon Nanotubes/Polyaniline Composites as a Pseudocapacitive Material with High Cycling Stability" Nanomaterials 5, no. 2: 1034-1047. https://0-doi-org.brum.beds.ac.uk/10.3390/nano5021034