1. Introduction

In recent times, the reality of material science as a subject area is still of interest considering the behavioural mechanisms of materials and the suitable modelling of their mathematical relationships [

1]. A concrete mix is optimised to reduce the constituents’ costs and expended time on conducting the concrete trial mixes without compromising the quality and performance of concrete under an applied loading condition [

2]. Aggregates and cement paste are the primary constituents of concrete (composite material). Although the water/cement ratio governs the quality of required cement paste while the required proportion of cement paste to attain a targeted concrete strength and quality depends on the aggregates’ characteristics such as types, voids, shapes, and surface area [

2]. Therefore, as reported in previous studies [

3,

4,

5], optimising a concrete mix can be conducted by adjusting the critical levels of mix factors such as binder/aggregate ratio, water/binder ratio, cementitious (binding) material contents, and binding contents ratio.

Box–Behnken design (BBD) is a statistical and analytical method of response surface that examines the effect of a set of quantitative experimental variables of factors on the response [

6]. Response surface methodology (RSM), a design of experiment (DOE), is usually engaged to identify a set of vital factors (operating conditions), which generate the “best” response [

6,

7]. Besides, RSM models a relationship between the quantitative factors and the response. Furthermore, BBD is a response surface three-level design where design points are either at the centre of the design or centred on the cube’s edges, equidistant from the centre [

6]. Unlike the central composite design of RSM, BBD allows efficient estimation of quadratic terms in a regression model and consists of fewer design points, hence less expensive to run [

8]. Besides, BBD ensures that all design points fall within the safe operating limits (within the nominal high and low levels) for the process [

6].

The early age compressive strength of concrete was conducted using RSM. The results indicated that the initial age strength could be predicted accurately via the developed models, which yielded about 85–90% coefficient of efficiency at 95% confidence bounds [

9]. Dai et al. [

10] optimised the mix quantities for cement paste backfill materials via RSM (four-factor and three-level). It was reported that the industrial standard backfilling materials was feasible and could be predicted via the RSM. Bahri et al. [

11] also optimised the mix proportions of high strength-performance concrete modified with rice husk ash (RHA) using RSM (five-factor and three-level). The statistical findings revealed that the response models accurately optimised the responses, compressive strength and slump, at about 5% less error and significantly fit to predict the mix factors. Moreover, in an attempt to optimise the alkali-slag concrete (ASC) under freeze-thaw cycles, Liu et al. [

12] adopted BBD. The results indicated that solutions ratio, slag content, and curing age (independent variables) were fitted accurately. The response models can be used to produce fracture toughness of alkali-slag concrete. A concrete modified with limestone filler was also optimised via RSM [

13]. The statistical response models indicated an optimum validity for mixtures comprising water/limestone filler ratios of 0.38–0.72 at 120 kg/m

3 of limestone filler and 250–400 kg/m

3 of cement. Despite the previous studies on optimising concrete mixtures incorporating supplementary cementitious materials (SCMs), no research is available to optimise a concrete mix modifying with cashew nut shell ash (CNA).

The utilisation of SCMs in concrete production reduces the constituents’ costs, energy consumption, and environmental impacts, contributing to energy and environmental preservation and sustainable products and development [

14]. Oyebisi et al. [

15] investigated the reactivity indexes and durability properties of geopolymer concrete (GPC), incorporating both ground granulated blast furnace slag (GGBFS) and corn cob ash (CCA) as SCMs. The results indicated that GGBFS and CCA’s oxide compositions enhanced the reactivity, compressive strength, and chemical resistance of GPC produced. Moreover, Mark et al. [

16] reviewed the effects of some SCMs, cupola furnace slag powder (CFSP), blast furnace slag powder (BFSP), silica fume (SF), fly ash (FA), rice husk ash (RHA), metakaolin (MK), coconut husk ash (CHA), palm oil fuel ash (POFA), wood waste ash (WWA), sugar cane bagasse ash (SCBA), corn cob ash (CCA), and bamboo leaf ash (BLA), on the workability and compressive strength of concrete. It was revealed that the incorporation of these twelve SCMs significantly improved the strength and workability of concrete. Akinwumi and Aidomojie [

17] examined the influence of corncob ash on lateritic soil’s geotechnical properties stabilised with Portland cement. The results showed that incorporating CCA into the soil generally reduced its plasticity, swell potential, and permeability. It also increased the soil’s strength. Besides its economic and environment-friendly characteristics compared with the cement-stabilisation, CCA improved the soil’s geotechnical properties for pavement layer material application. At 25–50% of SCMs by wt.% of cement, there are about 20–67% and 33–80% reduction in required energy and material cost, respectively [

18]. Consequent to the broader utilisation of some SCMs, CNA’s use as SCM in concrete production is rare. Cashew nutshell is a waste product obtained from agricultural produce. In 2017, about 4.5 million metric tonnes (MMT) was generated globally, with Nigeria generating about 0.1 MMT [

19]. From 2.5 MMT of cashew nuts generation, about 1.825 MMT of waste is obtained [

20]. However, it is worrisome to observe that this material is usually discarded as waste, causing environmental problems.

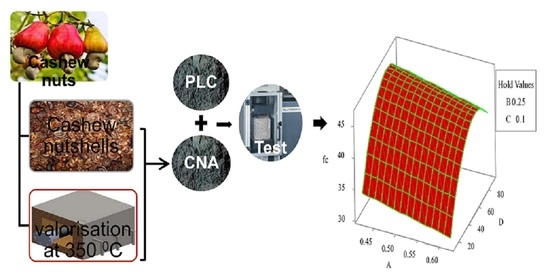

In this present study, an attempt was made to engage the application of a BBD of RSM to obtain an optimum proportioning of concrete strength using the values obtained from an experimental design. Design factors such as binders’ ratio, water/binder ratio, curing ages, and binder/aggregate ratio were selected as independent (continuous) variables. At the same time, the compressive strength was considered as a response variable. The data were analysed statistically via Minitab 17 software, and the regression model was developed for concrete strength as a function of mixture variables. The developed approach to optimising the mixtures of concrete proportions was based on the experimental works (involving the required characteristics of concrete performance) and the statistical analysis of data generated; this would reduce time, cost, and the number of trial mixes.

4. Conclusions

A simplified mechanism, optimising the concrete workability and strength modified with high silica and alumina precursor, was developed based on the statistical analysis obtained through an experimentally designed work. As a result of this mechanism, the following outcomes are drawn: At 5–15 wt.% substitution of CNA, there was about 3–6% increase in concrete’s compressive strengths for all concrete grades (M 25, M 30, and M 40) at 28 d curing. Moreover, the optimum values of water/binder ratio (A), binder/aggregate ratio (B), and SCM/cement ratio (C) exhibited a 5% increase in compressive strength at 28% decrease in curing age (D) compared with the target variables. This signifies a significant cost and time saving while maintaining the composite product’s quality and strength performance. On the other hand, as illustrated in Equation (10), the developed model has proved to be efficient such that a good relationship with high precision was obtained when compared with the previous concrete strength incorporating SCMs. In addition the slump obtained via optimisation and that of experimental values yielded the same results, hence exhibiting a strong precision, as illustrated in Equation (11); this can be used in the prediction of normal workability of concrete modified with CNA while saving cost and time of preparing experimental works. Finally, the possibility of using less water for the optimisation of concrete strength is attainable by blending PLC with anacardium occidentale nutshell ash (cashew nutshell ash, CNA). In addition this research can be applied in the normal reinforced concrete work without vibration.