Applying Systems Thinking to Engineering and Design

Abstract

:1. Introduction

1.1. Systems Thinking and Systems Engineering

1.2. Systems Engineering Failures Due to Lack of Systems Thinking

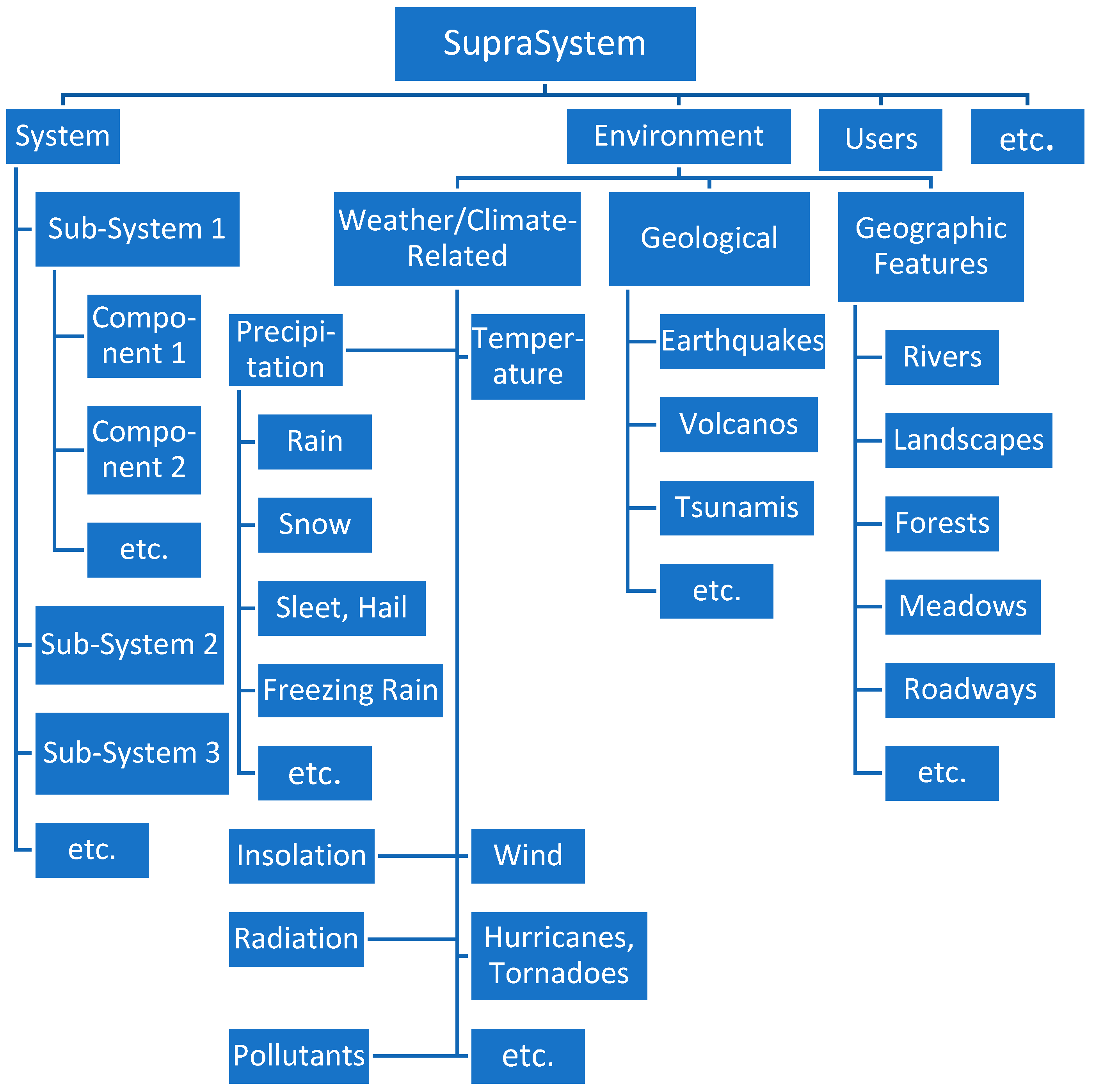

- Failure to identify relevant environmental factors such as wind, insolation, rain, and temperature;

- Failure to understand that most complex problems cannot be solved by purely technological means; they often involve organizational, political, economic, environmental, ethical, and sociological components.

- Failure to adequately address both planned and unplanned interactions among the system components themselves and between system components and the environment.

- Failure to recognize that many products are actually components of a User Experience System.

2. How to Engineer and Design Systems to Avoid Similar Issues

2.1. Identification of Relevant Environmental Factors such as Wind, Insolation, Rain, Temperature

- Developmental Control: the ability of the system designer to control the component;

- Operational Control: the ability of the system operator to control the component;

- Functional Allocation: the ability of the system designer/operator to assign functions to the component;

- Unity of Purpose: the degree to which the component is dedicated to the system’s successful performance.

2.2. Bounding the System Properly with Respect to Understanding That Most Complex Problems Cannot Be Solved by Purely Technological Means; They Often Involve Organizational, Political, Economic, Environmental, Ethical, and Sociological Components

- A water and pump operation training and education system;

- A cultural sensitivity system;

- A pump maintenance and repair system;

- A supply chain for repair parts;

- A money-generation and management system, including a farming sub-system;

- A village/social organization to appropriately divide the labor and decision-making.

- Will the new system or systemic change require any cultural adjustment? If so, cultural sensitivity and training will be required.

- Will the new system require training and education in its use, benefits, and maintenance?

- Will a cleaning, maintenance, and repair system need to be established?

- Will a repair parts supply chain need to be established?

- Is there a means to pay for repair, maintenance, legal issues, decommissioning?

2.3. Adequately Addressing Both Planned and Unplanned Interactions among the System Components Themselves and between System Components and the Environment

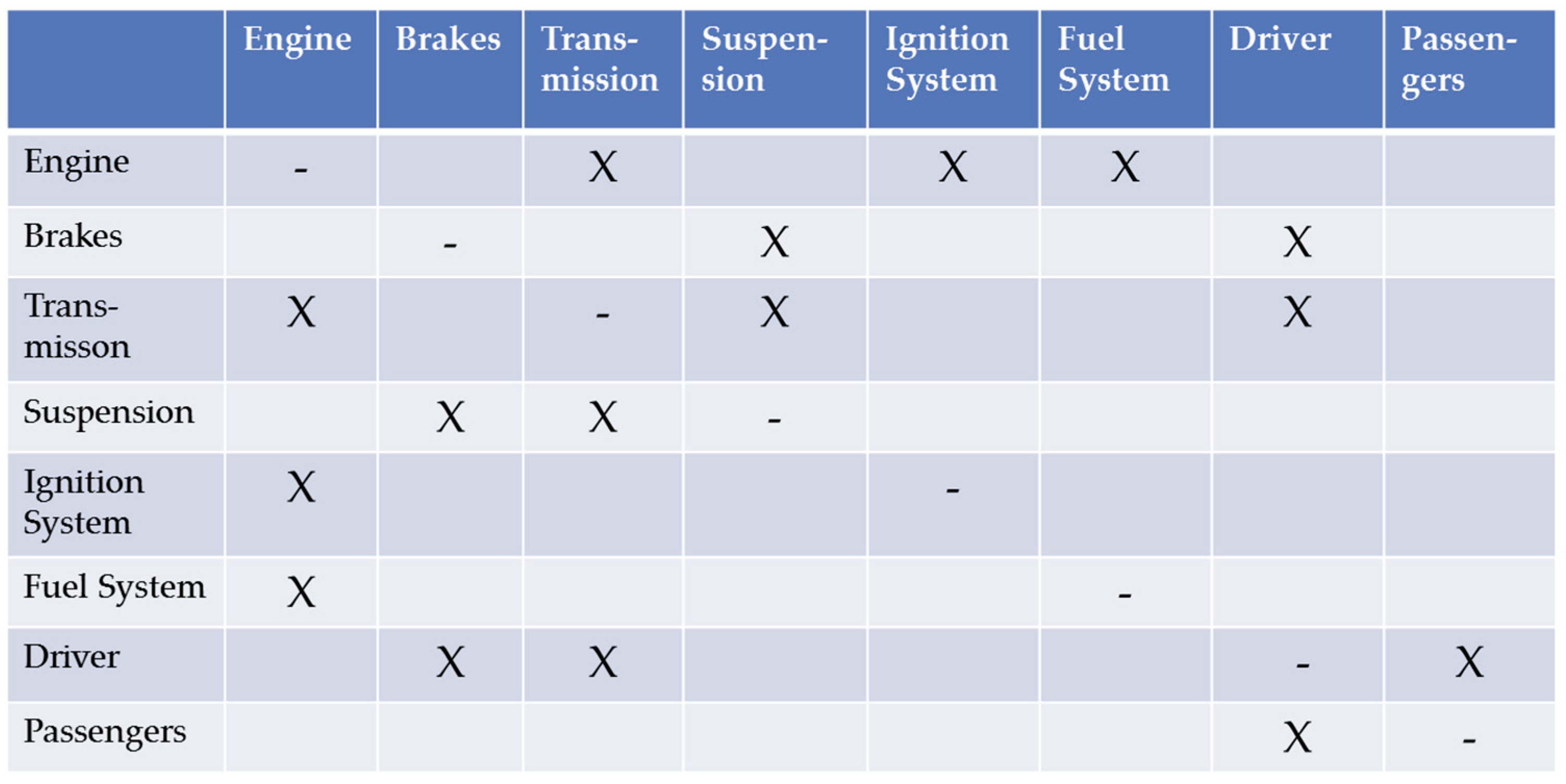

2.3.1. System Interrelationship Matrix

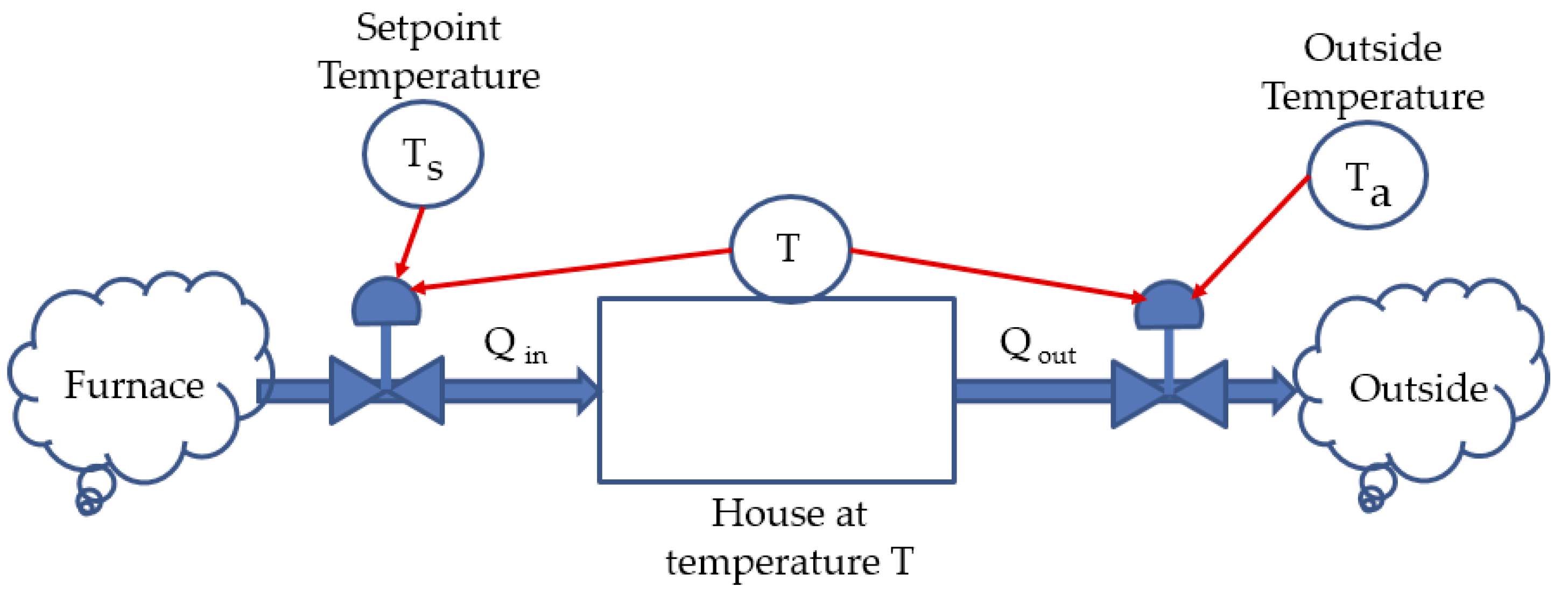

2.3.2. Stock-and-Flow Diagrams

2.3.3. Causal Loop Diagrams

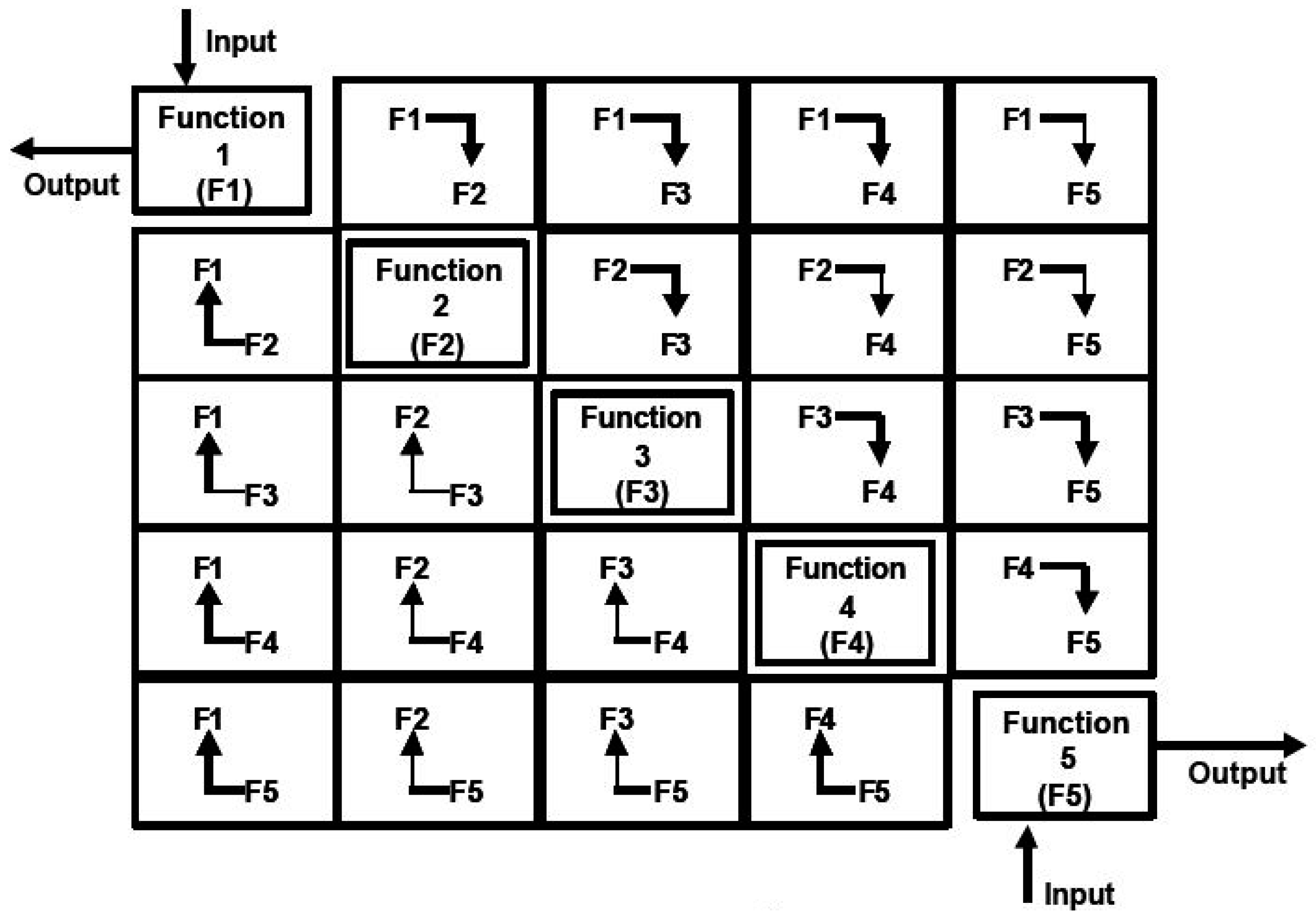

2.3.4. N2 Diagrams

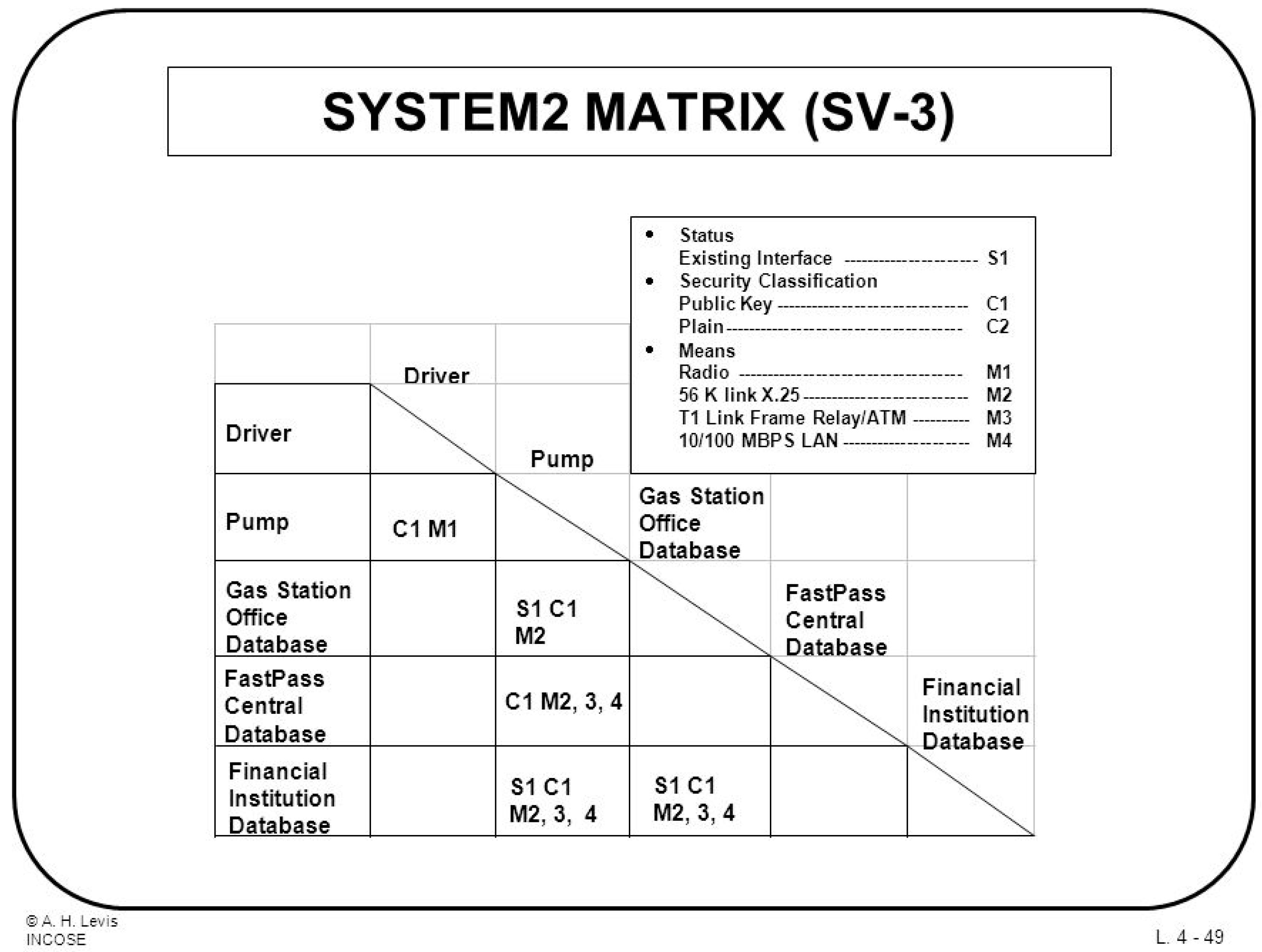

2.3.5. SV-3 System-System Matrix

- Status (e.g., existing, planned, potential, de-activated);

- Key interfaces;

- Category (e.g., command and control, intelligence, personnel, logistics);

- Classification-level (e.g., Restricted, Confidential, Secret, Top Secret);

- Communication means (e.g., Rim Loop Interface, Scalable Loop Interface).”

2.4. Recognizing That Many Products Are Part of a Larger User Experience System

- The automobile as a stand-alone product versus the car buying and owning experience. Car ownership involves car purchase, registration, annual inspections, maintenance, and disposal or trade-in as well as insurance. Cars wear out and new technology renders older models obsolete. There is no good reason that car dealers could not provide all these services for a fixed monthly fee. Some dealerships have already started down this path with service areas that provide free meals, entertainment, and drop-off services. Several manufacturers (Volvo, Cadillac, BMW) have adopted new “subscription services” in which a fixed monthly fee is paid by the user to cover lease, insurance, maintenance, and other expenses [46].

- Coffee. Is it the coffee itself, or is it the coffee-drinking experience? Starbucks (and others) attracts clients to not only buy and drink coffee, but to enjoy the coffeehouse experience, with free Wi-Fi, comfortable seating, and even fireplaces in some establishments.

- Clothes versus the clothes buying and owning experience. Clothes use involves clothing selection, travel to a store, fitting, matching, laundering and pressing, repair, and disposal. While many do not mind (or even enjoy) these activities, some do not. Enterprising Systems Thinking businesses could assume all these functions for a fixed monthly fee, thus providing a clothes use experience in which the clothes themselves are merely adjuncts.

- Flat Panel TV versus the home entertainment system experience. To many people, the home theater component selection, purchase, matching, interconnection, and set up is a harrowing experience. A Systems Thinking approach by subscription TV service providers (Comcast, Verizon, DirecTV, DishTV, etc.) would dictate that these onerous functions be included in the monthly subscription. This would ensure that users would always have the latest equipment set up and functioning optimally to receive the provider’s streaming content. It would be similar to a razor-blade or inkjet printer business model in which the asset (in this case the TV and associated hardware) is provided free or near-free to encourage the user to consume the razor blades or ink (in this case, the streaming services).

- Home Ownership. Certainly many houses are rented today; however, house buyers must assume the responsibility for lawn and yard maintenance, utilities, snow removal, pool maintenance, insurance, and all the other onerous responsibilities that come with home ownership. A Systems Thinking approach to the home owning experience would bundle these items in with monthly mortgage payments such that the owner pays one monthly fee for all home owning tasks and services, which are then provided by the mortgage company or their representatives.

3. Procedure

- Regional Architecture/Scoping the Problem;

- Feasibility Study/Concept Exploration;

- Concept of Operations;

- System Requirements;

- High-Level Design;

- Detailed Design;

- Software/Hardware Development/Field Installation;

- Unit Device Testing;

- Subsystem Validation;

- System Verification and Deployment;

- System Validation;

- Operations and Maintenance;

- Changes and Upgrades;

- Retirement/Replacement.

4. Conclusions and Recommendations

- Early in the design process, system engineers must ensure that they have captured all relevant components of the system, as well as the suprasystem in which the system of interest resides. Environmental factors such as wind, insolation, temperature, and the potential for dramatic incidents such as earthquakes, tsunamis, and hurricanes are notorious for being overlooked. The System Breakdown Structure (SBS) is an excellent tool for this.

- Once the relevant components of the system of interest and its suprasystem have been properly identified, all relevant relationships must be identified. The System Interrelationship Matrix (SIM) is an excellent tool for this. Stock-and-Flow diagrams and Causal Loop diagrams may also be helpful.

- Having identified all relevant system components and interrelationships, systems engineers must then realize that very few complex problems have purely technological solutions. Engineers also must consider the sociological, psychological, ethical, political, cultural, and economic factors that may impact the success of a complex system.

- Finally, in designing complex systems, engineers must understand that “products” are very often not stand-alone devices or systems, but instead part of a user experience system that comprises the user, the environment, aesthetics, psychological factors, system acquisition, maintenance, upgrades, and disposal. Failure to address these ancillary factors may cause the system to fail, either technically or commercially.

Author Contributions

Funding

Conflicts of Interest

References

- Monat, J.P.; Gannon, T.F. What is Systems Thinking? A Review of Selected Literature Plus Recommendations. Am. J. Syst. Sci. 2015, 4, 2. [Google Scholar]

- Kossiakoff, A.; Sweet, W.; Seymour, S.; Biemer, S. Systems Engineering: Principles and Practice, 2nd ed.; Wiley: Hoboken, NJ, USA, 2011. [Google Scholar]

- Lawson, H. A Journey Through the Systems Landscape; College Publications: London, UK, 2010; p. 6. [Google Scholar]

- Boyd, J.R. An Organic Design for Command and Control, a Discourse on Winning and Losing. Maxwell Air Force Base, Alabama Air University, Montgomery, AL, USA. Unpublished lecture notes. 1987. [Google Scholar]

- Shewhart, W.A. Statistical Method from the Viewpoint of Quality Control; U.S. Department of Agriculture: Dover, UK, 1939; p. 45.

- Kasser, J.; Mackley, T. Applying systems thinking and aligning it to systems engineering. INCOSE Int. Symp. 2008, 18, 1389–1405. [Google Scholar] [CrossRef] [Green Version]

- Godfrey, P. What is Systems Thinking? How does it relate to Systems Engineering? INCOSE UK zGuide 7, Issue 1. March 2010. Available online: https://incoseonline.org.uk/Program_Files/Publications/zGuides_7.aspx?CatID=publications&SubCat=zGuides (accessed on 10 April 2018).

- Pyster, A.; Olwell, D.; Hutchison, N.; Enck, S.; Anthony, J.; Henry, D.; Squires, A. (Eds.) Guide to the Systems Engineering Body of Knowledge (SEBoK), version 1.0; The Trustees of the Stevens Institute of Technology: Hoboken, NJ, USA, 2012; pp. 98–125. Available online: http://www.sebokwiki.org (accessed on 29 March 2018).

- INCOSE. INCOSE, Systems Engineering Handbook, 4th ed.; INCOSE-TP-2003-002-04-2015; Wiley: Hoboken, NJ, USA, 2015; pp. 18–21. [Google Scholar]

- Burge, S.E. Systems Engineering: Using Systems Thinking to Design Better Aerospace Systems. In Encyclopedia of Aerospace Engineering; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2010. [Google Scholar]

- Frank, M. Engineering Systems Thinking: Cognitive Competencies of Successful Systems Engineers. Procedia Comput. Sci. 2012, 8, 273–278. [Google Scholar] [CrossRef]

- Billah, K.Y.; Scanlan, R.H. Resonance, Tacoma Narrows bridge failure, and undergraduate physics textbooks. Am. J. Phys. 1991, 59, 118–124. [Google Scholar] [CrossRef]

- Petroski, H. Design Paradigms—Case Histories of Error and Judgment in Engineering; Cambridge University Press: New York, NY, USA, 1994; pp. 156–165. [Google Scholar]

- Gaal, R. This Month in Physics History, November 7, 1940: Collapse of the Tacoma Narrows Bridge. APS News. November 2016, Volume 25. Number 10. Available online: https://www.aps.org/publications/apsnews/201611/physicshistory.cfm (accessed on 14 August 2018).

- Dallard, P.; Fitzpatrick, A.J.; Flint, A.; le Bourva, S.; Low, A.; Smith, R.M.R.; Willford, M. The London Millennium Footbridge. Struct. Eng. 2001, 79, 17–35. [Google Scholar]

- Josephson, B. Out of Step on the Bridge. Guardian Letters. 14 June 2000. Available online: https://www.theguardian.com/theguardian/2000/jun/14/guardianletters3 (accessed on 7 May 2018).

- Strogatz, S.; Abrams, D.M.; McRobie, A.; Eckhardt, B.; Ott, E. Theoretical Mechanics: Crowd Synchrony on the Millennium Bridge. Nature 2005, 438, 43–44. [Google Scholar] [CrossRef] [PubMed]

- Bachmann, H.; Ammann, W. Vibrations in Structures Induced by Man and Machines; Structural Engineering Document 3e; International Association for Bridge and Structural Engineering (IABSE): Zurich, Switzerland, 1987; Chapter 2: Man-Induced Vibrations, Appendix A: Case Reports. [Google Scholar]

- Fujino, Y.; Pacheco, B.M.; Nakamura, S.-I.; Warnitchai, P. Synchronization of Human Walking Observed during Lateral Vibration of a Congested Pedestrian Bridge. Earthq. Eng. Struct. Dyn. 1993, 22, 741–758. [Google Scholar] [CrossRef]

- Wernimont, E.; Ventura, M.; Garboden, G.; Mullens, P. Past and Present Uses of Rocket Grade Hydrogen Peroxide; General Kinetics, LLC: Aliso Viejo, CA, USA, 2018; p. 92656. [Google Scholar]

- Duddu, P. The World’s Deadliest Torpedoes. Naval Technology. 8 June 2014. Available online: https://www.naval-technology.com/features/featurethe-worlds-deadliest-torpedoes-4286162/ (accessed on 7 May 2018).

- Guardian. What Really Happened to Russia’s ‘Unsinkable’ Sub. The Guardian, 4 August 2001. [Google Scholar]

- Faulconbridge, G. Nightmare at Sea. Moscow Times, 3 December 2004; Archived from the original on 28 February 2014. [Google Scholar]

- Garfield, L. The ‘Death Ray Hotel’ Burning Las Vegas Visitors Came Up with a Simple Fix. Business Insider. 30 June 2016. Available online: http://www.businessinsider.com/the-vdara-death-ray-hotel-is-still-burning-people-in-las-vegas-2016-6 (accessed on 7 May 2018).

- Maimon, A. Vdara Visitor: ‘Death Ray’ Scorched Hair. Las Vegas Review-Journal. 24 September 2010. Available online: https://www.reviewjournal.com/news/vdara-visitor-death-ray-scorched-hair/ (accessed on 7 May 2018).

- Hodge, D. Reflective “Death Ray” Torments Vegas Sunbathers. Reuters Environment. 1 October 2010. Available online: https://www.reuters.com/article/us-lasvegas-deathray-idUSTRE6904AR20101001 (accessed on 7 May 2018).

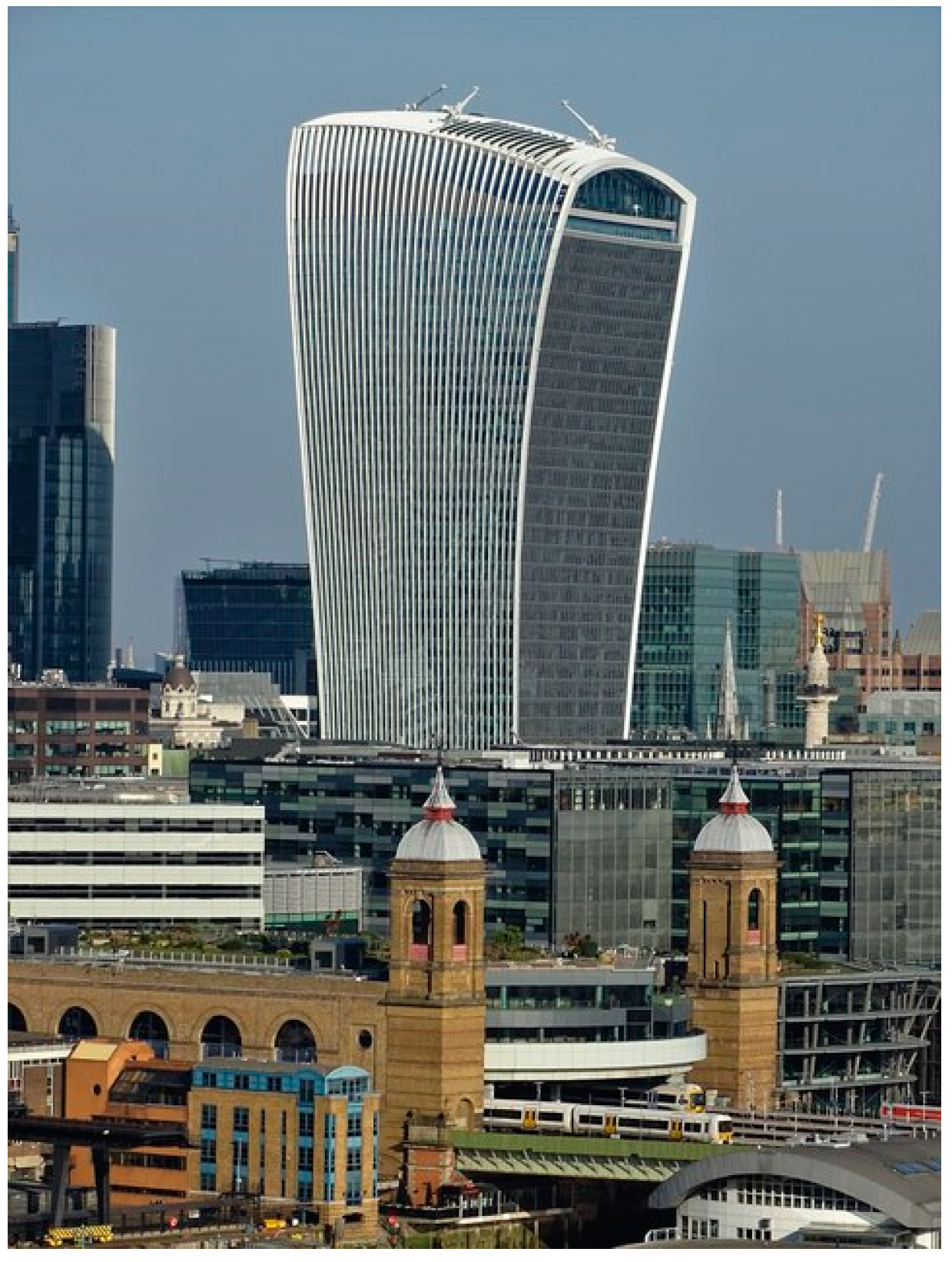

- Smith-Spark, L. Reflected Light from London Skyscraper Melts Car. CNN. 3 September 2013. Available online: http://edition.cnn.com/2013/09/03/world/europe/uk-london-building-melts-car/index.html (accessed on 7 May 2013).

- BBC. Who, What, Why: How Does a Skyscraper Melt a Car? 3 September 2013. Available online: http://www.bbc.com/news/magazine-23944679 (accessed on 7 May 2018).

- YouTube. Man Fries Egg in London Skyscraper Heat. TheNetFrancesco. 3 September 2013. Available online: https://www.youtube.com/watch?v=TGnZz8-PvdY (accessed on 7 May 2018).

- Sherwin, A. Walkie Talkie City Skyscraper Renamed Walkie Scorchie after Beam of Light Melts Jaguar Car Parked Beneath It. The Independent. 3 September 2013. Available online: https://www.independent.co.uk/arts-entertainment/architecture/walkie-talkie-city-skyscraper-renamed-walkie-scorchie-after-beam-of-light-melts-jaguar-car-parked-8794970.html (accessed on 7 May 2018).

- Washington Post News Service. London’s ‘Fryscraper’ Draws Crowd on Hottest Day. Mississauaga News. 6 September 2013. Available online: https://www.mississauga.com/news-story/4067822-london-s-fryscaper-draws-crowd-on-hottest-day/ (accessed on 7 May 2018).

- Rhee, J.; Ross, B.; Ferran, L.; Hosford, M. Toyota Recalls 2.17 Million Vehicles Over Pedal Entrapment. ABC News. 24 February 2011. Available online: https://abcnews.go.com/Blotter/toyota-recalls-21-million-vehicles-floor-mats-pedals/story?id=12989254 (accessed on 7 May 2018).

- Evans, S.; MacKenzie, A. The Toyota Recall Crisis: A Chronology of How the World’s Largest and Most Profitable Automaker Drove into a PR Disaster. Motor Trend. 27 January 2010. Available online: http://www.motortrend.com/news/toyota-recall-crisis/ (accessed on 7 May 2018).

- Cramer, M. 11 Terrible Automotive Engineering Decisions. 2010. Available online: https://jalopnik.com/5570865/11-terrible-automotive-engineering-decisions/ (accessed on 17 August 2018).

- Feldt, A.G. Chapter 2: General Systems Theory. 1986. Available online: http://www.holisticwisdom.org/hwpages/chapt%202%20-%20GST.htm (accessed on 18 June 2018).

- Jon. R.I.P Microsoft Zune (2006–2011). Methodshop. 2011. Available online: https://www.methodshop.com/2011/03/microsoft-zune-rip.shtml (accessed on 13 August 2018).

- Norman, D. Designing for People—Systems Thinking: A Product is more than the Product. Interactions 2009, 16, 52. [Google Scholar] [CrossRef]

- Johns Hopkins Whiting School of Engineering. System Context Diagrams. 1 February 2014. Available online: https://0-ep-jhu-edu.brum.beds.ac.uk/about-us/news-and-media/systems-context-diagrams (accessed on 8 June 2018).

- Monat, J.P.; Gannon, T.F. Using Systems Thinking to Solve Real-World Problems; College Publications: London, UK, 2017. [Google Scholar]

- The Systems Thinker. Guidelines for Drawing Causal Loop Diagrams; Pegasus Communications: Waltham, MA, USA, February 2011; Volume 22, No. 1; Available online: https://thesystemsthinker.com/wp-content/uploads/pdfs/220109pk.pdf (accessed on 11 June 2018).

- Kim, D.H. Introduction to Systems Thinking; Pegasus Communications: Waltham, MA, USA, 1999; pp. 5–10. [Google Scholar]

- Federal Aviation Administration. System Engineering Functional N2 Diagram; Federal Aviation Administration: Washington, DC, USA, 2006.

- Bechtel Jacobs Company. UF6 Cylinder Project Systems Engineering Management Plan. U.S. Dept. of Energy. July 1998. Available online: http://www.oakridge.doe.gov/duf6disposition/KTSO-017.pdf (accessed on 11 June 2018).

- U.S. Department of Defense, Chief Information Officer. DoDAF Viewpoints and Models, Systems Viewpoint, SV-3: Systems-Systems Matrix. Available online: https://dodcio.defense.gov/Library/DoD-Architecture-Framework/dodaf20_sv3/ (accessed on 11 June 2018).

- Wagenhals, L.; Levis, A. C4ISR Architectures and their Implementation Challenges, Lecture 4: A C4ISR Architecture Framework Implementation Process Case Study. INCOSE. Available online: http://slideplayer.com/slide/701808/ (accessed on 11 June 2018).

- Hyatt, K. Roadshow’s guide to car subscriptions, an alternative to buying or leasing. 14 June 2018. Available online: https://www.cnet.com/roadshow/news/new-car-subscription-service-guide-buying-leasing-2018/ (accessed on 27 June 2018).

- Blanchard, B.; Fabrycky, W. Systems Engineering and Analysis, 5th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2011. [Google Scholar]

| Systems Thinking Principle | Applicable to Systems Engineering and Design? |

|---|---|

| Holistic Perspective/Proper Definition of System Boundaries | Yes |

| Focus on Relationships | Yes |

| Sensitivity to Feedback | Yes |

| Awareness that Events and Patterns are caused by Underlying Structures and Forces | To a Degree |

| Dynamic Modeling | Sometimes |

| Systemic Root Cause Analysis | Yes, when troubleshooting |

| Sensitivity to Emergent Properties | Yes |

| Sensitivity to Unintended Consequences | Yes |

| Problem | Systems Thinking Issue |

|---|---|

| Galloping Gertie | Failure to adequately address planned and unplanned interactions between system components and the environment. |

| Millenium Bridge, London | Failure to adequately address planned and unplanned interactions among system components themselves and between system components and the environment. |

| Lockheed L-188 Electra Turboprop Airplane | Failure to adequately address planned and unplanned interactions among system components themselves and between system components and the environment. |

| Water of Ayolé | Failure to bound the system properly; specifically, to understand that most complex problems cannot be solved by purely technological means; they often involve organizational, political, economic, environmental, ethical, and sociological components. |

| Stow Center School Aquarium | Failure to bound the system properly; specifically, to understand that most complex problems cannot be solved by purely technological means; they often involve organizational, political, economic, environmental, ethical, and sociological components. |

| Russian K-141 Kursk Submarine | Failure to adequately address planned and unplanned interactions among system components themselves and between system components and the environment. |

| Vdara Hotel | Failure to identify relevant environmental factors. |

| 20 Fenchurch Street, London | Failure to identify relevant environmental factors. |

| Toyota Gas Pedal | Failure to adequately address planned and unplanned interactions among system components themselves and between system components and the environment. |

| Biodegradable German Car Wiring Insulation | Failure to identify relevant environmental factors. |

| Bhopal, India | Failure to identify relevant environmental factors; specifically, interactions between the system and neighboring people and between the system and environmental gases. |

| Microsoft Zune | Failure to recognize that many products are actually components of a User Experience System |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Monat, J.P.; Gannon, T.F. Applying Systems Thinking to Engineering and Design. Systems 2018, 6, 34. https://0-doi-org.brum.beds.ac.uk/10.3390/systems6030034

Monat JP, Gannon TF. Applying Systems Thinking to Engineering and Design. Systems. 2018; 6(3):34. https://0-doi-org.brum.beds.ac.uk/10.3390/systems6030034

Chicago/Turabian StyleMonat, Jamie P., and Thomas F. Gannon. 2018. "Applying Systems Thinking to Engineering and Design" Systems 6, no. 3: 34. https://0-doi-org.brum.beds.ac.uk/10.3390/systems6030034