1. Introduction

The concept of digital twin was first introduced in 2002 by Michael Grieves at the University of Michigan [

1]. Since then the concept has evolved with the advent of the Internet of Things (IoT). A digital twin is a dynamic virtual model of a system, process or service. Thus, a product, factory or a business service can have digital twins [

2,

3]. The vision of a digital twin calls for incorporating business, contextual and sensor data from physical systems (or processes) into the virtual system model of the digital twin to facilitate analysis, circumvent problems, and develop informed technology roadmaps. By integrating the virtual and physical worlds, the digital twin enables real-time monitoring of systems and processes and timely analysis of data to head off problems before they arise, schedule preventive maintenance to reduce/prevent downtimes, uncover new business opportunities, and plan for future upgrades and new developments. While virtual models tend to be generic representations of a system, part, or a family of parts, the digital twin represents an instance (i.e., a particular system or process). Digital twin technology has the potential to reduce the cost of system verification and testing while providing early insights into system behavior. Today, digital twin technology is an integral part of the Department of Defense’s (DoD’s) Digital Engineering initiative that seeks to connect systems and operations in a world of increasingly interconnected and smart physical devices [

4,

5,

6].

With the advent of the Internet of Things (IoT), digital twin technology has become cost-effective to implement and is gaining increasing acceptance in the Industrial Internet of Things (IIoT) community [

7], which tends to focus on large, complex, capital-intensive equipment. At the same time, the aerospace and defense industry, which continues to invest in Industry 4.0, has started to invest in digital twin technology. According to Gartner, by 2021 nearly half the major industrial companies will be leveraging digital twin technology to facilitate the assessment of system performance and technical risks, while achieving approximately 10% improvement in system effectiveness [

8].

A digital twin, by definition, requires a physical twin for data acquisition and context-driven interaction. The virtual system model in the digital twin can change in real-time as the state of the physical system changes (during operation). Today, a digital twin consists of connected products, typically utilizing the IoT, and a digital thread. The digital thread provides connectivity throughout the system’s lifecycle and collects data from the physical twin to update the models in the digital twin.

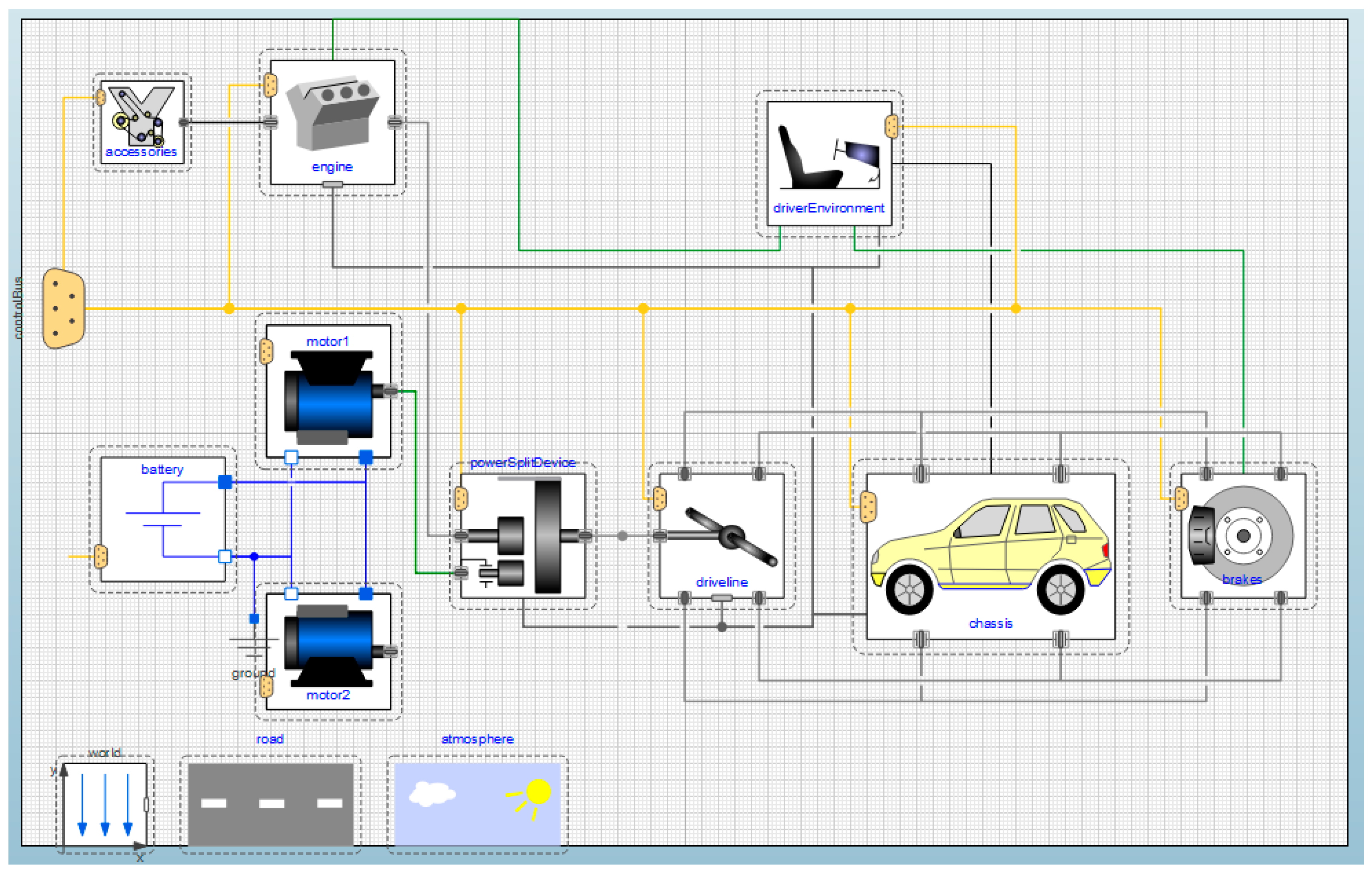

Figure 1 presents the digital twin concept within the context of model-based systems engineering (MBSE).

As shown in this figure, the digital twin links the virtual and physical environments. The physical environment includes the physical system, onboard and external sensors, communication interfaces, and possibly other vehicles operating in an open environment with access to GPS data. Both operational and maintenance data associated with the physical system are supplied to the virtual environment to update the virtual model in the digital twin. Thus, the digital twin becomes a precise and up-to-date representation of a physical system that also reflects the operational context of the physical twin. Importantly, the relationship with the physical twin can continue even after the sale of the physical twin, thereby making it possible to track the performance and maintenance history of each physical twin over time, detect and report anomalous behavior, and recommend/ schedule maintenance.

NASA and USAF (United States Air Force) researchers describe a digital twin as an integrated multi-physics, multiscale, probabilistic simulation of an as-built vehicle or system that uses the best available physical models, sensor updates, fleet history, etc., to mirror the life of its corresponding flying twin [

9]. The digital twin is ultra-realistic and may consider one or more important and interdependent vehicle systems such as airframe, propulsion and energy storage, life support, avionics and thermal protection. The extreme requirements of the digital twin necessitate the integration of design of materials and innovative material processing approaches. Manufacturing anomalies that may affect the vehicl, are also “explicitly considered, evaluated and monitored.” In addition to the high-fidelity physical models of the as-built structure, the digital twin integrates sensor data from the vehicle’s on-board integrated vehicle health management (IVHM) system, maintenance history and all available historical and fleet data obtained through techniques such as data mining and text mining [

9]. By combining data from these different sources of information, the digital twin can continually forecast vehicle health status, the remaining useful vehicle life, and the probability of mission success. The digital twin can also be used to predict system response to safety critical events and uncover new issues before they become acute by comparing predicted and actual responses. Finally, the systems on board the digital twin are capable of mitigating damage or degradation by activating self-healing mechanisms, or by recommending changes in mission profile to decrease loads, thereby increasing both the life span and the probability of mission success [

9].

The context of operation of the digital twin involves an instrumented testbed in which model-based systems engineering (MBSE) tools (e.g., system modeling and verification tools) and operational scenario simulations (e.g., discrete event simulations, agent-based simulations) are used to explore the behavior of virtual prototypes in a what-if simulation mode under the control of the experimenter. Insights from the operational environment are used to modify the system models used in the virtual prototype. Data supplied by the physical system is used by the virtual prototype to instantiate a digital twin. Subsequently, the digital twin is updated on an ongoing basis, so it faithfully mirrors the characteristics and history of the physical twin. Importantly, systems that collect and supply data from the operational environment contribute to insights needed for business intelligence (BI). For example, the DoD is presently altering its systems to comprehensively record all electronics warfare (EW) signals (data) from operational missions to analyze and better understand the operational environment and provide focused updates to our systems.

The MBSE tool suite in

Figure 1 includes system modeling methods (e.g., SysML models, Design Structure Matrix, process dependency structure matrix, probabilistic models such as Partially-Observable Markov Decision Process (POMDP), discrete event simulation [

10,

11], agent-based simulation, model-based storytelling [

12,

13], an MBSE knowledge base (that constitutes the authoritative sources of truth), and systems engineering life cycle process models. The virtual system model can range from lightweight models to full-up models. The lightweight models reflect simplified structure (e.g., simplified geometry) and simplified physics (e.g., reduced order models) to reduce computational load especially in upfront engineering activities. These lightweight models allow simulations of complex systems and system-of-systems (SoS) with fidelity in the appropriate dimensions to answer questions with minimal computation costs. These models can be shared within the organization and with the supplier network thereby increasing their understanding of the system being engineered. The digital twin concept also subsumes automated and manual processes in manufacturing environments. From the physical twin, performance, maintenance, and health data can be collected and supplied to the digital twin. This data includes operational environment characteristics, engine and battery status, and other such factors. The digital twin and the physical twin can both be supported by a shared MBSE repository, which also supports SE and data collection tools. The MBSE models constitute the authoritative sources of truth. This configuration also ensures bidirectional communication between the digital twin and the physical twin.

A digital twin is different from the traditional Computer Aided Design/Computer Aided Engineering (CAD/CAE) model in the following important ways:

- (a)

It is a specific instance that reflects the structure, performance, health status, and mission-specific characteristics such as miles flown, malfunctions experienced, and maintenance and repair history of the physical twin;

- (b)

It helps determine when to schedule preventive maintenance based on knowledge of the system’s maintenance history and observed system behavior;

- (c)

It helps in understanding how the physical twin is performing in the real world, and how it can be expected to perform with timely maintenance in the future;

- (d)

It allows developers to observe system performance to understand, for example, how modifications are performing, and to get a better understanding of the operational environment;

- (e)

It promotes traceability between life cycle phases through connectivity provided by the digital thread;

- (f)

It facilitates refinement of assumptions with predictive analytics-data collected from the physical system and incorporated in the digital twin can be analyzed along with other information sources to make predictions about future system performance;

- (g)

It enables maintainers to troubleshoot malfunctioning remote equipment and perform remote maintenance;

- (h)

It combines data from the IoT with data from the physical system to, for example, optimize service and manufacturing processes and identify needed design improvements (e.g., improved logistics support, improved mission performance);

- (i)

It reflects the age of the physical system by incorporating operational and maintenance data from the physical system into its models and simulations.

This paper is organized as follows.

Section 2 presents the digital twin rationale and potential uses.

Section 3 presents the levels of sophistication (maturity) of a digital twin.

Section 4 presents the relationship between the digital twin and MBSE, in terms of the relationship of the digital twin with simulation, machine learning, Internet of Things (IoT), and cost.

Section 5 offers concluding comments on the future prospects of digital twins in advancing MBSE.

2. Digital Twin Rationale and Potential Uses

A digital twin is first created when the physical system can start providing data to the virtual system model to create a model instance that reflects the structural, performance, maintenance, and operational health characteristics of the physical system [

11,

12]. The physical system can be said to be ”fit for purpose” if the digital twin’s behavior is analyzed and can be appropriately adjusted for a variety of contingency situations. For example, computer simulations of the braking system of a car can be run to understand how the vehicle (model) would perform in different real-world scenarios. This approach is faster and cheaper than building multiple physical vehicles to test. However, computer simulations tend to be confined to current events and operational environments. In other words, they do not have the ability to predict vehicle responses to future/envisioned scenarios. Also, braking systems are software-intensive systems, not merely a combination of mechanical and electronic subsystems. This is where digital twin and IoT can play important roles. A digital twin uses data collected from connected sensors onboard the physical vehicle to enable virtual testing. Furthermore, with IoT-provided data (e.g., temperature, humidity), it becomes possible to reflect system performance and health status in the digital twin and use that information to make predictions about the physical twin. Equipped with such data and knowledge, the digital twin can “tell” the story (i.e., events, experiences, history) of its physical twin over the physical twin’s life cycle.

Being a virtual representation, a digital twin is easier to manipulate and study in a controlled testbed environment than its physical counterpart in the operational environment. This flexibility enables cost-effective exploration of system behaviors and sensitivities to various types of system malfunctions and external disruptions. Second, data produced by the digital twin under various what-if conditions can be used to: improve future system designs; optimize maintenance cycles; surface ideas for new system applications; validate preliminary design decisions; and predict system response to different types of disruptions in the field. Specifically, the digital twin can be used to:

Validate system model with real world data

Operational environment data and the interactions of the system with that environment can be incorporated into the digital twin to validate its models and to make assessments and predictions.

Provide decision support and alerts to users

After incorporating operational, maintenance, and health data, the digital twin can be employed in a what-if analysis mode to produce tailored decision support information and alerts to operators/users of the physical system.

Predict changes in physical system over time

Simulation-based analysis of operational, maintenance, and health data from the physical twin can facilitate optimization of operations (including satisfying requirements and identifying root causes), enhance contingency planning and predicting system performance. The digital twin can also be embedded in the control loop to predict changes in the physical system and adjust/modify physical system parameters to deal with contingencies.

Discover new application opportunities and revenue streams

With a digital twin, different versions of systems can be evaluated to determine which features provide the “biggest bang for the buck.” Machine learning and other data science technologies can facilitate timely analysis of significant volumes of data generated, thereby providing insights into potential new uses and revenue streams.

Thus far, the initial series of digital twin initiatives have focused on complex, high-cost systems. However, today with advances in cost models for sensors, communication networks, analytics and simulation, it is possible to develop a digital twin for almost any system.

4. Digital Twin Technology and MBSE

Digital twins can be integrated through the digital thread to MBSE tool suites, and potentially become a core element of model-based systems engineering (MBSE). In fact, MBSE can serve as the starting point for the digital thread [

15,

16,

17]. Using data gathered from IoT, system simulations can be run to explore failure modes, leading to progressive design improvements over time. For example, a manufacturer can link a digital twin to its service history, manufacturing process, design history, real-time IoT data, configuration-specific simulation models, and expected failure modes using MBSE tools such as Design Failure Mode and Effects Analysis (DFMEA). The ability to compare simulation outputs with actual results can provide valuable insights about the physical twin. Using an appropriate MBSE tool, engineers can generate event-driven or agent-based simulations to explore the behavior and interactions of the digital twin, respectively. The digital twin can incorporate 3D data and simulations, along with their characterizations using methods such as response surface models. To gauge customer experience and the impact of innovation on that experience, the digital twin can be employed to simulate a plant, product or service at the right level of abstraction. For example, the DoD has a policy of barcoding line replaceable units for analysis in logistics support. The benefits of this policy would apply to digital twins.

4.1. Digital Twin and Simulation

Engineers can potentially use simulations linked to the digital twin to predict how the physical twin can be expected to perform in the real-world [

18,

19]. Contrast this with having to rely on the ideal and perceived worst-case conditions typically employed in the design process. Actual system performance data can be compared to data from the digital twin, prompting adjustment decisions that can contribute to successful mission outcomes [

20]. Also, by incorporating data from the physical twin into the digital twin, engineers can improve system models, and subsequently use the results of the analysis with the digital twin to improve the operation of the physical system in the real-world.

The value added by a digital twin to its physical twin stems from its ability to optimize both physical twin operation and maintenance schedule. Simulating digital twin behavior enables the determination and adjustment of real-world system behavior. Specifically, insights gained through simulation can guide changes needed in system design and manufacturing with the digital thread providing the necessary connectivity across the system life cycle.

The fidelity of the simulation will typically vary with the purpose of the simulation and the stage in the system life cycle [

18,

19]. A potential benefit would be to rehearse missions in specific operational conditions (terrain, weather, etc.) using the capabilities of the digital twin. For example, in the system design phase, a relatively slow, non-real-time simulation may suffice so long as it enables exploration and investigation of multiple different use cases under real world conditions. With access to IoT data, actual operational conditions can be simulated (with high confidence) to yield insights into expected outcomes.

An important use of simulation is in the assessment of the expected operational life of the system (i.e., low long the system can be expected to be operational). In this regard, a digital twin can keep track of its mortality based on the wear and tear experienced by the physical twin. By employing simulation, the digital twin can estimate the remaining working life of the physical twin and proactively schedule maintenance. In other words, predictive maintenance can be used to estimate how long the physical system can be expected to operate normally and use that knowledge to proactively schedule and perform system shut down rather than wait for the breakdown of the physical twin which can be both expensive and potentially catastrophic.

4.2. Digital Twin and Machine Learning

For simple applications, digital twin technology offers value without having to employ machine learning. Simple applications are characterized by a limited number of variables and an easily discoverable linear relationship between inputs and outputs. However, most real-world systems that contend with multiple data streams stand to benefit from machine learning and analytics to make sense of the data. Machine learning, in this context, implies any algorithm that is applied to a data stream to uncover/discover patterns that can be subsequently exploited in a variety of ways. For example, machine learning can automate complex analytical tasks. It can evaluate data in real-time, adjust behavior with minimal need for supervision, and increase the likelihood of desired outcomes. Machine learning can also contribute to producing actionable insights that can lead to cost savings. Smart buildings are an excellent example of applications that stand to benefit from machine learning capabilities in the digital twin [

21,

22]. Machine learning uses within a digital twin include: supervised learning (e.g., using neural network) of operator/user preferences and priorities in a simulation -based, controlled experimentation testbed [

14]; unsupervised learning of objects and patterns using, for example, clustering techniques in virtual and real-world environments [

23,

24]; and reinforcement learning of system and environment states in uncertain, partially observable operational environments [

25,

26].

4.3. Digital Twin and Internet of Things (IoT)

Linking digital twins to the IoT brings the data needed to understand how the physical twin (e.g., manufacturing assembly line, autonomous vehicles network) behaves and performs in the operational environment [

27,

28,

29]. Furthermore, the combination of IoT and digital twins can enhance preventive maintenance and analytics/AI (artificial intelligence)-based optimization of the physical system and operational processes. Acting as a bridge between the physical and virtual worlds, the IoT can deliver performance, maintenance and health data from the physical twin to the digital twin. Combining insights from the real-world data with predictive modeling can enhance the ability to make informed decisions that can potentially lead to the creation of effective systems, optimized production operations, and new business models. Multi-source/multi-sensor information (e.g., outside temperature, moisture content, production status of current batch) can be delivered to the digital twin along with information from traditional sensors (e.g., SCADA) to facilitate predictive modeling. Furthermore, the IoT enables much needed flexibility when it comes to system mobility, location and monetization options. Such flexibility contributes to the creation of business options such as selling a capability (i.e., product as a service) versus selling the product itself. For example, Caterpillar sells the capability to move dirt (i.e., a service) versus selling the equipment (i.e., product).

Importantly, the combination of digital twin and IoT allows an organization to gain insights into how a system/product is being used by customers. Such insights can enable customers to optimize maintenance schedule and resource utilization, proactively predict potential product failures, and avoid/reduce system downtimes. Ultimately, the digital twin is a key enabler for improving system maintenance over time based on system operation and maintenance history. The benefits of the IoT can be further amplified through the integration of the IoT with multiple digital twins, each monitored from a central location that oversees maintenance schedules and cycles. In this latter case, data ownership becomes somewhat complicated especially when equipment is rented.

While access to execution data can contribute to improving manufacturing operations, the reality is that most manufacturers tend to have limited equipment data for optimization. In contrast, suppliers typically have a multitude of interconnected equipment and devices supplying data that can be exploited. Importantly, vendors indicate that customers would be willing to share data with suppliers. If this is the case, then timely optimization is achievable. Perhaps the greatest potential benefits of the IoT is in the service area. For example, service that is continually informed about the operational state and health status of the system can be effective in ensuring cost savings and high availability. In a similar vein, predictive analytics can be employed, for example, to pre-fetch and rapidly deliver a required part to a maintenance crew.

4.4. Digital Twin and Cost

Cost is always an important consideration when deciding to integrate digital twins into MBSE and systems engineering processes [

30]. Clearly defined scope and purpose are prerequisites to estimating the cost for implementing digital twins. While a digital twin requires a greater upfront investment, the inclusion of digital twin(s) can be expected to provide significant return on investment down the line in the systems life cycle. Based on the sophistication level, time and effort required for generating a virtual system representation, costs can vary. However, in today’s world, most organizations are pursuing the creation of virtual system models anyway because of their value in reducing verification and test durations and costs. The digital twin is a logical next step in this progression. The cost of the digital twin is a function of the number of components in the system, the interfaces and dependencies among the components, the complexity of the algorithms employed to implement specific functions, and the knowledge and know-how required to build the digital twin. Importantly, architecting the digital twin for reuse can further reduce costs.

5. Future Prospects

In the future, digital twin technology can be expected to become a central capability in MBSE because it can enable MBSE to span the full system life cycle while at the same time helping MBSE to penetrate new markets such as manufacturing, construction and real estate. Specifically, digital twins can be exploited in upfront engineering (e.g., system conceptualization and model verification), testing (e.g., model-based system validation), system maintenance (e.g., condition-based maintenance), and smart manufacturing. On the flip side, MBSE can contribute a variety of system modeling constructs and modeling languages that digital twins can exploit in virtual system representation.

In the near-term, digital twin technology can be expected to be integrated into manufacturing and maintenance activities to enhance predictive maintenance and design [

31,

32]. At the same time, digital twin technology will continue to gain ground in the construction, building and real estate industries because of real-time access to system data which is essential for functions such as adaptive energy management. The latter is key to applications such as efficient energy management.

Maintenance will be a major contribution area for digital twins. For example, digital twins will help organizations transition from schedule-based to condition-based maintenance, thereby substantially reducing system maintenance costs while also enhancing system availability. In a similar vein, digital twins can be exploited in aircraft engine maintenance. Currently, aircraft engines are routinely taken apart and rebuilt based on the number of hours flown, regardless of whether most of those hours are simply cruising at altitude or performing high-G maneuvers. Digital twin technology can help us better understand maintenance needs and schedule maintenance accordingly. For example, the Nunn–McCurdy breach on the C-130 AMP, which was primarily due to “tail-number diversity” would be better understood with digital twins.

The building and real estate industries are currently poised to exploit digital twins in the different construction phases, from design to construction management to operation and ultimately demolition. The need for digital twins in the building construction and real estate industries originates from the need for increasingly sophisticated dashboard software for users to view everything they need to know about their projects and properties in a convenient form and format. However, as the real estate universe continues to digitize, and building and property data becomes increasingly more complex and abundant, there has been an exponential growth in the number of tools, data formats and data services. As a result, generating actionable information from diverse data supplied by different tools is becoming increasingly difficult. Despite this recognition, the software dashboards in current use continue to rely on traditional bar graphs and pie charts to visualize system state and status information, largely ignoring the tools and data services building owners rely on today. A next-generation dashboard tied to one or more digital twins can dramatically improve timely decision-making and plan execution on the construction projects and property maintenance. In addition, digital twins will continue to earn ROI from multiple projects and properties over their life cycle. In the initial stages, architects, planners and property managers will be able to realize gains in the planning and design stages. In the later stages, they will derive benefits from the digital twin-provided ability to streamline energy and maintenance functions.

For architects, engineers and planners, digital twin technology can become a source of sustainable competitive advantage by linking projects and properties to real-time data with user-customizable smart dashboards. Zoning, permitting, traffic and air quality data can be linked to the digital twin, and accounted for in making siting and structural component placement decisions. For example, pedestrian traffic information can be used to determine where to place an entrance to a building. Similarly, property managers interested in reducing energy consumption will be able to exploit the digital twin to rapidly determine energy use and usage profile of each tenant and use that information to optimize and dynamically adjust energy usage in the building. Real-time sensor data from throughout the building such as those connected to HVAC and lighting can make this possible [

21,

22]. Timely maintenance can also be expected to contribute to tenant satisfaction, while faster time-to-market will contribute to increase in sales.

For businesses and manufacturers, digital twin technology can provide a window into system performance [

27,

28,

29,

33,

34,

35]. For example, a digital twin can potentially help identify equipment faults and troubleshoot equipment remotely thereby alleviating a key customer concern. In addition to improving virtual system models, a digital twin can potentially improve physical system operations and sustainment. A digital twin can also help with product differentiation, product quality and add-on services. Knowing how customers are using the product post-purchase, can provide useful insights including identifying and eliminating unwanted product functionality and features, as well as unwanted components thereby saving both time and money. A digital twin can enable visualization of remote physical systems (e.g., a system engineer in Washington D.C. can use the digital twin to troubleshoot a landing gear problem of an airplane parked at a gate of Los Angeles airport). Multimodality sensors (e.g., sight, sound, vibration, altitude) can serve to deliver data from physical systems to digital twins anywhere in the world. These flexible capabilities can potentially lead to clear understanding of the state of remote systems through multi-perspective visualization [

12,

13].

The digital twin story is just beginning to be written with leadership provided by the U.S. Department of Defense (through its Digital Engineering initiative), the IIoT community and Industry 4.0. Digital twin technology is key to acquiring early insights into system performance and technical risks [

36]. The digital thread can facilitate upstream and downstream transfer of knowledge from one program to another. Within the MBSE rubric, digital twins can become the single authoritative sources of truth about the system over its life cycle. By exploiting simulation-based modeling and data analytics, the digital twin can help quantify margins and uncertainties in cost and performance. The combination of digital connectivity provided by the digital thread and the trusted data and knowledge supplied by the digital twin can accelerate the transformation of systems engineering processes employed in MBSE [

18,

19].

Despite the promise of digital twin technology for MBSE, there are a few concerns that need to be resolved before wide-scale adoption of digital twin technology can be achieved. For example, being a relatively new concept, digital twin raises concerns about privacy and ownership. To many the extensive sharing of data with suppliers and potential customers is disconcerting. There are also concerns about intellectual property (IP) and legal considerations. For example, will operators want to report operational data to the manufacturer? And who owns the data provided by the digital twin? Ultimately, who reaps the benefit? And, does the operator want to share manufacturing execution data with the device manufacturer? Does the operator want to share such data with competing device manufacturers? If the operator decides not to share such data with everyone, then who owns that data?

The digital engineering community is working diligently on answering these questions any more. In the meantime, digital twin technology is continuing to make impressive inroads in several industries including aerospace and defense, manufacturing, building construction and real estate.