The Effects of Thermal Treatment and Steam Addition on Integrated CuO/CaO Chemical Looping Combustion for CO2 Capture

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Characterization

2.3. CaL/CLC Cyclic Reactivity Measurement

3. Results and Discussion

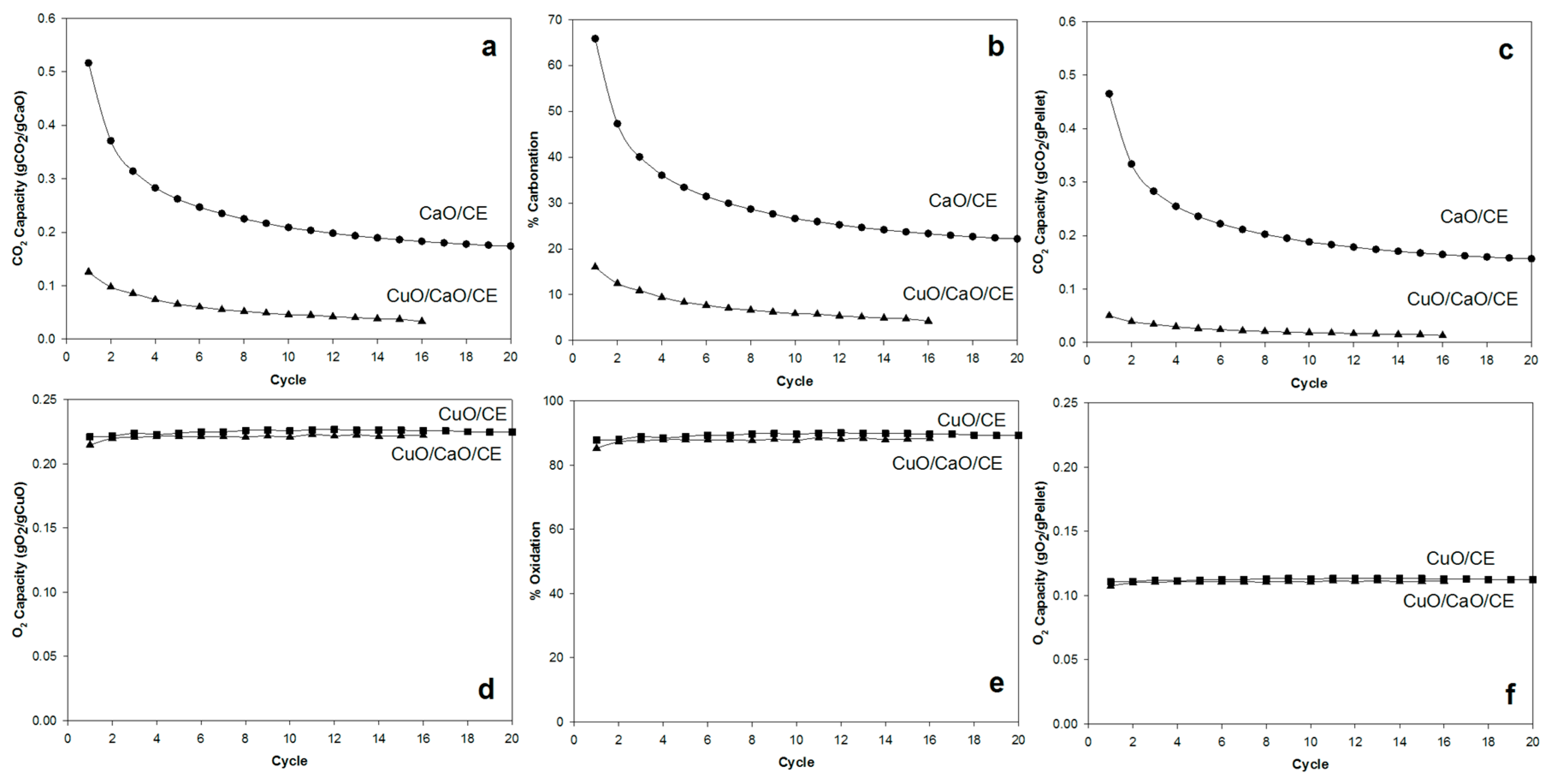

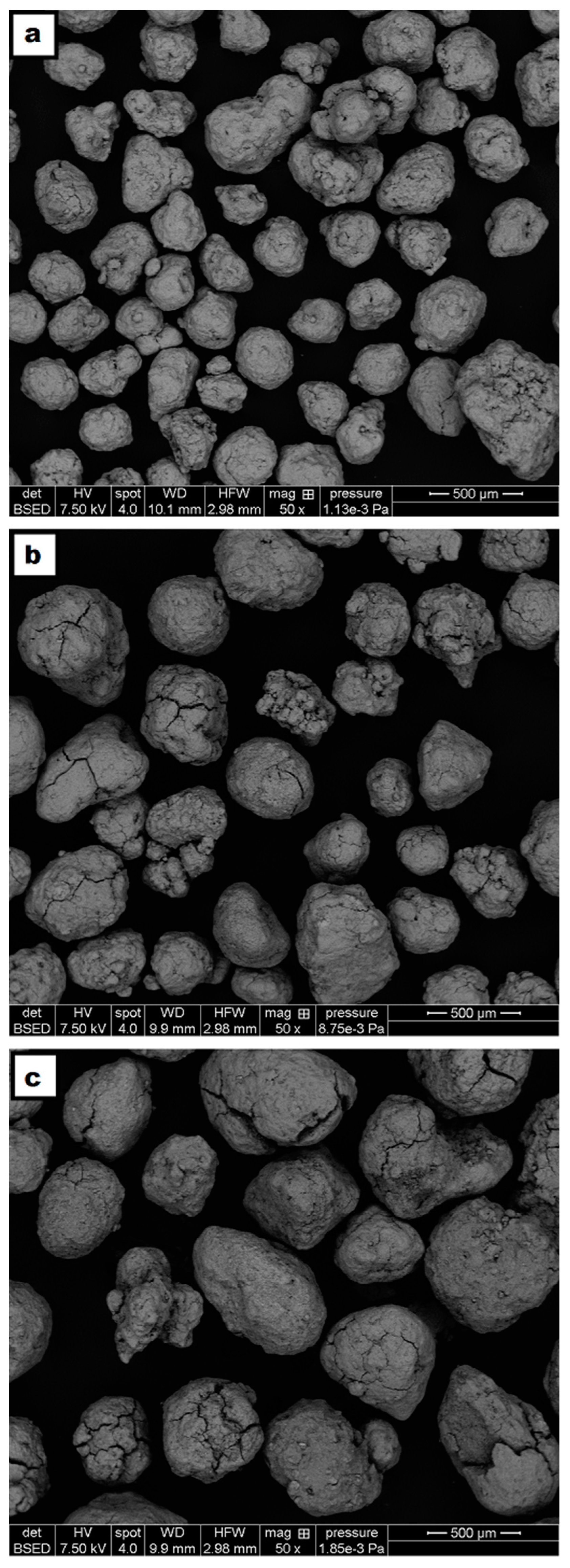

3.1. Performance of Pellets over Multiple CaL and/or CLC Cycles

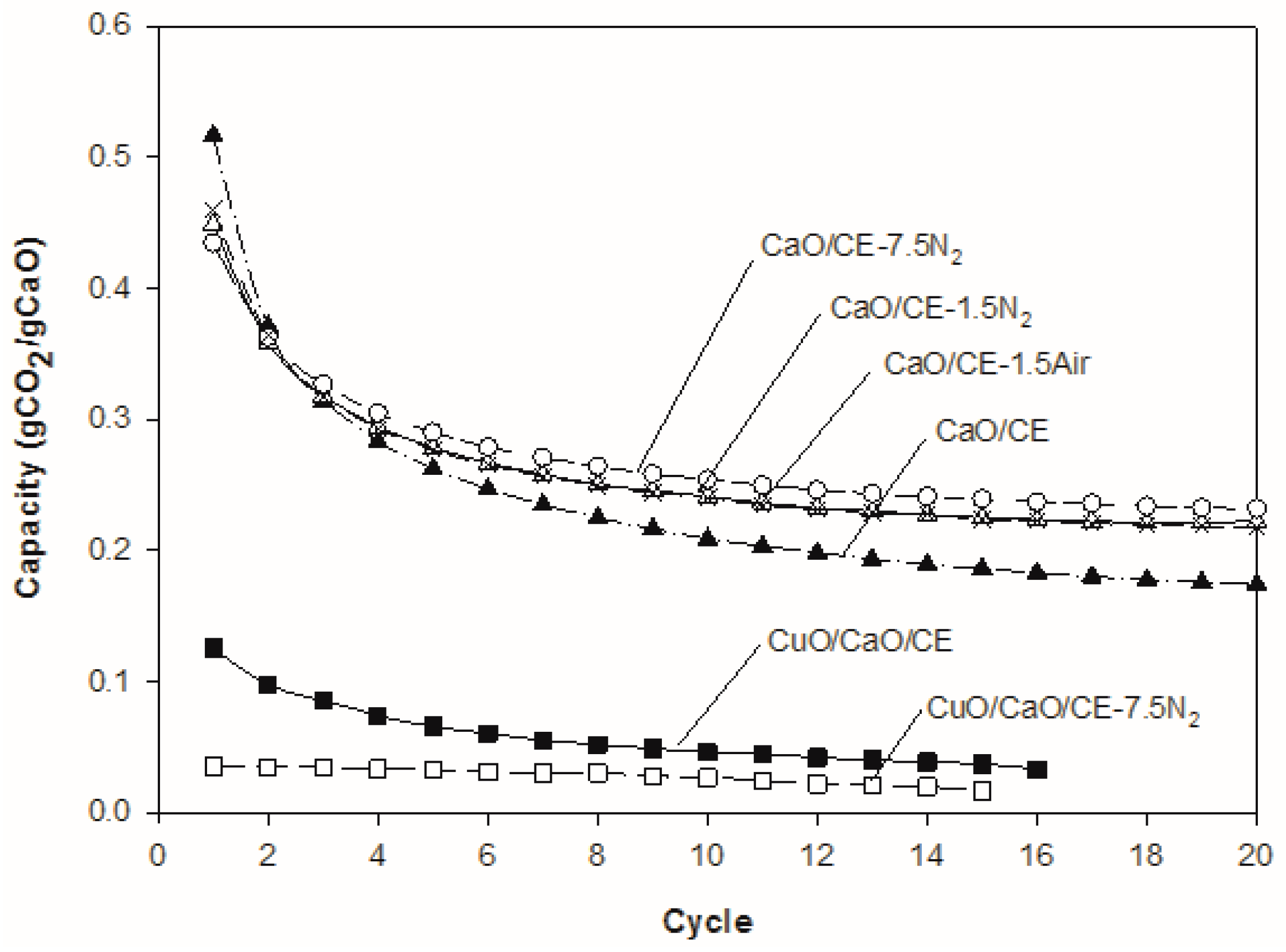

3.2. Effect of Thermal Pre-Treatments on CO2 Capacity

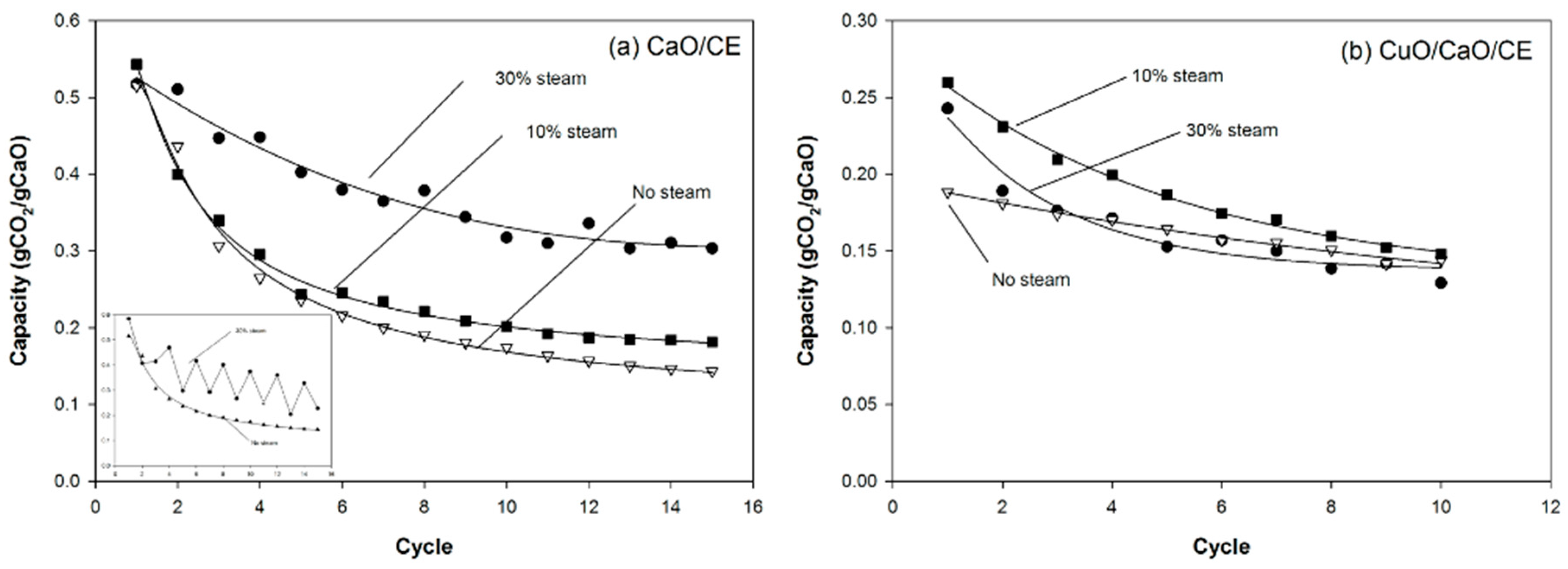

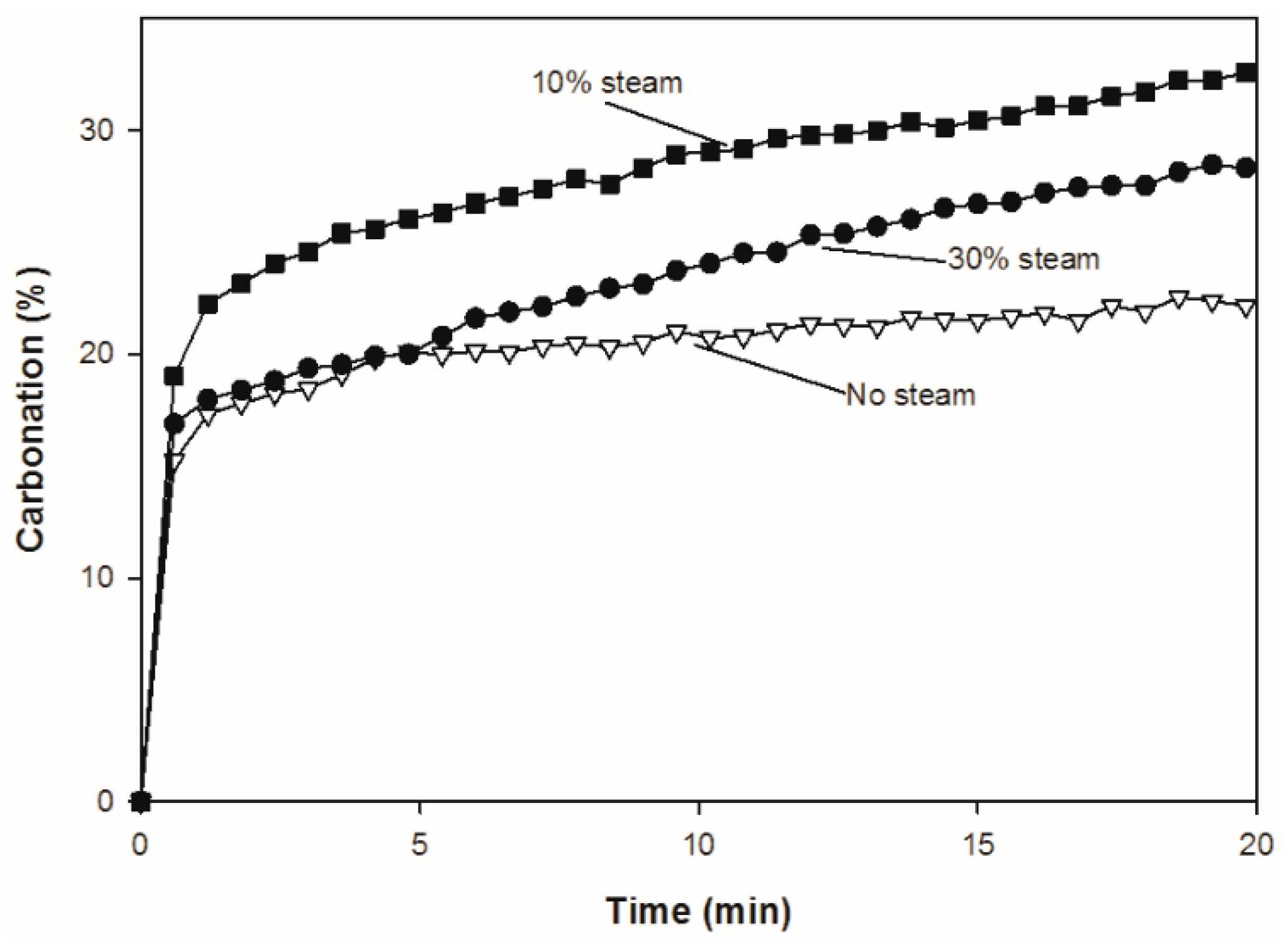

3.3. Effect of Steam Addition on CO2 Capacity

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, L.; Zhao, N.; Wei, W.; Sun, Y. A review of research progress on CO2 capture, storage, and utilization in Chinese academy of sciences. Fuel 2013, 108, 112–130. [Google Scholar] [CrossRef]

- Adanez, J.; Abad, A.; Garcia-Labiano, F.; Gayan, P.; de Diego, L.F. Progress in chemical-looping combustion and reforming technologies. Prog. Energy Combust. Sci. 2012, 38, 215–282. [Google Scholar] [CrossRef] [Green Version]

- Manovic, V.; Anthony, E.J. Integration of calcium and chemical looping combustion using composite CaO/CuO-based materials. Environ. Sci. Technol. 2011, 45, 10750–10756. [Google Scholar] [CrossRef] [PubMed]

- Rahman, R.A.; Mehrani, P.; Lu, D.Y.; Anthony, E.J.; Macchi, A. Investigating the use of CaO/CuO sorbents for in situ CO2 capture in a biomass gasifier. Energy Fuels 2015, 29, 3808–3819. [Google Scholar] [CrossRef]

- Butler, J.W.; Lim, C.J.; Grace, J.R. CO2 capture capacity of CaO in long series of pressure swing sorption cycles. Chem. Eng. Res. Design 2011, 89, 1794–1804. [Google Scholar] [CrossRef]

- Rout, K.R.; Fermoso, J.; Chen, D.; Jakobsen, H.A. Kinetic rate of uptake of a synthetic Ca-based sorbent: Experimental data and numerical simulations. Fuel 2014, 120, 53–65. [Google Scholar] [CrossRef]

- Blamey, J.; Anthony, E.J.; Wang, J.; Fennell, P.S. The calcium looping cycle for large-scale CO2 capture. Prog. Energy Combust. Sci. 2010, 36, 260–279. [Google Scholar] [CrossRef]

- Abanades, J.C.; Murillo, R.; Fernandez, J.R.; Grasa, G.; Martínez, I. New CO2 capture process for hydrogen production combining Ca and Cu chemical loops. Environ. Sci. Technol. 2010, 44, 6901–6904. [Google Scholar] [CrossRef] [PubMed]

- Kazi, S.S.; Aranda, A.; Meyer, J.; Mastin, J. High performance CaO-based sorbents for pre- and post- combustion CO2 capture at high temperature. Energy Procedia 2014, 63, 2207–2215. [Google Scholar] [CrossRef] [Green Version]

- Manovic, V.; Anthony, E.J. Lime-based sorbents for high-temperature CO2 capture—A review of sorbent modification methods. Int. J. Environ. Res. Public Health 2010, 7, 3129–3140. [Google Scholar] [CrossRef] [PubMed]

- Manovic, V.; Wu, Y.; He, I.; Anthony, E.J. Core-in-shell CaO/CuO-based composite for CO2 capture. Ind. Eng. Chem. Res. 2011, 50, 12384–12391. [Google Scholar] [CrossRef]

- Mattisson, T.; Järdnäs, A.; Lyngfelt, A. Reactivity of some metal oxides supported on alumina with alternating methane and oxygen application for chemical-looping combustion. Energy Fuels 2003, 17, 643–651. [Google Scholar] [CrossRef]

- García-Labiano, F.; de Diego, L.F.; Adánez, J.; Abad, A.; Gayán, P. Temperature variations in the oxygen carrier particles during their reduction and oxidation in a chemical-looping combustion system. Chem. Eng. Sci. 2005, 60, 851–862. [Google Scholar] [CrossRef] [Green Version]

- Leion, H.; Lyngfelt, A.; Mattisson, T. Solid fuels in chemical-looping combustion using a NiO-based oxygen carrier. Chem. Eng. Res. Design 2009, 87, 1543–1550. [Google Scholar] [CrossRef]

- Duhoux, B. Combined Calcium Looping and Chemical Looping Combustion Process Simulation Applied to CO2 Capture. M.Sc. Thesis, University of Ottawa, Ottawa, NO, Canada, 2015. [Google Scholar]

- Qin, C.; Yin, J.; Liu, W.; An, H.; Feng, B. Behavior of CaO/CuO based composite in a combined calcium and copper chemical looping process. Ind. Eng. Chem. Res. 2012, 51, 12274–12281. [Google Scholar] [CrossRef]

- Qin, C.; Yin, J.; Luo, C.; An, H.; Liu, W.; Feng, B. Enhancing the performance of CaO/CuO based composite for CO2 capture in a combined Ca-Cu chemical looping process. Chem. Eng. J. 2013, 228, 75–86. [Google Scholar] [CrossRef]

- Manovic, V.; Fennell, P.S.; Al-Jeboori, M.J.; Anthony, E.J. Steam-enhanced calcium looping cycles with calcium aluminate pellets doped with bromides. Ind. Eng. Chem. Res. 2013, 52, 7677–7683. [Google Scholar] [CrossRef]

- Manovic, V.; Anthony, E.J. Carbonation of CaO-based sorbents enhanced by steam addition. Ind. Eng. Chem. Res. 2010, 49, 9105–9110. [Google Scholar] [CrossRef]

- Champagne, S.; Lu, D.Y.; Macchi, A.; Symonds, R.T.; Anthony, E.J. Influence of steam injection during calcination on the reactivity of CaO-based sorbent for carbon capture. Ind. Eng. Chem. Res. 2013, 52, 2241–2246. [Google Scholar] [CrossRef]

- Dobner, S.; Sterns, L.; Graff, R.A.; Squires, A.M. Cyclic calcination and recarbonation of calcined dolomite. Ind. Eng. Chem. Process Design Dev. 1977, 16, 479–486. [Google Scholar] [CrossRef]

- Yang, S.; Xiao, Y. Steam catalysis in cao carbonation under low steam partial pressure. Ind. Eng. Chem. Res. 2008, 47, 4043–4048. [Google Scholar] [CrossRef]

- Symonds, R.T.; Lu, D.Y.; Macchi, A.; Hughes, R.W.; Anthony, E.J. CO2 capture from syngas via cyclic carbonation/calcination for a naturally occurring limestone: Modelling and bench-scale testing. Chem. Eng. Sci. 2009, 64, 3536–3543. [Google Scholar] [CrossRef]

- Dou, B.; Song, Y.; Liu, Y.; Feng, C. High temperature CO2 capture using calcium oxide sorbent in a fixed-bed reactor. J. Hazard. Mater. 2010, 183, 759–765. [Google Scholar] [CrossRef] [PubMed]

- Arias, B.; Grasa, G.; Abanades, J.C.; Manovic, V.; Anthony, E.J. The effect of steam on the fast carbonation reaction rates of CaO. Ind. Eng. Chem. Res. 2012, 51, 2478–2482. [Google Scholar] [CrossRef]

- Xu, L.; Sithambaram, S.; Zhang, Y.; Chen, C.-H.; Jin, L.; Joesten, R.; Suib, S.L. Novel urchin-like CuO synthesized by a facile reflux method with efficient olefin epoxidation catalytic performance. Chem. Mater. 2009, 21, 1253–1259. [Google Scholar] [CrossRef]

- Valverde, J.M.; Sanchez-Jimenez, P.E.; Perez-Maqueda, L.A. High and stable CO2 capture capacity of natural limestone at Ca-looping conditions by heat pretreatment and recarbonation synergy. Fuel 2014, 123, 79–85. [Google Scholar] [CrossRef]

| Pellets | Composition (wt %) | Surface Area | Pore Volume | ||

|---|---|---|---|---|---|

| Cu | Ca | Cement | (m2/g) * | (cm3/g) * | |

| CuO/CaO/CE | 50 | 40 | 10 | 15 ± 1.1 | 0.078 ± 0.006 |

| CaO/CE | - | 90 | 10 | 20 ± 0.6 | 0.11 ± 0.008 |

| CuO/CE | 50 | - | 50 | 34 ± 3.1 | 0.052 ± 0.004 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Recio, A.; Liew, S.C.; Lu, D.; Rahman, R.; Macchi, A.; Hill, J.M. The Effects of Thermal Treatment and Steam Addition on Integrated CuO/CaO Chemical Looping Combustion for CO2 Capture. Technologies 2016, 4, 11. https://0-doi-org.brum.beds.ac.uk/10.3390/technologies4020011

Recio A, Liew SC, Lu D, Rahman R, Macchi A, Hill JM. The Effects of Thermal Treatment and Steam Addition on Integrated CuO/CaO Chemical Looping Combustion for CO2 Capture. Technologies. 2016; 4(2):11. https://0-doi-org.brum.beds.ac.uk/10.3390/technologies4020011

Chicago/Turabian StyleRecio, Alvaro, Sip Chen Liew, Dennis Lu, Ryad Rahman, Arturo Macchi, and Josephine M. Hill. 2016. "The Effects of Thermal Treatment and Steam Addition on Integrated CuO/CaO Chemical Looping Combustion for CO2 Capture" Technologies 4, no. 2: 11. https://0-doi-org.brum.beds.ac.uk/10.3390/technologies4020011