Heat Treatment Consideration in Structural Simulations of Machine Elements: Analysis of a Starter Clutch Barrel

Abstract

:1. Introduction

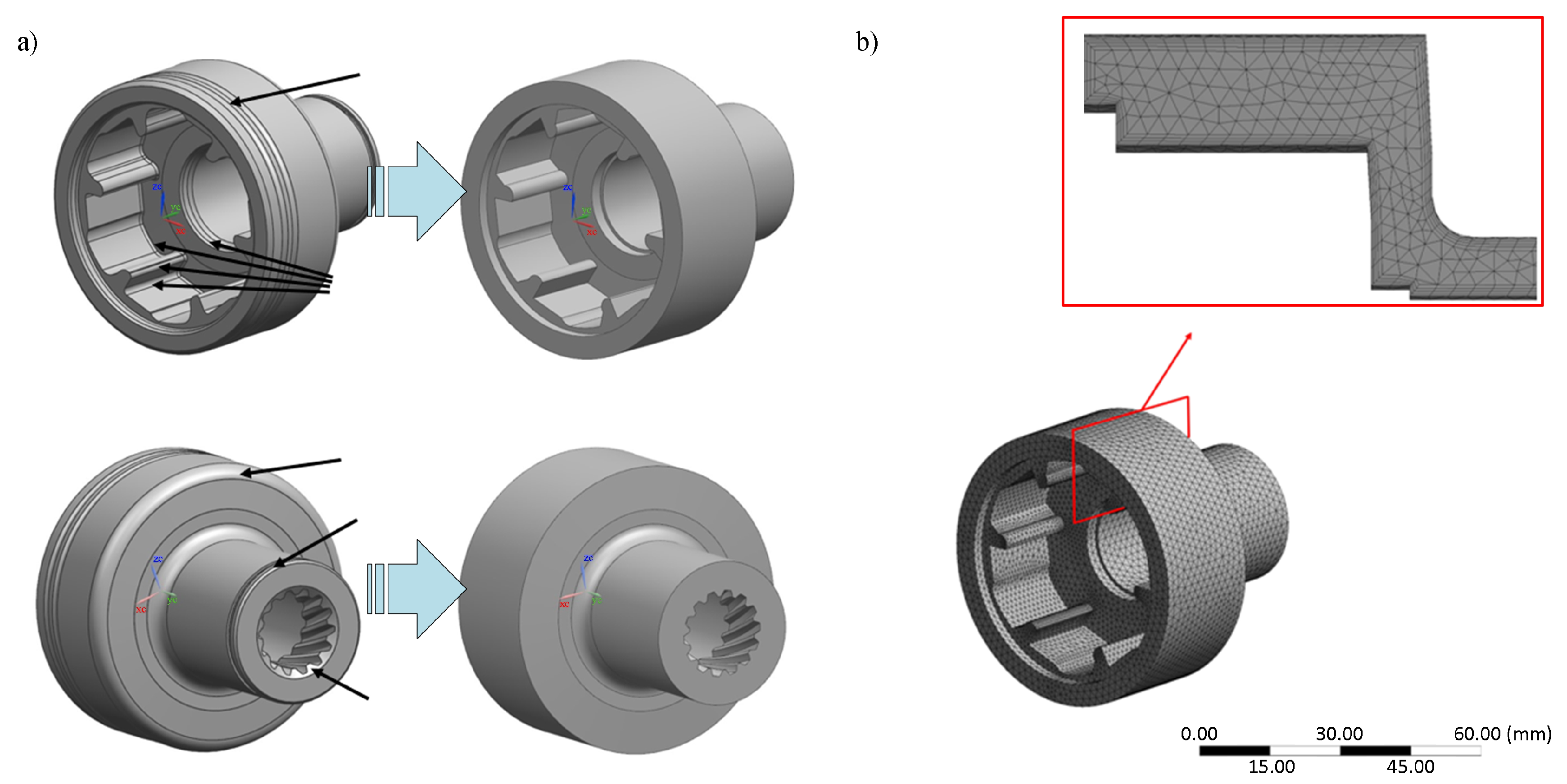

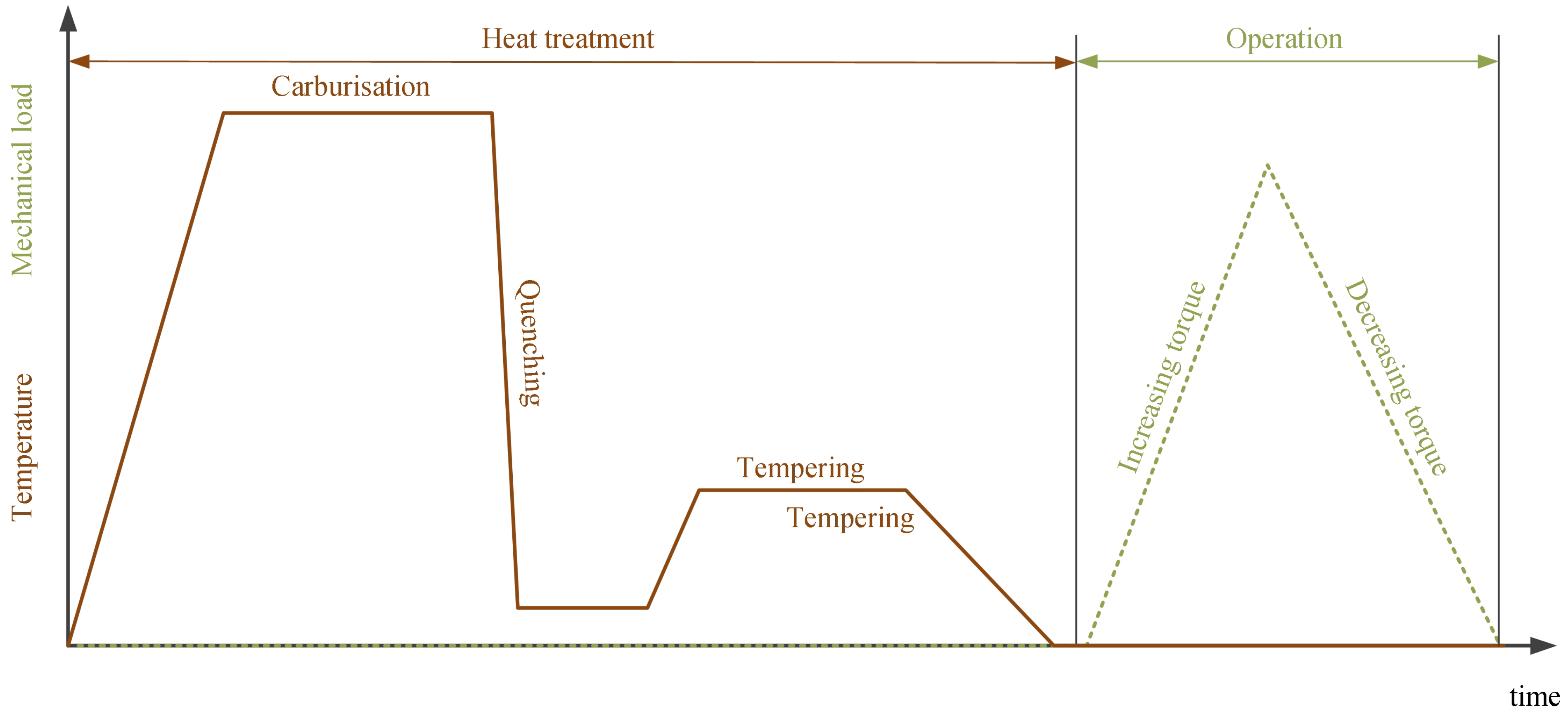

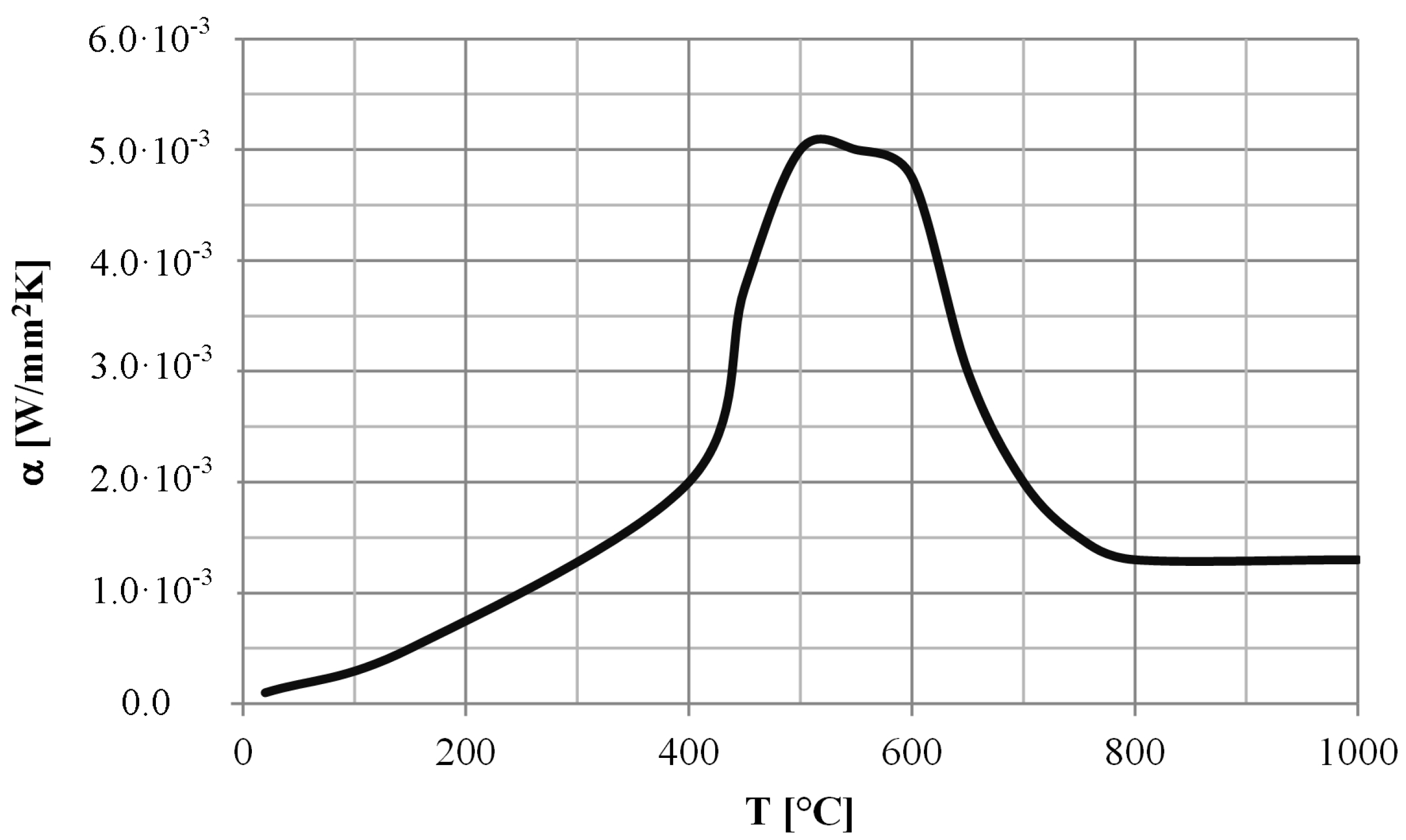

2. Method

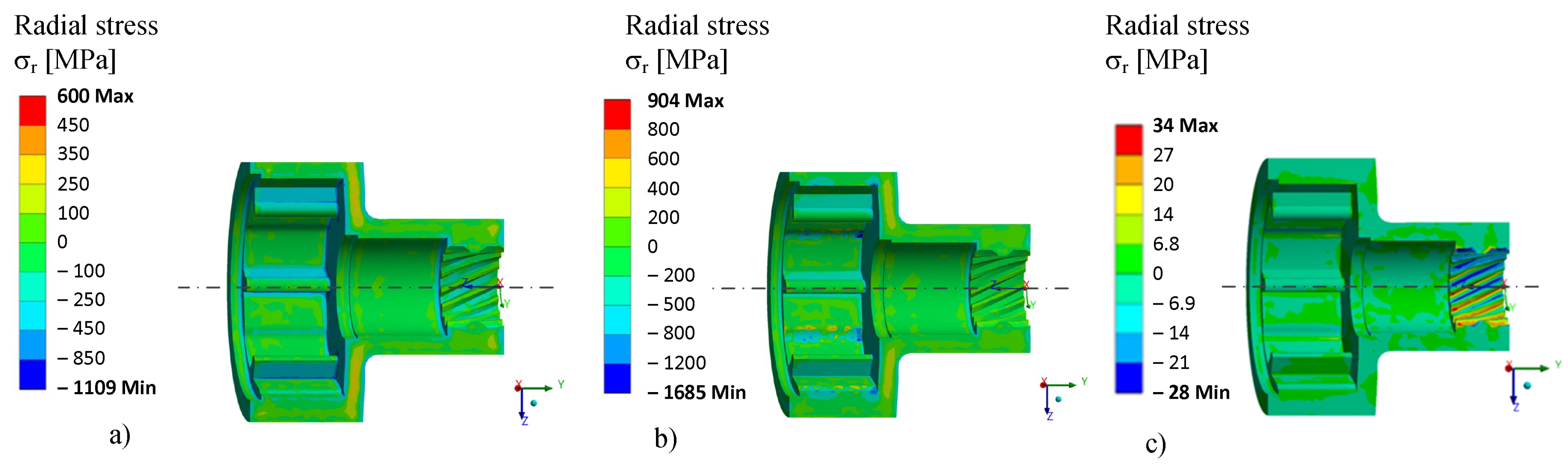

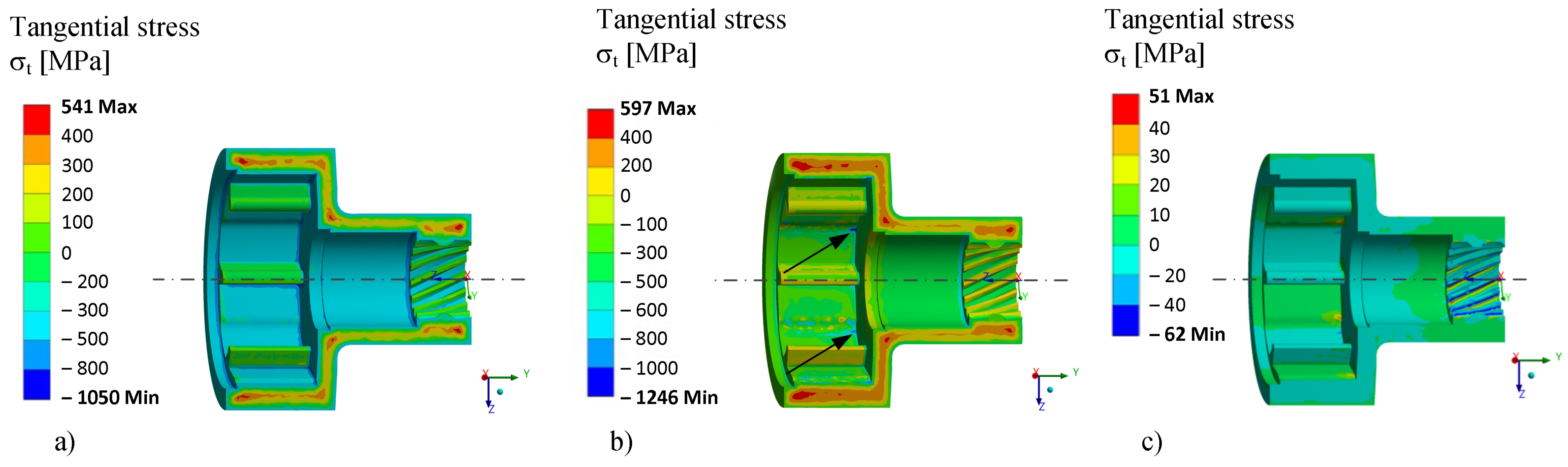

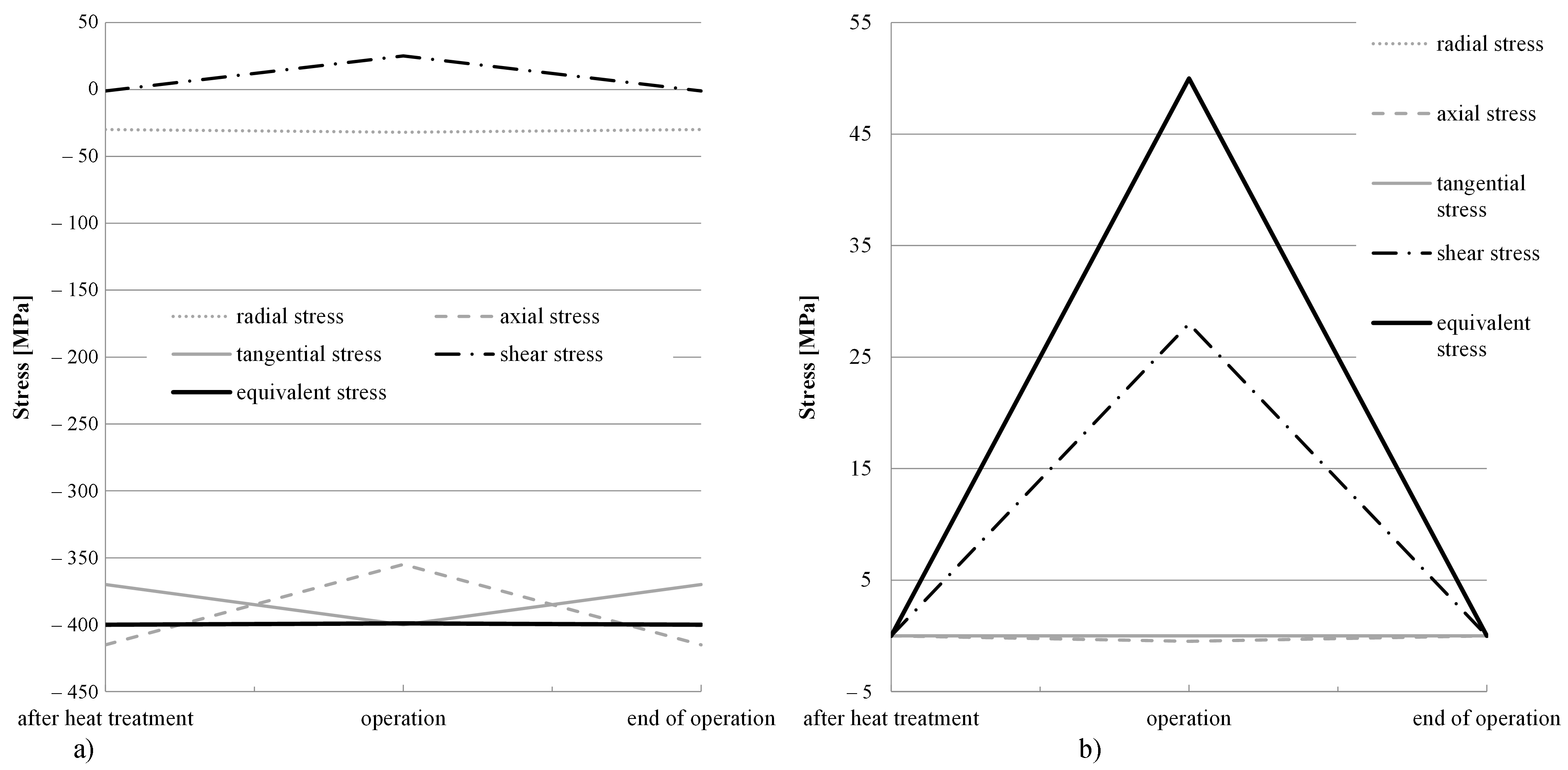

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bartošák, M.; Horváth, J.; Pitrmuc, Z.; Rohlová, M. Life assessment of a low-alloy martensitic steel under isothermal low-cycle fatigue-creep and thermo-mechanical fatigue-creep loading conditions. Int. J. Fatigue 2021, 145, 106092. [Google Scholar] [CrossRef]

- Šeruga, D.; Hansenne, E.; Haesen, V.; Nagode, M. Durability prediction of EN 1.4512 exhaust mufflers under thermomechanical loading. Int. J. Mech. Sci. 2014, 84, 199–207. [Google Scholar] [CrossRef]

- Ubertalli, G.; Matteis, P.; Ferraris, S.; Marcianò, C.; D’Aiuto, F.; Tedesco, M.M.; De Caro, D. High Strain Rate Behavior of Aluminum Alloy for Sheet Metal Forming Processes. Metals 2020, 10, 242. [Google Scholar] [CrossRef] [Green Version]

- Nagode, M.; Šeruga, D.; Hack, M.; Hansenne, E. Damage Operator-Based Lifetime Calculation Under Thermomechanical Fatigue and Creep for Application on Uginox F12T EN 1.4512 Exhaust Downpipes. Strain 2011, 48, 198–207. [Google Scholar] [CrossRef]

- Xu, C.; Yu, M.; Wu, H. Simulation Analysis of Quenching Process of High Strength Steel Based on ABAQUS. IOP Conf. Ser. Mater. Sci. Eng. 2018, 423, 012075. [Google Scholar] [CrossRef]

- Kopec, M.; Kukla, D.; Brodecki, A.; Kowalewski, Z. Effect of high temperature exposure on the fatigue damage development of X10CrMoVNb9-1 steel for power plant pipes. Int. J. Press. Vessel. Pip. 2021, 189, 104282. [Google Scholar] [CrossRef]

- Gong, X.; Wang, T.; Li, Q.; Liu, Y.; Zhang, H.; Zhang, W.; Wang, Q.; Wang, Q. Cyclic responses and microstructure sensitivity of Cr-based turbine steel under different strain ratios in low cycle fatigue regime. Mater. Des. 2021, 201, 109529. [Google Scholar] [CrossRef]

- Nagode, M.; Laengler, F.; Hack, M. Damage operator based lifetime calculation under thermo-mechanical fatigue for application on Ni-resist D-5S turbine housing of turbocharger. Eng. Fail. Anal. 2011, 18, 1565–1575. [Google Scholar] [CrossRef]

- Pérez Caro, L.; Odenberger, E.L.; Schill, M.; Niklasson, F.; Åkerfeldt, P.; Oldenburg, M. Springback prediction and validation in hot forming of a double-curved component in alloy 718. Int. J. Mater. Form. 2021. [Google Scholar] [CrossRef]

- Klemenc, J.; Šeruga, D.; Nagode, A.; Nagode, M. Comprehensive Modelling of the Hysteresis Loops and Strain-Energy Density for Low-Cycle Fatigue-Life Predictions of the AZ31 Magnesium Alloy. Materials 2019, 12, 3692. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bammann, D.; Prantil, V.; Kumar, A. Development of a carburizing and quenching simulation tool: A material model for low carbon steels undergoing phase transformations. In Proceedings of the International Conference on Quenching and the Control of Distortion, Cleveland, OH, USA, 4–7 November 1996. [Google Scholar]

- Greif, D.; Kopun, R.; Kosir, N.; Zhang, D. Numerical Simulation Approach for Immersion Quenching of Aluminum and Steel Components. Int. J. Automot. Eng. 2017, 8, 45–49. [Google Scholar] [CrossRef] [Green Version]

- Tian, Y.; Tan, Z.; Li, H.; Gao, B.; Zhu, J.; Liu, Y.; Zhang, M. A new finite element model for Mn-Si-Cr bainitic/martensitic product quenching process: Simulation and experimental validation. J. Mater. Process. Technol. 2021, 294, 117137. [Google Scholar] [CrossRef]

- Esfahani, A.K.; Babaei, M.; Sarrami-Foroushani, S. A numerical model coupling phase transformation to predict microstructure evolution and residual stress during quenching of 1045 steel. Math. Comput. Simul. 2021, 179, 1–22. [Google Scholar] [CrossRef]

- Tong, D.; Gu, J.; Yang, F. Numerical simulation on induction heat treatment process of a shaft part: Involving induction hardening and tempering. J. Mater. Process. Technol. 2018, 262, 277–289. [Google Scholar] [CrossRef]

- Song, G.S.; Liu, X.H.; Wang, G.D.; Xu, X.Q. Numerical Simulation on Carburizing and Quenching of Gear Ring. J. Iron Steel Res. Int. 2007, 14, 47–52. [Google Scholar] [CrossRef]

- Guo, J.; Deng, X.; Wang, H.; Zhou, L.; Xu, Y.; Ju, D. Modeling and Simulation of Vacuum Low Pressure Carburizing Process in Gear Steel. Coatings 2021, 11, 1003. [Google Scholar] [CrossRef]

- Ferguson, B.L.; Li, Z.; Freborg, A.M. Heat Treat Simulation Used to Improve Gear Performance. In Heat Treating Progress; ASM International: Almere, The Netherlands, 2007; Volume 7. [Google Scholar]

- SongSong, S.; Xingzhe, Z.; Chang, W.; Maosong, W.; Fengkui, Z. Crankshaft high cycle bending fatigue research based on the simulation of electromagnetic induction quenching and the mean stress effect. Eng. Fail. Anal. 2021, 122, 105214. [Google Scholar] [CrossRef]

- Lombardi, A.; Sediako, D.; Machin, A.; Ravindran, C.; MacKay, R. Effect of solution heat treatment on residual stress in Al alloy engine blocks using neutron diffraction. Mater. Sci. Eng. A 2017, 697, 238–247. [Google Scholar] [CrossRef]

- Fomin, A.; Koshuro, V.; Shchelkunov, A.; Aman, A.; Fomina, M.; Kalganova, S. Simulation and experimental study of induction heat treatment of titanium disks. Int. J. Heat Mass Transf. 2021, 165, 120668. [Google Scholar] [CrossRef]

- Xue, W.; Pyle, R. Optimal Design of Roller One Way Clutch for Starter Drives; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2004. [Google Scholar]

- Alberg, H. Material Modelling for Simulation of Heat Treatment. Ph.D. Thesis, Lulea University of Technology, Lulea, Sweden, 2003. [Google Scholar]

- ASM International Handbook Committee. ASM Handbook, Volume 1: Properties and Selection: Irons, Steels, and High-Performance Alloys; ASM International: Almere, The Netherlands, 1990. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Šeruga, D.; Kavčič, M.; Klemenc, J.; Nagode, M. Heat Treatment Consideration in Structural Simulations of Machine Elements: Analysis of a Starter Clutch Barrel. Technologies 2021, 9, 73. https://0-doi-org.brum.beds.ac.uk/10.3390/technologies9040073

Šeruga D, Kavčič M, Klemenc J, Nagode M. Heat Treatment Consideration in Structural Simulations of Machine Elements: Analysis of a Starter Clutch Barrel. Technologies. 2021; 9(4):73. https://0-doi-org.brum.beds.ac.uk/10.3390/technologies9040073

Chicago/Turabian StyleŠeruga, Domen, Matija Kavčič, Jernej Klemenc, and Marko Nagode. 2021. "Heat Treatment Consideration in Structural Simulations of Machine Elements: Analysis of a Starter Clutch Barrel" Technologies 9, no. 4: 73. https://0-doi-org.brum.beds.ac.uk/10.3390/technologies9040073