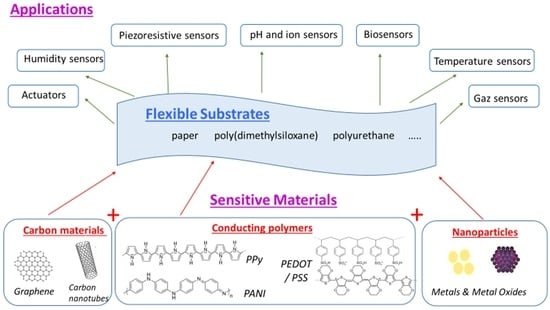

Flexible Sensors Based on Conductive Polymers

Abstract

:1. Introduction

- (i)

- (ii)

- by modifying the structure of the conductive polymer. CPs have a highly π-conjugated structure that leads to rigidity and high stiffness. By changing the synthesis method or by adding counterions, [15] soft polymers, [16] ionic liquids, [17] surfactants, [18,19] or polyvinyl alcohol [20], the CPs will increase their flexibility and stretchability.

- (iii)

2. Piezoresistive Sensors

2.1. Polypyrrole

2.2. Polyaniline

2.3. PEDOT

3. Gas Sensors

- PET: camphor sulfonic acid-doped PANI/α-Fe2O3 (PFC) [116], inkjet-printed polyaniline–dodecyl benzenesulfonic acid nanoparticles deposited onto screen-printed silver interdigitated electrodes, [117] rGO-PANI hybrids [118], composite nanostructured films, hierarchically nanostructured PANI covering a transparent conducting film of carbon nanotube (CNT) networks, [119] or nontransparent CNT [120] or rGO, [115] S and N co-doped graphene quantum dots-PANI composite film [121], metal oxide-PANI composite (Iron oxide, [122] ferric oxide, [123] tin oxide, [124] zinc oxide [125]), interdigital electrodes carbon based printed on an active PANI film [126]; rambutan-like polyaniline hollow nanosphere and graphene oxide, [127] PANI polymerized-electrospun poly(methyl methacrylate) on Au/Ni interdigitated electrode [128];

- Polyimide (PI): PANI/SrGe4O9 nanocomposites (PSN) via the in situ chemical oxidation polymerization method on seven pairs of Au interdigitated electrodes [131];

- Flexible porous polyvinylidene fluoride (PVDF): PANI film with PSS as additive [134];

- On twistable and tailorable nanocomposites (NCPs) textiles: graphene oxide-aniline polymerized in situ by vanadium pentoxide [135];

- Cellulose acetate nanofibers, prepared by electrospinning, followed by deacetylation. On these regenerated cellulose fibers, titanium dioxide nanoparticles were absorbed followed by in situ polymerization of aniline [136].

4. pH and Ions Sensors

5. Biosensors

6. Temperature Sensors

7. Humidity

8. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yan, Y.; Yang, G.; Xu, J.L.; Zhang, M.; Kuo, C.C.; Wang, S.D. Conducting polymer-inorganic nanocomposite-based gas sensors: A review. Sci. Technol. Adv. Mater. 2020, 21, 768–786. [Google Scholar] [CrossRef] [PubMed]

- Costa, J.C.; Spina, F.; Lugoda, P.; Garcia-Garcia, L.; Roggen, D.; Münzenrieder, N. Flexible sensors—From materials to applications. Technologies 2019, 7, 35. [Google Scholar] [CrossRef] [Green Version]

- Lange, U.; Roznyatovskaya, N.V.; Mirsky, V.M. Conducting polymers in chemical sensors and arrays. Anal. Chim. Acta 2008, 614, 1–26. [Google Scholar] [CrossRef]

- Zanardi, C.; Terzi, F.; Seeber, R. Polythiophenes and polythiophene-based composites in amperometric sensing. Anal. Bioanal. Chem. 2013, 405, 509–531. [Google Scholar] [CrossRef] [PubMed]

- Tseghai, G.B.; Mengistie, D.A.; Malengier, B.; Fante, K.A.; van Langenhove, L. PEDOT: PSS-based conductive textiles and their applications. Sensors 2020, 20, 1881. [Google Scholar] [CrossRef] [Green Version]

- Arman Kuzubasoglu, B.; Kursun Bahadir, S. Flexible temperature sensors: A review. Sens. Actuators A Phys. 2020, 315, 112282. [Google Scholar] [CrossRef]

- Tai, H.; Duan, Z.; Wang, Y.; Wang, S.; Jiang, Y. Paper-based sensors for gas, humidity, and strain detections: A review. ACS Appl. Mater. Interfaces 2020, 12, 31037–31053. [Google Scholar] [CrossRef]

- Weng, B.; Shepherd, R.L.; Crowley, K.; Killard, A.J.; Wallace, G.G. Printing conducting polymers. Analyst 2010, 135, 2779–2789. [Google Scholar] [CrossRef]

- Stempien, Z.; Rybicki, T.; Rybicki, E.; Kozanecki, M.; Szynkowska, M.I. In-situ deposition of polyaniline and polypyrrole electroconductive layers on textile surfaces by the reactive Ink-Jet printing technique. Synth. Met. 2015, 202, 49–62. [Google Scholar] [CrossRef]

- Crowley, K.; Smyth, M.R.; Killard, A.J.; Morrin, A. Printing polyaniline for sensor applications. Chem. Pap. 2013, 67, 771–780. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, H.; Han, W.; Lin, H.; Li, R.; Zhu, J.; Huang, W. 3D printed flexible strain sensors: From printing to devices and signals. Adv. Mater. 2021, 33, 2004782. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Seyedin, S.; Qin, S.; Lynch, P.A.; Wang, Z.; Yang, W.; Wang, X.; Razal, J.M. Fast and scalable wet-spinning of highly conductive PEDOT: PSS fibers enables versatile applications. J. Mater. Chem. A 2019, 7, 6401–6410. [Google Scholar] [CrossRef]

- Zhou, J.; Li, E.Q.; Li, R.; Xu, X.; Ventura, I.A.; Moussawi, A.; Anjum, D.H.; Hedhili, M.N.; Smilgies, D.; Lubineau, G.; et al. Semi-metallic, strong and stretchable wet-spun conjugated polymer microfibers. J. Mater. Chem. C 2015, 3, 2528–2538. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.X.; Yu, G.F.; Zhang, J.; Yu, M.; Ramakrishna, S.; Long, Y.Z. Conductive polymer ultrafine fibers via electrospinning: Preparation, physical properties and applications. Prog. Mater. Sci. 2021, 115, 100704. [Google Scholar] [CrossRef]

- Donoval, M.; Micjan, M.; Novota, M.; Nevrela, J.; Kovacova, S.; Pavuk, M.; Juhasz, P.; Jagelka, M.; Kovac, J.; Jakabovic, J.; et al. Relation between secondary doping and phase separation in PEDOT: PSS films. Appl. Surf. Sci. 2017, 395, 86–91. [Google Scholar] [CrossRef]

- Li, P.; Sun, K.; Ouyang, J. Stretchable and conductive polymer films prepared by solution blending. ACS Appl. Mater. Interfaces 2015, 7, 18415–18423. [Google Scholar] [CrossRef]

- Rivnay, J.; Inal, S.; Collins, B.A.; Sessolo, M.; Stavrinidou, E.; Strakosas, X.; Tassone, C.; Delongchamp, D.M.; Malliaras, G.G. Structural control of mixed ionic and electronic transport in conducting polymers. Nat. Commun. 2016, 7, 11287. [Google Scholar] [CrossRef] [Green Version]

- Dauzon, E.; Lin, Y.; Faber, H.; Yengel, E.; Sallenave, X.; Plesse, C.; Goubard, F.; Amassian, A.; Anthopoulos, T.D. Stretchable and transparent conductive PEDOT: PSS-based electrodes for organic photovoltaics and strain sensors applications. Adv. Funct. Mater. 2020, 30, 2001251. [Google Scholar] [CrossRef]

- Vosgueritchian, M.; Lipomi, D.J.; Bao, Z. Highly conductive and transparent PEDOT: PSS films with a fluorosurfactant for stretchable and flexible transparent electrodes. Adv. Funct. Mater. 2012, 22, 421–428. [Google Scholar] [CrossRef]

- Gao, Q.; Wang, M.; Kang, X.; Zhu, C.; Ge, M. Continuous Wet-Spinning Of Flexible And Water-Stable Conductive PEDOT: PSS/PVA composite fibers for wearable sensors. Compos. Commun. 2020, 17, 134–140. [Google Scholar] [CrossRef]

- Rong, Q.; Lei, W.; Liu, M. Conductive hydrogels as smart materials for flexible electronic devices. Chem.-A Eur. J. 2018, 24, 16930–16943. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Xu, T.; Zhang, X. Multifunctional conductive hydrogel-based flexible wearable sensors. TrAC-Trends Anal. Chem. 2021, 134, 116130. [Google Scholar] [CrossRef]

- Zhao, H.; Su, R.; Teng, L.; Tian, Q.; Han, F.; Li, H.; Cao, Z.; Xie, R.; Li, G.; Liu, X.; et al. Recent advances in flexible and wearable sensors for monitoring chemical molecules. Nanoscale 2022, 14, 1653–1669. [Google Scholar] [CrossRef] [PubMed]

- Nag, A.; Mukhopadhyay, S.C.; Kosel, J. Wearable flexible sensors: A review. IEEE Sens. J. 2017, 17, 3949–3960. [Google Scholar] [CrossRef] [Green Version]

- Nagamine, K.; Tokito, S. Organic-transistor-based biosensors interfaced with human skin for non-invasive perspiration analysis. Sens. Actuators B Chem. 2021, 349, 130778. [Google Scholar] [CrossRef]

- Chung, M.; Fortunato, G.; Radacsi, N. Wearable flexible sweat sensors for healthcare monitoring: A review. J. R. Soc. Interface 2019, 16, 20190217. [Google Scholar] [CrossRef]

- Wang, C.; Shirzaei Sani, E.; Gao, W. Wearable bioelectronics for chronic wound management. Adv. Funct. Mater. 2021, 2111022. [Google Scholar] [CrossRef]

- Blachowicz, T.; Ehrmann, G.; Ehrmann, A. Textile-based sensors for biosignal detection and monitoring. Sensors 2021, 21, 6042. [Google Scholar] [CrossRef]

- Krifa, M. Electrically conductive textile materials—Application in flexible sensors and antennas. Textiles 2021, 1, 239–257. [Google Scholar] [CrossRef]

- Gualandi, I.; Tessarolo, M.; Mariani, F.; Possanzini, L.; Scavetta, E.; Fraboni, B. Textile chemical sensors based on conductive polymers for the analysis of sweat. Polymers 2021, 13, 894. [Google Scholar] [CrossRef]

- Wang, L.; Fu, X.; He, J.; Shi, X.; Chen, T.; Chen, P.; Wang, B.; Peng, H. Application challenges in fiber and textile electronics. Adv. Mater. 2020, 32, 1901971. [Google Scholar] [CrossRef]

- Feron, K.; Lim, R.; Sherwood, C.; Keynes, A.; Brichta, A.; Dastoor, P.C. Organic bioelectronics: Materials and biocompatibility. Int. J. Mol. Sci. 2018, 19, 2382. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, S.; Ozlu, B.; Eom, T.; Martin, D.C.; Shim, B.S. Electrically conducting polymers for bio-interfacing electronics: From neural and cardiac interfaces to bone and artificial tissue biomaterials. Biosens. Bioelectron. 2020, 170, 112620. [Google Scholar] [CrossRef] [PubMed]

- Possanzini, L.; Tessarolo, M.; Mazzocchetti, L.; Campari, E.G.; Fraboni, B. Impact of fabric properties on textile pressure sensors performance. Sensors 2019, 19, 4686. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pani, D.; Achilli, A.; Bonfiglio, A. Survey on textile electrode technologies for electrocardiographic (ECG) monitoring, from metal wires to polymers. Adv. Mater. Technol. 2018, 3, 1800008. [Google Scholar] [CrossRef]

- Pani, D.; Achilli, A.; Spanu, A.; Bonfiglio, A.; Gazzoni, M.; Botter, A. Validation of polymer-based screen-printed textile electrodes for surface EMG detection. IEEE Trans. Neural Syst. Rehabil. Eng. 2019, 27, 1370–1377. [Google Scholar] [CrossRef] [PubMed]

- Tai, H.; Wang, S.; Duan, Z.; Jiang, Y. Evolution of breath analysis based on humidity and gas sensors: Potential and challenges. Sens. Actuators B Chem. 2020, 318, 128104. [Google Scholar] [CrossRef]

- le Maout, P.; Wojkiewicz, J.L.; Redon, N.; Lahuec, C.; Seguin, F.; Dupont, L.; Mikhaylov, S.; Noskov, Y.; Ogurtsov, N.; Pud, A. Polyaniline nanocomposites based sensor array for breath ammonia analysis. Portable e-Nose approach to non-invasive diagnosis of chronic kidney disease. Sens. Actuators B Chem. 2018, 274, 616–626. [Google Scholar] [CrossRef]

- Mattana, G.; Kinkeldei, T.; Leuenberger, D.; Ataman, C.; Ruan, J.J.; Molina-Lopez, F.; Quintero, A.V.; Nisato, G.; Tröster, G.; Briand, D.; et al. Woven temperature and humidity sensors on flexible plastic substrates for E-textile applications. IEEE Sens. J. 2013, 13, 3901–3909. [Google Scholar] [CrossRef]

- Ibanez, J.G.; Rincón, M.E.; Gutierrez-Granados, S.; Chahma, M.; Jaramillo-Quintero, O.A.; Frontana-Uribe, B.A. Conducting polymers in the fields of energy, environmental remediation, and chemical-chiral sensors. Chem. Rev. 2018, 118, 4731–4816. [Google Scholar] [CrossRef]

- Wong, Y.C.; Ang, B.C.; Haseeb, A.S.M.A.; Baharuddin, A.A.; Wong, Y.H. Review—Conducting polymers as chemiresistive gas sensing materials: A review. J. Electrochem. Soc. 2020, 167, 037503. [Google Scholar] [CrossRef]

- Alrammouz, R.; Podlecki, J.; Abboud, P.; Sorli, B.; Habchi, R. A review on flexible gas sensors: From materials to devices. Sens. Actuators A Phys. 2018, 284, 209–231. [Google Scholar] [CrossRef]

- Shakeel, A.; Rizwan, K.; Farooq, U.; Iqbal, S.; Altaf, A.A. Advanced polymeric/inorganic nanohybrids: An integrated platform for gas sensing applications. Chemosphere 2022, 294, 133772. [Google Scholar] [CrossRef] [PubMed]

- Tomić, M.; Šetka, M.; Vojkůvka, L.; Vallejos, S. Vocs sensing by metal oxides, conductive polymers, and carbon-based materials. Nanomaterials 2021, 11, 552. [Google Scholar] [CrossRef]

- Nazmul Islam, G.M.; Collie, S.; Qasim, M.; Azam Ali, M. Highly stretchable and flexible melt spun thermoplastic conductive yarns for smart textiles. Nanomaterials 2020, 10, 2324. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Wang, M.Y. Multi-axis soft sensors based on dielectric elastomer. Soft Robot. 2016, 3, 3–12. [Google Scholar] [CrossRef]

- Chen, J.; Yu, Q.; Cui, X.; Dong, M.; Zhang, J.; Wang, C.; Fan, J.; Zhu, Y.; Guo, Z. An overview of stretchable strain sensors from conductive polymer nanocomposites. J. Mater. Chem. C 2019, 7, 11710–11730. [Google Scholar] [CrossRef]

- Ouyang, J. Application of intrinsically conducting polymers in flexible electronics. SmartMat 2021, 2, 263–285. [Google Scholar] [CrossRef]

- Veeramuthu, L.; Venkatesan, M.; Benas, J.-S.; Cho, C.-J.; Lee, C.-C.; Lieu, F.-K.; Lin, J.-H.; Lee, R.-H.; Kuo, C.-C. Recent progress in conducting polymer composite/nanofiber-based strain and pressure sensors. Polymers 2021, 13, 4281. [Google Scholar] [CrossRef]

- Li, Y.; Tatum, W.K.; Onorato, J.W.; Zhang, Y.; Luscombe, C.K. Low elastic modulus and high charge mobility of low-crystallinity indacenodithiophene-based semiconducting polymers for potential applications in stretchable electronics. Macromolecules 2018, 51, 6352–6358. [Google Scholar] [CrossRef]

- Brady, S.; Diamond, D.; Lau, K.T. Inherently conducting polymer modified polyurethane smart foam for pressure sensing. Sens. Actuators A Phys. 2005, 119, 398–404. [Google Scholar] [CrossRef]

- Tjahyono, A.P.; Aw, K.C.; Travas-Sejdic, J. A novel polypyrrole and natural rubber based flexible large strain sensor. Sens. Actuators B Chem. 2012, 166–167, 426–437. [Google Scholar] [CrossRef]

- Pan, L.; Chortos, A.; Yu, G.; Wang, Y.; Isaacson, S.; Allen, R.; Shi, Y.; Dauskardt, R.; Bao, Z. An ultra-sensitive resistive pressure sensor based on hollow-sphere microstructure induced elasticity in conducting polymer film. Nat. Commun. 2014, 5, 3002. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhong, W.; Liu, Q.; Wu, Y.; Wang, Y.; Qing, X.; Li, M.; Liu, K.; Wang, W.; Wang, D. A nanofiber based artificial electronic skin with high pressure sensitivity and 3D conformability. Nanoscale 2016, 8, 12105–12112. [Google Scholar] [CrossRef] [PubMed]

- Shao, Q.; Niu, Z.; Hirtz, M.; Jiang, L.; Liu, Y.; Wang, Z.; Chen, X. High-performance and tailorable pressure sensor based on ultrathin conductive polymer film. Small 2014, 10, 1466–1472. [Google Scholar] [CrossRef]

- Chen, J.; Liu, J.; Thundat, T.; Zeng, H. Polypyrrole-doped conductive supramolecular elastomer with stretchability, rapid self-healing, and adhesive property for flexible electronic sensors. ACS Appl. Mater. Interfaces 2019, 11, 18720–18729. [Google Scholar] [CrossRef]

- Darabi, M.A.; Khosrozadeh, A.; Mbeleck, R.; Liu, Y.; Chang, Q.; Jiang, J.; Cai, J.; Wang, Q.; Luo, G.; Xing, M. Skin-inspired multifunctional autonomic-intrinsic conductive self-healing hydrogels with pressure sensitivity, stretchability, and 3D printability. Adv. Mater. 2017, 29, 1700533. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Wen, J.Y.; Ma, M.G.; Li, M.F.; Peng, F.; Bian, J. Anti-freezing, water-retaining, conductive, and strain-sensitive hemicellulose/polypyrrole composite hydrogels for flexible sensors. J. Mater. Res. Technol. 2021, 14, 555–566. [Google Scholar] [CrossRef]

- Gan, D.; Han, L.; Wang, M.; Xing, W.; Xu, T.; Zhang, H.; Wang, K.; Fang, L.; Lu, X. Conductive and tough hydrogels based on biopolymer molecular templates for controlling in situ formation of polypyrrole nanorods. ACS Appl. Mater. Interfaces 2018, 10, 36218–36228. [Google Scholar] [CrossRef]

- Cheng, H.; Wang, B.; Tan, Y.; Yin, Y.; Wang, C. Low-cost, highly sensitive, and flexible piezoresistive pressure sensor characterized by low-temperature interfacial polymerization of polypyrrole on latex sponge. Macromol. Mater. Eng. 2021, 306, 2000772. [Google Scholar] [CrossRef]

- Li, M.; Li, H.; Zhong, W.; Zhao, Q.; Wang, D. Stretchable conductive polypyrrole/polyurethane (PPy/PU) strain sensor with netlike microcracks for human breath detection. ACS Appl. Mater. Interfaces 2014, 6, 1313–1319. [Google Scholar] [CrossRef] [PubMed]

- Niu, H.; Zhou, H.; Wang, H.; Lin, T. Polypyrrole-coated PDMS fibrous membrane: Flexible strain sensor with distinctive resistance responses at different strain ranges. Macromol. Mater. Eng. 2016, 301, 707–713. [Google Scholar] [CrossRef]

- Li, Y.; Cheng, X.Y.; Leung, M.Y.; Tsang, J.; Tao, X.M.; Yuen, M.C.W. A flexible strain sensor from polypyrrole-coated fabrics. Synth. Met. 2005, 155, 89–94. [Google Scholar] [CrossRef]

- Wang, J.P.; Xue, P.; Tao, X.M. Strain sensing behavior of electrically conductive fibers under large deformation. Mater. Sci. Eng. A 2011, 528, 2863–2869. [Google Scholar] [CrossRef]

- Li, T.; Wang, X.; Jiang, S.; Ding, X.; Li, Q. Study on electromechanical property of polypyrrole-coated strain sensors based on polyurethane and its hybrid covered yarns. Sens. Actuators A Phys. 2020, 306, 111958. [Google Scholar] [CrossRef]

- Irfan, M.S.; Gill, Y.Q.; Ullah, S.; Naeem, M.T.; Saeed, F.; Hashmi, M. Polyaniline-NBR blends by in situ polymerization: Application as stretchable strain sensors. Smart Mater. Struct. 2019, 28, 095024. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, Y.; Liu, Q.; Cheng, W.; Wang, X.; Pan, L.; Xu, B.; Xu, H. A self-healable, highly stretchable, and solution processable conductive polymer composite for ultrasensitive strain and pressure sensing. Adv. Funct. Mater. 2018, 28, 1705551. [Google Scholar] [CrossRef]

- Ge, G.; Cai, Y.; Dong, Q.; Zhang, Y.; Shao, J.; Huang, W.; Dong, X. A flexible pressure sensor based on RGO/polyaniline wrapped sponge with tunable sensitivity for human motion detection. Nanoscale 2018, 10, 10033–10040. [Google Scholar] [CrossRef]

- Xu, R.; Wang, W.; Sun, J.; Wang, Y.; Wang, C.; Ding, X.; Ma, Z.; Mao, Y.; Yu, D. A flexible, conductive and simple pressure sensor prepared by electroless silver plated polyester fabric. Colloids Surf. A Physicochem. Eng. Asp. 2019, 578, 123554. [Google Scholar] [CrossRef]

- Park, H.; Jeong, Y.R.; Yun, J.; Hong, S.Y.; Jin, S.; Lee, S.J.; Zi, G.; Ha, J.S. Stretchable array of highly sensitive pressure sensors consisting of polyaniline nanofibers and Au-coated polydimethylsiloxane micropillars. ACS Nano 2015, 9, 9974–9985. [Google Scholar] [CrossRef]

- Yu, G.F.; Yan, X.; Yu, M.; Jia, M.Y.; Pan, W.; He, X.X.; Han, W.P.; Zhang, Z.M.; Yu, L.M.; Long, Y.Z. Patterned, highly stretchable and conductive nanofibrous PANI/PVDF strain sensors based on electrospinning and in situ polymerization. Nanoscale 2016, 8, 2944–2950. [Google Scholar] [CrossRef] [PubMed]

- Maity, K.; Garain, S.; Henkel, K.; Schmeißer, D.; Mandal, D. Self-powered human-health monitoring through aligned PVDF nanofibers interfaced skin-interactive piezoelectric sensor. ACS Appl. Polym. Mater. 2020, 2, 862–878. [Google Scholar] [CrossRef]

- Jiang, Y.; Chen, Y.; Wang, W.; Yu, D. A Wearable strain sensor based on polyurethane nanofiber membrane with silver nanowires/polyaniline electrically conductive dual-network. Colloids Surf. A Physicochem. Eng. Asp. 2021, 629, 127477. [Google Scholar] [CrossRef]

- Kayser, L.V.; Lipomi, D.J. Stretchable conductive polymers and composites based on PEDOT and PEDOT: PSS. Adv. Mater. 2019, 31, 1806133. [Google Scholar] [CrossRef] [Green Version]

- Losaria, P.M.; Yim, J.H. A highly stretchable large strain sensor based on PEDOT–thermoplastic polyurethane hybrid prepared via in situ vapor phase polymerization. J. Ind. Eng. Chem. 2019, 74, 108–117. [Google Scholar] [CrossRef]

- Savagatrup, S.; Chan, E.; Renteria-Garcia, S.M.; Printz, A.D.; Zaretski, A.V.; O’Connor, T.F.; Rodriquez, D.; Valle, E.; Lipomi, D.J. Plasticization of PEDOT: PSS by common additives for mechanically robust organic solar cells and wearable sensors. Adv. Funct. Mater. 2015, 25, 427–436. [Google Scholar] [CrossRef]

- Liu, N.; Fang, G.; Wan, J.; Zhou, H.; Long, H.; Zhao, X. Electrospun PEDOT: PSS-PVA nanofiber based ultrahigh-strain sensors with controllable electrical conductivity. J. Mater. Chem. 2011, 21, 18962–18966. [Google Scholar] [CrossRef]

- Sun, B.; Long, Y.Z.; Liu, S.L.; Huang, Y.Y.; Ma, J.; Zhang, H.D.; Shen, G.; Xu, S. Fabrication of curled conducting polymer microfibrous arrays via a novel electrospinning method for stretchable strain sensors. Nanoscale 2013, 5, 7041–7045. [Google Scholar] [CrossRef]

- Lin, D.-P.; He, H.-W.; Huang, Y.-Y.; Han, W.-P.; Yu, G.-F.; Yan, X.; Long, Y.-Z.; Xia, L.-H. Twisted microropes for stretchable devices based on electrospun conducting polymer fibers doped with ionic liquid. J. Mater. Chem. C 2014, 2, 8962–8966. [Google Scholar] [CrossRef]

- Fan, X.; Xu, B.; Wang, N.; Wang, J.; Liu, S.; Wang, H.; Yan, F. Highly conductive stretchable all-plastic electrodes using a novel dipping-embedded transfer method for high-performance wearable sensors and semitransparent organic solar cells. Adv. Electron. Mater. 2017, 3, 1600471. [Google Scholar] [CrossRef]

- Kim, H.; Kim, G.; Kim, T.; Lee, S.; Kang, D.; Hwang, M.S.; Chae, Y.; Kang, S.; Lee, H.; Park, H.G.; et al. Transparent, flexible, conformal capacitive pressure sensors with nanoparticles. Small 2018, 14, 1703432. [Google Scholar] [CrossRef] [PubMed]

- Choong, C.L.; Shim, M.B.; Lee, B.S.; Jeon, S.; Ko, D.S.; Kang, T.H.; Bae, J.; Lee, S.H.; Byun, K.E.; Im, J.; et al. Highly stretchable resistive pressure sensors using a conductive elastomeric composite on a micropyramid array. Adv. Mater. 2014, 26, 3451–3458. [Google Scholar] [CrossRef] [PubMed]

- Han, S.; Liu, C.; Huang, Z.; Zheng, J.; Xu, H.; Chu, S.; Wu, J.; Liu, C. High-performance pressure sensors based on 3D microstructure fabricated by a facile transfer technology. Adv. Mater. Technol. 2019, 4, 1800640. [Google Scholar] [CrossRef]

- Fu, H.; Jin, Y.; Ou, H.; Huang, P.; Liu, C.; Luo, Y.; Xiao, Z. High-performance ag nanowires/PEDOT: PSS composite electrodes for PVDF-HFP piezoelectric nanogenerators. J. Mater. Sci. Mater. Electron. 2021, 32, 21178–21187. [Google Scholar] [CrossRef]

- Bandodkar, A.J.; Nuñez-Flores, R.; Jia, W.; Wang, J. All-printed stretchable electrochemical devices. Adv. Mater. 2015, 27, 3060–3065. [Google Scholar] [CrossRef] [PubMed]

- Lo, L.W.; Zhao, J.; Wan, H.; Wang, Y.; Chakrabartty, S.; Wang, C. An inkjet-printed PEDOT: PSS-based stretchable conductor for wearable health monitoring device applications. ACS Appl. Mater. Interfaces 2021, 13, 21693–21702. [Google Scholar] [CrossRef]

- Rong, Q.; Lei, W.; Chen, L.; Yin, Y.; Zhou, J.; Liu, M. Anti-freezing, conductive self-healing organohydrogels with stable strain-sensitivity at subzero temperatures. Angew. Chem.-Int. Ed. 2017, 56, 14159–14163. [Google Scholar] [CrossRef]

- Roh, E.; Hwang, B.U.; Kim, D.; Kim, B.Y.; Lee, N.E. Stretchable, transparent, ultrasensitive, and patchable strain sensor for human-machine interfaces comprising a nanohybrid of carbon nanotubes and conductive elastomers. ACS Nano 2015, 9, 6252–6261. [Google Scholar] [CrossRef]

- Zhao, P.; Zhang, R.; Tong, Y.; Zhao, X.; Zhang, T.; Tang, Q.; Liu, Y. Strain-discriminable pressure/proximity sensing of transparent stretchable electronic skin based on PEDOT: PSS/SWCNT electrodes. ACS Appl. Mater. Interfaces 2020, 12, 55083–55093. [Google Scholar] [CrossRef]

- Fan, X.; Wang, N.; Wang, J.; Xu, B.; Yan, F. Highly sensitive, durable and stretchable plastic strain sensors using sandwich structures of PEDOT: PSS and an elastomer. Mater. Chem. Front. 2018, 2, 355–361. [Google Scholar] [CrossRef]

- Zhou, J.; Hsieh, Y.L. Conductive polymer protonated nanocellulose aerogels for tunable and linearly responsive strain sensors. ACS Appl. Mater. Interfaces 2018, 10, 27902–27910. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Seyedin, S.; Razal, J.M.; Innis, P.C.; Jeiranikhameneh, A.; Beirne, S.; Wallace, G.G. Knitted strain sensor textiles of highly conductive all-polymeric fibers. ACS Appl. Mater. Interfaces 2015, 7, 21150–21158. [Google Scholar] [CrossRef]

- Kim, D.; Ahn, S.K.; Yoon, J. Highly stretchable strain sensors comprising double network hydrogels fabricated by microfluidic devices. Adv. Mater. Technol. 2019, 4, 1800739. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, S.; Li, Z.; Lu, T.J.; Lin, H.; Zhu, Y.; Ahadian, S.; Emaminejad, S.; Dokmeci, M.R.; Xu, F.; et al. Harnessing the wide-range strain sensitivity of bilayered PEDOT: PSS films for wearable health monitoring. Matter 2021, 4, 2886–2901. [Google Scholar] [CrossRef] [PubMed]

- Rohtlaid, K.; Nguyen, G.T.M.; Ebrahimi-Takalloo, S.; Nguyen, T.N.; Madden, J.D.W.; Vidal, F.; Plesse, C. Asymmetric PEDOT: PSS trilayers as actuating and sensing linear artificial muscles. Adv. Mater. Technol. 2021, 6, 2001063. [Google Scholar] [CrossRef]

- Zhang, L.; Li, J.; Yue, S.; He, H.; Ouyang, J. Biocompatible blends of an intrinsically conducting polymer as stretchable strain sensors for real-time monitoring of starch-based food processing. Adv. Funct. Mater. 2021, 31, 2102745. [Google Scholar] [CrossRef]

- Gao, Q.; Meguro, H.; Okamoto, S.; Kimura, M. Flexible tactile sensor using the reversible deformation of Poly(3-Hexylthiophene) nanofiber assemblies. Langmuir 2012, 28, 17593–17596. [Google Scholar] [CrossRef]

- Liu, B.; Liu, X.; Yuan, Z.; Jiang, Y.; Su, Y.; Ma, J.; Tai, H. A flexible NO2 gas sensor based on polypyrrole/nitrogen-doped multiwall carbon nanotube operating at room temperature. Sens. Actuators B Chem. 2019, 295, 86–92. [Google Scholar] [CrossRef]

- Bayrakli, I.; Turkmen, A.; Akman, H.; Sezer, M.T.; Kutluhan, S. Applications of external cavity diode laser-based technique to noninvasive clinical diagnosis using expired breath ammonia analysis: Chronic kidney disease, epilepsy. J. Biomed. Opt. 2016, 21, 087004. [Google Scholar] [CrossRef]

- DuBois, S.; Eng, S.; Bhattacharya, R.; Rulyak, S.; Hubbard, T.; Putnam, D.; Kearney, D.J. Breath ammonia testing for diagnosis of hepatic encephalopathy. Dig. Dis. Sci. 2005, 50, 1780–1784. [Google Scholar] [CrossRef]

- Davies, S.; Spanel, P.; Smith, D. Quantitative analysis of ammonia on the breath of patients in end-stage renal failure. Kidney Int. 1997, 52, 223–228. [Google Scholar] [CrossRef] [Green Version]

- Amano, A.; Yoshida, Y.; Oho, T.; Koga, T. Monitoring ammonia to assess halitosis. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 2002, 94, 692–696. [Google Scholar] [CrossRef] [PubMed]

- Kearney, D.J.; Hubbard, T.; Putnam, D. Breath ammonia measurement in helicobacter pylori infection. Dig. Dis. Sci. 2002, 47, 2523–2530. [Google Scholar] [CrossRef] [PubMed]

- Yeole, B.; Sen, T.; Hansora, D.; Mishra, S. Electrical and gas sensing behaviour of polypyrrole/silver sulphide nanocomposites. Am. J. Sens. Technol. 2017, 4, 10–20. [Google Scholar] [CrossRef]

- Yang, L.; Yang, L.; Wu, S.; Wei, F.; Hu, Y.; Xu, X.; Zhang, L.; Sun, D. Three-dimensional conductive organic sulfonic acid co-doped bacterial cellulose/polyaniline nanocomposite films for detection of ammonia at room temperature. Sens. Actuators B Chem. 2020, 323, 128689. [Google Scholar] [CrossRef]

- Chartuprayoon, N.; Hangarter, C.M.; Rheem, Y.; Jung, H.; Myung, N.V. Wafer-scale fabrication of single polypyrrole nanoribbon-based ammonia sensor. J. Phys. Chem. C 2010, 114, 11103–11108. [Google Scholar] [CrossRef]

- Armitage, B.I.; Murugappan, K.; Lefferts, M.J.; Cowsik, A.; Castell, M.R. Conducting polymer percolation gas sensor on a flexible substrate. J. Mater. Chem. C 2020, 8, 12669–12676. [Google Scholar] [CrossRef]

- She, C.; Li, G.; Zhang, W.; Xie, G.; Zhang, Y.; Li, L.; Yue, F.; Liu, S.; Jing, C.; Cheng, Y.; et al. A flexible polypyrrole/silk-fiber ammonia sensor assisted by silica nanosphere template. Sens. Actuators A Phys. 2021, 317, 112436. [Google Scholar] [CrossRef]

- Wang, W.; Li, Z.; Jiang, T.; Zhao, Z.; Li, Y.; Wang, Z.; Wang, C. Sulfonated poly(ether ether ketone)/polypyrrole core-shell nanofibers: A novel polymeric adsorbent/conducting polymer nanostructures for ultrasensitive gas sensors. ACS Appl. Mater. Interfaces 2012, 4, 6080–6084. [Google Scholar] [CrossRef]

- Kumar, L.; Rawal, I.; Kaur, A.; Annapoorni, S. Flexible room temperature ammonia sensor based on polyaniline. Sens. Actuators B Chem. 2017, 240, 408–416. [Google Scholar] [CrossRef]

- Bandgar, D.K.; Navale, S.T.; Nalage, S.R.; Mane, R.S.; Stadler, F.J.; Aswal, D.K.; Gupta, S.K.; Patil, V.B. Simple and low-temperature polyaniline-based flexible ammonia sensor: A step towards laboratory synthesis to economical model design. J. Mater. Chem. C 2015, 3, 9461–9468. [Google Scholar] [CrossRef]

- Maity, D.; Kumar, R.T.R. Polyaniline anchored MWCNTs on fabric for high performance wearable ammonia sensor. ACS Sens. 2018, 3, 1822–1830. [Google Scholar] [CrossRef]

- Qi, J.; Xu, X.; Liu, X.; Lau, K.T. Fabrication of textile based conductometric polyaniline gas sensor. Sens. Actuators B Chem. 2014, 202, 732–740. [Google Scholar] [CrossRef]

- Hong, K.H.; Oh, K.W.; Kang, T.J. Polyaniline-nylon 6 composite fabric for ammonia gas sensor. J. Appl. Polym. Sci. 2004, 92, 37–42. [Google Scholar] [CrossRef]

- Guo, Y.; Wang, T.; Chen, F.; Sun, X.; Li, X.; Yu, Z.; Wan, P.; Chen, X. Hierarchical graphene-polyaniline nanocomposite films for high-performance flexible electronic gas sensors. Nanoscale 2016, 8, 12073–12080. [Google Scholar] [CrossRef] [PubMed]

- Bandgar, D.K.; Navale, S.T.; Navale, Y.H.; Ingole, S.M.; Stadler, F.J.; Ramgir, N.; Aswal, D.K.; Gupta, S.K.; Mane, R.S.; Patil, V.B. Flexible camphor sulfonic acid-doped PAni/α-Fe2O3 nanocomposite films and their room temperature ammonia sensing activity. Mater. Chem. Phys. 2017, 189, 191–197. [Google Scholar] [CrossRef] [Green Version]

- Crowley, K.; Morrin, A.; Hernandez, A.; O’Malley, E.; Whitten, P.G.; Wallace, G.G.; Smyth, M.R.; Killard, A.J. Fabrication of an ammonia gas sensor using inkjet-printed polyaniline nanoparticles. Talanta 2008, 77, 710–717. [Google Scholar] [CrossRef]

- Bai, S.; Zhao, Y.; Sun, J.; Tian, Y.; Luo, R.; Li, D.; Chen, A. Ultrasensitive room temperature NH3 sensor based on a graphene-polyaniline hybrid loaded on PET thin film. Chem. Commun. 2015, 51, 7524–7527. [Google Scholar] [CrossRef]

- Wan, P.; Wen, X.; Sun, C.; Chandran, B.K.; Zhang, H.; Sun, X.M.; Chen, X. Flexible transparent films based on nanocomposite networks of polyaniline and carbon nanotubes for high-performance gas sensing. Small 2015, 11, 5409–5415. [Google Scholar] [CrossRef]

- Xue, L.; Wang, W.; Guo, Y.; Liu, G.; Wan, P. Flexible polyaniline/carbon nanotube nanocomposite film-based electronic gas sensors. Sens. Actuators B Chem. 2017, 244, 47–53. [Google Scholar] [CrossRef] [Green Version]

- Gavgani, J.N.; Hasani, A.; Nouri, M.; Mahyari, M.; Salehi, A. Highly sensitive and flexible ammonia sensor based on s and n co-doped graphene quantum dots/polyaniline hybrid at room temperature. Sens. Actuators B Chem. 2016, 229, 239–248. [Google Scholar] [CrossRef]

- Bandgar, D.K.; Navale, S.T.; Naushad, M.; Mane, R.S.; Stadler, F.J.; Patil, V.B. Ultra-sensitive polyaniline-iron oxide nanocomposite room temperature flexible ammonia sensor. RSC Adv. 2015, 5, 68964–68971. [Google Scholar] [CrossRef]

- Zhu, C.; Cakmak, U.; Sheikhnejad, O.; Cheng, X.; Zhang, X.; Xu, Y.; Gao, S.; Zhao, H.; Huo, L.; Major, Z. One step synthesis of PANI/Fe2O3 nanocomposites and flexible film for enhanced NH3 sensing performance at room temperature. Nanotechnology 2019, 30, 255502. [Google Scholar] [CrossRef] [PubMed]

- Bai, S.; Tian, Y.; Cui, M.; Sun, J.; Tian, Y.; Luo, R.; Chen, A.; Li, D. Polyaniline@SnO2 heterojunction loading on flexible PET thin film for detection of NH3 at room temperature. Sens. Actuators B Chem. 2016, 226, 540–547. [Google Scholar] [CrossRef]

- Bai, S.; Ye, J.; Luo, R.; Chen, A.; Li, D. Hierarchical polyaniline microspheres loading on flexible PET films for NH3 sensing at room temperature. RSC Adv. 2016, 6, 6939–6945. [Google Scholar] [CrossRef]

- Syrový, T.; Kuberský, P.; Sapurina, I.; Pretl, S.; Bober, P.; Syrová, L.; Hamáček, A.; Stejskal, J. Gravure-printed ammonia sensor based on organic polyaniline colloids. Sens. Actuators B Chem. 2016, 225, 510–516. [Google Scholar] [CrossRef]

- Li, S.; Wang, T.; Yang, Z.; He, J.; Wang, J.; Zhao, L.; Lu, H.; Tian, T.; Liu, F.; Sun, P.; et al. Room temperature high performance NH3 sensor based on GO-rambutan-like polyaniline hollow nanosphere hybrid assembled to flexible PET substrate. Sens. Actuators B Chem. 2018, 273, 726–734. [Google Scholar] [CrossRef]

- Jia, X.S.; Tang, C.C.; Yan, X.; Yu, G.F.; Li, J.T.; Zhang, H.D.; Li, J.J.; Gu, C.Z.; Long, Y.Z. Flexible polyaniline/poly (methyl methacrylate) composite fibers via electrospinning and in situ polymerization for ammonia gas sensing and strain sensing. J. Nanomater. 2016, 2016, 91028. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Xie, G.; Tai, H.; Su, Y.; Yang, B.; Zhang, Q.; Du, X.; Jiang, Y. Ultrasensitive flexible self-powered ammonia sensor based on triboelectric nanogenerator at room temperature. Nano Energy 2018, 51, 231–240. [Google Scholar] [CrossRef]

- Wang, S.; Liu, B.; Duan, Z.; Zhao, Q.; Zhang, Y.; Xie, G.; Jiang, Y.; Li, S.; Tai, H. PANI nanofibers-supported Nb2CTx nanosheets-enabled selective NH3 detection driven by TENG at room temperature. Sens. Actuators B Chem. 2021, 327, 128923. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, J.; Jiang, Y.; Duan, Z.; Liu, B.; Zhao, Q.; Wang, S.; Yuan, Z.; Tai, H. Ultrasensitive flexible NH3 gas sensor based on polyaniline/SrGe4O9 nanocomposite with Ppt-level detection ability at room temperature. Sens. Actuators B Chem. 2020, 319, 128293. [Google Scholar] [CrossRef]

- Pang, Z.; Nie, Q.; Lv, P.; Yu, J.; Huang, F.; Wei, Q. Design of flexible PANI-coated CuO-TiO2-SiO2 heterostructure nanofibers with high ammonia sensing response values. Nanotechnology 2017, 28, 225501. [Google Scholar] [CrossRef] [PubMed]

- Pang, Z.; Nie, Q.; Zhu, Y.; Ge, M.; Chen, M. Enhanced ammonia sensing characteristics of CeO2-decorated SiO2/PANI free-standing nanofibrous membranes. J. Mater. Sci. 2019, 54, 2333–2342. [Google Scholar] [CrossRef]

- Lv, D.; Shen, W.; Chen, W.; Tan, R.; Xu, L.; Song, W. PSS-PANI/PVDF composite based flexible NH3 sensors with Sub-Ppm detection at room temperature. Sens. Actuators B Chem. 2021, 328, 129085. [Google Scholar] [CrossRef]

- Xing, X.; Du, L.; Feng, D.; Wang, C.; Tian, Y.; Li, Z.; Liu, H.; Yang, D. Twistable and tailorable V2O5/PANI/GO nanocomposites textile for wearable ammonia sensing. Sens. Actuators B Chem. 2022, 351, 130944. [Google Scholar] [CrossRef]

- Pang, Z.; Yang, Z.; Chen, Y.; Zhang, J.; Wang, Q.; Huang, F.; Wei, Q. A room temperature ammonia gas sensor based on cellulose/TiO2/PANI composite nanofibers. Colloids Surf. A Physicochem. Eng. Asp. 2016, 494, 248–255. [Google Scholar] [CrossRef]

- Serafini, M.; Mariani, F.; Gualandi, I.; Decataldo, F.; Possanzini, L.; Tessarolo, M.; Fraboni, B.; Tonelli, D.; Scavetta, E. A wearable electrochemical gas sensor for ammonia detection. Sensors 2021, 21, 7905. [Google Scholar] [CrossRef]

- Kwon, O.S.; Park, E.; Kweon, O.Y.; Park, S.J.; Jang, J. Novel flexible chemical gas sensor based on Poly(3,4-Ethylenedioxythiophene) nanotube membrane. Talanta 2010, 82, 1338–1343. [Google Scholar] [CrossRef]

- Wongchoosuk, C.; Jangtawee, P.; Lokavee, S.; Udomrat, S.; Sudkeaw, P.; Kerdcharoen, T. Novel flexible NH3 gas sensor prepared by ink-jet printing technique. Adv. Mater. Res. 2012, 506, 39–42. [Google Scholar] [CrossRef]

- Seekaew, Y.; Lokavee, S.; Phokharatkul, D.; Wisitsoraat, A.; Kerdcharoen, T.; Wongchoosuk, C. Low-cost and flexible printed graphene-PEDOT: PSS gas sensor for ammonia detection. Org. Electron. 2014, 15, 2971–2981. [Google Scholar] [CrossRef]

- Su, P.G.; Lee, C.T.; Chou, C.Y. Flexible NH3 sensors fabricated by in situ self-assembly of polypyrrole. Talanta 2009, 80, 763–769. [Google Scholar] [CrossRef] [PubMed]

- Su, P.G.; Shiu, C.C. Flexible H2 sensor fabricated by layer-by-layer self-assembly of thin films of polypyrrole and modified in situ with Pt nanoparticles. Sens. Actuators B Chem. 2011, 157, 275–281. [Google Scholar] [CrossRef]

- Jin, Z.H.; Liu, Y.L.; Chen, J.J.; Cai, S.L.; Xu, J.Q.; Huang, W.H. Conductive polymer-coated carbon nanotubes to construct stretchable and transparent electrochemical sensors. Anal. Chem. 2017, 89, 2032–2038. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Li, D.; Liang, S.; Li, X.; Zhan, S.; Liu, M. Novel flexible room temperature NO2 gas sensor based on polypyrrole coated SnO2 nanoparticles. In Proceedings of the 8th Annual IEEE International Conference on Nano/Micro Engineered and Molecular Systems, Suzhou, China, 7–10 April 2013; pp. 266–269. [Google Scholar] [CrossRef]

- Lin, Y.; Huang, L.; Chen, L.; Zhang, J.; Shen, L.; Chen, Q.; Shi, W. Fully gravure-printed NO2 gas sensor on a polyimide foil using WO3-PEDOT: PSS nanocomposites and Ag electrodes. Sens. Actuators B Chem. 2015, 216, 176–183. [Google Scholar] [CrossRef]

- Bahoumina, P.; Hallil, H.; Lachaud, J.L.; Abdelghani, A.; Frigui, K.; Bila, S.; Baillargeat, D.; Ravichandran, A.; Coquet, P.; Paragua, C.; et al. Microwave flexible gas sensor based on polymer multi wall carbon nanotubes sensitive layer. Sens. Actuators B Chem. 2017, 249, 708–714. [Google Scholar] [CrossRef]

- Almukhlifi, H.A.; Khasim, S.; Pasha, A. Fabrication and testing of low-cost and flexible smart sensors based on conductive PEDOT-PSS nanocomposite films for the detection of liquefied petroleum gas (LPG) at room temperature. Mater. Chem. Phys. 2021, 263, 124414. [Google Scholar] [CrossRef]

- Sun, J.; Shu, X.; Tian, Y.; Tong, Z.; Bai, S.; Luo, R.; Li, D.; Liu, C.C. Facile preparation of polypyrrole-reduced graphene oxide hybrid for enhancing NH3 sensing at room temperature. Sens. Actuators B Chem. 2017, 241, 658–664. [Google Scholar] [CrossRef]

- Liu, C.; Tai, H.; Zhang, P.; Yuan, Z.; Du, X.; Xie, G.; Jiang, Y. A high-performance flexible gas sensor based on self-assembled PANI-CeO2 nanocomposite thin film for trace-level NH3 detection at room temperature. Sens. Actuators B Chem. 2018, 261, 587–597. [Google Scholar] [CrossRef]

- Gusain, A.; Joshi, N.J.; Varde, P.V.; Aswal, D.K. Flexible NO gas sensor based on conducting polymer poly[N-9′-heptadecanyl-2,7-carbazole-alt-5,5-(4′,7′-Di-2-thienyl-2′,1′,3′-benzothiadiazole)] (PCDTBT). Sens. Actuators B Chem. 2017, 239, 734–745. [Google Scholar] [CrossRef]

- Zhang, D.; Fan, X.; Hao, X.; Dong, G. Facile fabrication of polyaniline nanocapsule modified zinc oxide hexagonal microdiscs for H2S gas sensing applications. Ind. Eng. Chem. Res. 2019, 58, 1906–1913. [Google Scholar] [CrossRef]

- Paul, S.; Amalraj, F.; Radhakrishnan, S. CO sensor based on polypyrrole functionalized with iron porphyrin. Synth. Met. 2009, 159, 1019–1023. [Google Scholar] [CrossRef]

- Zhang, D.; Wu, Z.; Zong, X. Metal-organic frameworks-derived zinc oxide nanopolyhedra/S, N: Graphene quantum dots/polyaniline ternary nanohybrid for high-performance acetone sensing. Sens. Actuators B Chem. 2019, 288, 232–242. [Google Scholar] [CrossRef]

- Hicks, S.M.; Killard, A.J. Electrochemical impedance characterisation of tungsten trioxide-polyaniline nanocomposites for room temperature acetone sensing. Sens. Actuators B Chem. 2014, 194, 283–289. [Google Scholar] [CrossRef]

- Sinha, M.; Verma, P.; Panda, S. Metal-phthalocyanine modified doped polyaniline for VOC sensing applications. Flex. Print. Electron. 2020, 5, 014014. [Google Scholar] [CrossRef]

- Mabrook, M.F.; Pearson, C.; Petty, M.C. Inkjet-printed polypyrrole thin films for vapour sensing. Sens. Actuators B Chem. 2006, 115, 547–551. [Google Scholar] [CrossRef]

- Manjakkal, L.; Dervin, S.; Dahiya, R. Flexible potentiometric PH sensors for wearable systems. RSC Adv. 2020, 10, 8594–8617. [Google Scholar] [CrossRef] [Green Version]

- Rahimi, R.; Ochoa, M.; Parupudi, T.; Zhao, X.; Yazdi, I.K.; Dokmeci, M.R.; Tamayol, A.; Khademhosseini, A.; Ziaie, B. A low-cost flexible pH sensor array for wound assessment. Sens. Actuators B Chem. 2016, 229, 609–617. [Google Scholar] [CrossRef] [Green Version]

- Rahimi, R.; Ochoa, M.; Tamayol, A.; Khalili, S.; Khademhosseini, A.; Ziaie, B. Highly stretchable potentiometric pH sensor fabricated via laser carbonization and machining of carbon−polyaniline composite. ACS Appl. Mater. Interfaces 2017, 9, 9015–9023. [Google Scholar] [CrossRef]

- Park, H.J.; Yoon, J.H.; Lee, K.G.; Choi, B.G. Potentiometric performance of flexible pH sensor based on polyaniline nanofiber arrays. Nano Converg. 2019, 6, 9. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Mao, Y.; Xiao, C.; Xu, X.; Li, X. Flexible pH sensor based on a conductive PANI membrane for pH monitoring. RSC Adv. 2019, 10, 21–28. [Google Scholar] [CrossRef] [Green Version]

- Yoon, J.H.; Kim, S.M.; Park, H.J.; Kim, Y.K.; Oh, D.X.; Cho, H.W.; Lee, K.G.; Hwang, S.Y.; Park, J.; Choi, B.G. Highly self-healable and flexible cable-type pH sensors for real-time monitoring of human fluids. Biosens. Bioelectron. 2020, 150, 111946. [Google Scholar] [CrossRef] [PubMed]

- Zhai, Q.; Yap, L.W.; Wang, R.; Gong, S.; Guo, Z.; Liu, Y.; Lyu, Q.; Wang, J.; Simon, G.P.; Cheng, W. Vertically aligned gold nanowires as stretchable and wearable epidermal ion-selective electrode for noninvasive multiplexed sweat analysis. Anal. Chem. 2020, 92, 4647–4655. [Google Scholar] [CrossRef]

- Reid, D.O.; Smith, R.E.; Garcia-Torres, J.; Watts, J.F.; Crean, C. Solvent treatment of wet-spun PEDOT: PSS fibers for fiber-based wearable pH sensing. Sensors 2019, 19, 4213. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, Y.; Lim, T.; Kim, C.H.; Yeo, C.S.; Seo, K.; Kim, S.M.; Kim, J.; Park, S.Y.; Ju, S.; Yoon, M.H. Organic electrochemical transistor-based channel dimension-independent single-strand wearable sweat sensors. NPG Asia Mater. 2018, 10, 1086–1095. [Google Scholar] [CrossRef]

- Mariani, F.; Gualandi, I.; Tessarolo, M.; Fraboni, B.; Scavetta, E. PEDOT: Dye-based, flexible organic electrochemical transistor for highly sensitive pH monitoring. ACS Appl. Mater. Interfaces 2018, 10, 22474–22484. [Google Scholar] [CrossRef]

- Mariani, F.; Gualandi, I.; Tonelli, D.; Decataldo, F.; Possanzini, L.; Fraboni, B.; Scavetta, E. Design of an electrochemically gated organic semiconductor for pH sensing. Electrochem. Commun. 2020, 116, 106763. [Google Scholar] [CrossRef]

- Bhattacharyya, D.; Senecal, K.; Marek, P.; Senecal, A.; Gleason, K.K. High surface area flexible chemiresistive biosensor by oxidative chemical vapor deposition. Adv. Funct. Mater. 2011, 21, 4328–4337. [Google Scholar] [CrossRef]

- Wang, Y.; Qing, X.; Zhou, Q.; Zhang, Y.; Liu, Q.; Liu, K.; Wang, W.; Li, M.; Lu, Z.; Chen, Y.; et al. The woven fiber organic electrochemical transistors based on polypyrrole nanowires/reduced graphene oxide composites for glucose sensing. Biosens. Bioelectron. 2017, 95, 138–145. [Google Scholar] [CrossRef]

- Li, J.; Rossignol, F.; Macdonald, J. Inkjet printing for biosensor fabrication: Combining chemistry and technology for advanced manufacturing. Lab A Chip 2015, 15, 2538–2558. [Google Scholar] [CrossRef]

- Cai, Y.; Liang, B.; Chen, S.; Zhu, Q.; Tu, T.; Wu, K.; Cao, Q.; Fang, L.; Liang, X.; Ye, X. One-step modification of nano-polyaniline/glucose oxidase on double-side printed flexible electrode for continuous glucose monitoring: Characterization, cytotoxicity evaluation and in vivo experiment. Biosens. Bioelectron. 2020, 165, 112408. [Google Scholar] [CrossRef]

- Li, L.; Pan, L.; Ma, Z.; Yan, K.; Cheng, W.; Shi, Y.; Yu, G. All inkjet-printed amperometric multiplexed biosensors based on nanostructured conductive hydrogel electrodes. Nano Lett. 2018, 18, 3322–3327. [Google Scholar] [CrossRef]

- Zahed, M.A.; Barman, S.C.; Das, P.S.; Sharifuzzaman, M.; Yoon, H.S.; Yoon, S.H.; Park, J.Y. Highly Flexible and conductive poly(3,4-ethylene dioxythiophene)-poly (styrene sulfonate) anchored 3-dimensional porous graphene network-based electrochemical biosensor for glucose and pH detection in human perspiration. Biosens. Bioelectron. 2020, 160, 112220. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Wang, L.; Zhang, Y.; Pan, J.; Li, S.; Sun, X.; Zhang, B.; Peng, H. Weaving sensing fibers into electrochemical fabric for real-time health monitoring. Adv. Funct. Mater. 2018, 28, 1804456. [Google Scholar] [CrossRef]

- Song, J.; Teng, H.; Xu, Z.; Liu, N.; Xu, L.; Liu, L.; Gao, F.; Luo, X. Free-standing electrochemical biosensor for carcinoembryonic antigen detection based on highly stable and flexible conducting polypyrrole nanocomposite. Microchem. Acta 2021, 188, 217. [Google Scholar] [CrossRef] [PubMed]

- Gao, F.; Song, J.; Xu, Z.; Xu, L.; Guo, Y.; Miao, L.; Luo, X. All-polymer free-standing electrodes for flexible electrochemical sensors. Sens. Actuators B Chem. 2021, 334, 129675. [Google Scholar] [CrossRef]

- Trung, T.Q.; Ramasundaram, S.; Hwang, B.U.; Lee, N.E. An all-elastomeric transparent and stretchable temperature sensor for body-attachable wearable electronics. Adv. Mater. 2016, 28, 502–509. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Cao, L.; Wang, J.; Chen, L. Sandwich-like polypyrrole/reduced graphene oxide nanosheets integrated gelatin hydrogel as mechanically and thermally sensitive skinlike bioelectronics. ACS Sustain. Chem. Eng. 2020, 8, 10726–10739. [Google Scholar] [CrossRef]

- Han, S.; Jiao, F.; Khan, Z.U.; Edberg, J.; Fabiano, S.; Crispin, X. Thermoelectric polymer aerogels for pressure–temperature sensing applications. Adv. Funct. Mater. 2017, 27, 1703549. [Google Scholar] [CrossRef] [Green Version]

- Mutee ur Rehman, M.; Muqeet Rehman, M.; Sajid, M.; Lee, J.W.; Na, K.H.; Ko, J.B.; Choi, K.H. Significance of encapsulating organic temperature sensors through spatial atmospheric atomic layer deposition for protection against humidity. J. Mater. Sci. Mater. Electron. 2018, 29, 14396–14405. [Google Scholar] [CrossRef]

- Honda, W.; Harada, S.; Arie, T.; Akita, S.; Takei, K. Wearable, human-interactive, health-monitoring, wireless devices fabricated by macroscale printing techniques. Adv. Funct. Mater. 2014, 24, 3299–3304. [Google Scholar] [CrossRef]

- Xu, G.; Lu, Y.; Cheng, C.; Li, X.; Xu, J.; Liu, Z.; Liu, J.; Liu, G.; Shi, Z.; Chen, Z.; et al. Battery-free and wireless smart wound dressing for wound infection monitoring and electrically controlled on-demand drug delivery. Adv. Funct. Mater. 2021, 31, 2100852. [Google Scholar] [CrossRef]

- Kulkarni, M.V.; Apte, S.K.; Naik, S.D.; Ambekar, J.D.; Kale, B.B. Ink-Jet printed conducting polyaniline based flexible humidity sensor. Sens. Actuators B Chem. 2013, 178, 140–143. [Google Scholar] [CrossRef]

- Zhao, H.; Wang, Z.; Li, Y.; Yang, M. Single-sided and integrated polyaniline/poly(vinylidene fluoride) flexible membrane with micro/nanostructures as breathable, nontoxic and fast response wearable humidity sensor. J. Colloid Interface Sci. 2022, 607, 367–377. [Google Scholar] [CrossRef] [PubMed]

| Materials | Response Time (ms) | Sensitivity (kPa−1) | Detection Limit (Pa) | Maximum Detection Pressure | Voltage (V) | Ref. |

|---|---|---|---|---|---|---|

| PEDOT:PSS/AgNWs | 60 | 6.13 (<5 kPa), 0.97 (20–90 kPa) | 20 | 90 | 0.1 | [83] |

| PEDOT:PSS | NA | 4.88 (0.37–5.9 kPa) | 13 | 8 | 0.2 | [82] |

| PPy@poly(vinyl alcohol-co-ethylene) nanofibers | NA | 1.24 (<150 Pa), 0.89 (<1 kPa), 0.02 (1–7 kPa) | 1.3 | 7 | 2 | [54] |

| PANI nanofibers/Au deposited PDMS nanopilars | 50 | 2 | 15 | 0.22 | 1 | [70] |

| Target Gas | Substrate | Polymer Based Sensing | Fabrication Technique | Sensibility Cg; S | Ref. |

|---|---|---|---|---|---|

| NH3 | PI/Si wafers | PPy nanoribbons | LPNE | 1 ppm, 80% | [106] |

| PET/Au-IDEs | PPy networks | CA, 1.3 V | 0.01 ppm, 39.4% | [107] | |

| PET | PPy/rGo | In situ polymerization | 10 ppm, 50% | [148] | |

| PET | PPy | LBL | 50 ppm, 77.75% | [141] | |

| Silk | PPy | In situ polymerization, SiO2 NS template | 1 ppm, 73.25% | [108] | |

| PI/Au-IDEs | PANI/SrGe4O9 nanocomposites | In situ polymerization | 0.2–10 ppm, 20.59% | [131] | |

| PAN fibers | SPEEK/PPy core−shell nanofibers | Electrospinning, solution-phase polyamidation | 20 ppb, 3.8% | [109] | |

| PET | PANI film | In situ polymerization | 25 ppm, 3.86% | [110] | |

| PET | PANI | In situ polymerization | 100 ppm, 26% | [111] | |

| PP-woven fabric | PANI/MWCNTs | In situ polymerization | 20 ppm, 61.54% | [112] | |

| PET | PANI/CNT | In situ polymerization | 50 ppm, 25% | [120] | |

| PI/Au-IDEs | PANI/CeO2 | In situ self-assembly | 10–50 ppm, 106.9–262.7% | [149] | |

| PET | PANI/α-Fe2O3 | In situ polymerization | 100 ppm, 39% | [122] | |

| PET | CSA doped PANI/α-Fe2O3 | In situ polymerization | 100 ppm, 72% | [116] | |

| PET | PANI/S,N, GQDs | Drop casting, in situ polymerization | 100 ppm, 42% | [121] | |

| Filter paper | PEDOT Nanotubes | VDP | 60 ppm, <30% | [138] | |

| Photo paper | PEDOT/PSS | TIJ | 100 ppm, <35% | [139] | |

| Transparent substrate/Ag IDEs | PEDOT/PSS | Inkjet printing | 500 ppm, 9.6% | [140] | |

| PET/Ag-C IDEs | PANI NPs | Inkjet printing | 100 ppm, 70% | [117] | |

| PET | PANI/rGO | In situ polymerization | 100 ppm, <35% | [118] | |

| PET | PANI/FMWCNT | In situ polymerization | 100 ppm, 30% | [119] | |

| PET/Au-IDEs | PANI/Nb2CTx | In situ polymerization | 10 ppm, <60% | [130] |

| Target Gas | Substrate | Polymer Based Sensing | Fabrication Technique | Sensibility Cg; S | Ref. |

|---|---|---|---|---|---|

| NO2 | PET/Cr-Au IDEs | PPy/(PSS/PAH)/MPS | LBL | 5 ppm, 19.16% | [141] |

| PI | PPy/N-MWCNT | In situ self-assembly/annealing treatment | <5 ppm; 24.82% | [98] | |

| BOPET | PCDTBT | Spin coating | 100 ppm, 2% | [150] | |

| Silk | PPy | In situ polymerization, SiO2 NS template | 100 ppm, 8.9% | [108] | |

| NO | BOPET | PCDTBT | Spin coating | 100 ppm, 80.6% | [150] |

| H2 | PET | PPy/Pt NPs | LBL | 1000 ppm, 22% | [142] |

| PET/Cr-Au IDEs | PPy/(PSS/PAH)/MPS | LBL | 1000 ppm, 0.46% | [141] | |

| H2S | FR4/Ni-Cu IDEs | PANI/ZnO | In situ polymerisation | 100 ppb, 3.2% | [151] |

| BOPET | PCDTBT | Spin coating | 100 ppm, 2% | [150] | |

| Cl2 | BOPET | PCDTBT | Spin coating | 100 ppm, 2.2% | [150] |

| CO | PE/Au-IDEs | PPy-FeTPPCl | Spin-coated | 300 ppm, 6.8% | [152] |

| PET/Cr-Au IDEs | PPy/(PSS/PAH)/MPS | LBL | 200 ppm, 0.21% | [141] | |

| BOPET | PCDTBT | Spin coating | 100 ppm, 2.1% | [150] | |

| Acetone | PET | ZnO/GQDs-S,N/PANI | Drop-casting | 0.5 ppm, 2% | [153] |

| PET/Ag IDEs | WO3/PANI | Drop-casting | 100 ppm, 6.5% | [154] | |

| Fabric | PANI | LBL | 50 ppm, 24% | [113] | |

| PI/Cu-IDEs | PANI/Ni-Pc | Chemical polymerization | 150 ppm, 50% | [155] | |

| Silk | PPy | In situ polymerization, SiO2 NS template | 100 ppm, 1.14% | [108] | |

| PP-woven fabric | PANI/ MWCNTs | In situ polymerization | 100 ppm, 12.67% | [112] | |

| Methanol | PE | PPy | Ink-jet | 5000 ppm, 88% | [156] |

| PP-woven fabric | PANI/ MWCNTs | In situ polymerization | 100 ppm, 8.37% | [112] | |

| Ethanol | PE | PPy | Ink-jet | 5000 ppm, 68% | [156] |

| Fabric | PANI | LBL | 32.5 ppm, 65% | [113] | |

| PI/Cu-IDEs | PANI/Cu-Pc | Chemical polymerization | 150 ppm, 32% | [155] | |

| BOPET | PCDTBT | Spin coating | 100 ppm, 1.8% | [150] | |

| Silk | PPy | In situ polymerization, SiO2 NS template | 100 ppm, 0.84% | [108] | |

| PP-woven fabric | PANI/ MWCNTs | In situ polymerization | 100 ppm, 10.45% | [112] | |

| Propanol | PE | PPy | Ink-jet | 5000 ppm, 55% | [156] |

| Iso-propanol | PI/Cu-IDEs | PANI/Fe-Pc | Chemical polymerization | 150 ppm, 45% | [155] |

| PP-woven fabric | PANI/MWCNTs | In situ polymerization | 100 ppm, 6.97% | [112] | |

| n-butanol | PP-woven fabric | PANI/MWCNTs | In situ polymerization | 100 ppm, 8.91% | [112] |

| Chloroform | PE | PPy | Ink-jet | 5000 ppm, 40% | [156] |

| PP-woven fabric | PANI/MWCNTs | In situ polymerization | 100 ppm, 14.5% | [112] | |

| Ethanediol | Silk | PPy | In situ polymerization, SiO2 NS template | 100 ppm, 1.07% | [108] |

| Ether | Silk | PPy | In situ polymerization, SiO2 NS template | 100 ppm, 0.47% | [108] |

| Formaldehide | PI/Cu-IDEs | PANI/Zn-Pc | Chemical polymerization | 150 ppm, 260% | [155] |

| Benzene | PE | PPy | Ink-jet | 5000 ppm, 30% | [156] |

| PP-woven fabric | PANI/MWCNTs | In situ polymerization | 100 ppm, 7.84% | [112] | |

| Xylene | PP-woven fabric | PANI/MWCNTs | In situ polymerization | 100 ppm, 11.03% | [112] |

| Cyclohexane | Silk | PPy | In situ polymerization, SiO2 NS template | 100 ppm, 0.85% | [108] |

| Trichloromethane | Fabric | PANI | LBL | 90 ppm, 150% | [113] |

| Ethyl acetate | Fabric | PANI | LBL | 75 ppm, 5.5% | [113] |

| Acetyl acetone | Silk | PPy | In situ polymerization, SiO2 NS template | 100 ppm, 3.85% | [108] |

| Toluene | Fabric | PANI | LBL | 32.5 ppm, 45% | [113] |

| Silk | PPy | In situ polymerization, SiO2 NS template | 100 ppm, 0.24% | [108] | |

| PP-woven fabric | PANI/MWCNTs | In situ polymerization | 100 ppm, 9.42% | [112] | |

| LPG | PET | PEDOT/PSS | Spin coating | 100 ppm, 79% | [147] |

| DMF | Silk | PPy | In situ polymerization, SiO2 NS template | 100 ppm, 0.89% | [108] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pavel, I.-A.; Lakard, S.; Lakard, B. Flexible Sensors Based on Conductive Polymers. Chemosensors 2022, 10, 97. https://0-doi-org.brum.beds.ac.uk/10.3390/chemosensors10030097

Pavel I-A, Lakard S, Lakard B. Flexible Sensors Based on Conductive Polymers. Chemosensors. 2022; 10(3):97. https://0-doi-org.brum.beds.ac.uk/10.3390/chemosensors10030097

Chicago/Turabian StylePavel, Ileana-Alexandra, Sophie Lakard, and Boris Lakard. 2022. "Flexible Sensors Based on Conductive Polymers" Chemosensors 10, no. 3: 97. https://0-doi-org.brum.beds.ac.uk/10.3390/chemosensors10030097