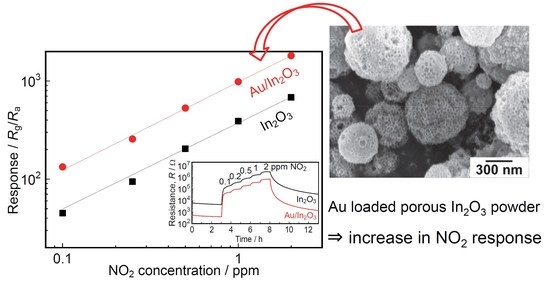

Enhanced NO2-Sensing Properties of Au-Loaded Porous In2O3 Gas Sensors at Low Operating Temperatures

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of In2O3 Powders by Ultrasonic Spray Pyrolysis

2.2. Fabrication of Thick Film Sensors and Measurement of Their Gas Sensing Properties

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Taguchi, N. Japanese Patent Application No. 45-38200. 1962. [Google Scholar]

- Chiba, A. Development of the TGA gas sensor. In Chemical Sensor Technology; Yamauchi, S., Ed.; Kodansha and Elsevier: Amsterdam, The Netherlands, 1992; Volume 4, pp. 1–18. [Google Scholar]

- Yamazoe, N. Toward innovations of gas sensor technology. Sens. Actuators B 2005, 108, 2–14. [Google Scholar] [CrossRef]

- Kim, T.-H.; Jeong, S.-Y.; Moon, Y.K.; Lee, J.-H. Dual-mode gas sensor for ultrasensitive and highly selective detection of xylene and toluene using Nb-doped NiO hollow spheres. Sens. Actuators B 2019, 301, 127140. [Google Scholar] [CrossRef]

- Prajapati, C.S.; Bhat, N. Ppb level detection of NO2 using a WO3 thin film based sensor: Material optimization, device fabrication and packaging. RSC Adv. 2018, 8, 6590–6599. [Google Scholar] [CrossRef] [Green Version]

- Weinberger, B.; Laskin, D.L.; Heck, D.E.; Laskin, J.D. The toxicology of inhaled nitric oxide. Toxicol. Sci. 2001, 59, 5–16. [Google Scholar] [CrossRef] [Green Version]

- Bernstein, J.A.; Alexis, N.; Barnes, C.; Bernstein, I.L.; Bernstein, J.; Nel, A.; Peden, D.; Sanchez, D.D.; Tarlo, S.M.; Williams, P.B. Health effects of air pollution. J. Allergy Clin. Immunol. 2004, 114, 1116–1123. [Google Scholar] [CrossRef] [PubMed]

- National Ambient Air Quality Standards for Pollutants Considered Harmful to Public Health and the Environment. Available online: https://www.epa.gov/criteria-air-pollutants/naaqs-table (accessed on 10 June 2020).

- Wang, J.; Zhang, W.; Cao, R.; You, X.; Lai, H. Analysis of nitrogen dioxide in environment. Adv. Biosci. Biotechnol. 2016, 7, 278–288. [Google Scholar] [CrossRef] [Green Version]

- Reference Method for the Determination of Nitrogen Dioxide in the Atmosphere (Chemiluminescence). Available online: https://www3.epa.gov/ttn/amtic/files/ambient/pm25/qa/no2.pdf (accessed on 8 July 2020).

- Choi, S.-B.; Lee, W.S.; Lee, C.; Lee, S. Enhanced NO2 gas-sensing performance of Pd/ZnO-codecorated SnO2 nanorod sensors. Appl. Phys. A 2018, 124, 817. [Google Scholar] [CrossRef]

- Kim, H.J.; Jo, S.B.; Ahn, J.H.; Hwang, B.W.; Chae, H.J.; Kim, S.Y.; Huh, J.S.; Ragupathy, D.; Lee, S.C.; Kim, J.C. SnO2 nanowire gas sensors for detection of ppb level NOx gas. Adsorption 2019, 25, 1259–1269. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, C.; Wang, Z.; Song, Z.; Zhou, X.; Han, N.; Chen, Y. Sputtered SnO2: NiO thin films on self-assembled Au nanoparticle arrays for MEMS compatible NO2 gas sensors. Sens. Actuators B 2019, 278, 28–38. [Google Scholar] [CrossRef]

- Yang, L.; Marikutsa, A.; Rumyantseva, M.; Konstantinova, E.; Khmelevsky, N.; Gaskov, A. Quasi similar routes of NO2 and NO sensing by nanocrystalline WO3: Evidence by in situ DRIFT spectroscopy. Sensors 2019, 19, 3405. [Google Scholar] [CrossRef] [Green Version]

- Yan, D.; Li, S.; Liu, S.; Tan, M.; Cao, M. Electrodeposited tungsten oxide films onto porous silicon for NO2 detection at room temperature. J. Alloys Compd. 2018, 735, 718–727. [Google Scholar] [CrossRef]

- Tamaki, J.; Naruo, C.; Yamamoto, Y.; Matsuoka, M. Sensing properties to dilute chlorine gas of indium oxide based thin film sensors prepared by electron beam evaporation. Sens. Actuators B 2002, 83, 190–194. [Google Scholar] [CrossRef]

- Xu, X.; Zhao, P.; Wang, D.; Sun, P.; You, L.; Sun, Y.; Liang, X.; Liu, F.; Chen, H.; Lu, G. Preparation and gas sensing properties of hierarchical flower-like In2O3 microspheres. Sens. Actuators B 2013, 176, 405–412. [Google Scholar] [CrossRef]

- Gao, L.; Cheng, Z.; Xiang, Q.; Zhang, Y.; Xu, J. Porous corundum-type In2O3 nanosheets: Synthesis and NO2 sensing properties. Sens. Actuators B 2015, 208, 436–443. [Google Scholar] [CrossRef]

- Xu, P.; Cheng, Z.; Pan, Q.; Xu, J.; Xiang, Q.; Yu, W.; Chu, Y. High aspect ratio In2O3 nanowires: Synthesis, mechanism and NO2 gas-sensing properties. Sens. Actuators B 2008, 130, 802–808. [Google Scholar] [CrossRef]

- Li, S.; Cheng, M.; Liu, G.; Zhao, L.; Zhang, B.; Gao, Y.; Lu, H.; Wang, H.; Zhao, J.; Liu, F.; et al. High-response and low-temperature nitrogen dioxide gas sensor based on gold-loaded mesoporous indium trioxide. J. Colloid Interface Sci. 2018, 5224, 368–378. [Google Scholar] [CrossRef]

- Steffes, H.; Imawan, C.; Solzbacher, F.; Obermeier, E. Enhancement of NO2 sensing properties of In2O3-based thin films using an Au or Ti surface modification. Sens. Actuators B 2001, 78, 106–112. [Google Scholar] [CrossRef]

- Yu, Y.-T.; Majhi, S.M.; Song, H.-G. Synthesis and gas sensing properties of Au@In2O3 core-shell Nanoparticles. Procedia Eng. 2016, 168, 227–230. [Google Scholar] [CrossRef]

- Liu, Y.; Gao, X.; Li, F.; Lu, G.; Zhang, T.; Barsan, N. Pt-In2O3 mesoporous nanofibers with enhanced gas sensing performance towards ppb-level NO2 at room temperature. Sens. Actuators B 2018, 260, 927–936. [Google Scholar] [CrossRef]

- Wang, Z.; Men, G.; Zhang, R.; Gu, F.; Han, D. Pd loading induced excellent NO2 gas sensing of 3DOM In2O3 at room temperature. Sens. Actuators B 2018, 263, 218–228. [Google Scholar] [CrossRef]

- Chen, K.; Lu, H.; Li, G.; Zhang, J.; Tian, Y.; Gao, Y.; Guo, Q.; Lu, H.; Gao, J. Surface functionalization of porous In2O3 nanofibers with Zn nanoparticles for enhanced low-temperature NO2 sensing properties. Sens. Actuators B 2020, 308, 127716. [Google Scholar] [CrossRef]

- Yang, Q.; Wang, Y.; Liu, J.; Liu, J.; Gao, Y.; Sun, P.; Jie, Z.; Zhang, T.; Wang, Y.; Lu, G. Enhanced sensing response towards NO2 based on ordered mesoporous Zr-doped In2O3 with low operating temperature. Sens. Actuators B 2017, 241, 806–813. [Google Scholar] [CrossRef]

- Kim, J.-H.; Mirzaei, A.; Kim, H.W.; Kim, S.S. Low-voltage-driven sensors based on ZnO nanowires for room-temperature detection of NO2 and CO gases. ACS Appl. Mater. Interfaces 2019, 11, 24172–24183. [Google Scholar] [CrossRef] [PubMed]

- Chena, R.; Wangb, J.; Xiang, L. Facile synthesis of mesoporous ZnO sheets assembled by small nanoparticles for enhanced NO2 sensing performance at room temperature. Sens. Actuators B 2018, 270, 207–215. [Google Scholar] [CrossRef]

- Dilonardo, E.; Penza, M.; Alvisi, M.; Franco, C.D.; Palmisano, F.; Torsi, L.; Cioffi, N. Evaluation of gas-sensing properties of ZnO nanostructures electrochemically doped with Au nanophase. Beilstein. J. Nanotechnol. 2016, 7, 22–31. [Google Scholar] [CrossRef] [Green Version]

- Degler, D.; Weimar, U.; Barsan, N. Current understanding of the fundamental mechanisms of doped and loaded semiconducting metal-oxide-based gas sensing materials. ACS Sens. 2019, 4, 2228–2249. [Google Scholar] [CrossRef]

- Gurlo, A.; Bârsan, N.; Ivanovskaya, M.; Weimar, U.; Göpel, W. In2O3 and MoO3–In2O3 thin film semiconductor sensors: Interaction with NO2 and O3. Sens. Actuators B 1998, 47, 92–99. [Google Scholar] [CrossRef]

- Ivanovskaya, M.; Gurlo, A.; Bogdanov, P. Mechanism of O3 and NO2 detection and selectivity of In2O3 sensors. Sens. Actuators B 2001, 77, 264–267. [Google Scholar] [CrossRef]

- Staerz, A.; Boehme, I.; Degler, D.; Bahri, M.; Doronkin, D.E.; Zimina, A.; Brinkmann, H.; Herrmann, S.; Junker, B.; Ersen, O.; et al. Rhodium oxide surface-loaded gas sensors. Nanomaterials 2018, 8, 892. [Google Scholar] [CrossRef] [Green Version]

- Hashimoto, M.; Inoue, H.; Hyodo, T.; Shimizu, Y.; Egashira, M. Preparation and gas sensor application of ceramic particles with submicron-size spherical macropores. Sens. Lett. 2008, 6, 887–890. [Google Scholar] [CrossRef]

- Hyodo, T.; Inoue, H.; Motomura, H.; Matsuo, K.; Hashishin, T.; Tamaki, J.; Shimizu, Y.; Egashira, M. NO2 sensing properties of macroporous In2O3-based powders fabricated by utilizing ultrasonic spray pyrolysis employing polymethylmethacrylate microspheres as a template. Sens. Actuators B 2010, 151, 265–273. [Google Scholar] [CrossRef] [Green Version]

- Hyodo, T.; Furuno, S.-I.; Fujii, E.; Matsuo, K.; Motokucho, S.; Kojio, K.; Shimizu, Y. Porous In2O3 powders prepared by ultrasonic-spray pyrolysis as a NO2-sensing material: Utilization of polymethylmethacrylate microspheres synthesized by ultrasonic-assisted emulsion polymerization as a template. Sens. Actuators B 2013, 187, 495–502. [Google Scholar] [CrossRef] [Green Version]

- Hyodo, T.; Fujii, E.; Ishida, K.; Ueda, T.; Shimizu, Y. Microstructural control of porous In2O3 powders prepared by ultrasonic-spray pyrolysis employing self-synthesized polymethylmethacrylate microspheres as a template and their NO2-sensing properties. Sens. Actuators B 2017, 244, 992–1003. [Google Scholar] [CrossRef] [Green Version]

- Ueda, T.; Ishida, K.; Kamada, K.; Hyodo, T.; Shimizu, Y. Improvement in NO2 sensing properties of semiconductor-type gas sensors by introducing a metal into porous In2O3 powders. Front. Mater. 2019, 6, 81. [Google Scholar] [CrossRef]

- Yamazoe, N.; Sakai, G.; Shimanoe, K. Oxide semiconductor gas sensors. Catal. Surv. Asia 2003, 7, 63–75. [Google Scholar] [CrossRef]

- Choi, S.-W.; Jung, S.-H.; Kim, S.S. Significant enhancement of the NO2 sensing capability in networked SnO2 nanowires by Au nanoparticles synthesized via g-ray radiolysis. J. Hazard. Mater. 2011, 193, 243–248. [Google Scholar] [CrossRef]

- Mun, Y.; Park, S.; An, S.; Lee, C.; Kim, H.W. NO2 gas sensing properties of Au-functionalized porous ZnO nanosheets enhanced by UV irradiation. Ceram. Int. 2013, 39, 8615–8622. [Google Scholar] [CrossRef]

- Shim, Y.-S.; Moon, H.G.; Kim, D.H.; Zhang, L.; Yoon, S.-J.; Yoon, Y.S.; Kang, C.-Y.; Jang, H.W. Au-decorated WO3 cross-linked nanodomes for ultrahigh sensitive and selective sensing of NO2 and C2H5OH. RSC Adv. 2013, 3, 10452–10459. [Google Scholar] [CrossRef]

- Miura, N.; Wang, J.; Elumalai, P.; Ueda, T.; Terada, D.; Hasei, M. Improving NO2 sensitivity by adding WO3 during processing of NiO sensing-electrode of mixed-potential-type zirconia-based sensor. J. Electrochem. Soc. 2007, 154, J246–J252. [Google Scholar] [CrossRef]

- Kim, C.H.; Qi, G.; Dahlberg, K.; Li, W. Strontium-doped perovskites rival platinum catalysts for treating NOx in simulated diesel exhaust. Science 2020, 327, 1624–1627. [Google Scholar] [CrossRef]

- Roso, S.; Bittencourt, C.; Umek, P.; Gonzalez, O.; Guell, F.; Urakawa, A.; Llobet, E. Synthesis of single crystalline In2O3 octahedra for the selective detection of NO2 and H2 at trace levels. J. Mater. Chem. C 2016, 4, 9418–9427. [Google Scholar] [CrossRef] [Green Version]

- Srivastava, R.K.; Lal, P.; Dwivedi, R.; Srivastava, S.K. Sensing mechanism in tin oxide-based thick-film gas sensors. Sens. Actuators B 1994, 21, 213–218. [Google Scholar] [CrossRef]

- Fua, H.; Li, Y.; Yua, Z.; Shena, J.; Lia, J.; Zhanga, M.; Dinga, T.; Xua, L.; Lee, S.S. Ammonium removal using a calcined natural zeolite modified with sodium. J. Hazard. Mater. 2020, 393, 122481. [Google Scholar] [CrossRef] [PubMed]

- Dada, A.O.; Olalekan, A.P.; Olatunya, A.M.; Dada, O. Langmuir, Freundlich, Temkin and Dubinin–Radushkevich isotherms studies of equilibrium sorption of Zn2+ unto phosphoric acid modified rice husk. J. Appl. Chem. 2012, 3, 38–45. [Google Scholar]

- Roso, S.; Degler, D.; Llobet, E.; Barsan, N.; Urakawa, A. Temperature-dependent NO2 sensing mechanisms over indium oxide. ACS Sens. 2017, 2, 1272–1277. [Google Scholar] [CrossRef]

- Barsan, N.; Weimar, U. Conduction model of metal oxide gas sensors. J. Electroceram. 2001, 7, 143–167. [Google Scholar] [CrossRef]

- Klein, A.; Körber, C.; Wachau, A.; Säuberlich, F.; Gassenbauer, Y.; Schafranek, R.; Harvey, S.P.; Mason, T.O. Surface potentials of magnetron sputtered transparent conducting oxides. Thin Solid Films 2009, 518, 1197–1203. [Google Scholar] [CrossRef]

- Sato, Y.; Ashida, T.; Oka, N.; Shigesato, Y. Carrier density dependence of optical band gap and work function in Sn-doped In2O3 films. Appl. Phys. Express 2010, 3, 061101. [Google Scholar] [CrossRef]

- Sato, Y.; Tokumaru, R.; Nishimura, E.; Song, P.-K.; Shigesato, Y.; Utsumi, K.; Iigusa, H. Structural, electrical, and optical properties of transparent conductive In2O3-SnO2 films. J. Vac. Sci. Technol. A 2005, 23, 1167–1172. [Google Scholar] [CrossRef]

- Tani, T. Analysis of work functions of noble metals in ambient atmosphere in commemoration of journal award. J. Soc. Photogr. Sci. Technol. Jpn. 2015, 78, 16–22. [Google Scholar]

- Manaka, T.; Lim, E.; Tamura, R.; Iwamoto, M. Control of the nano electrostatic phenomena at a pentacene/metal interface for improvement of the organic FET devices. Thin Solid Films 2006, 499, 386–391. [Google Scholar] [CrossRef]

- Yamashita, D.; Ishizaki, A. In situ measurements of change in work function of Pt, Pd and Ausurfaces during desorption of oxygen by using photoemission yield spectrometer in air. Appl. Surf. Sci. 2016, 363, 240–244. [Google Scholar] [CrossRef]

- Wan, A.; Hwang, J.; Amy, F.; Kahn, A. Impact of electrode contamination on the a-NPD/Au hole injection barrier. Org. Electron. 2005, 6, 47–54. [Google Scholar] [CrossRef]

| Material of Sensing Layer | Fabrication Technique | Structure of In2O3 | Appropriate Operating Temperature/°C | NO2 Response a | NO2 Detection Limit/ppm | Year | Ref. |

|---|---|---|---|---|---|---|---|

| In2O3 | Hydrothermal synthesis | Flower-like particle | 150 | 74 (0.5 ppm) | 0.04 | 2013 | [17] |

| In2O3 | Hydrothermal synthesis | Porous nanosheet | 250 | 164 (50 ppm) | 1 | 2015 | [18] |

| In2O3 | Hydrothermal synthesis | Nanofiber | 250 | 2.57 (1 ppm) | 1 | 2008 | [19] |

| Au/In2O3 | Casting using SBA-15 b | Porous particle | 65 | 472 (0.5 ppm) | 0.01 | 2018 | [20] |

| Au/In2O3 | Magnetron sputtering | Thin film | 350 | 142 (10 ppm) | 10 | 2001 | [21] |

| Au/In2O3 | Hydrothermal synthesis | Core–shell | 300 | 15 (100 ppm) | 100 | 2016 | [22] |

| Pt/In2O3 | Electrospinning | Nanowire | 80 | 19.2 (0.5 ppm) | 0.01 | 2018 | [23] |

| Pd/In2O3 | Casting using PMMA c | Porous particle | Room temperature | 980 (0.5 ppm) | 0.1 | 2018 | [24] |

| Zn/In2O3 | Electrospinning | Nanowire | 50 | 130 (5 ppm) | 0.05 | 2020 | [25] |

| Zr/In2O3 | Casting using SBA-15 b | Porous particle | 75 | 169 (1 ppm) | 0.02 | 2017 | [26] |

| Au/In2O3 | Ultrasonic spray pyrolysis | Porous particle | 30 | 10000 (0.25 ppm) | 0.025 | 2019 | [38] |

| 30 °C | 100 °C | 200 °C | 300 °C | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sensor | The Order of NO2 Exposure | a | b | r | a | b | r | a | b | r | a | b | R |

| In2O3 | 1st | 2.10 × 108 | 0.38 | 0.637 | 1.15 × 106 | 0.69 | 0.987 | 7.65 × 106 | 0.96 | 0.996 | 2.21 × 106 | 0.33 | 0.996 |

| 2nd | 2.63 × 108 | 0.38 | 0.540 | 1.82 × 106 | 0.68 | 0.992 | 11.2 × 106 | 0.89 | 0.996 | 2.39 × 106 | 0.29 | 1.000 | |

| Au/In2O3 | 1st | 2.23 × 107 | 0.37 | 0.890 | 2.44 × 105 | 0.84 | 0.999 | 1.20 × 106 | 0.72 | 1.000 | 9.97 × 104 | 0.45 | 0.993 |

| 2nd | 2.71 × 107 | 0.31 | 0.889 | 4.51 × 105 | 0.78 | 0.999 | 1.62 × 106 | 0.70 | 0.998 | 15.7 × 104 | 0.41 | 1.000 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ueda, T.; Boehme, I.; Hyodo, T.; Shimizu, Y.; Weimar, U.; Barsan, N. Enhanced NO2-Sensing Properties of Au-Loaded Porous In2O3 Gas Sensors at Low Operating Temperatures. Chemosensors 2020, 8, 72. https://0-doi-org.brum.beds.ac.uk/10.3390/chemosensors8030072

Ueda T, Boehme I, Hyodo T, Shimizu Y, Weimar U, Barsan N. Enhanced NO2-Sensing Properties of Au-Loaded Porous In2O3 Gas Sensors at Low Operating Temperatures. Chemosensors. 2020; 8(3):72. https://0-doi-org.brum.beds.ac.uk/10.3390/chemosensors8030072

Chicago/Turabian StyleUeda, Taro, Inci Boehme, Takeo Hyodo, Yasuhiro Shimizu, Udo Weimar, and Nicolae Barsan. 2020. "Enhanced NO2-Sensing Properties of Au-Loaded Porous In2O3 Gas Sensors at Low Operating Temperatures" Chemosensors 8, no. 3: 72. https://0-doi-org.brum.beds.ac.uk/10.3390/chemosensors8030072