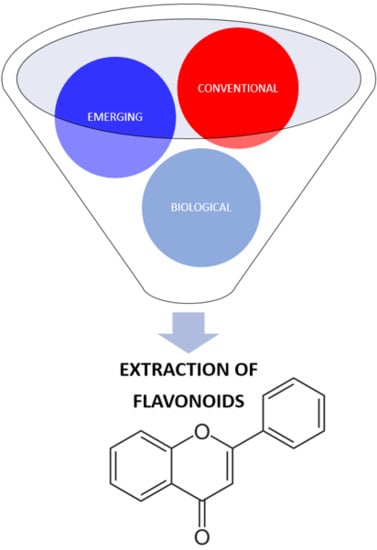

Conventional and Emerging Extraction Processes of Flavonoids

Abstract

:1. Introduction

2. Flavonoids

2.1. Flavanones

2.2. Flavonols

2.3. Flavones

2.4. Anthocyanins

2.5. Flavanols

2.6. Isoflavones

3. Isolation and Extraction Methods

3.1. Conventional Methods

3.2. Emerging and Advanced Methods

3.2.1. Microwave-Assisted Extraction

3.2.2. Ultrasound-Assisted Extraction

3.2.3. Supercritical Fluid Extraction

3.2.4. Enzyme and Microorganism-Assisted Extraction

4. Transformation of Flavonoids

4.1. Microbial Biotransformation

4.2. Enzyme-Catalyzed Transformation

5. Human Health and Biological Properties

6. Concluding Remarks

Author Contributions

Funding

Conflicts of Interest

References

- Guo, L.; Gao, L.; Ma, X.; Guo, F.; Ruan, H.; Bao, Y.; Wang, Y. Functional analysis of flavonoid 3′-hydroxylase and flavonoid 3′,5′-hydroxylases from tea plant (Camellia sinensis), involved in the B-ring hydroxylation of flavonoids. Gene 2019, 717, 144046. [Google Scholar] [CrossRef]

- Raffa, D.; Maggio, B.; Raimondi, M.V.; Plescia, F.; Daidone, G. Recent discoveries of cancer flavonoids. EJMC 2017, 142, 213–228. [Google Scholar]

- Aherne, S.A.; O’Brien, N.M. Dietary flavonols: Chemistry, food content, and metabolism. Nutrition 2002, 18, 75–81. [Google Scholar] [CrossRef]

- Amri, F.S.; Hossain, M.A. Comparison of total phenols, flavonoids and antioxidant potential of local and imported ripe bananas. EJBAS 2018, 5, 245–251. [Google Scholar] [CrossRef] [Green Version]

- Miao, M.; Cao, L.; Xu, K.; Xin, W.; Zheng, Y. Intervention action of total flavonoids from root of Ilex pubescens in cerebral ischemic tolerance with blood stasis. Saudi J. Biol. Sci. 2017, 24, 729–736. [Google Scholar] [CrossRef]

- Moon, K.M.; Lee, B.; Cho, W.K.; Lee, B.S.; Kim, C.K.; Ma, J.Y. Swertiajaponin as an anti-browning and antioxidant flavonoid. Food Chem. 2018, 252, 207–214. [Google Scholar] [CrossRef]

- Diwan, V.; Brown, L.; Gobe, G.C. The flavonoid rutin improves kidney and heart structure and function in an adenine-induced rat model of chronic kidney disease. J. Funct. Foods 2017, 33, 85–93. [Google Scholar] [CrossRef]

- Geleijnse, J.M.; Launer, L.J.; Van der Kuip, D.A.; Hofman, A.; Witteman, J.C. Inverse association of tea and flavonoid intakes with incident myocardial infarction: The Rotterdam study. AJCN 2002, 75, 880–886. [Google Scholar] [CrossRef]

- Spagnuolo, C.; Moccia, S.; Ruso, G.L. Anti-inflammatory effects of flavonoids in neurodegenerative disorders. EJMC 2018, 153, 105–115. [Google Scholar] [CrossRef]

- Stahl, W.; Ale-Agha, N.; Polidori, M.C. Non-antioxidant properties of carotenoids. JBC 2002, 383, 553–558. [Google Scholar] [CrossRef]

- Xu, M.S.; Chen, S.; Wang, W.Q.; Liu, S.Q. Employing bifunctional enzymes for enhanced extraction of bioactives from plants: Flavonoids as an example. J. Agric. Food Chem. 2013, 61, 7941–7948. [Google Scholar] [CrossRef]

- Zuiter, A.S.; Zarqa, J. Proanthocyanidin: Chemistry and biology: From phenolic compounds to proanthocyanidins. In Reference Module in Chemistry, Molecular Sciences and Chemical Engineering; Reedijk, J., Ed.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 1–29. [Google Scholar]

- Karabin, M.; Hudcova, T.; Jelinek, L.; Dostalek, P. Biotransformation and biological activities of hop flavonoids. Biotech. Adv. 2015, 33, 1063–1090. [Google Scholar] [CrossRef]

- Sharma, V.; Janmeda, P. Extraction, isolation and identification of flavonoid from Euphorbia neriifolia leaves. AJC 2017, 10, 509–514. [Google Scholar] [CrossRef]

- Arora, S.; Itankar, P. Extraction, isolation and identification of flavonoid from Chenopodium album aerial parts. JTCM 2018, 8, 476–482. [Google Scholar] [CrossRef]

- Martens, S.; Mithöfer, A. Flavones and flavone synthases. Phytochemistry 2005, 66, 2399–2407. [Google Scholar] [CrossRef]

- De Villiers, A.; Venter, P.; Pasch, H. Recent advances and trends in the liquid-chromatography-mass spectrometry analysis of flavonoids. J. Chromatogr. A 2016, 1430, 16–78. [Google Scholar] [CrossRef]

- Olagaray, K.E.; Bradford, B.J. Plant flavonoids to improve productivity of ruminants—A review. Anim. Feed Sci. Tech. 2019, 251, 21–36. [Google Scholar] [CrossRef]

- Ververidis, F.; Trantas, E.; Douglas, C.; Vollmer, G.; Kretzschmar, G.; Panopoulos, N. Biotechnology of flavonoids and other phenylpropanoid-derived natural products. Part I: Chemical diversity, impacts on plant biology and human health. Biotechnol. J. 2007, 2, 1214–1234. [Google Scholar] [CrossRef]

- Kale, A.; Gawande, S.; Kotwal, S. Cancer phytotherapeutics: Role for flavonoids at the cellular level. Phytother. Res. 2008, 22, 567–577. [Google Scholar] [CrossRef]

- Cassidy, A.; Kay, C. Phytochemicals: Classification and occurrence. In Encyclopedia of Human Nutrition; Caballero, B., Ed.; Elsevier: Amsterdam, The Netherlands, 2013; pp. 39–46. [Google Scholar]

- Rybarczyk-Plonska, A.; Wold, A.B.; Bengtsson, G.B.; Borge, G.I.A.; Hansen, M.K.; Hagen, S.F. Flavonols in broccoli (Brassica oleracea L. var. italica) flower buds as affected by postharvest temperature and radiation treatments. Postharvest Biol. Technol. 2016, 116, 105–114. [Google Scholar] [CrossRef]

- Cui, B.; Hu, Z.; Zhang, Y.; Hu, J.; Yin, W.; Feng, Y.; Xie, Q.; Chen, G. Anthocyanins and flavonols are responsible for purple color of Lablab purpureus (L.) sweet pods. Plant Physiol. Biochem. 2016, 103, 183–190. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Simon, J.E.; Ferruzzi, M.G.; Ho, L.; Pasinetti, G.M.; Wu, Q. Quantification of anthocyanidins in the grapes and grape juice products with acid assisted hydrolysis using LC/MS. JFF 2012, 4, 710–717. [Google Scholar] [CrossRef]

- Oliveira, J.; Mateus, N.; de Freitas, V. Flavanols: Catechins and proanthocyanidins. In Natural Products; Ramawat, K.G., Mérillon, J.M., Eds.; Springer: Berlin/Heidelberg, Germany, 2013; pp. 1753–1801. [Google Scholar]

- Pons, Z.; Margalef, M.; Bravo, F.I.; Arola-Arnal, A.; Muguerza, B. Grape seed flavanols decrease blood pressure via Sirt-1 and confer a vasoprotective pattern in rats. JFF 2016, 24, 164–172. [Google Scholar] [CrossRef]

- Vuong, Q.V.; Golding, J.B.; Nguyen, M.; Roach, P.D. Extraction and isolation of catechins from tea. JSS 2010, 33, 3415–3428. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.C.; Kim, P.H.; Eun, J.B. Influence of high-intensity ultrasound application on the physicochemical properties, isoflavones composition and antioxidant activity of tofu whey. LWT-Food Sci. Technol. 2020, 117, 108618. [Google Scholar] [CrossRef]

- Duru, K.C.; Kovaleva, E.; Danilova, I.; Belousova, A. Production and assessment of novel probiotic fermented oat flour enriched with isoflavones. LWT-Food Sci. Technol. 2019, 117, 108618. [Google Scholar] [CrossRef]

- Nemitz, M.C.; Argenta, D.F.; Koester, L.S.; Bassani, V.L.; von Poser, G.L.; Teixeira, H.F. The international scenario of patents concerning isoflavones. Trends Food Sci. Technol. 2016, 49, 85–95. [Google Scholar] [CrossRef]

- Ganzera, M. Supercritical fluid chromatography for the separation of isoflavones. J. Pharm. Biomed. Anal. 2015, 107, 364–369. [Google Scholar] [CrossRef]

- Alara, O.R.; Abdurahman, N.H.; Ukaegbu, C.I. Soxhlet extraction pf phenolic compounds from Vernonia cinereal leaves and its antioxidant activity. J. Appl. Res. Med. Aromat. Plants 2018, 11, 12–17. [Google Scholar]

- Sati, P.; Dhyani, P.; Bhatt, I.D.; Pandey, A. Ginkgo biloba flavonoid glycosides in antimicrobial perspective with reference to extraction method. JTCM 2019, 9, 15–23. [Google Scholar] [CrossRef]

- Mackela, I.; Andriekus, T.; Venskutonis, P.R. Biorefinning of buckwheat (Fagopyru, esculentum) hulls by using supercritical fluid, Soxhlet, pressurized liquid and enzyme-assisted extraction methods. JFE 2017, 213, 38–46. [Google Scholar] [CrossRef]

- Cujic, N.; Svikin, K.; Jankovic, T.; Pljevljakusic, D.; Zdunic, G.; Ibric, S. Optimization of polyphenols extraction from dried chokeberry using maceration as traditional technique. Food Chem. 2016, 194, 135–142. [Google Scholar] [CrossRef]

- Pereira, S.V.; Reis, R.A.S.P.; Garbuio, D.C.; de Freitas, L.A.P. Dynamic maceration of Matricaria chamomilla inflorescences: Optimal conditions for flavonoids and antioxidant activity. Rev. Bras. Farmacogn. 2018, 28, 111–117. [Google Scholar] [CrossRef]

- Agustin-Salazar, S.; Medina-Juárez, L.A.; Soto-Valdez, H.; Manzanares-López, F.; Gámez-Meza, N. Influence of the solvent system on the composition of phenolic substances and antioxidant capacity of extracts of grape (Vitis vinifera L.) marc. AJGWR 2014, R20, 208–213. [Google Scholar] [CrossRef]

- Albuquerque, B.R.; Prieto, M.A.; Vazquez, J.A.; Barreirio, M.F.; Barros, L.; Ferreira, I.C.F.R. Recovery of bioactive compounds form Arbutus unedo L. fruits: Comparative optimization study of maceration/microwave/ultrasound extraction techniques. Food Res. Int. 2018, 109, 455–471. [Google Scholar] [CrossRef] [Green Version]

- Farzaneth, V.; Carvalho, I.S. Modelling of Microwave Assisted Extraction (MAE) of Anthocyanins (TMA). JARMAP 2017, 6, 92–100. [Google Scholar]

- Ye, C.L.; Liu, X.G. Extraction of flavonoids from Tetrastigma hemsleyanum diels et gilg and their antioxidant activity. JFPP 2015, 39, 2197–2205. [Google Scholar]

- Safdar, M.N.; Kausar, T.; Jabbar, S.; Mumtaz, A.; Ahad, K.; Saddozai, A.A. Extraction and quantification of polyphenols from kinnow (Citrus reticulate L.) peel using ultrasound and maceration techniques. JFDA 2017, 25, 488–500. [Google Scholar] [CrossRef] [Green Version]

- Bergeron, C.; Gafner, S.; Clausen, E.; Carrier, D.J. Comparison of the Chemical Composition of Extracts from Scutellaria lateriflora Using Accelerated Solvent Extraction and Supercritical Fluid Extraction versus Standard Hot Water or 70% Ethanol Extraction. J. Agric. Food Chem. 2005, 53, 3076–3080. [Google Scholar] [CrossRef]

- Yu, M.; Wang, B.; Qi, Z.; Xin, G.; Li, Q. Response Surface method was used to optimize the ultrasonic assisted extraction of flavonoids from Crinum asiaticum. Saudi J. Biol. Sci. 2019, 26, 2079–2084. [Google Scholar] [CrossRef]

- Daud, M.N.H.; Fatanah, D.N.; Abdullah, N.; Ahmad, R. Evaluation of antioxidant potential of Artocarpus heterophyllus L. J33 variety fruit waste from different extraction methods and identification of phenolic constituents by LCMS. Food Chem. 2017, 232, 621–632. [Google Scholar] [CrossRef] [PubMed]

- Szewczyk, K.; Olech, M. Optimization of extraction method for LC-MS based determination of phenolic acid profiles in different Impatiens species. Phytochem. Lett. 2017, 20, 322–330. [Google Scholar] [CrossRef]

- Wu, X.; Beecher, G.R.; Holden, J.M.; Haytowitz, D.B.; Gebhardt, S.E.; Prior, R.L. Lipophilic and Hydrophilic Antioxidant Capacities of Common Foods in The United States. J. Agric. Food Chem. 2004, 52, 4026–4037. [Google Scholar] [CrossRef]

- Rafińska, K.; Pomastowski, P.; Rudnicka, J.; Krakowska, A.; Maruska, A.; Narkute, M.; Buszewski, B. Effect of solvent and extraction technique on composition and biological activity of Lepidium sativum extracts. Food Chem. 2019, 289, 16–25. [Google Scholar] [CrossRef] [PubMed]

- Ku, C.S.; Jang, J.P.; Mun, S.P. Exploitation of polyphenol-rich pine barks for potent antioxidant activity. J. Wood Sci. 2007, 53, 524–528. [Google Scholar] [CrossRef]

- Bahorun, T.; Luximon-Ramma, A.; Crozier, A.; Aruoma, O.I. Total phenol, flavonoid, proanthocyanidin and vitamin C levels and antioxidant activities of Mauritian vegetables. J. Sci. Food Agric. 2004, 84, 1553–1561. [Google Scholar] [CrossRef]

- Chu, Y.-F.; Sun, J.; Wu, X.; Liu, R.H. Antioxidant and Antiproliferative Activities of Common Vegetables. J. Agric. Food Chem. 2002, 50, 6910–6916. [Google Scholar] [CrossRef]

- Zhang, D.; Hamauzu, Y. Phenolics, ascorbic acid, carotenoids and antioxidant activity of broccoli and their changes during conventional and microwave cooking. Food Chem. 2004, 88, 503–509. [Google Scholar] [CrossRef]

- Anokwuru, C.P.; Anyasor, G.N.; Ajibaye, O.; Fakoya, O.; Okebugwu, P. Effect of extraction solvents on phenolic, flavonoid and antioxidant activities of three nigerian medicinal plants. Nat. Sci. 2011, 9, 53–61. [Google Scholar]

- Vieitez, I.; Maceiras, L.; Jachmanián, I.; Alborés, S. Antioxidant and antibacterial activity of different extracts from herbs obtained by maceration or supercritical technology. JSF 2018, 133, 58–64. [Google Scholar] [CrossRef]

- Moreira, M.M.; Barroso, M.F.; Boeykens, A.; Withouck, H.; Morais, S.; Delerue-Matos, C. Valorization of apple tree wood residues by polyphenols extraction: Comparison between conventional and microwave-assisted extraction. Ind. Crop. Prod. 2017, 104, 210–220. [Google Scholar] [CrossRef] [Green Version]

- Aspé, E.; Fernández, K. The effect of different extraction techniques on extraction yield, total phenolic, and anti-radical capacity of extracts from Pinus radiata Bark. Ind. Crop. Prod. 2011, 34, 838–844. [Google Scholar] [CrossRef]

- Lamounier, K.C.; Cunha, L.C.S.; de Morais, S.A.L.; de Aquino, F.J.T.; Chang, R.; do Nascimento, E.A.; de Souza, M.G.M.; Martins, C.H.G.; Cunha, W.R. Chemical analysis and study of phenolics, antioxidant activity, and antibacterial effect of the wood and bark of Maclura tinctoria (L.) D. Don ex Steud. Altern. Med. 2012, 2012, 1–7. [Google Scholar]

- Zhu, H.B.; Wang, Y.Z.; Liu, Y.X.; Xia, Y.L.; Tang, T. Analysis of flavonoids in Portulaca oleracea L. by uv-vis spectrophotometry with comparative study on different extraction technologies. Food Anal. Methods 2010, 3, 90–97. [Google Scholar] [CrossRef]

- Li, H.; Deng, Z.; Wu, T.; Liu, R.; Loewen, S.; Tsao, R. Microwave-assisted extraction of phenolics with maximal antioxidant activities in tomatoes. Food Chem. 2012, 130, 928–936. [Google Scholar] [CrossRef]

- Cardoso-Ugarte, G.A.; Juárez-Becerra, G.P.; Sosa-Morales, M.E.; López-Malo, A. Microwave-assisted Extraction of Essential Oils from Herbs. JMPEE 2013, 47, 63–72. [Google Scholar] [CrossRef]

- Casazza, A.A.; Aliakbarian, B.; Mantegna, S.; Cravotto, G.; Perego, P. Extraction of phenolics from Vitis vinífera wastes using non-conventional techniques. J. Food Eng. 2010, 100, 50–55. [Google Scholar] [CrossRef]

- Pan, Y.M.; He, C.H.; Wang, H.S.; Ji, X.W.; Wang, K.; Liu, P.Z. Antioxidant activity of microwave-assisted extract of Buddleia officinalis and its major active component. Food Chem. 2010, 121, 497–502. [Google Scholar] [CrossRef]

- Feng, R.Z.; Wang, Q.; Tong, W.Z.; Xiong, J.; Wei, Q.; Zhou, W.H.; Yin, Z.Q.; Yin, X.Y.; Wang, L.Y.; Chen, Y.Q.; et al. Extraction and antioxidant activity of flavonoids of Morus nigra. Int. J. Clin. Exp. Med. 2015, 8, 22328–22336. [Google Scholar]

- Alara, O.R.; Abdurahman, N.H.; Olalere, O.A. Optimization of microwave-assisted extraction of flavonoids antioxidants from Vernonia amygdalina leaf using response surface methodology. Food Bioprod. Process. 2018, 107, 36–48. [Google Scholar] [CrossRef] [Green Version]

- Bimakr, M.; Rahman, R.A.; Taip, F.S.; Ganjloo, A.; Salleh, L.M.; Selamat, J.; Hamid, A.; Zaidul, I.S.M. Comparison of different extraction methods for the extraction of major bioactive flavonoid compounds from spearmint (Mentha spicata L.) leaves. Food Bioprod. Process. 2011, 89, 67–72. [Google Scholar] [CrossRef]

- Hartonen, K.; Parshintsev, J.; Sandberg, K.; Bergelin, E.; Nisula, L.; Riekkola, M.L. Isolation of flavonoids from aspen knotwood by pressurized hot water extraction and comparison with other extraction techniques. Talanta 2007, 74, 32–38. [Google Scholar] [CrossRef] [PubMed]

- Jha, P.; Das, A.J.; Deka, S.C. Optimization of ultrasound and microwave assisted extractions of polyphenols from black rice (Oryza sativa cv. Poireton) husk. J. Food Sci. Technol. 2017, 54, 3847–3858. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-Pérez, C.; Gilbert-López, B.; Mendiola, J.A.; Quirantes-Piné, R.; Segura-Carretero, A.; Ibáñez, E. Optimization of microwave-assisted extraction and pressurized liquid extraction of phenolic compounds from Moringa oleifera leaves by multi-response surface methodology. Electrophoresis 2016, 37, 1938–1946. [Google Scholar] [CrossRef]

- Zekovic, Z.; Vladic, J.; Vidovic, S.; Adamovic, D.; Pavlic, B. Optimization of microwave-assisted extraction (MAE) of coriander phenolic antioxidants—Response surface methodology approach. J. Sci. Food Agric. 2016, 96, 4613–4622. [Google Scholar] [CrossRef] [PubMed]

- Bouras, M.; Chadni, M.; Barba, F.J.; Grimi, N.; Bals, O.; Vorobiev, E. Optimization of microwave-assisted extraction of polyphenols from Quercus bark. Ind. Crop. Prod. 2015, 77, 590–601. [Google Scholar] [CrossRef]

- The, S.S.; Niven, B.E.; Bekit, A.E.A.; Carne, A.; Birch, E.J. Microwave and pulsed electric field extraction of polyphenols from defatted canola seeds cake. Int. J. Food Sci. Technol. 2015, 50, 1109–1115. [Google Scholar]

- Liazid, A.; Guerrero, R.F.; Cantos, E.; Palma, M.; Barroso, C.G. Microwave assisted extraction of anthocyanins from grape skins. Food Chem. 2011, 124, 1238–1243. [Google Scholar] [CrossRef]

- Tan, S.N.; Yong, J.W.H.; Teo, C.C.; Ge, L.; Chan, Y.W.; Hew, C.S. Determination of metabolites in Uncaria sinensis by HPLC and GC-MS after green solvent microwave-assisted extraction. Talanta 2011, 83, 891–898. [Google Scholar] [CrossRef]

- Inoue, T.; Tsubaki, S.; Ogawa, K.; Onishi, K.; Azuma, J.I. Isolation of hesperidin from peels of thinned Citrus unshiu fruits by microwave-assisted extraction. Food Chem. 2010, 123, 542–547. [Google Scholar] [CrossRef]

- Li, J.; Zu, Y.G.; Fu, Y.J.; Yang, Y.C.; Li, S.M.; Li, Z.N.; Wink, M. Optimization of microwave-assisted extraction of triterpene saponins from defatted residue of yellow horn (Xanthoceras sorbifolia Bunge.) kernel and evaluation of its antioxidant activity. Innov. Food Sci. Emerg. Technol. 2010, 11, 637–643. [Google Scholar] [CrossRef]

- Ballard, T.S.; Mallikarjunan, P.; Zhou, K.; O’Keefe, S. Microwave-assisted extraction of phenolic antioxidant compounds from peanut skins. Food Chem. 2010, 120, 1185–1192. [Google Scholar] [CrossRef]

- Kong, Y.; Zu, Y.-G.; Fu, Y.-J.; Liu, W.; Chang, F.-R.; Li, J.; Chen, Y.-H.; Zhang, S.; Gu, C.-B. Optimization of microwave-assisted extraction of cajaninstilbene acid and pinostrobin from pigeonpea leaves followed by RP-HPLC-DAD determination. J. Food Compos. Anal. 2010, 23, 382–388. [Google Scholar] [CrossRef]

- Yang, Z.; Zhai, W. Optimization of microwave-assisted extraction of anthocyanins from purple corn (Zea mays L.) cob and identification with HPLC–MS. Innov. Food Sci. Emerg. Technol. 2010, 11, 470–476. [Google Scholar] [CrossRef]

- Wang, Y.L.; Xi, G.S.; Zheng, Y.C.; Miao, F.S. Microwave-assisted extraction of flavonoids from Chinese herb Radix puerariae (Ge Gen). J. Med. Plants Res. 2010, 4, 304–308. [Google Scholar]

- Périno-Issartier, S.; Zille, H.; Abert-Vian, M.; Chemat, F. Solvent free microwave-assisted extraction of antioxidants from sea buckthorn (Hippophae rhamnoides) food by-products. Food Bioprocess. Technol. 2010, 4, 1020–1028. [Google Scholar] [CrossRef]

- Tsubaki, S.; Sakamoto, M.; Azuma, J. Microwave-assisted extraction of phenolic compounds from tea residues under autohydrolytic conditions. Food Chem. 2010, 123, 1255–1258. [Google Scholar] [CrossRef]

- Victório, C.P.; Lage, C.L.S.; Kuster, R.M. Flavonoid extraction from Alpinia zerumbet (Pers.) Burtt et Smith leaves using different techniques and solvents. Eclet. Quim. 2009, 34, 19–24. [Google Scholar]

- Yang, L.; Jiang, J.-G.; Li, W.-F.; Chen, J.; Wang, D.-Y.; Zhu, L. Optimum extraction Process of polyphenols from the bark of Phyllanthus emblica L. based on the response surface methodology. J. Sep. Sci. 2009, 32, 1437–1444. [Google Scholar] [CrossRef]

- Hayat, K.; Hussain, S.; Abbas, S.; Farooq, U.; Ding, B.; Xia, S.; Jia, C.; Zhang, X.; Xia, W. Optimized microwave-assisted extraction of phenolic acids from citrus mandarin peels and evaluation of antioxidant activity in vitro. Sep. Purif. Technol. 2009, 70, 63–70. [Google Scholar] [CrossRef]

- Zheng, X.; Wang, X.; Lan, Y.; Shi, J.; Xue, S.J.; Liua, C. Application of response surface methodology to optimize microwave-assisted extraction of silymarin from milk thistle seeds. Sep. Purif. Technol. 2009, 70, 34–40. [Google Scholar] [CrossRef]

- Li, W.; Li, T.; Tang, K. Flavonoids from mulberry leaves by microwave-assisted extract and anti-fatigue activity. Afr. J. Agric. Res. 2009, 4, 898–902. [Google Scholar]

- Vian, M.A.; Maingonnat, J.F.; Chemat, F. Clean recovery of antioxidant flavonoids from onions: Optimising solvent free microwave extraction method. J. Chroma A 2009, 1216, 7700–7707. [Google Scholar]

- Chen, L.; Jin, H.; Ding, L.; Zhang, H.; Li, J.; Qu, C. Dynamic microwave-assisted extraction of flavonoids from Herba epimedii. Sep. Purif. Technol. 2008, 59, 50–57. [Google Scholar] [CrossRef]

- Wang, J.X.; Xiao, X.H.; Li, G.K. Study of vacuum microwave-assisted extraction of polyphenolic compounds and pigment from Chinese herbs. J. Chroma A 2008, 1198–1199, 45–53. [Google Scholar] [CrossRef] [PubMed]

- Xiao, W.; Han, L.; Shi, B. Microwave-assisted extraction of flavonoids from Radix astragali. Sep. Purif. Technol. 2008, 62, 614–618. [Google Scholar] [CrossRef]

- Chen, L.G.; Ding, L.; Yu, A.M.; Yang, R.L.; Wang, X.P.; Li, J.T.; Jin, H.Y.; Zhang, H.Q. Continuous determination of total flavonoids in Platycladus orientalis (L.) Franco by dynamic microwave-assisted extraction coupled with on-line derivatization and ultraviolet-visible detection. Anal. Chim. Acta 2007, 596, 164–170. [Google Scholar] [CrossRef]

- Liu, Z.; Ding, L.; Zhang, H.; Hu, X.; Bu, F. Comparison of the different extraction methods of flavonoids in Epimedium koreamum Nakai by HPLC-DAD-ESI-MSn. J. Liq. Chromatogr. Relat. Tech. 2006, 29, 719–731. [Google Scholar] [CrossRef]

- Japón-Luján, R.; Luque-Rodríguez, J.M.; Luque de Castro, M.D. Multivariate optimisation of the microwave-assisted extraction of oleuropein and related biophenols from olive leaves. Anal. Bioanal. Chem. 2006, 385, 753–759. [Google Scholar]

- Liu, Z.; Yan, G.; Bu, F.; Sun, J.; Hu, X.; Zhang, H. Analysis of chemical composition of Acanthopanax senticosusleaves applying high-pressure microwave-assisted extraction. Chem. Anal. 2005, 50, 851–861. [Google Scholar]

- Li, H.; Chen, B.; Zhang, Z.; Yao, S. Focused microwave-assisted solvent extraction and HPLC determination of effective constituents in Eucommia ulmodies Oliv. (E. ulmodies). Talanta 2004, 63, 659–665. [Google Scholar] [CrossRef]

- Williams, G.J.; Zhang, C.; Thorson, J.S. Expanding the promiscuity of a natural-product glycosyltransferase by directed evolution. Nat. Chem. Biol. 2007, 3, 657–662. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, T.M.S.; dos Santos, J.A.; Modesto, L.A.; Souza, L.S.; dos Santos, M.P.; Bezerra, D.G.; de Paula, J.A.M. An eco-friendly method for extraction and quantification of flavonoids in Dysphania ambrosioides. Braz. J. Pharmacogn. 2019, 29, 266–270. [Google Scholar] [CrossRef]

- Um, M.; Han, T.H.; Lee, J.W. Ultrasound-assisted extraction and antioxidant activity of phenolic and flavonoid compounds and ascorbic acid from rugosa rose (Rosa rugosa Thunb.) fruit. Food Sci. Biotech. 2018, 27, 375–382. [Google Scholar] [CrossRef]

- Maran, J.P.; Manikandan, S.; Nivetha, C.V.; Dinesh, R. Ultrasound assisted extraction of bioactive compounds from Nephelium lappaceum L. fruit peel using central composite face centered response surface design. Arab. J. Chem. 2017, 10, S1145–S1157. [Google Scholar] [CrossRef] [Green Version]

- Ghasemzadeh, A.; Jaafar, H.; Karimi, E.; Rahmat, A. Optimization of ultrasound-assisted extraction of flavonoid compounds and their pharmaceutical activity from curry leaf (Murraya koenigii L.) using response surface methodology. BMC Complement. Altern. Med. 2014, 14, 318. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, C.; Li, Y.; Yao, L.; Wu, G.; Chang, J.; Shu, C.; Chen, M. Optimization of ultrasonic-assisted extraction of flavonoid from Portulaca oleracea L. by response surface methodology and chemical composition analysis. J. Korean Soc. Appl. Biol. Chem. 2014, 57, 647–653. [Google Scholar] [CrossRef]

- Memon, A.A.; Memon, N.; Luthria, D.L.; Bhanger, M.I.; Pitafi, A.A. Phenolic Acids Profiling and Antioxidant Potential of Mulberry (Morus laevigata W., Morus nigra L., Morus alba L.) Leaves and Fruits Grown in Pakistan. Pol. J. Food Nutr. Sci. 2010, 60, 25–32. [Google Scholar]

- Babova, O.; Occhipintia, A.; Capuzzo, A.; Maffei, M.E. Extraction of bilberry (Vaccinium myrtillus) antioxidants using supercritical/subcritical CO2 and ethanol as co-solvent. J. Supercrit. Fluids 2016, 107, 358–363. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Yang, B.; Du, X.; Yi, C. Optimisation of supercritical extraction of flavonoids from Pueraria lobata. Food Chem. 2008, 108, 737–741. [Google Scholar] [CrossRef]

- Chen, Y.; Xie, M.-Y.; Gong, X.F. Microwave-assisted extraction used for the isolation of total triterpenoid saponins from Ganoderma atrum. J. Food Eng. 2007, 81, 162–170. [Google Scholar] [CrossRef]

- Flórez, N.; Conde, E.; Domínguez, H. Microwave assisted water extraction of plant compounds. J. Chem. Technol. Biotech. 2015, 90, 590–607. [Google Scholar] [CrossRef]

- Krishnan, R.Y.; Chandran, M.N.; Vadivel, V.; Rajan, K.S. Insights on the influence of microwave irradiation on the extraction of flavonoids from Terminalia chebula. Sep. Purif. Technol. 2016, 170, 224–233. [Google Scholar] [CrossRef]

- Cassol, L.; Rodrigues, E.; Noreña, C.P.Z. Extracting phenolic compounds from Hibiscus sabdariffa L. calyx using microwave assisted extraction. Ind. Crop. Prod. 2019, 133, 168–177. [Google Scholar] [CrossRef]

- Akbari, S.; Abdurahman, N.H.; Yunus, R.M.; Fayaz, F. Microwave-assisted extraction of saponin, phenolic and flavonoid compounds from Trigonella foenum-graecum seed based on two level factorial design. J. Appl. Res. Med. Aromat. Plants 2019, 14, 100212. [Google Scholar] [CrossRef]

- Ling, Y.Y.M.; Fun, P.S.; Yeop, A.; Yusoff, M.M.; Gimbun, J. Assessment of maceration, ultrasonic and microwave assisted extraction for total phenolic content, total flavonoid content and Kaempferol yield form Cassia alata via Microstructures Analysis. Mater. Today Proc. 2019, 19, 1273–1279. [Google Scholar] [CrossRef]

- Tomaz, I.; Maslov, L.; Stupic, D.; Prenier, D.; Asperger, D.; Karoglan Kontić, J. Multi-response optimization of ultrasound-assisted extraction for recovery of flavonoids from red grape skins using response surface methodology. Phytochem. Anal. 2015, 27, 13–22. [Google Scholar] [CrossRef]

- Castro-López, C.; Rojas, R.; Sánchez-Alejo, E.J.; Niño-Medina, G.; Martínez-Ávila, G.C.G. Phenolic Compounds Recovery from Grapefruit and By- Products: An Overview of Extraction Methods, Grape and Wine Biotechnology, Antonio Morata and Iris Loira; IntechOpen: London, UK, 2016. [Google Scholar] [CrossRef]

- Chludil, H.D.; Corbino, G.B.; Leicach, S.R. Soil Quality Effects on Chenopodium album Flavonoid Content and Antioxidant Potential. J. Agric. Food Chem. 2008, 56, 5050–5056. [Google Scholar] [CrossRef]

- Wang, X.H.; Wang, J.P. Effective extraction with deep eutectic solvents and enrichment by microporous adsorption resin of flavonoids from Carthamus tinctorius L. J. Pharm. Biomed. 2019, 176, 112804. [Google Scholar] [CrossRef]

- Chen, M.C.A.J.; Zhang, H.; Li, Z.; Zhao, L.; Qiu, H. Effective extraction of flavonoids from Lycium barbarum L. fruits by deep eutectic solvents-based ultrasound-assisted extraction. Talanta 2019, 203, 16–22. [Google Scholar]

- Singanusong, R.; Nipornram, S.; Tochampa, W.; Rattanatraiwong, P. Low Power Ultrasound-Assisted Extraction of Phenolic Compounds from Mandarin (Citrus reticulata Blanco cv. Sainampueng) and Lime (Citrus aurantifolia) Peels and the Antioxidant. Food Anal. Methods 2015, 8, 1112–1123. [Google Scholar] [CrossRef]

- Piana, F.; Ciulu, M.; Quirantes-Piné, R.; Sanna, G.; Segura-Carretero, A.; Spano, N.; Mariani, A. Simple and rapid procedures for the extraction of bioactive compounds from Guayule leaves). Ind. Crop. Prod. 2018, 116, 162–169. [Google Scholar] [CrossRef]

- Nagendra-Prasad, K.; Yang, B.; Zhao, M.; Ruenroengklin, N.; Jiang, Y. Application of ultrasonication or high-pressure extraction of flavonoids from litchi fruit pericarp. J. Food Process. Eng. 2009, 32, 828–843. [Google Scholar] [CrossRef]

- Zhang, Q.A.; Fan, X.H.; Li, T.; Zhang, Z.Q.; Liu, Y.K.; Li, X.P. Optimization of ultrasound extraction for flavonoids from semen astragali complanati and its identification by HPLC-DAD-MS/MS. Int. J. Food Sci. Technol. 2013, 48, 1970–1976. [Google Scholar] [CrossRef]

- Xie, Z.; Sun, Y.; Lam, S.; Zhao, M.; Liang, Z.; Yu, X.; Yang, D.; Xu, X. Extraction and isolation of flavonoid glycosides from Flos Sophorae Immaturus using ultrasonic-assisted extraction followed by high-speed countercurrent chromatography. J. Sep. Sci. 2014, 37, 957–965. [Google Scholar] [CrossRef] [PubMed]

- Dassoff, E.S.; Li, Y.O. Mechanisms and effects of ultrasound-assisted supercritical CO2 extraction. Trends Food Sci. Tech. 2019, 86, 492–501. [Google Scholar] [CrossRef]

- Román Páez, M.; Rivera Narváez, C.; Cardona Bermúdez, L.; Muñoz, L.; Gómez, D.; Passaro Carvalho, C.; Quiceno Rico, J. Guía de Extracción por Fluidos Supercríticos: Fundamentos y Aplicaciones; Servicio Nacional de Aprendizaje—SENA: Rionegro, Colombia, 2016. [Google Scholar]

- Verma, D.K.; Dhakane, J.P.; Mahato, D.K.; Billoria, S.; Bhattacharjee, P.; Srivastav, P.P. Supercritical Fluid Extraction (SCFE) for Rice Aroma Chemicals: Recent and Advance Extraction Method. In Science and Technology of Aroma, Flavour and Fragrance in Rice; Verma, D.K., Srivastav, P.P., Eds.; Apple Academic Press: Waretown, NJ, USA, 2018; pp. 179–198. [Google Scholar]

- Belbaki, A.; Louaer, W.; Menial, A.H. Supercritical CO2 extraction of oil from Crushed Algerian olives. J. Supercrit. Fluids 2017, 130, 165–171. [Google Scholar] [CrossRef]

- Kavoura, D.; Kyriakopoulou, K.; Papaefstahiou, G.; Spanidi, E.; Gardikis, K.; Louli, V.; Aligiannis, N.; Krokida, M.; Magoulas, K. Supercritical CO2 extraction of Salvia fruticosa. J. Supercrit. Fluids 2019, 146, 159–164. [Google Scholar] [CrossRef]

- Song, L.; Liu, P.; Yan, Y.; Huang, Y.; Bai, B.; Hou, X.; Zhang, L. Supercritical CO2 fluid extraction of flavonoid compounds from Xinjiang jujube (Ziziphus jujube Mill.) leaves and associated biological activities and flavonoid compositions. Ind. Crop. Prod. 2019, 139, 111508. [Google Scholar] [CrossRef]

- Panja, P. Green extraction methods of food polyphenols from vegetable materials. Curr. Opin. Food Sci. 2018, 23, 173–182. [Google Scholar] [CrossRef]

- Alvarez, M.; Cabred, S.; Ramírez, C.; Fanovich, M. Valorization of an agroindustrial soybean residue by supercritical flfluid extraction of phytochemical compounds. J. Supercrit. Fluids 2019, 143, 90–96. [Google Scholar] [CrossRef]

- Ouédraogo, J.C.; Dicko, C.; Kini, F.; Bonzi-Coulibaly, Y.; Dey, E. Enhanced extraction of flflavonoids from Odontonema strictum leaves with antioxidant activity using supercritical carbon dioxide flfluid combined with ethanol. J. Supercrit. Fluids 2018, 131, 66–71. [Google Scholar] [CrossRef]

- Krakowska, A.; Rafinska, K.; Walczak, J.; Buszewski, B. Enzyme-assisted optimized supercritical flfluid extraction to improve Medicago sativa polyphenolics isolation. Ind. Crop. Prod. 2018, 124, 931–940. [Google Scholar] [CrossRef]

- Kala, H.K.; Mehta, R.; Sen, K.K.; Tandey, R.; Mandal, V. Critical analysis of research trends and issues in microwave assisted extraction of phenolics: Have we really done enough. Trends Anal. Chem. 2016, 85, 140–152. [Google Scholar] [CrossRef]

- Ilina, A.D. The use of enzymes and microorganisms for solving fundamental and applied problems. Herald of the Russian Academy of Sciences. Rep. Bashortostan 2013, 18, 40–43. [Google Scholar]

- Zha, J.; Wu, X.; Gong, G.; Koffas, M.A.G. Pathway enzyme engineering for flavonoid production in recombinant microbes. Metab. Eng. Commun. 2019, 9, e00104. [Google Scholar] [CrossRef]

- Castro-Vazquez, L.; Alañón, M.E.; Rodríguez-Robledo, V.; Pérez-Coello, M.S.; Hermosín-Gutierrez, I.; Díaz-Maroto, M.C.; Jordán, J.; Galindo, M.F.; Arroyo-Jimenez, M.D.M. Bioactive flavonoids, antioxidant behaviour, and cytoprotective effects of dried grapefruit peels (Citrus paradisi macf.). Oxid. Med. Cell. Longev. 2016. [Google Scholar] [CrossRef] [Green Version]

- Lagaert, S.; Belien, T.; Volckaert, G. Plant cell walls: Protecting the barrier form degradation by microbial enzymes. Semin. Cell Dev. Biol. 2009, 20, 1064–1073. [Google Scholar] [CrossRef]

- Landbo, A.K.; Meyer, A.S. Enzyme-assisted extraction of antioxidative phenols from black currant juice press residues (Ribes nigrum). J. Agric. Food Chem. 2001, 49, 3169–3177. [Google Scholar] [CrossRef]

- Kammerer, D.; Claus, A.; Schieber, A.; Carle, R. A novel process for the recovery of polyphenols from grape (Vitis vinifera L.) pomace. J. Food Sci. 2005, 70, C157–C163. [Google Scholar] [CrossRef]

- Maier, T.; Göppert, A.; Kammerer, D.R.; Schieber, A.; Carle, R. Optimization of a process for enzyme-assisted pigment extraction from grape (Vitis vinifera L.) pomace. EFRT 2008, 227, 267–275. [Google Scholar] [CrossRef]

- Fu, Y.J.; Liu, W.; Zu, Y.G.; Tong, M.H.; Li, S.M.; Yan, M.M.; Efferth, T.; Luo, H. Enzyme assisted extraction of luteolin and apigenin from pigeonpea [Cajanus cajan (L.) Millsp.] leaves. Food Chem. 2008, 111, 508–512. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhou, M.M.; Chen, P.L.; Cao, Y.Y.; Tan, X.L. Optimization of ultrasonic-assisted enzymatic hydrolysis for the extraction of luteolin and apigenin from celery. J. Food Sci. 2011, 76, C680–C685. [Google Scholar] [CrossRef] [PubMed]

- Pan, M.; Wang, S.K.; Yuan, X.L.; Xie, R.Y.; Hong, Y.C.; Liu, H.J. Process study on the ultrasonic assisted enzymatic extraction of flavonoids from shepherd’s purse. Adv. Mater. Res. 2013, 634, 1281–1286. [Google Scholar] [CrossRef]

- Tchabo, W.; Ma, Y.; Engmann, F.N.; Zhang, H. Ultrasound-assisted enzymatic extraction (UAEE) of phytochemical compounds from mulberry (Morus nigra) must and optimization study using response surface methodology. Ind. Crop. Prod. 2015, 63, 214–225. [Google Scholar] [CrossRef]

- Wu, D.; Gao, T.; Yang, H.; Du, Y.; Li, C.; Wei, L.; Zhou, T.; Lu, J.; Bi, H. Simultaneous microwave/ultrasonic-assisted enzymatic extraction of antioxidant ingredients from Nitraria tangutorun Bobr. juice by-products. Ind. Crop. Prod. 2015, 66, 229–238. [Google Scholar] [CrossRef]

- Tomaz, I.; Maslov, L.; Stupić, D.; Preiner, D.; Ašperger, D.; Kontić, J.K. Recovery of flavonoids from grape skins by enzyme-assisted extraction. Sep. Sci. Technol. 2016, 51, 255–268. [Google Scholar] [CrossRef]

- Chávez-Santoscoy, R.A.; Lazo-Vélez, M.A.; Serna-Sáldivar, S.O.; Gutiérrez-Uribe, J.A. Delivery of flavonoids and saponins from black bean (Phaseolus vulgaris) seed coats incorporated into whole wheat bread. Int. J. Mol. Sci. 2016, 17, 222. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xu, S.L.; Zhu, K.Y.; Bi, C.W.; Yan, L.; Men, S.W.; Dong, T.T.; Tsim, K.W. Flavonoids, derived from traditional chinese medicines, show roles in the differentiation of neurons: Possible targets in developing health food products. Birth Defects Res. Part C Embryo Today 2013, 99, 292–299. [Google Scholar] [CrossRef]

- Chen, S.; Xing, X.H.; Huang, J.J.; Xu, M.S. Enzyme-assisted extraction of flavonoids from Ginkgo biloba leaves: Improvement effect of flavonol transglycosylation catalyzed by Penicillium decumbens cellulase. Enzym. Microb. Tech. 2011, 48, 100–105. [Google Scholar] [CrossRef]

- Huynh, N.T.; Van Camp, J.; Smagghe, G.; Raes, K. Improved release and metabolism of flavonoids by steered fermentation processes: A review. Int. J. Mol. Sci. 2014, 15, 19369–19388. [Google Scholar] [CrossRef]

- Cao, H.; Chen, X.; Jassbim, A.R.; Xiao, J. Microbial biotransformation of bioactive flavonoids. Biotech. Adv. 2015, 33, 214–223. [Google Scholar] [CrossRef] [PubMed]

- Frauzino-Araújo, K.C.; de, M.B.; Costa, E.M.; Pazini, F.; Valadares, M.C.; de Oliveira, V. Bioconversion of quercetin and rutin and the cytotoxicity activities of the transformed products. Food Chem. Toxicol. 2013, 51, 93–96. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.H.; Oh, E.T.; Chun, S.C.; Keum, Y.S. Biotransformation of isoflavones by Aspergillus niger and Cuuninghamella elegans. J. Korean Soc. Appl. Biol. Chem. 2014, 57, 523–527. [Google Scholar] [CrossRef]

- Xin, X.; Fan, G.J.; Sun, Z.; Li, Y.; Lan, R.; Chen, L.; Dong, P. Biotransformation of major flavonoid glycosides in herb epimedii by fungus Cunninghamella blakesleana. J. Mol. Catal. B Enzym. 2015, 122, 141–146. [Google Scholar] [CrossRef]

- Jin, S.; Wang, W.; Luo, M.; Mu, F.S.; Li, C.Y.; Fu, Y.J.; Zu, Y.G.; Feng, C. Enhanced extraction genistein from pigeon pea [Cajanus cajan (L.) Millsp.] roots with the biotransformation of immobilized edible Aspergillus oryzae and Monacus anka and antioxidant activity evaluation. Process Biochem. 2013, 48, 1285–1292. [Google Scholar] [CrossRef]

- Huynh, T.N.; Smagghe, G.; Gonzales, G.B.; Camp, J.V.; Raes, K. Extraction and bioconversion of kaempferol metabolites from cauliflower outer leaves through fungal fermentation. Biochem. Eng. J. 2016, 116, 27–33. [Google Scholar] [CrossRef]

- Madeira, J.V., Jr.; Mayumi-Nakajima, V.; Alves-Macedo, J.; Alves-Macedo, G. Rich bioactive phenolic extract production by microbial transformation of Brazilian Citrus residues. Chem. Eng. Res. Des. 2014, 92, 1802–1810. [Google Scholar] [CrossRef]

- Stahlhut, S.G.; Siedler, S.; Malla, S.; Harrison, S.J.; Maury, J.; Neves, A.R.; Forster, J. Assembly of a novel biosynthetic pathway for production of the plant flavonoid fisetin in Escherichia coli. Metab. Eng. 2015, 31, 84–93. [Google Scholar] [CrossRef] [Green Version]

- Chiang, C.M.; Ding, H.Y.; Lu, J.Y.; Chang, T.S. Biotransformation of isoflavones daidzein and genistein by recombinant Pichia pastoris expressing membrane-anchoring and reductase fusion chimeric CYP105D7. J. Taiwan Inst. Chem. Eng. 2016, 60, 26–31. [Google Scholar] [CrossRef]

- Yu, L.; Gao, F.; Yang, L.; Xu, L.; Wang, Z.; Ye, H. Biotransformation of puerarin into puerarin-6´´-O-phosphate by Bacillus cereus. J. Ind. Microbiol. Biotech. 2012, 39, 299–305. [Google Scholar] [CrossRef]

- Sordon, A.; Poplonski, J.; Tronina, T.; Huszcza, E. Regioselective O-glycosylation of flavonoids by fungi Beauveraia bassiana, Absidia coerulea and Absidia glauca. Bioorg. Chem. 2019, 93, 102750. [Google Scholar] [CrossRef] [PubMed]

- Bok, S.H.; Jeong, T.S.; Lee, S.K.; Kim, J.R.; Moon, S.S.; Choi, M.S.; Hyun, B.H.; Lee, C.H.; Choi, Y.K. Flavanone Derivatives and Composition for Preventing or Treating Blood Lipid Level-Related Diseases Comprising Same. U.S. Patent 6455577, 24 September 2002. [Google Scholar]

- Hidalgo, A.; Bornscheuer, U.T. Directed evolution of lipases and esterases for organic synthesis. In Biocatalysis in the Pharmaceutical and Biotechnology Industries; Patel, R.M., Ed.; CRC Press: Boca Raton, FL, USA; Taylor and Francis: New York, NY, USA, 2006; pp. 159–175. [Google Scholar]

- Tian, L.; Dixon, R.A. Engineering isoflavone metabolism with an artificial bifunctional enzyme. Planta 2006, 224, 496–507. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kurisawa, M.; Chung, J.E.; Uyama, H.; Kobayashi, S. Enzymatic synthesis and antioxidant properties of poly(rutin). Biomacromolecules 2003, 4, 1394–1399. [Google Scholar] [CrossRef] [PubMed]

- Mandalari, G.; Bennett, R.N.; Kirby, A.R.; Lo Curto, R.B.; Bisignano, G.; Waldron, K.W.; Faulds, C.B. Enzymatic hydrolysis of flavonoids and pectic oligosaccharides from bergamot (Citrus bergamia Risso) peel. J. Agric. Food Chem. 2006, 54, 8307–8313. [Google Scholar] [CrossRef] [PubMed]

- Jiao, J.; Gai, Q.Y.; Wang, W.; Zang, Y.P.; Niu, L.L.; Fu, Y.J.; Wang, X. Remarjable enhancement of flavonoid production in a co-cultivation system of Isatis tinctorial L. hairy root cultures and immobilized Aspergillus niger. Ind. Crop. Prod. 2018, 112, 252–261. [Google Scholar] [CrossRef]

- Ralston, L.; Subramanian, S.; Matsuno, M.; Yu, O. Partial reconstruction of flavonoid and isoflavonoid biosynthesis in yeast using soybean type I and type II chalcone isomerases. Plant Physiol. 2005, 137, 1375–1388. [Google Scholar] [CrossRef] [Green Version]

- Lindahl, S.; Ekman, A.; Khan, S.; Wennerberg, C.; Börjesson, P.; Sjöberg, P.J.; Karlsson, E.N.; Turner, C. Exploring the possibility of using a thermostable mutant of b-glucosidase for rapid hydrolysis of quercetin glucosides in hot water. Green Chem. 2010, 12, 159–168. [Google Scholar] [CrossRef]

- Ihara, N.; Kurisawa, M.; Chung, J.E.; Uyama, H.; Kobayashi, S. Enzymatic synthesis of a catechin conjugate of polyhedral oligomeric silsesquioxane and evaluation of its antioxidant activity. Appl. Microbiol. Biotech. 2005, 66, 430–433. [Google Scholar] [CrossRef]

- Yaipakdee, P.; Robertson, L.W. Enzymatic halogenation of flavanones and flavones. Phytochemistry 2001, 57, 341–347. [Google Scholar] [CrossRef]

- Danieli, B.; Luisetti, M.; Riva, S.; Bertinotti, A.; Ragg, E.; Scaglioni, L.; Bombardelli, E. Regioselective enzyme-mediated acylation of polyhydroxy natural compounds. A remarkable, highly efficient preparation of 6ʹ-acetyl and 6ʹ-O-carboxyacetyl ginsenoside Rg1. J. Org. Chem. 1995, 60, 3637–3642. [Google Scholar] [CrossRef]

- Chung, J.E.; Kurisawa, M.; Uyama, H.; Kobayashi, S. Enzymatic synthesis and antioxidant property of gelatin-catechin conjugates. Biotechnol. Lett. 2003, 25, 1993–1997. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y.M.; Wu, Q.; Wu, W.B.; Zhang, Q.Y.; Lin, X.F. Controllable regioselective acylation of rutin catalyzed by enzymes in non-aqueous solvents. Biotechnol. Lett. 2005, 27, 1591–1595. [Google Scholar] [CrossRef] [PubMed]

- Vitali, A.; Giardina, B.; Delle Monache, G.; Rocca, F.; Silvestrini, A.; Tafi, A.; Botta, B. Chalcone dimethylallyltransferase from Morus nigra cell cultures. Substrate specificity studies. FEBS Lett. 2004, 557, 33–38. [Google Scholar] [CrossRef] [Green Version]

- Moon, Y.H.; Lee, J.H.; Ahn, J.S.; Nam, S.H.; Oh, D.K.; Park, D.H.; Chung, H.J.; Kang, S.; Day, D.F.; Kim, D. Synthesis, structure analyses, and characterization of novel epigallocatechin gallate (EGCG) glycosides using the glucansucrase from Leuconostoc mesenteroides B-1299CB. J. Agric. Food Chem. 2006, 54, 1230–1237. [Google Scholar] [CrossRef] [PubMed]

- Nielsen, I.L.F.; Chee, W.S.S.; Poulsen, L.; Offord-Cavin, E.; Rasmussen, S.E.; Frederiksen, H.; Enslen, M.; Barron, D.; Horcajada, M.N.; Williamson, G. Bioavailability is improved by enzymatic modification of the citrus flavonoid hesperidin in humans: A randomized, double-blind, crossover trial. J. Nutr. 2006, 136, 404–408. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ozaki, T.; Mishima, S.; Nishiyama, M.; Kuzuyama, T. NovQ is a prenyltransferase capable of catalyzing the addition of a dimethylallyl group to both phenylpropanoids and flavonoids. J. Antibiot. 2009, 62, 385–392. [Google Scholar] [CrossRef] [Green Version]

- Kobayashi, R.; Itou, T.; Hanaya, K.; Shoji, M.; Hada, N.; Sugai, T. Chemo-enzymatic transformation of naturally abundant naringin to luteolin, a flavonoid with various biological effects. J. Mol. Catal. B Enzym. 2013, 92, 14–18. [Google Scholar] [CrossRef]

- Adamczak, M.; Krishna, S.H. Strategies for improving enzymes for efficient biocatalysis. Food Technol. Biotechnol. 2004, 42, 251–264. [Google Scholar]

- Enaud, E.; Humeau, C.; Piffaut, B.; Girardin, M. Enzymatic synthesis of new aromatic esters of phloridzin. J. Mol. Catal. B Enzym. 2004, 27, 1–6. [Google Scholar] [CrossRef]

- Chebil, L.; Humeau, C.; Falcimaigne, A.; Engasser, J.M.; Ghoul, M. Enzymatic acylation of flavonoids. Process Biochem. 2006, 41, 2237–2251. [Google Scholar] [CrossRef]

- Das, S.; Rosazza, J.P.N. Microbial and enzymatic transformations of flavonoids. J. Nat. Prod. 2006, 69, 499–508. [Google Scholar] [CrossRef] [PubMed]

- Viskupicova, J.; Ondrejovic, M.; Maliar, T. Enzyme-mediated preparation of flavonoid esters and their applications. Biochemistry 2012, 10, 263–286. [Google Scholar]

- Peterson, J.J.; Dwyer, J.T.; Jacques, P.F.; McCullough, M.L. Associations between flavonoids and cardiovascular disease incidence or mortality in European and US populations. Nutr. Rev. 2012, 70, 491–508. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Koirala, N.; Thuan, N.H.; Ghimire, G.P.; Thang, D.V.; Sohng, J.K. Methylation of flavonoids: Chemical structures, bioactivities, progress and perspectives for biotechnological production. Enzym. Microb. Technol. 2016, 86, 103–116. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.L.; Fan, M.X.; Wu, J.L.; Li, N.; Guo, M.Q. Antioxidant and anti-inflammatory properties of flavonoids from lotus plumule. Food Chem. 2019, 277, 706–712. [Google Scholar] [CrossRef] [PubMed]

- Treml, J.; Smejkal, K. Flavonoids as potent scavengers of hydroxyl radicals. Compr. Rev. Food Sci. Food Saf. 2016, 15, 720–738. [Google Scholar] [CrossRef]

- Agati, G.; Tattini, M. Multiple functional roles of flavonoids in photoprotection. New Phytol. 2010, 186, 786–793. [Google Scholar] [CrossRef]

| Type | Substrate | Solvent | Temperature (°C) | Time | Analysis | Yields | Bioactivities/Bioactives | References |

|---|---|---|---|---|---|---|---|---|

| ASE | Impatiens glandulifera (roots) | Methanol (80%) | 80 | 30 min | LC-MS | 257.34 µg PAC/g of dw | Phenolic acid content | [45] |

| ASE | Impatiens glandulifera (flowers) | Methanol (80%) | 80 | 30 min | LC-MS | 188.86 µg PAC/g of dw | Phenolic acid content | [45] |

| ASE | Broccoli | Acetone/water/acetic acid (70:29,5:0.5 v/v/v) | 70–80 | 5 min | - | 3377 ± 62 mg GAE/100 g edp | AoA | [46] |

| ASE | Cabbage common | Acetone/water/acetic acid (70:29,5:0.5 v/v/v) | 70–80 | 5 min | - | 2037 ± 31 mg GAE/100 g edp | AoA | [46] |

| ASE | Cabbage red | Acetone/water/acetic acid (70:29,5:0.5 v/v/v) | 70–80 | 5 min | - | 2547 ± 18 mg GAE/100 g edp | AoA | [46] |

| ASE | Cauliflower | Acetone/water/acetic acid (70:29,5:0.5 v/v/v) | 70–80 | 5 min | - | 274 mg GAE/100 g edp | AoA | [46] |

| ASE | Lepidium sativum | Ethanol (96%) | 50 | 5 min | GC-MS | 58 mg RuE/g dm of flavonoid content | AmA and CtA | [47] |

| ASE | Impatiens glandulifera (leaves) | Methanol (80%) | 80 | 30 min | LC-MS | 244.73 µg PAC/g of dw | Phenolic acid content | [45] |

| HWE | Pine (Pinus rigida × taedaand Pinus koraiensis) bark | Boiling water | 100 | 1 h | - | 111–862 mg CAE/g dw | AoA | [48] |

| Maceration | Broccoli | Acetone/water (70:30 v/v) | 4 | 24 h | LC-MS | 82.2 ± 8.9 mg GAE/100 g edp | AoA | [49] |

| Maceration | Cauliflower | Acetone/water (70:30 v/v) | 4 | 24 h | LC-MS | 27.8 ± 71.5 mg GAE/100 g edp | AoA | [49] |

| Maceration | Chinese cabbage | Acetone/water (70:30 v/v) | 4 | 24 h | LC-MS | 118.9 ± 712.5 mg GAE/100 g edp | AoA | [49] |

| Maceration | White cabbage | Acetone/water (70:30 v/v) | 4 | 24 h | LC-MS | 15.37 ± 2.1 mg GAE/100 g edp | AoA | [49] |

| Maceration | Broccoli | Acetone/water (80:20 v/v) | Room temperature | 8 min | - | 80.87 ± 1.2 mg GAE/100 g edp | AoA and ApA | [50] |

| Maceration | Cabbage | Acetone/water (80:20 v/v) | Room temperature | 8 min | - | 36.77 ± 6.9 mg GAE/100 g edp | AoA and ApA | [50] |

| Maceration | Broccoli | Methanol/water (80/20 v/v) | Room temperature | - | - | 34.571.0 mg GAE/100 g edp | AoA | [51] |

| Maceration | Solanum scabrum leaves | Acetone | - | 72 h | - | 34.2 g GAE/100g | AoA | [52] |

| Maceration | Lepidium sativum | Ethanol (96%) | 50 | 24 h | GC-MS | 25 mg RuE/g dw | AmA and CtA | [47] |

| Maceration | Banana | Water | - | - | - | 8.51 µg QuE/g dw | AoA | [42] |

| Maceration | Pitanga | Ethanol (75%) and Hexane | 25 | 4 h | - | 232.2 mg GAE/g and 12.4 mg GAE/g dw, respectively | AoA and AbA | [53] |

| Maceration | Artocarpus heterophyllus wastes | Ethanol (70%) and ethanol pure | 25 | 72 h | LC-MS | 871.4 mg QuE/g dw | AoA | [44] |

| Maceration | Kinnow mandarin | Methanol (80%) | - | - | LC-MS | 28.40 mg GAE/g dw | AoA and AmA | [41] |

| Maceration | Apple tree wood residues | 50% Ethanol | 55 | 2 h | LC-PdAD | 43.2 mg GAE/g dw | Food, pharmaceutical and cosmeticapplications | [54] |

| Maceration | Pinus radiata bark | Acetone:water 70:30 v/v | 40 | 180 min | - | 412 ± 0 mg CAE/g | ArA | [55] |

| Maceration | Quercus (Q. robur L.) bark | Water | 25 | 120 min | - | 3.7 ± 0.6 mg GAE/g | AoA and AbA | [56] |

| Maceration | Chokeberry (Aronia melanocarpa) | 50% Ethanol. Ratio 1:20 | Ambient temperature | 60 min | LC-MS | 27.7 mg GAE/g dw | Extraction of bioactive compounds | [35] |

| Percolation | Artocarpus heterophyllus wastes | Ethanol (70%) | 25 | 1 h | LC-MS | 511.6 mg QuE/g dw | AoA | [44] |

| Reflux | Portulaca oleracea L. | Ethanol–water (70:30, v/v) | - | 150 min | - | 6.8 mg RuE/g | Flavonoid content | [57] |

| RSlSE | Tomatoes | Ethanol (60%) | Room temperature | 15 h | HPLC | 602.91 mg GAE/100 g dw (TPC) | AoA | [58] |

| SDE | Dried leaves of basil (Ocimum basilicum L.), and epazote (Chenopodium ambrosioides L.). | Water | - | 30 min | GC-MS | 0.47 y 0.39% yield of EO from basil and epazote | Essential oil extraction | [59] |

| SlE | Vitis vinifera waste | Methanol or with ethanol | 25 | 19 h | HPLC | 67.88 mg GAE/g dw | ArA | [60] |

| Soxhlet | Portulaca oleracea L. | Ethanol–water (70:30, v/v) | - | 300 min | - | 7.0 mg RuE/g | Flavonoid content | [57] |

| Soxhlet | Buddleia officinalis Maxim | Ethanol (95%) | - | 2 h | - | 62.56 mg CAE/g dw | AoA | [61] |

| Soxhlet | Morus nigra (dried) | Petroleum ether | 50 | 3 h | - | 58.94% of flavonoid yield | AoA | [62] |

| Soxhlet | Fresh leaves of Vernoniaamygdalina | Water | 100 | 8 h | GC-MS | - | AoA | [63] |

| Soxhlet | Vernonia cinerea leaves | Ethanol (60%) | - | 2 h | LC–Q-TOF–MS | 26.22 mg QuE/g dw | AoA | [32] |

| Soxhlet | Artocarpus heterophyllus wastes | Ethanol (70% and pure) | Boiling point | 5 h | LC-MS | 381.4 mg QuE/g dw | AoA | [44] |

| Soxhlet | Impatiens glandulifera (leaves) | Chloroform, 80% Methanol and pure Methanol | - | 72 h | LC-ESI-MS | 286.39 mg PAC/g dw | AoA | [45] |

| Soxhlet | Impatiens glandulifera (roots) | Chloroform, 80% Methanol and pure Methanol | - | 72 h | LC-MS | 281.82 mg PAC/g dw | AoA | [45] |

| Soxhlet | Impatiens glandulifera (flowers) | Chloroform, 80% Methanol and pure Methanol | - | 72 h | LC-MS | 188.07 mg PAC/g dw | AoA | [45] |

| Soxhlet | Pinus radiata bark | Acetone:water 70:30 v/v | 82 | 60, 120, 180, and 360 min | - | 622 ± 40 mg CAE/g | ArA | [55] |

| Soxhlet | Spearmint (Mentha spicata L.) | Methanol | 40 | 6 h | HPLC | 0.144 mg CAE/g dw | Flavonoid extraction | [64] |

| Soxhlet | Knotwood (Populus tremula) | Methanol | - | 48 h | LC-MS | 11.5 mg/g | Flavonoid extraction | [65] |

| Substrate | Extraction Conditions | Analysis | Bioactive | Bioactivity | References | ||

|---|---|---|---|---|---|---|---|

| Solvent | Temperature (°C) | Time | |||||

| (A) Microwave-Assisted Extraction | |||||||

| Fresh leaves of Vernonia amygdalina | Water | 100 | 7 min | GC-MS | 87.05 mg QuE/g total flavonoid content | AoA | [63] |

| Black rice (Oryza sativa cv. Poireton) husk | Ethanol 40%–70% (relation m/v (1:20, 1:35, 1:50) | 40–60 | 20–60 s | HPLC | Gallic acid, p-coumaric acid, ferulic acid, quercetin, salicylic acid, quimic acid, apigenin, syringic acid, chlorogenic acid, catechin | AoA | [66] |

| Apple tree wood residues | Ethanol (60%) | 100 | 20 min | HPLC-PdAD | 47.7 mg GAE/g dw | Pharmaceutical and cosmetic applications | [54] |

| Moringa oleifera leaves | Water, ethanol:water, and etanol | 50–180 | 3–20 min | HPLC–ESI–Q-TOF–MS | Quercetin sambubioside/Quercetin-3-vicianoside, kaempferol diglycoside, multiflorin B, kaempferol-3-O-glucosidde, vitexin, quercetin-3-O-glucosidde, quercetin malonylglucoside, quercetin hydroxyl methylglutaroyl, glycoside, quercetin triacetylgalactoside, quercetin acetyl glycoside, isorhamnetin-3-O-glucoside, quercetin, kaempferol | AoA | [67] |

| Coriander (Coriandrum sativum L.) seeds | Ethanol (52%) | 35 min | - | 382.32 mg GAE/100 g dw | AoA | [68] | |

| Quercus (Q. robur L) bark | Water | 100 | 120 min | HPLC-PdAD-ESI-MS/MS | 16.50 ± 0.07 mg GAE/g dw | AoA | [69] |

| Canola seed cake | Ethanol (10%) | 70 | 20 min | - | - | Polyphenols extraction | [70] |

| Tomatoes | Ethanol | Room temperature | 10 min | HPLC | 646.40 mg GAE/100 g dw (TPC) | AoA | [58] |

| Pinus radiata bark | acetone:water 70:30 v/v | - | 3 min | - | 479 ± 49 mg CAE/g dw | ArA | [55] |

| Grape skins | 40% methanol | 100 | 5 min | HPLC | 1.858 mL AntE/g of MEC/MoS | Anthocyanins extraction | [71] |

| Uncaria sinensis | Ultra pure water | 100 | 20 min | LC-MS | 44 mg EpiCAE/100 g | Quality of medicinal herbs | [72] |

| Buddleia officinalis Maxim | Ethanol (65%–100%) | 40–78 | 10–30 min | - | 75.33 mg CAE/g dw | AoA | [61] |

| Citrus unshiu | Ethanol (70%) | 140 | 8 min | HPLC-PdAD | 47.7 mg HspE/g of MEC/MoS | TpP | [73] |

| Defatted residue of yellow horn | Etanol (40%) | 50 | 7 min, 3 extraction cycles | - | 11.62% (triterpene saponins) MEAC × 100/MoS | Food and pharmaceutical industries | [74] |

| Peanut skins | Ethanol (30%) | - | 30 s | HPLC and LC–MS–MS | 144 mg PAC/g of MEC/MoS | AoA | [75] |

| Pigeonpea (Cajanus cajan) leaves | Ethanol (80%) | 65 | 1 min (2 min total), 2 extraction cycles | RP-HPLC-PdAD | 18.8 mg AAE/g and 3.5 mg PinE/g of MEC/MoS | TpP | [76] |

| Portulaca oleracea L. | Ethanol–water (70:30, v/v) | 50 | 9 min | -- | 7.1 mg RuE/g | Flavonoid content | [57] |

| Purple corn | 15 M HCl: 95% ethanol in 15:85 ratio | 55 | 19 min | LC-MS | 1.851 mg AntE/g of MEC/MoS | Anthocyanin extraction | [77] |

| Radix puerariae | Ethanol (70%) | - | 6 min | - | 8.37 mg RuE/g | Flavonoid content | [78] |

| Sea buckthorn (Hippophae rhamnoides) food by-products | Water | 20–100 | 15 min | HPLC | Flavonol isorhamnetin 3O-rutinoside | AoA | [79] |

| Tea residues(oolong) | Water | 230 | 2 min | GC-MS | 144.0 mg GAE/g dw | AoA | [80] |

| Tea residues (green) | Water | 230 | 2 min | GC-MS | 87.2 mg GAE/g dw | AoA | [80] |

| Vitis vinifera seed | Methanol | 110 | 60 min | HPLC | 86.2 mg GAE/g and 46.8 mg CAE/g dw | ArA | [60] |

| Alpinia zerumbet (Pers.) Burtt et Smith leaves | Ethanol (70%) | 60–70 | 3s | HPLC | 11% w/w | Flavonoid extraction | [81] |

| Bark of Phyllanthus emblica L. | Aqueous ethanol (75%) | 45 | 25 min | - | 19.78 % | AoA | [82] |

| Citrus mandarin peels | Methanol (66%) | 1–120 | 49 s | HPLC | 3779.37 μg PAC/g of MEC/MoS | Phenolic acids extraction | [83] |

| Milk thistle seed | Ethanol (82%) | 112 | 60 min | - | 56.67 mg SilE/g of MEC/MoS | Silymarin extraction | [84] |

| Morus alba L. leaves | Ethanol (60%) | 100 | 5 min | - | 2.4% flavonoid | AfA | [85] |

| Onion (Allium cepa L.) | Methanol (80%) | 2–100 | Up to 60 min | HPLC | 330.46 mg of flavonol content | Food application | [86] |

| Herba epimedii | Ethanol | - | - | HPLC | 921 peak Area of total flavonoids | Flavonoid extraction | [87] |

| Myrica rubra leaves | - | 60 | 20 min | HPLC | - | Polyphenol extraction | [88] |

| Radix astragali | Ethanol (90%) | 110 | 50 min | HPLC | 1.190 mg flavonoids/g | Flavonoid extraction | [89] |

| Radix astragali roots | Ethanol (90%) | 110 | 25 min (50 min total), 2 extraction cycles | - | 1.19 mg/g (flavonoids) of MEC/MoS | Flavonoid extraction | [89] |

| Platycladus orientalis leaves | Methanol (80%) | - | 5 min | - | 1.72% (flavonoids) MEAC × 100/MoS | Flavonoid extraction | [90] |

| Epimedium koreamum Nakai | Ethanol (40%) | - | 15 min | LC-ESI-MS | 280 m AU/min | Flavonoid extraction | [91] |

| Olive leaves | Ethanol (80%) | - | 8 min | HPLC- PdAD | 95% (oleuropein) MEAC × 100/MTACcS | Biophenols extraction | [92] |

| Acanthopanax senticosusleaves | Ethanol (50%) | 10 min | ESI-MS | - | Flavonoid extraction | [93] | |

| Eucommia ulmodies oliv. | Methanol:water:acetic acid (20:80:1.0, v/v) | - | 30–40 s | HPLC | 75.6%–83.2% (geniposidic acid) and 77.4%–86.3% (chlorogenic acid) of MEAC × 100/MTACcS | TpP | [94] |

| Capsicum fruit | Acetone | - | 15 min | GC-MS | 0.48 mg CpE/g fw | Food aditives | [95] |

| (B) Ultrasound-Assisted Extraction | |||||||

| Dysphania ambrosioides (L) | Ethanol (57% w/w) | 57 | 60 min | - | 1.09% of flavonoids equivalents of rutin | Flavonoid extraction | [96] |

| Lepidium sativum seeds | Ethanol | 50 | 24 h | GC-MS | 97 mg GAE/g dm | AmA and CtA | [47] |

| Fruit of rugose rose (Rosa rugose Thumb) | Ethanol (50%) | 50 | 40 min | - | 31.88 mg /g dw | AoA | [97] |

| Impatiens glandulifera (flowers) | Methanol (80 %) | 30 | 60 min | LC-MS | 216.03 µg/g dw | AoA | [45] |

| Impatiens glandulifera (leaves) | Methanol (80 %) | 30 | 60 min | LC-MS | 291.55 µg/g dw | AoA | [45] |

| Impatiens glandulifera (roots) | Methanol (80 %) | 30 | 60 min | LC-MS | 286.04 µg/g dw | AoA | [45] |

| Kinnow mandarin | Ethanol (80%) | 35, 45, 55 | 40–70 min | HPLC | 28.40 mg GAE/g extract | AoA and AmA | [41] |

| Nephelium lappaceum L. fruit peel | Solid–liquid ratio 1:18.6 g/mL | 50 | 20 min | - | 10.26 ± 0.69 mg AntE/100 g; 552.64 ± 1.57 mg GAE/100 g; 104 ± 1.13 mg RuE/100 g | Flavonoid extraction | [98] |

| Curry leaf (Murraya koenigii L.) | Methanol 80% 55.9% 145.49 W | 55.9 | - | UHP-LC | 0.482 mg CAE/g dw; 0.517 mg NrgE/g dw; 0.394 mg QuE/g dw | Pharmaceutical application | [99] |

| Portulaca oleracea L | Ethanol 39.01% | 55.25 | 15 min | - | 16.25 mg RuE/g dw | - | [100] |

| Pinus radiata bark | acetone:water 70:30 v/v | - | 3-12 min | - | 388 ± 7 mg CAE/g bark | ArA | [55] |

| Morus laevigata W. M. alba L. and M. nigra L | Methanol (80%) | - | - | HPLC | 3.89 to 11.79 µmoL GAE/100 g | AoA | [101] |

| Portulaca oleracea L. | Ethanol–water (70:30, v/v) | 25 | 60 min | - | 6.7 mg RuE/g | Flavonoid content | [57] |

| Vitis vinifera seed | Methanol | 25 | 60 min | HPLC | 55.9 mg GAE/g and 39.5 mg CAE/g dw | ArA | [60] |

| (C) Supercritical Fluid Extraction | |||||||

| Dried bilberry fruits (V. myrtillus L.) | CO2 + Ethanol (10%) | - | 30 min | HPLC-PdAD-ESI-MS/MS | 0.62 mg AntE/g dw | AoA | [102] |

| Spearmint (Mentha spicata L.) | Absolute ethanol (EtOH) Flow rate: 3 g/min Pressure: 200 bar | 60 | 60 min | HPLC | 0.140 mg CAE/g dw | Bioactive flavonoid extraction | [64] |

| Pueraria lobata | Ethanol Flow rate: 3 g/min Pressure: 20.04 MPa | 50.24 | 90 min | - | 16.95 ± 0.43 mg flavonoid/g dw | Flavonoid extraction | [103] |

| Ganoderma atrum | CO2 + ethanolFlow rate: 30 L/h (80 g sample) Pressure: 25 MPa | 55 | 3 h | - | 1.52% (triterpenoid saponins) MEAC × 100/MoS | Triterpenoid saponins extraction | [104] |

| Lepidium sativum | CO2 + ethanol (96 %) | 50 | 70 min | GC-MS MALDI-TOF-MS | 58 mg RuE/g dm (Total flavonoid) | AmA and CtA | [47] |

| Source | Enzyme (s) | Compound (s) | Reference |

|---|---|---|---|

| Ginkgo biloba leaves | Cellulase | Flavonols | [143] |

| Grape (Vitis vinifera) skins | Oenological preparation (pectinase + cellulase + hemicellulase) | Anthocyanins, flavonol glycosides, and flavan-3-ols | [144] |

| Mulberry (Morus nigra) must | Pectinase | Anthocyanins and nonanthocyanin flavonoids | [141] |

| Nitraria tangutorum juice by-products | Cellulase | Anthocyanins and nonanthocyanin flavonoids | [142] |

| Shepherd’s purse (Capsella bursa-pastoris) pulp | Pectinase and cellulase | Flavonoids | [140] |

| Glycyrrhizae radix | Cellulase | Liquiritigenin and isoliquiritigenin | [145] |

| Celery (Apium graveolens) leaves | Pectinase | Luteolin and apigenin | [139] |

| Scutellariae radix | Naringinase | Bacalein and wogonin | [146] |

| Grape (Vitis vinifera) pomace | Pectinase and cellulase | Anthocyanins and nonanthocyanin flavonoids | [137] |

| Pigeonpea (Cajanus cajan) leaves | Pectinase | Luteolin and apigenin | [138] |

| Grape (Vitis vinifera) pomace | Pectinase and cellulase | Anthocyanins and nonanthocyanin flavonoids | [136] |

| Black currant (Ribes nigrum) pomace | Pectinase | Anthocyanins | [135] |

| Enzymes Type | Transformation | Reference | |

|---|---|---|---|

| Esterases | Esterases (carboxyl esterases) | Reaction similar to lipases, but with short-chain fatty acids and difference in the interfacial activation. Low practical applications in enzymatic transformation of flavonoids with a short aliphatic chain length such as acetate, propionate, and butyrate. | [160] |

| Isomerase | Chalcone isomerase (CHI) | Cyclization of chalcone to form flavanone, transformation of chalcone and 6′-deoxychalcone into (2S)-naringerin and (2S)-5-deoxyflavanone. Soybean CHIs do not require the 4’-hydroxy moiety on the substrate for high enzyme activity. | [161] |

| Laccase | Laccase from Myceliophthora | Synthesis of a flavonoid polymer and high molecular fraction of extracted flavonoids from rutin as substrate in the mixture of methanol and buffer. Oxidation of catechin in the presence of gelatin and synthesize the gelatin-catechin conjugate. | [162,163] |

| Lipase | Candida antarctica lipase B | Acetylation only on the primary 6′-OH of the isoquercitrin glucose and the secondary 4′-OH of the rutin rhamnose were expected to be acetylated. | [164] |

| Pseudomonas cepacea lipase | Acetylation occurred only on 3′-OH, 5′-OH, and 7-OH hydroxyls. | ||

| Pectinase and Cellulase | Commercial Cellulases from Trichoderma viride | Transglucosylation activity toward (+)-catechin and (−)-epigallocatechin gallate (EGCG) using dextrin as a glucosyl donor. EGCG glucosides were functionally superior to EGCG as food additives. | [146,165,166] |

| Pectinolytic and Cellulolytic Enzymes | Hydrolysis of main- and side-chain of polysaccharides, and glycosidase activities. | ||

| Peroxidase | Chloroperoxidase | Halogenation of naringenin and hersperetin, at C-6 and C-8 with chloride and bromide ions. | [167,168] |

| Horseradish peroxidase | Conjugation of green-tea catechin with amine substituted octahedral silsesquioxane. | ||

| Protease | Alkaline protease from Bacillus subtilis | Synthesis of 3″-O-substituted vinyl rutin esters in pyridine. | [169,170,171] |

| Novozym 435 | Synthesis of 4″- O-substituted vinyl rutin esters in tert-butanol. | ||

| Proteases | Hydrolytic and synthetic functions. Enzymatic transformations of flavonoids were affected by the type, origin and concentration of enzymes, nature of flavonoids, donor and optimal conditions (temperature, substrates, and solvent). | ||

| Subtilisin (serine protease) | Flavonoid ester synthesis, the selective rutin acylation in organic solvents with excellent selectivity. The structure of the sugar moiety affected the regioselectivity. | ||

| Transferase | Glycosyltransferases (GTs) | Glycosylation of on one or more of five hydroxyl groups of flavonol quercetin, as well as formation of hesperetin-7-glucoside. Some natural GTs is characterized by low specificity and other by the stringent specificity for glycosylation patterns. Positions, number, and length of the sugar moieties are significant factors for yield reaction. | [95,172,173,174,175] |

| Prenyltransferase (from Morus nigra) | Exclusive prenylation of chalcones (1, 2, 3, bearing two hydroxyl groups (C-2′, C-4′) on ring A) with a 2′, 4′ dihydroxy substitution and the isoflavone genistein. The position of substituents in ring B appeared to be critical for the prenylation. | ||

| Prenyltransferase (NovQ): | Transferring of a dimethylallyl group to the B-ring of flavonoids. Genistein and naringenin and yielded two products with a dimethylallyl group at C-3′ or O-4′. | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chávez-González, M.L.; Sepúlveda, L.; Verma, D.K.; Luna-García, H.A.; Rodríguez-Durán, L.V.; Ilina, A.; Aguilar, C.N. Conventional and Emerging Extraction Processes of Flavonoids. Processes 2020, 8, 434. https://0-doi-org.brum.beds.ac.uk/10.3390/pr8040434

Chávez-González ML, Sepúlveda L, Verma DK, Luna-García HA, Rodríguez-Durán LV, Ilina A, Aguilar CN. Conventional and Emerging Extraction Processes of Flavonoids. Processes. 2020; 8(4):434. https://0-doi-org.brum.beds.ac.uk/10.3390/pr8040434

Chicago/Turabian StyleChávez-González, Mónica L., Leonardo Sepúlveda, Deepak Kumar Verma, Hugo A. Luna-García, Luis V. Rodríguez-Durán, Anna Ilina, and Cristobal N. Aguilar. 2020. "Conventional and Emerging Extraction Processes of Flavonoids" Processes 8, no. 4: 434. https://0-doi-org.brum.beds.ac.uk/10.3390/pr8040434