Actuator and Sensor Fault Classification for Wind Turbine Systems Based on Fast Fourier Transform and Uncorrelated Multi-Linear Principal Component Analysis Techniques

Abstract

:1. Introduction

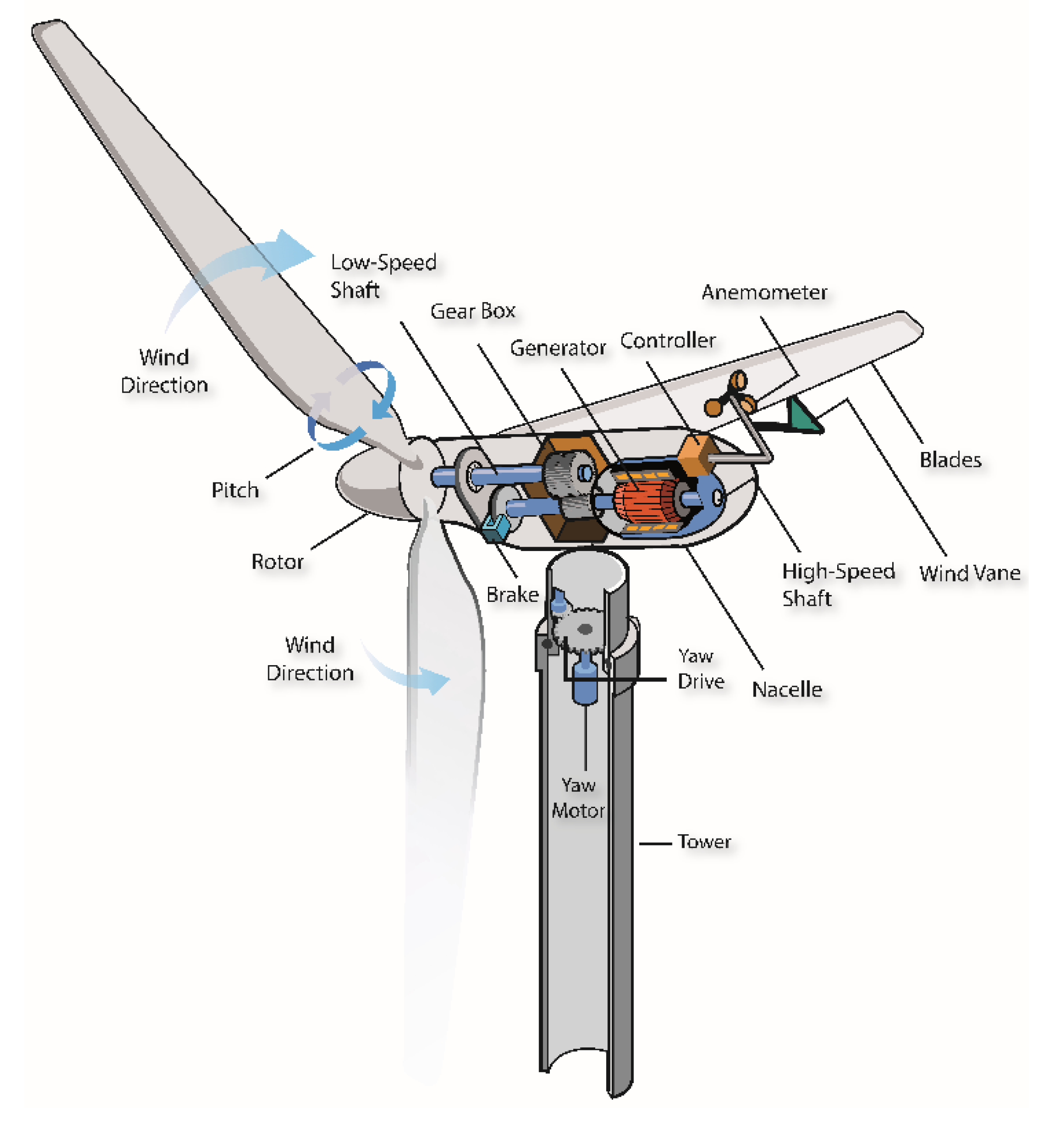

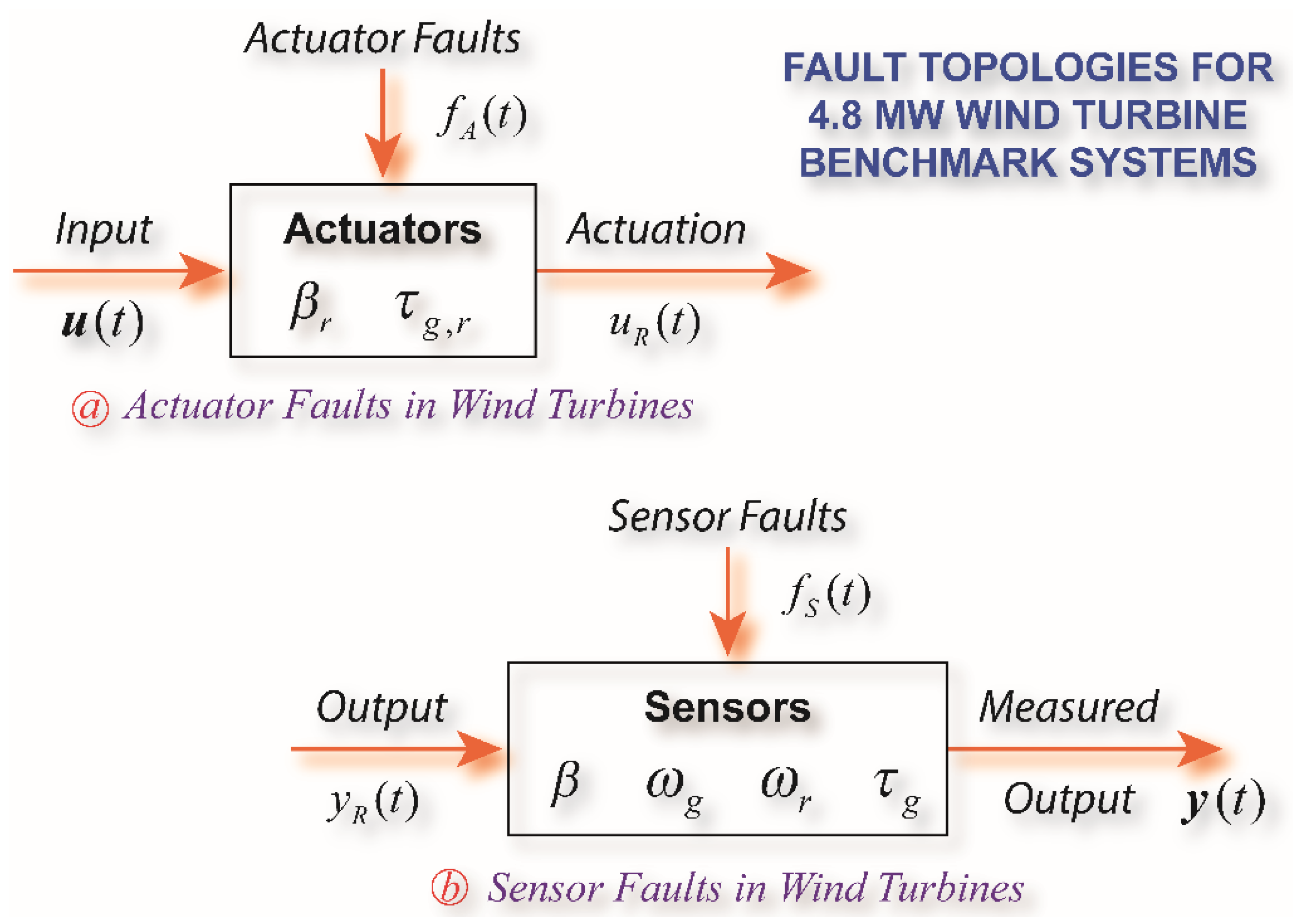

2. Wind Turbine Benchmark Systems

3. Methodology

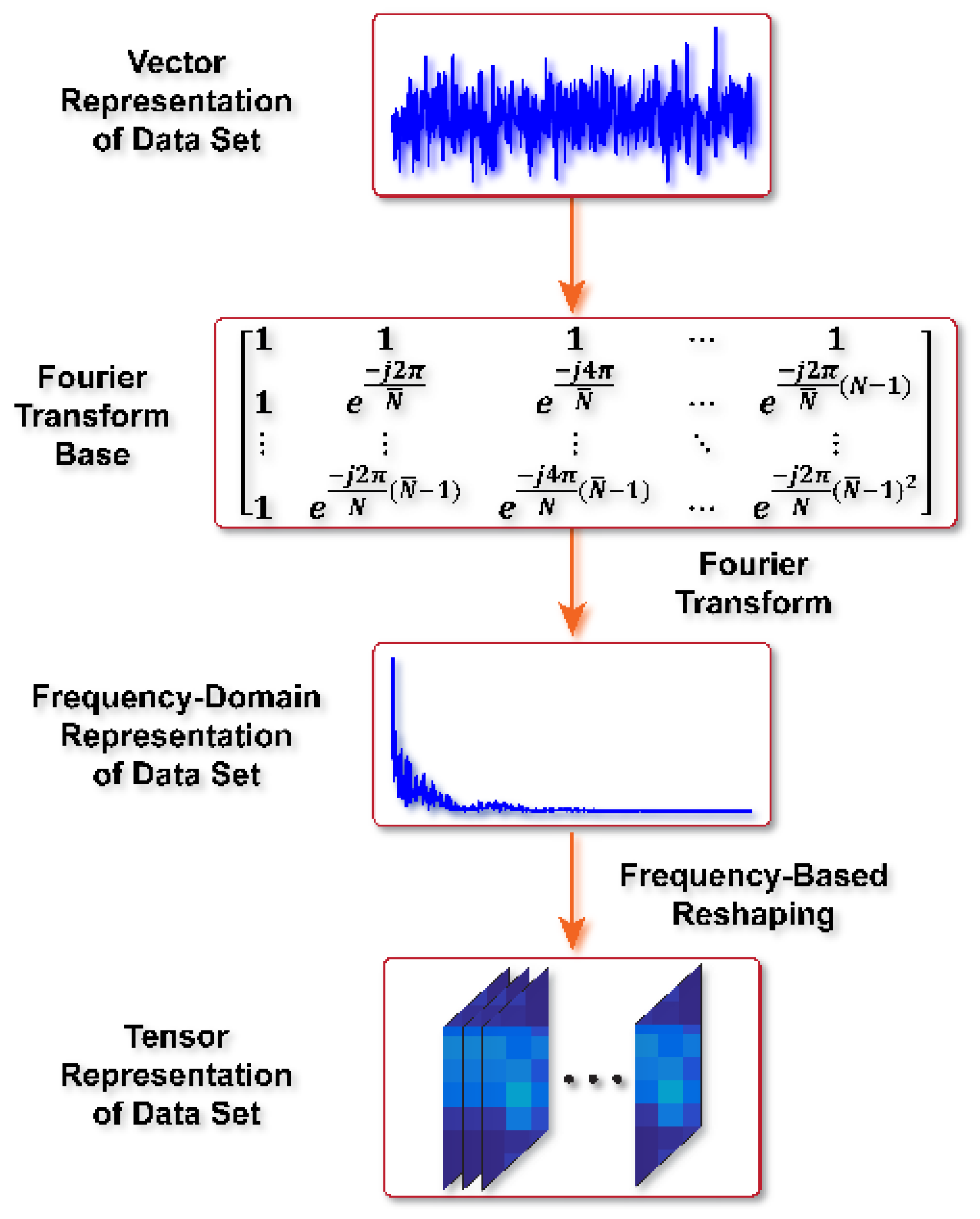

3.1. Data Set Construction

3.2. Data Set Pre-Processing

3.3. Dimensionality Reduction and Feature Extraction for Wind Turbines by Using the Uncorrelated Multi-Linear Principal Component Analysis Method

- Step 1:

- Explore the first projection direction by maximizing .

- Step 2:

- Compute the second project direction by maximizing subjected to .

- Step 3:

- Determine the third project direction by maximizing subjected to .

- Step 4:

- Calculate the p-th project direction by maximizing subjected to when .

- Step 5:

- Based on all the obtained project directions from the steps above, the final features can be obtained by:

3.4. FFT Plus UMPCA Algorithm

| Algorithm 1 |

| Input: Date set . Output: Significant features .

|

4. Experimentation Designs

4.1. Brief Description and Definition

- (1)

- ‘EL’: Percentage (P);

- (2)

- ‘SWD’: Amplitude (A) and Bias (B), namely A/B

- (3)

- ‘RN’: Mean (M), and Variance (V), namely M/V;

- (4)

- ‘EL + SWD’: Percentage (P), Amplitude (A), and Bias (B), namely P/A/B;

- (5)

- ‘EL + RN’: Percentage (P), Mean (M), and Variance (V), namely P/M/V;

- (6)

- ‘SWD + RN’: Amplitude (A), Bias (B), Mean (M), and Variance (V), namely A/B/M/V;

- (7)

- ‘EL + SWD + RN’: Percentage (P), Amplitude (A), Bias (B), Mean (M), and Variance (V), namely P/A/B/M/V.

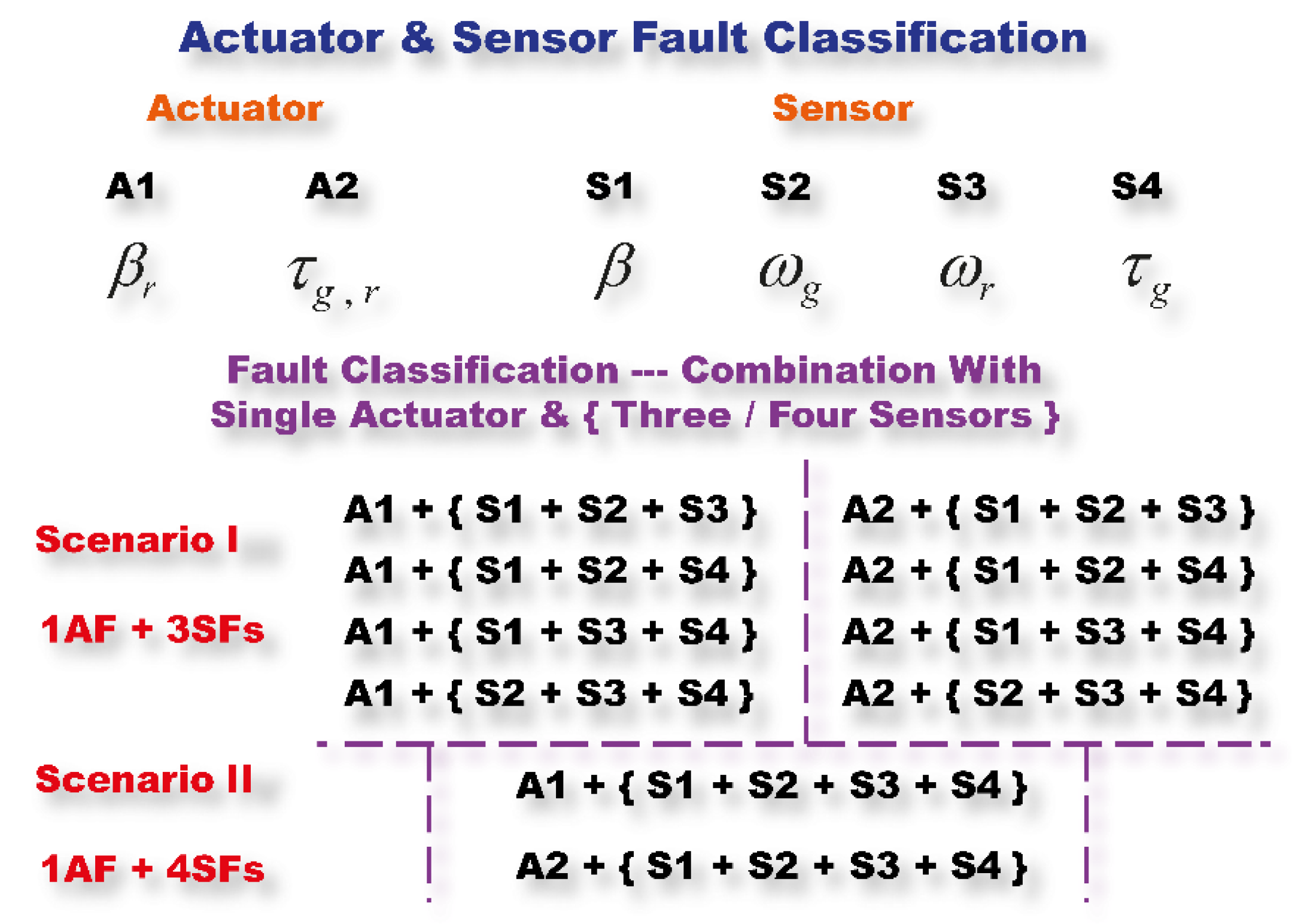

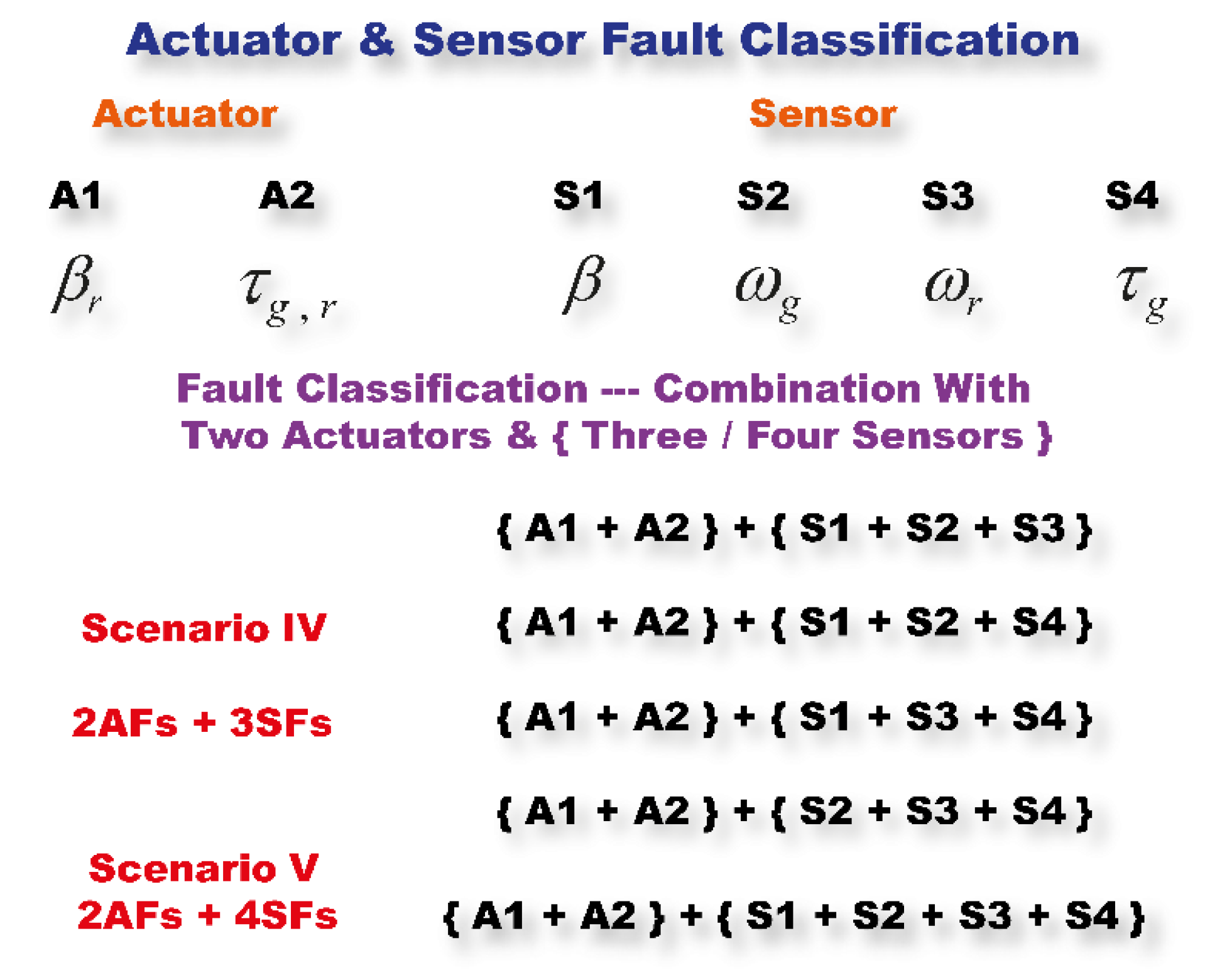

4.2. Experimental Statement

- (i)

- Scenario I: single actuator and three sensor faults, ‘1AF + 3SFs’; Types of fault: ;

- (ii)

- Scenario II: single actuator and four sensor faults, ‘1AF + 4SFs’; Types of fault: ;

- (iii)

- Scenario III: two actuators and two sensor faults, ‘2AFs + 2SFs’; Types of fault: ;

- (iv)

- Scenario IV: two actuators and three sensor faults, ‘2AFs + 3SFs’; Types of fault: ;

- (v)

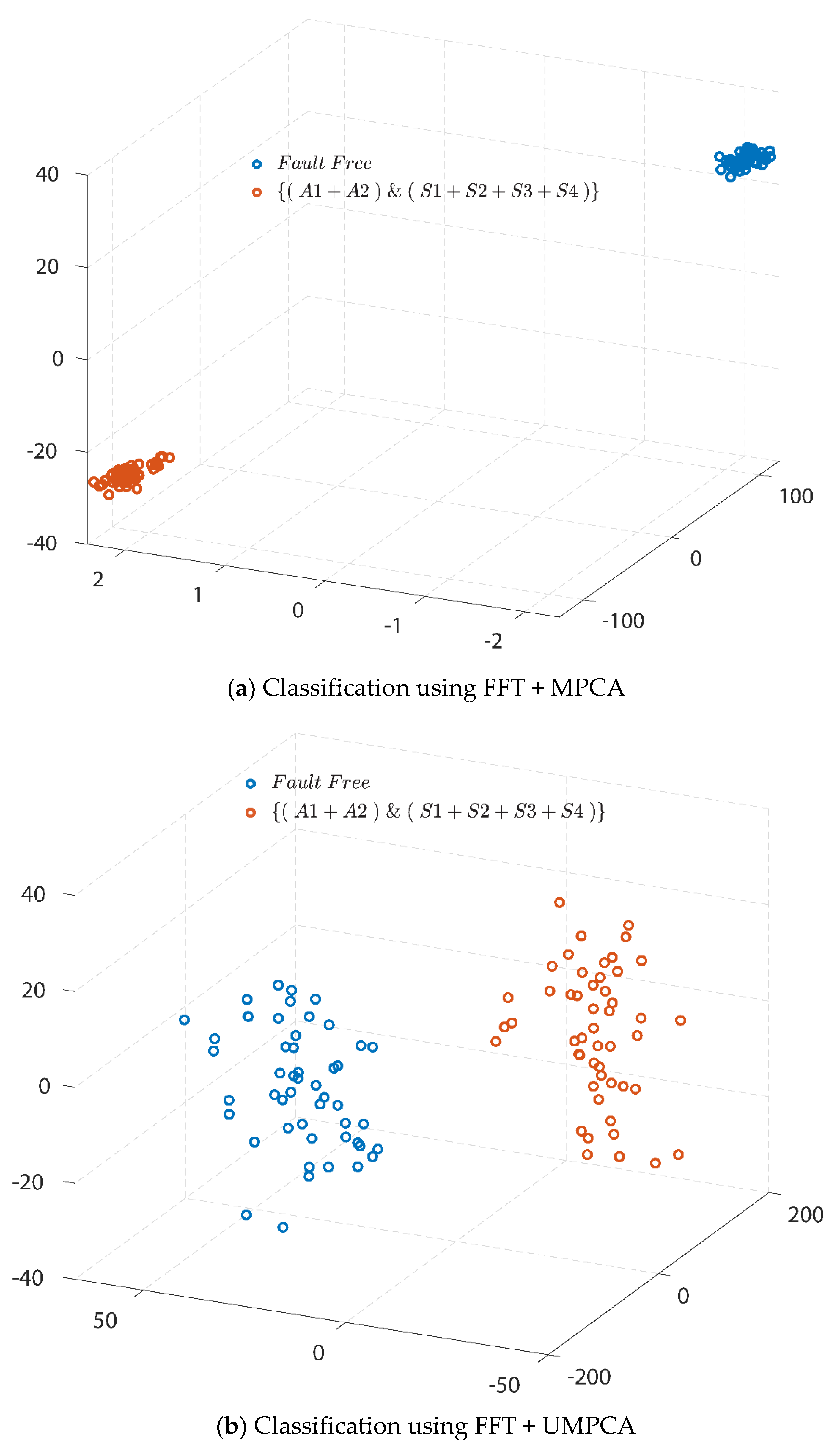

- Scenario V: two actuators and four sensor faults, ‘2AFs + 4SFs’; Types of fault: .

5. Simulation Results

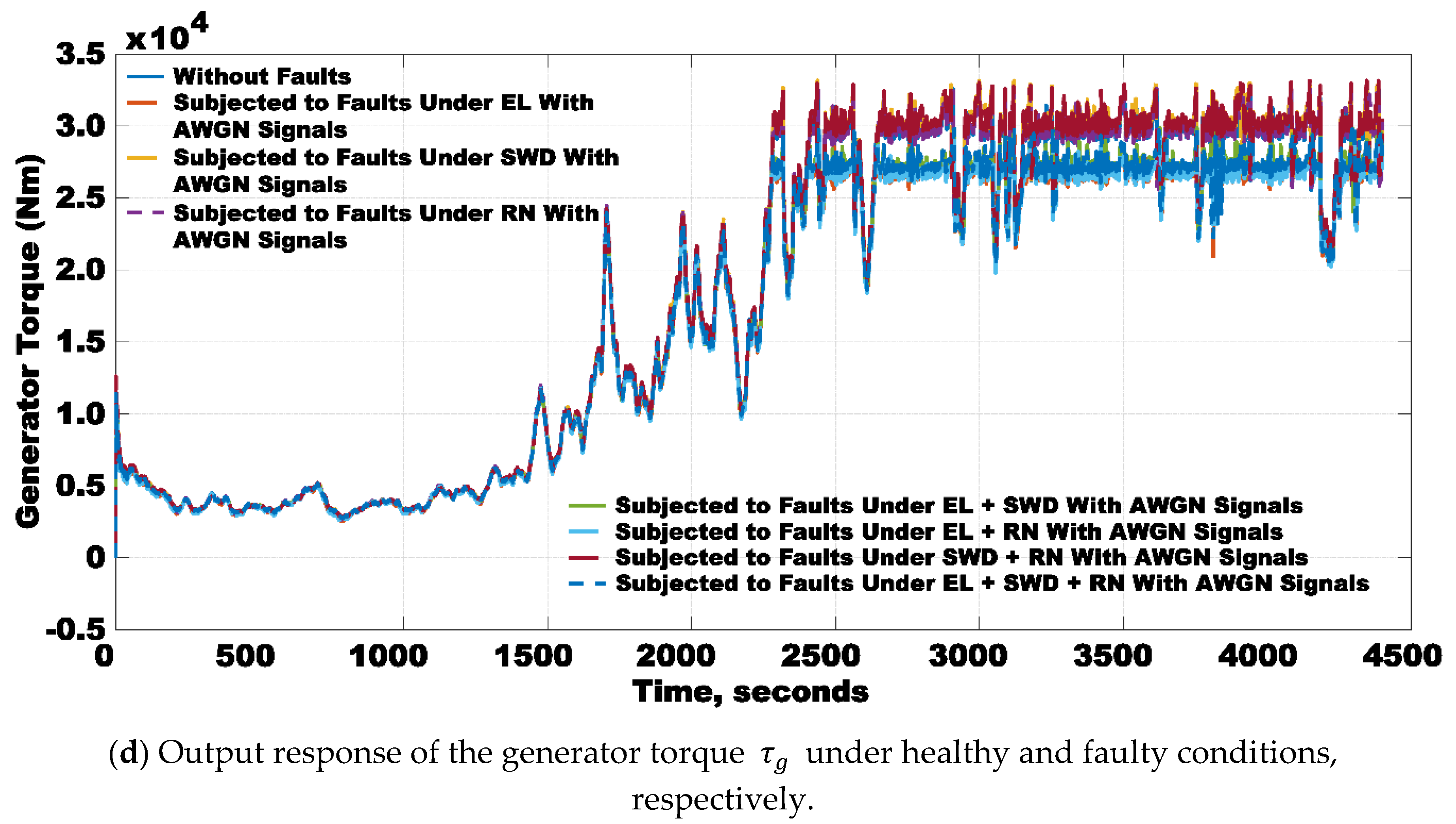

5.1. Time-Domain Space Characteristics of Wind Turbine Benchmark Systems

5.2. Feature Extractions and Fault Classifications for Scenario I

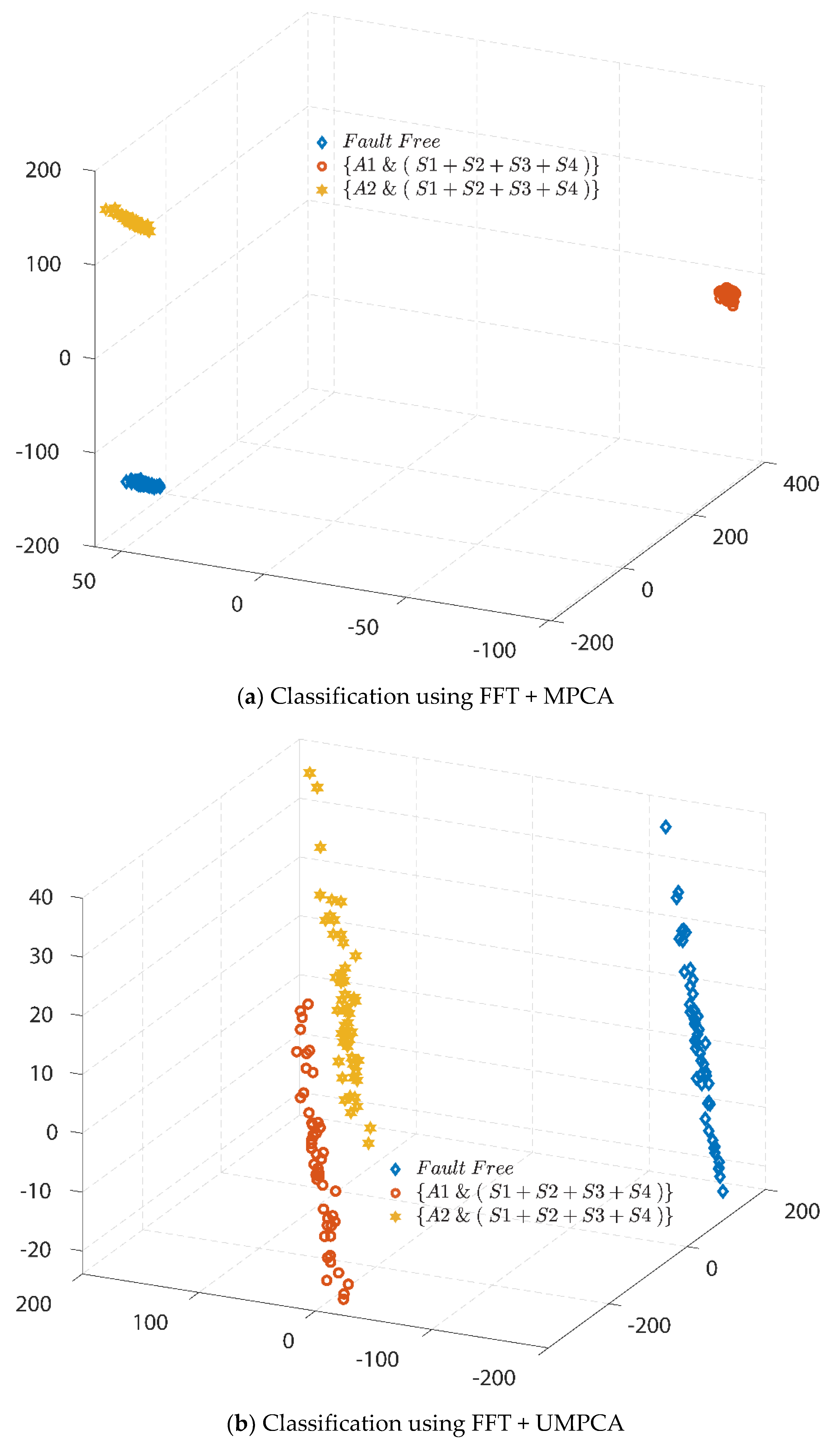

5.3. Feature Extractions and Fault Classifications Based under Scenario II

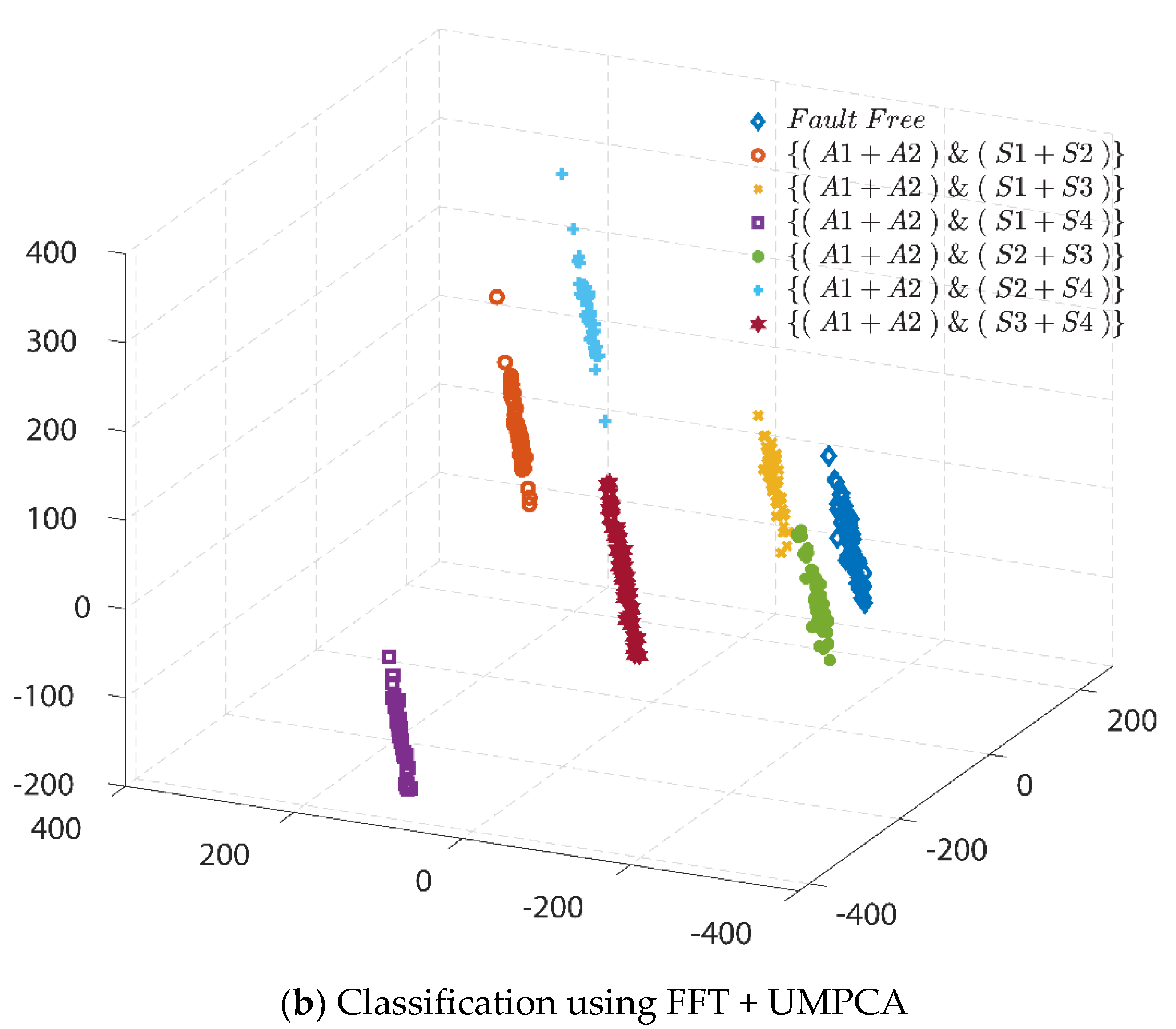

5.4. Feature Extractions and Fault Classifications under Scenario III

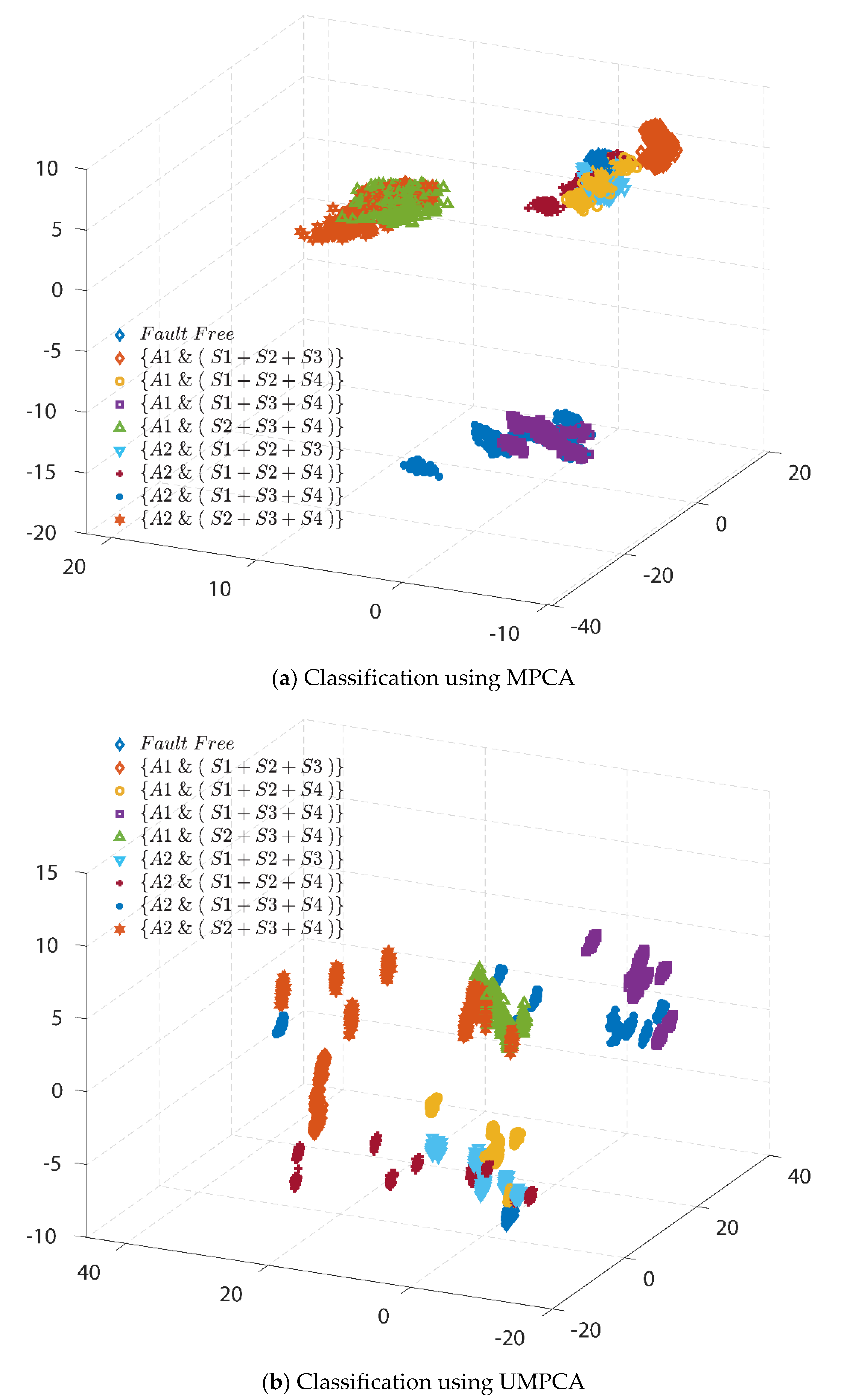

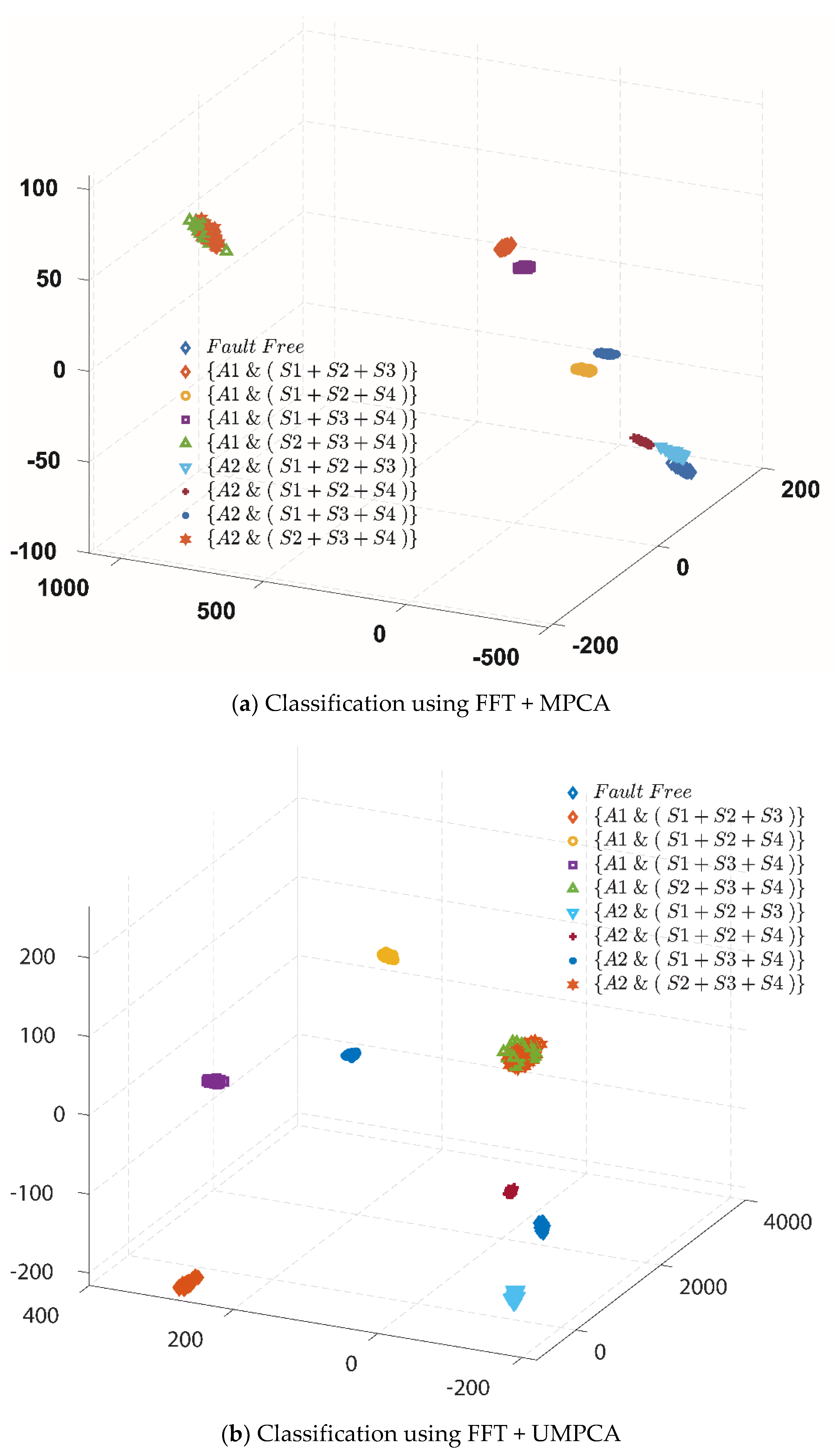

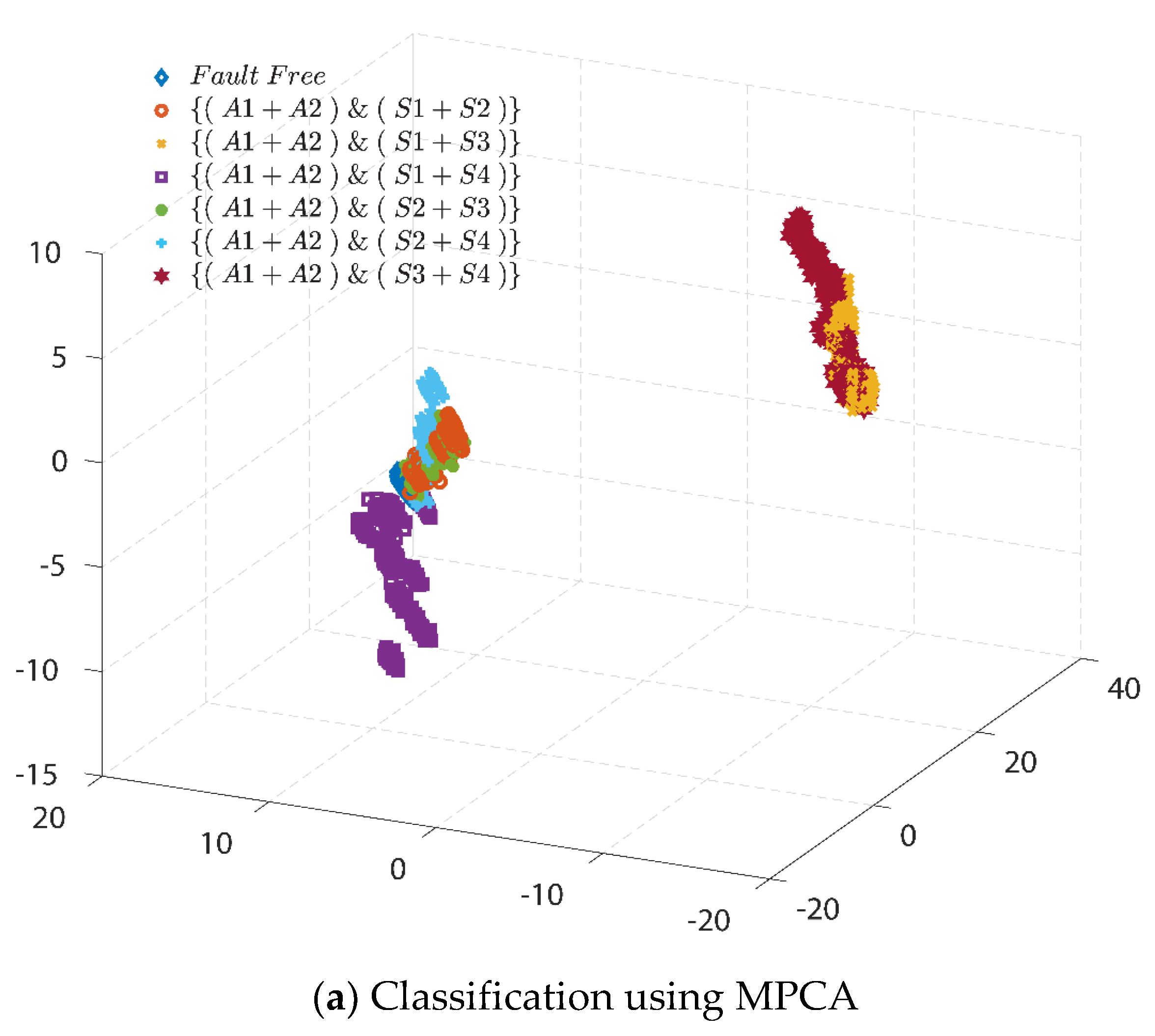

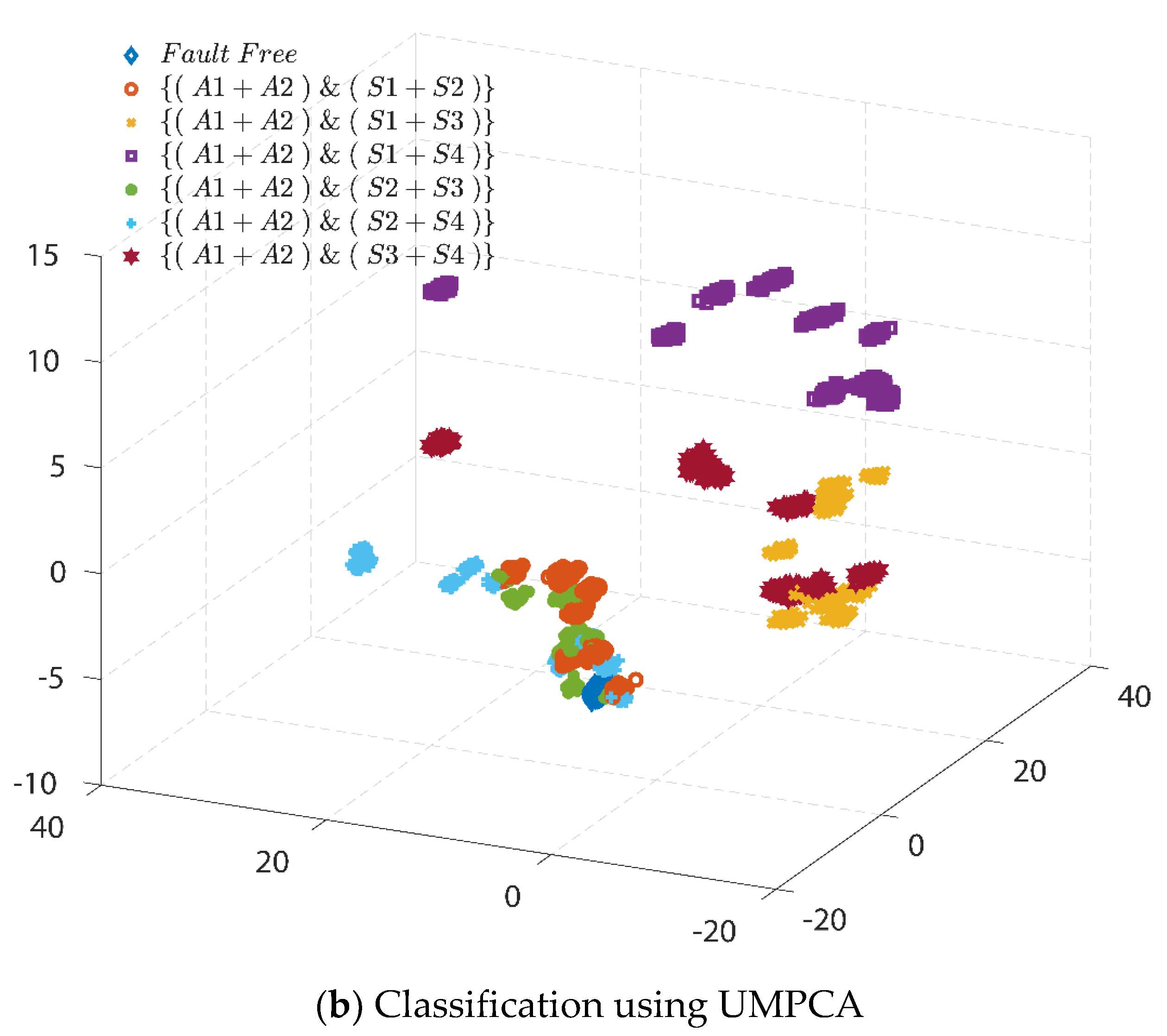

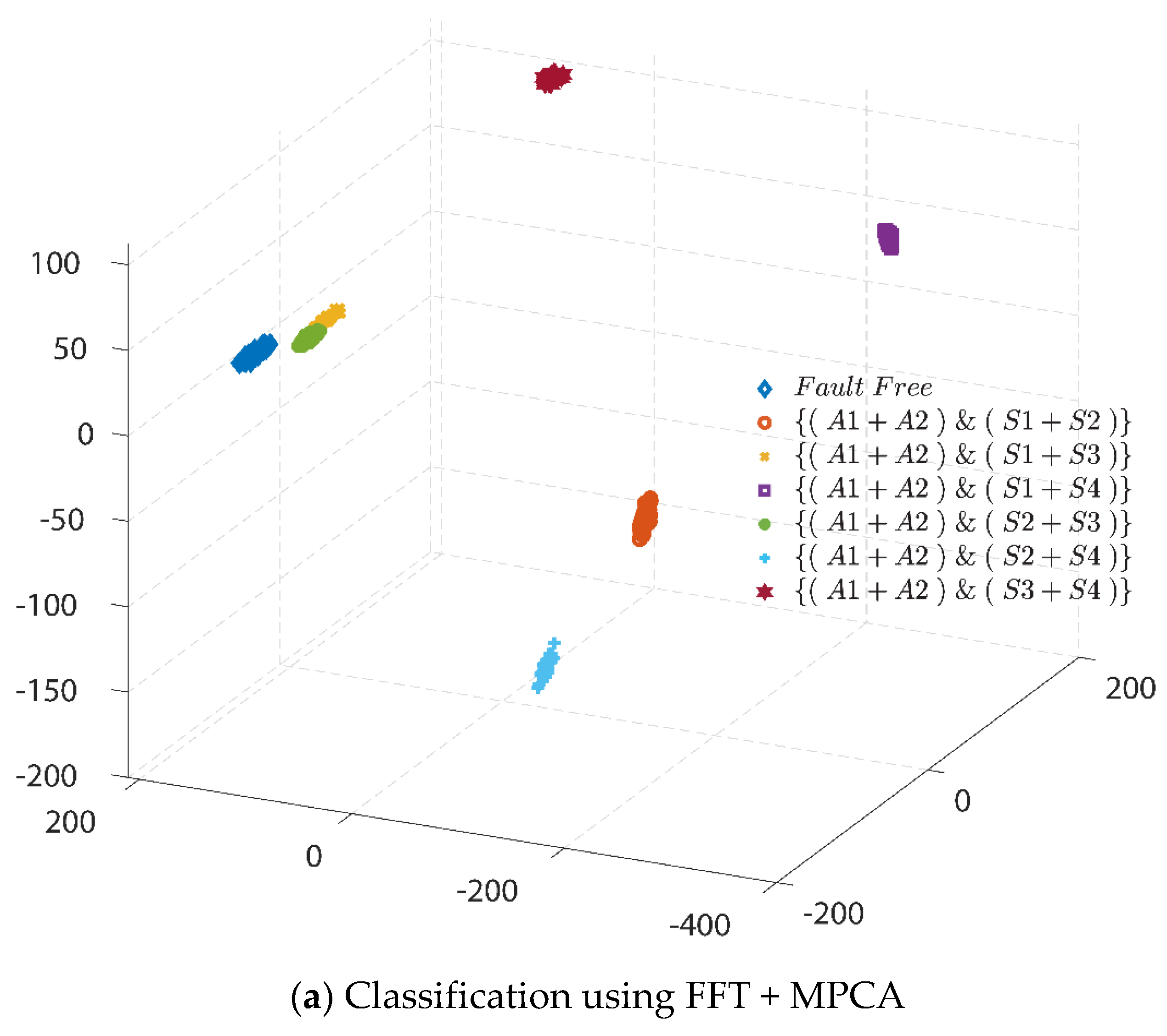

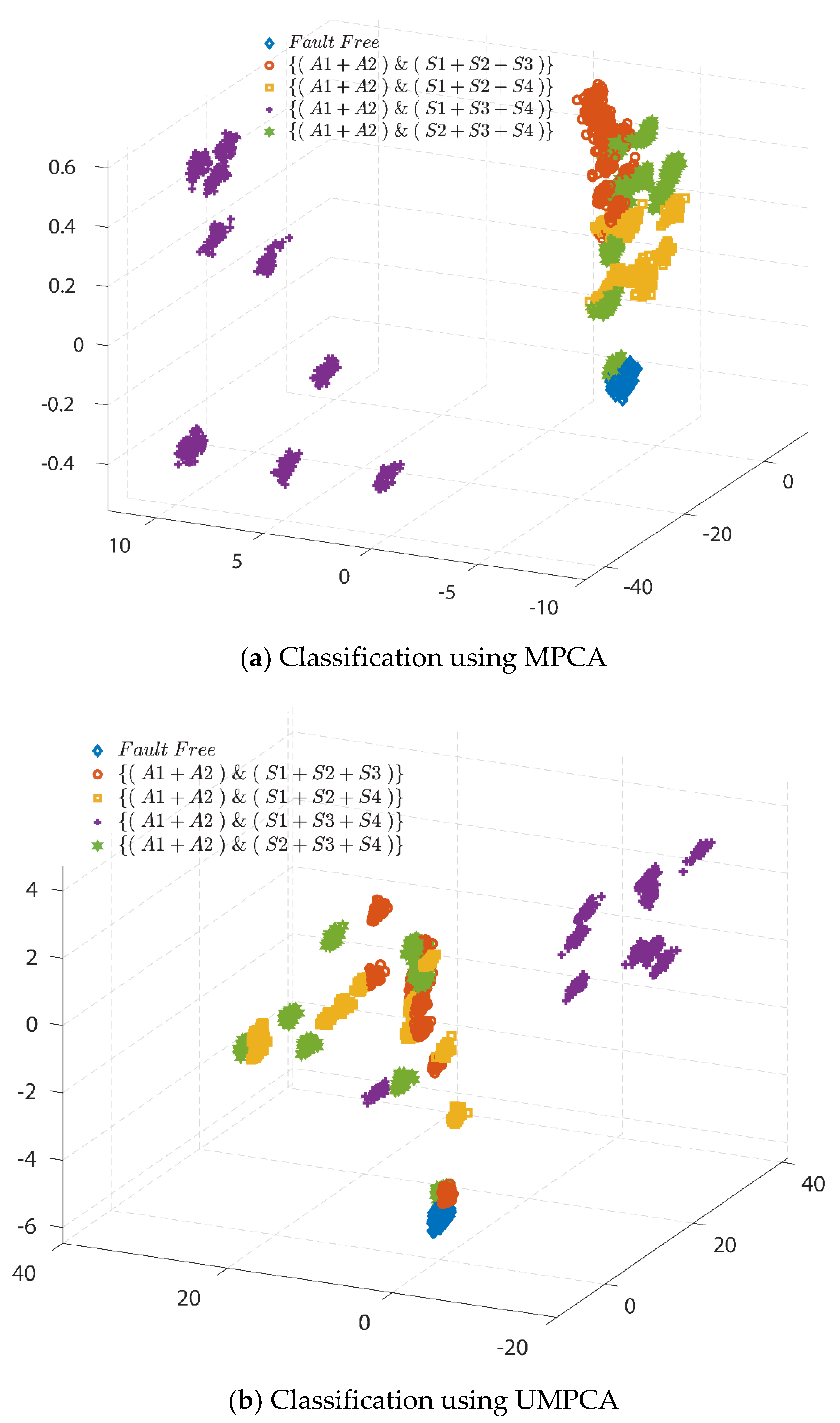

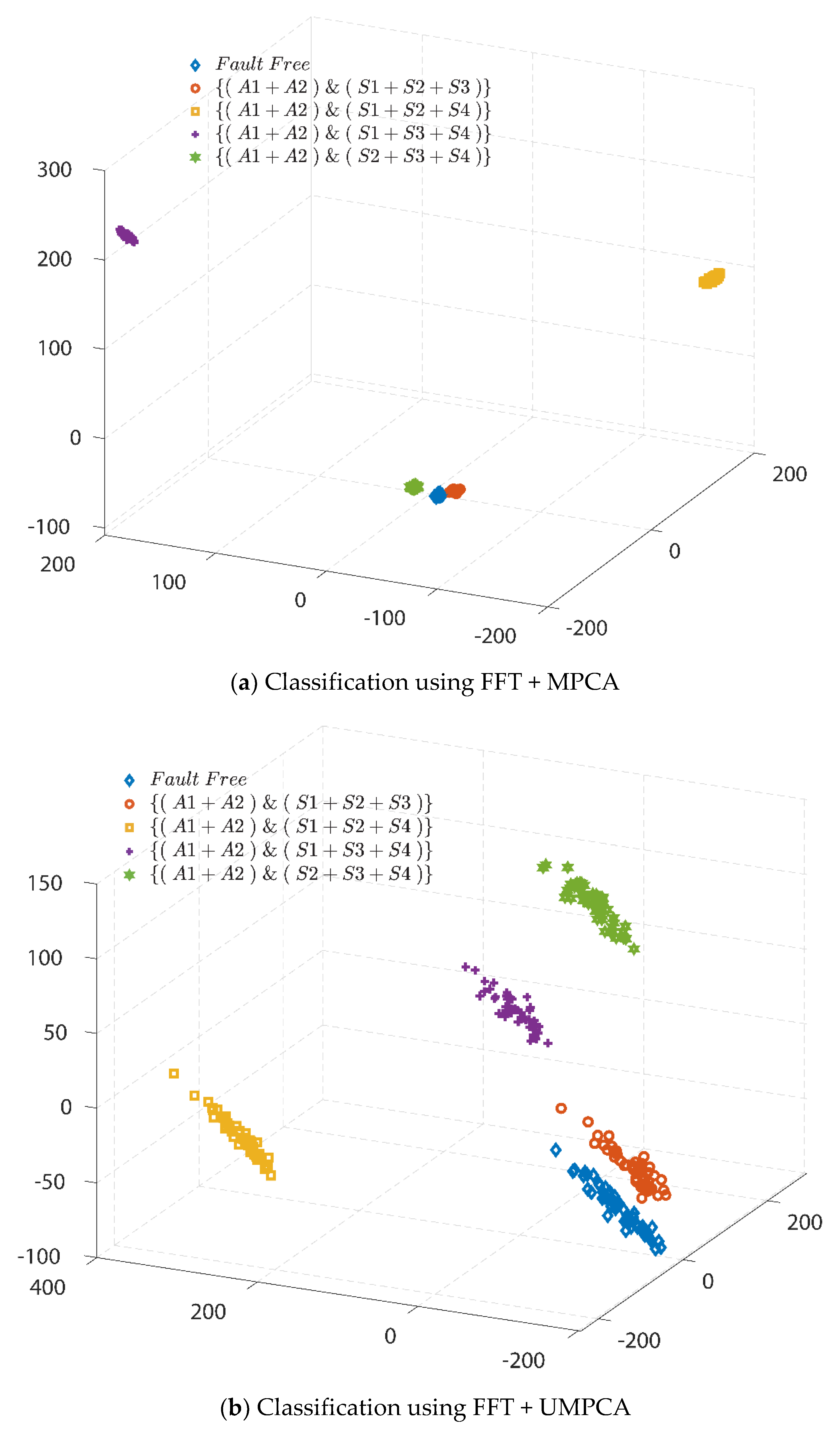

5.5. Feature Extractions and Fault Classifications Based under Scenario IV

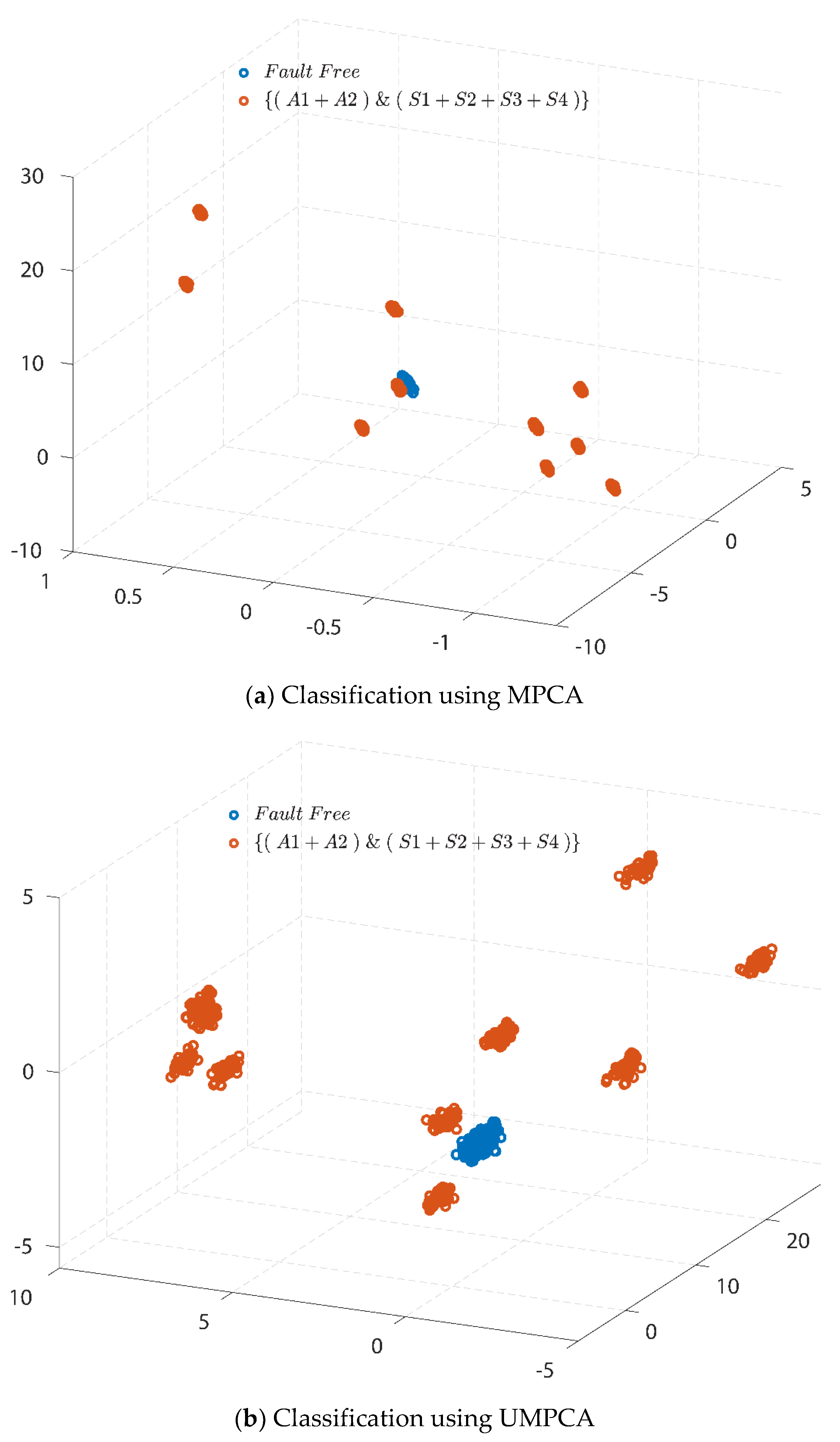

5.6. Feature Extractions and Fault Classifications Based under Scenario V

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rashid, M.H. Electric Renewable Energy Systems; Elsevier, Academic Press: San Diego, CA, USA, 2016. [Google Scholar]

- Gao, R.; Gao, Z. Pitch control for wind turbine systems using optimization, estimation and compensation. Renew. Energy 2016, 91, 501–515. [Google Scholar] [CrossRef]

- Wind Europe. Wind Energy in Europe in 2019: Trends and Statistics. 2020. Available online: https://windeurope.org/wp-content/uploads/files/about-wind/statistics/WindEurope-Annual-Statistics-2019.pdf (accessed on 10 August 2020).

- Gao, Z.; Sheng, S. Real-time monitoring, prognosis, and resilient control for wind turbine systems. Renew. Energy 2018, 116, 1–4. [Google Scholar] [CrossRef]

- Hameed, Z.; Hong, Y.; Cho, Y.; Ahn, S.-H.; Song, C. Condition monitoring and fault detection of wind turbines and related algorithms: A review. Renew. Sustain. Energy Rev. 2009, 13, 1–39. [Google Scholar] [CrossRef]

- Márquez, F.; Tobias, A.M.; Pérez, J.M.P.; Papaelias, M. Condition monitoring of wind turbines: Techniques and methods. Renew. Energy 2012, 46, 169–178. [Google Scholar] [CrossRef]

- Liu, X.; Gao, Z.; Chen, M.Z.Q. Takagi–Sugeno Fuzzy Model Based Fault Estimation and Signal Compensation with Application to Wind Turbines. IEEE Trans. Ind. Electron. 2017, 64, 5678–5689. [Google Scholar] [CrossRef]

- Simani, S.; Farsoni, S.; Castaldi, P. Fault Diagnosis of a Wind Turbine Benchmark via Identified Fuzzy Models. IEEE Trans. Ind. Electron. 2014, 62, 3775–3782. [Google Scholar] [CrossRef]

- Rahimilarki, R.; Gao, Z.; Zhang, A.; Binns, R. Robust Neural Network Fault Estimation Approach for Nonlinear Dynamic Systems with Applications to Wind Turbine Systems. IEEE Trans. Ind. Inform. 2019, 15, 6302–6312. [Google Scholar] [CrossRef]

- Chen, J.; Patton, R.J. Robust Model-Based Fault Diagnosis for Dynamic Systems; Kluwer: Boston, MA, USA, 1999. [Google Scholar]

- Venkatasubramanian, V.; Rengaswamy, R.; Yin, K.; Kavuri, S.N. A review of process fault detection and diagnosis. Comput. Chem. Eng. 2003, 27, 293–311. [Google Scholar] [CrossRef]

- Gao, Z.; Cecati, C.; Ding, S.X. A Survey of Fault Diagnosis and Fault-Tolerant Techniques—Part I: Fault Diagnosis with Model-Based and Signal-Based Approaches. IEEE Trans. Ind. Electron. 2015, 62, 3757–3767. [Google Scholar] [CrossRef] [Green Version]

- Gao, Z.; Cecati, C.; Ding, S.X. A Survey of Fault Diagnosis and Fault-Tolerant Techniques Part II: Fault Diagnosis with Knowledge-Based and Hybrid/Active Approaches. IEEE Trans. Ind. Electron. 2015, 62, 3768–3774. [Google Scholar] [CrossRef] [Green Version]

- Gao, Z.; Ding, S.X.; Cecati, C. Real-time fault diagnosis and fault-tolerant control. IEEE Trans. Ind. Electron. 2015, 62, 3752–3756. [Google Scholar] [CrossRef] [Green Version]

- Zhang, D.; Gao, Z. Improvement of Refrigeration Efficiency by Combining Reinforcement Learning with a Coarse Model. Processes 2019, 7, 967. [Google Scholar] [CrossRef] [Green Version]

- Bergen, K.J.; Johnson, P.A.; De Hoop, M.V.; Beroza, G.C. Machine learning for data-driven discovery in solid Earth geoscience. Science 2019, 363, eaau0323. [Google Scholar] [CrossRef] [PubMed]

- Oh, H.; Jung, J.H.; Jeon, B.C.; Youn, B.D. Scalable and Unsupervised Feature Engineering Using Vibration-Imaging and Deep Learning for Rotor System Diagnosis. IEEE Trans. Ind. Electron. 2018, 65, 3539–3549. [Google Scholar] [CrossRef]

- Song, W.; Wen, L.; Gao, L.; Li, X. Unsupervised fault diagnosis method based on iterative multi-manifold spectral clustering. IET Collab. Intell. Manuf. 2019, 1, 48–55. [Google Scholar] [CrossRef]

- Holtzman, B.K.; Paté, A.; Paisley, J.; Waldhauser, F.; Repetto, D. Machine learning reveals cyclic changes in seismic source spectra in Geysers geothermal field. Sci. Adv. 2018, 4, 5. [Google Scholar] [CrossRef] [Green Version]

- Phan, H.T.H.; Kumar, A.; Feng, D.; Fulham, M.J.; Kim, J. Unsupervised Two-Path Neural Network for Cell Event Detection and Classification Using Spatiotemporal Patterns. IEEE Trans. Med. Imaging 2018, 38, 1477–1487. [Google Scholar] [CrossRef]

- Zhao, R.; Wang, D.; Yan, R.; Mao, K.; Shen, F.; Wang, J. Machine Health Monitoring Using Local Feature-Based Gated Recurrent Unit Networks. IEEE Trans. Ind. Electron. 2018, 65, 1539–1548. [Google Scholar] [CrossRef]

- Elforjani, M.; Shanbr, S. Prognosis of Bearing Acoustic Emission Signals Using Supervised Machine Learning. IEEE Trans. Ind. Electron. 2018, 65, 5864–5871. [Google Scholar] [CrossRef] [Green Version]

- Adeli, E.; Thung, K.-H.; An, L.; Wu, G.; Shi, F.; Wang, P.; Shen, D. Semi-Supervised Discriminative Classification Robust to Sample-Outliers and Feature-Noises. IEEE Trans. Pattern Anal. Mach. Intell. 2019, 41, 515–522. [Google Scholar] [CrossRef]

- Razavi-Far, R.; Hallaji, E.; Farajzadeh-Zanjani, M.; Saif, M.; Kia, S.H.; Henao, H.; Capolino, G.-A. Information Fusion and Semi-Supervised Deep Learning Scheme for Diagnosing Gear Faults in Induction Machine Systems. IEEE Trans. Ind. Electron. 2019, 66, 6331–6342. [Google Scholar] [CrossRef]

- Zhao, M.; Kang, M.; Tang, B.; Pecht, M. Multiple Wavelet Coefficients Fusion in Deep Residual Networks for Fault Diagnosis. IEEE Trans. Ind. Electron. 2019, 66, 4696–4706. [Google Scholar] [CrossRef]

- Ge, Z.; Song, Z.; Ding, S.X.; Huang, B. Data Mining and Analytics in the Process Industry: The Role of Machine Learning. IEEE Access 2017, 5, 20590–20616. [Google Scholar] [CrossRef]

- Guo, M.-F.; Yang, N.-C.; Chen, W.-F. Deep-Learning-Based Fault Classification Using Hilbert–Huang Transform and Convolutional Neural Network in Power Distribution Systems. IEEE Sens. J. 2019, 19, 6905–6913. [Google Scholar] [CrossRef]

- Pan, T.; Chen, J.; Zhou, Z.; Wang, C.; He, S. A Novel Deep Learning Network via Multiscale Inner Product With Locally Connected Feature Extraction for Intelligent Fault Detection. IEEE Trans. Ind. Inform. 2019, 15, 5119–5128. [Google Scholar] [CrossRef]

- Abid, A.; Khan, M.T.; Khan, M.S. Multidomain Features-Based GA Optimized Artificial Immune System for Bearing Fault Detection. IEEE Trans. Syst. Man Cybern. Syst. 2020, 50, 348–359. [Google Scholar] [CrossRef]

- Isermann, R. Fault detection with Principal Component Analysis (PCA). In Fault-Diagnosis Systems; Springer: Berlin/Heidelberg, Germany, 2006; pp. 267–278. [Google Scholar]

- Luu, K.; Savvides, M.; Bui, T.D.; Suen, C.Y. Compressed Submanifold Multifactor Analysis. IEEE Trans. Pattern Anal. Mach. Intell. 2016, 39, 444–456. [Google Scholar] [CrossRef]

- He, H.; Tan, Y. Pattern Clustering of Hysteresis Time Series with Multivalued Mapping Using Tensor Decomposition. IEEE Trans. Syst. Man Cybern. Syst. 2017, 48, 993–1004. [Google Scholar] [CrossRef]

- Yan, S.; Xu, N.; Yang, Q.; Zhang, L.; Tang, X.; Zhang, H.-J. Multilinear discriminant analysis for face recognition. IEEE Trans. Image Process. 2007, 16, 212–220. [Google Scholar] [CrossRef]

- Liu, J.; Rao, B.D. Robust PCA via l0 − l1 Regularization. IEEE Trans. Signal Process. 2018, 67, 535–549. [Google Scholar] [CrossRef]

- Lenz, M.; Mueller, F.-J.; Zenke, M.; Schuppert, A.A. Principal components analysis and the reported low intrinsic dimensionality of gene expression microarray data. Sci. Rep. 2016, 6, 1–11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhou, F.; Park, J.H.; Liu, Y. Differential feature based hierarchical PCA fault detection method for dynamic fault. Neurocomputing 2016, 202, 27–35. [Google Scholar] [CrossRef]

- Vaswani, N.; Bouwmans, T.; Javed, S.; Narayanamurthy, P. Robust Subspace Learning: Robust PCA, Robust Subspace Tracking, and Robust Subspace Recovery. IEEE Signal Process. Mag. 2018, 35, 32–55. [Google Scholar] [CrossRef] [Green Version]

- Shi, Q.; Cheung, Y.-M.; Zhao, Q.; Lu, H. Feature Extraction for Incomplete Data Via Low-Rank Tensor Decomposition With Feature Regularization. IEEE Trans. Neural Netw. Learn. Syst. 2018, 30, 1803–1817. [Google Scholar] [CrossRef] [PubMed]

- Lu, H.; Plataniotis, K.N.; Venetsanopoulos, A. Multilinear Subspace Learning; Dimensionality Reduction of Multidimensional Data; Chapman and Hall/CRC: New York, NY, USA, 2013. [Google Scholar]

- Zhou, C.; Wang, L.; Zhang, Q.; Wei, X. Face recognition based on PCA and logistic regression analysis. Optik 2014, 125, 5916–5919. [Google Scholar] [CrossRef]

- Huang, Y.; Guan, Y. On the linear discriminant analysis for large number of classes. Eng. Appl. Artif. Intell. 2015, 43, 15–26. [Google Scholar] [CrossRef]

- Fu, Y.; Liu, Y.; Gao, Z. Fault Classification in Wind Turbines Using Principal Component Analysis Technique. In Proceedings of the 2019 IEEE 17th International Conference on Industrial Informatics (INDIN); Institute of Electrical and Electronics Engineers (IEEE), Helsinki-Espoo, Finland, 22–25 July 2019; Volume 1, pp. 1303–1308. [Google Scholar]

- Odgaard, P.F.; Stoustrup, J.; Kinnaert, M. Fault Tolerant Control of Wind Turbines—A benchmark model. In Proceedings of the 7th IFAC Symposium on Fault Detection, Supervision and Safety of Technical Processes, Barcelona, Spain, 30 June–3 July 2009; Volume 1, pp. 155–160. [Google Scholar]

- Odgaard, P.; Kinnaert, M.; Stoustrup, J. Fault-Tolerant Control of Wind Turbines: A Benchmark Model. IEEE Trans. Control Syst. Technol. 2013, 21, 1168–1182. [Google Scholar] [CrossRef] [Green Version]

- Vaibhav, V. Higher Order Convergent Fast Nonlinear Fourier Transform. IEEE Photonics Technol. Lett. 2018, 30, 700–703. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Patel, V.M.; Petropulu, A.P. Multidimensional Sparse Fourier Transform Based on the Fourier Projection-Slice Theorem. IEEE Trans. Signal Process. 2019, 67, 54–69. [Google Scholar] [CrossRef]

- Fu, Y.; Liu, Y.; Zhang, A.; Gao, Z. Multiple Actuator Fault Classification for Wind Turbine Systems by Integrating Fast Fourier Transform (FFT) and Multi-linear Principal Component Analysis (MPCA). In Proceedings of the IECON 2019—45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Portugal, 14–17 October 2019; Volume 1, pp. 3761–3766. [Google Scholar]

- Lu, H.; Plataniotis, K.N.K.; Venetsanopoulos, A.N. Uncorrelated multilinear principal component analysis for unsupervised multilinear subspace learning. IEEE Trans. Neural Netw. 2009, 20, 1820–1836. [Google Scholar] [CrossRef] [Green Version]

| Symbol | Definition | Symbol | Definition |

|---|---|---|---|

| Pitch angle Reference | Torsion Angle | ||

| Generator Torque Reference | Damping Ratio | ||

| Pitch Angle | Torsion Damping Coefficient | ||

| Generator Rotating Speed | Generator External Damping | ||

| Rotor Angular Speed | Rotor External Damping | ||

| Generator Torque | Torque Coefficient | ||

| Generator and Converter Parameter | Generator Moment of Inertia | ||

| Efficiency of Drive Train | Rotor Moment of Inertia | ||

| Tip-Speed-Ratio | Torsion Stiffness | ||

| Natural Frequency | Gear Ratio | ||

| Air Density | Rotor Radius |

| Actuator | Sensor | |||||

|---|---|---|---|---|---|---|

| Symbol | ||||||

| Acronym | A1 | A2 | S1 | S2 | S3 | S4 |

| Operation Conditions | Abbreviations | Parameters | Acronyms |

|---|---|---|---|

| Fault Free | FF | - | - |

| Effectiveness Losses | EL | Percentage | P |

| Sinusoidal Wave Disturbances | SWD | Amplitude & Bias | A/B |

| Random Numbers | RN | Mean & Variance | M/V |

| Effectiveness Losses + Sinusoidal Wave Disturbances | EL + SWD | Percentage + Amplitude + Bias | P/A/B |

| Effectiveness Losses + Random Numbers | EL + RN | Percentage + Mean + Variance | P/M/V |

| Sinusoidal Wave Disturbances + Random Numbers | SWD + RN | Amplitude + Bias + Mean + Variance | A/B/M/V |

| Effectiveness Losses + Sinusoidal Wave Disturbances + Random Numbers | EL + SWD + RN | Amplitude + Bias + Mean + Variance | P/A/B/M/V |

| Faulty Conditions | Name of Parameters | Actuator and Sensor Faults | |||||

|---|---|---|---|---|---|---|---|

| Actuator | Sensor | ||||||

| EL | P | 1.00–20.00% | |||||

| SWD | A | 0.01–0.20 | 5.20–9.00 | 0.01–0.20 | 5.20–9.00 | 0.01–0.20 | 5.20–9.00 |

| B | 0.10–2.00 | 501–520 | 0.10–2.00 | 50.10–52.00 | 0.01–0.20 | 501–520 | |

| RN | M | 0.10–2.00 | 1.00–20.00 | 0.10–2.00 | 1.00–20.00 | 0.01–0.20 | 1.00–20.00 |

| V | 0.20–2.10 | 91.00–110.00 | 0.20–2.10 | 1.10–2.05 | 0.01–0.20 | 91.00–110.00 | |

| EL + SWD | P/A/B | : P/A/B—From 1.00%/0.01/0.10 to 20.00%/0.20/2.00; | |||||

| : P/A/B—From 1.00%/5.20/501 to 20.00%/9.00/520; | |||||||

| : P/A/B—From 1.00%/0.01/0.10 to 20.00%/0.20/2.00; | |||||||

| : P/A/B—From 1.00%/5.20/50.10 to 20.00%/9.00/52.00; | |||||||

| : P/A/B—From 1.00%/0.01/0.01 to 20.00%/0.20/0.20; | |||||||

| : P/A/B—From 1.00%/5.20/501 to 20.00%/9.00/520. | |||||||

| EL + RN | P/M/V | : P/M/V—From 1.00%/0.10/0.20 to 20.00%/2.00/2.10; | |||||

| : P/M/V—From 1.00%/1.00/91 to 20.00%/20.00/110; | |||||||

| : P/M/V—From 1.00%/0.10/0.20 to 20.00%/2.00/2.10; | |||||||

| : P/M/V—From 1.00%/1.00/1.10 to 20.00%/20.00/2.05; | |||||||

| : P/M/V—From 1.00%/0.01/0.01 to 20.00%/0.20/0.20; | |||||||

| : P/M/V—From 1.00%/1.00/91 to 20.00%/20.00/110. | |||||||

| SWD + RN | A/B/M/V | : A/B/M/V—From 0.01/0.10/0.10/0.20 to 0.20/2.00/2.00/2.10; | |||||

| : A/B/M/V—From 5.20/501/1.00/91 to 9.00/520/20.00/110; | |||||||

| : A/B/M/V—From 0.01/0.10/0.10/0.20 to 0.20/2.00/2.00/2.10; | |||||||

| : A/B/M/V—From 5.20/50.10/1.00/1.10 to 9.00/52.00/20.00/2.05; | |||||||

| : A/B/M/V—From 0.01/0.01/0.01/0.01 to 0.20/0.20/0.20/0.20; | |||||||

| : A/B/M/V—From 5.20/501/1.00/91 to 9.00/520/20.00/110. | |||||||

| EL + SWD + RN | P/A/B/M/V | : P/A/B/M/V—From 1.00%/0.01/0.10/0.10/0.20 | |||||

| to 20.00%/0.20/2.00/2.00/2.10; | |||||||

| : P/A/B/M/V—From 1.00%/5.20/501/1.00/91 | |||||||

| to 20.00%/9.00/520/20.00/110; | |||||||

| : P/A/B/M/V—From 1.00%/0.01/0.10/0.10/0.20 | |||||||

| to 20.00%/0.20/2.00/2.00/2.10; | |||||||

| : P/A/B/M/V—From 1.00%/5.20/501/1.00/1.10 | |||||||

| to 20.00%/9.00/52.00/20.00/2.05; | |||||||

| : P/A/B/M/V—From 1.00%/0.01/0.01/0.01/0.01 | |||||||

| to 20.00%/0.20/0.20/0.20/0.20; | |||||||

| : P/A/B/M/V—From 1.00%/5.20/501/1.00/91 | |||||||

| to 20.00%/9.00/520/20.00/110. | |||||||

| Name of Experimentation | Types | Data Sets with AWGN Noises Based on Different Topologies of Data-Driven Methodologies | |

|---|---|---|---|

| MPCA | UMPCA | ||

| FF + 1AF + 3SFs | 9 | ||

| FF + 1AF + 4SFs | 3 | ||

| FF + 2AFs + 2SFs | 7 | ||

| FF + 2AFs + 3SFs | 5 | ||

| FF + 2AFs + 4SFs | 2 | ||

| Name of Experimentation | Types | Data Sets with AWGN Noises Based on Different Topologies of Data-Driven Methodologies | |

|---|---|---|---|

| FFT + MPCA | FFT + UMPCA | ||

| FF + 1AF + 3SFs | 9 | ||

| FF + 1AF + 4SFs | 3 | ||

| FF + 2AFs + 2SFs | 7 | ||

| FF + 2AFs + 3SFs | 5 | ||

| FF + 2AFs + 4SFs | 2 | ||

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, Y.; Gao, Z.; Liu, Y.; Zhang, A.; Yin, X. Actuator and Sensor Fault Classification for Wind Turbine Systems Based on Fast Fourier Transform and Uncorrelated Multi-Linear Principal Component Analysis Techniques. Processes 2020, 8, 1066. https://0-doi-org.brum.beds.ac.uk/10.3390/pr8091066

Fu Y, Gao Z, Liu Y, Zhang A, Yin X. Actuator and Sensor Fault Classification for Wind Turbine Systems Based on Fast Fourier Transform and Uncorrelated Multi-Linear Principal Component Analysis Techniques. Processes. 2020; 8(9):1066. https://0-doi-org.brum.beds.ac.uk/10.3390/pr8091066

Chicago/Turabian StyleFu, Yichuan, Zhiwei Gao, Yuanhong Liu, Aihua Zhang, and Xiuxia Yin. 2020. "Actuator and Sensor Fault Classification for Wind Turbine Systems Based on Fast Fourier Transform and Uncorrelated Multi-Linear Principal Component Analysis Techniques" Processes 8, no. 9: 1066. https://0-doi-org.brum.beds.ac.uk/10.3390/pr8091066