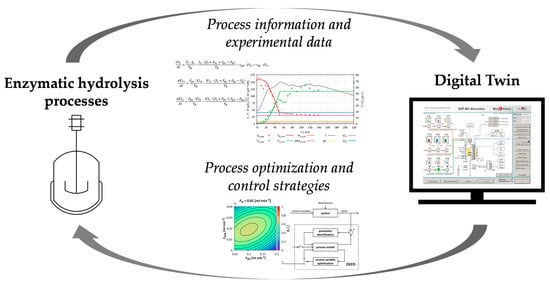

Development of a Digital Twin for Enzymatic Hydrolysis Processes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Development of the Enzymatic Hydrolysis Process Model

2.2. Integration of the Mathematical Model for the Combined Starch Hydrolysis and Proteolysis into an Existing DT of a 20 L STR

2.3. Enzymatic Hydrolysis Processes (Starch Hydrolysis and Proteolysis)

2.3.1. Starch Hydrolysis

2.3.2. Proteolysis

3. Results

3.1. Process Description of the Enzymatic Hydrolysis Processes (Starch Hydrolysis and Proteolysis)

3.2. Mathematical Modeling of the Enzymatic Hydrolysis Process Combining Starch Hydrolysis and Proteolysis

3.3. Temperature- and pH-Dependency of the Enzymes Used in Starch Hydrolysis and Proteolysis

3.4. Designing Experiments Using the Model of the Enzymatic Hydrolysis Processes

3.4.1. Starch Hydrolysis

3.4.2. Proteolysis

3.5. Application of the DT for Enzymatic Hydrolysis Processes

4. Discussion and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Vaccari, M.; Di Bacci Capaci, R.; Brunazzi, E.; Tognotti, L.; Pierno, P.; Vagheggi, R.; Pannocchia, G. Optimally Managing Chemical Plant Operations: An Example Oriented by Industry 4.0 Paradigms. Ind. Eng. Chem. Res. 2021, 60, 7853–7867. [Google Scholar] [CrossRef]

- Liu, M.; Fang, S.; Dong, H.; Xu, C. Review of digital twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 2021, 58, 346–361. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inf. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Appl, C.; Moser, A.; Baganz, F.; Hass, V.C. Digital Twins for Bioprocess Control Strategy Development and Realisation. Adv. Biochem. Eng. Biotechnol. 2021, 177, 63–94. [Google Scholar] [CrossRef] [PubMed]

- Narayanan, H.; Luna, M.F.; von Stosch, M.; Cruz Bournazou, M.N.; Polotti, G.; Morbidelli, M.; Butté, A.; Sokolov, M. Bioprocessing in the Digital Age: The Role of Process Models. Biotechnol. J. 2020, 15, e1900172. [Google Scholar] [CrossRef] [PubMed]

- Grieves, M. Origins of the Digital Twin Concept. Available online: https://www.researchgate.net/publication/307509727_Origins_of_the_Digital_Twin_Concept (accessed on 27 September 2021).

- Glaessgen, E.; Stargel, D. The Digital Twin Paradigm for Future NASA and U.S. Air Force Vehicles. AIAA Meet. Pap. 2012, 22267B. [Google Scholar] [CrossRef] [Green Version]

- El Saddik, A. Digital Twins: The Convergence of Multimedia Technologies. IEEE MultiMedia 2018, 25, 87–92. [Google Scholar] [CrossRef]

- He, R.; Chen, G.; Dong, C.; Sun, S.; Shen, X. Data-driven digital twin technology for optimized control in process systems. ISA Trans. 2019, 95, 221–234. [Google Scholar] [CrossRef]

- Zobel-Roos, S.; Schmidt, A.; Mestmäcker, F.; Mouellef, M.; Huter, M.; Uhlenbrock, L.; Kornecki, M.; Lohmann, L.; Ditz, R.; Strube, J. Accelerating Biologics Manufacturing by Modeling or: Is Approval under the QbD and PAT Approaches Demanded by Authorities Acceptable Without a Digital-Twin? Processes 2019, 7, 94. [Google Scholar] [CrossRef] [Green Version]

- Blesgen, A.; Hass, V.C. Efficient Biogas Production through Process Simulation. Energy Fuels 2010, 24, 4721–4727. [Google Scholar] [CrossRef]

- Moser, A.; Appl, C.; Brüning, S.; Hass, V.C. Mechanistic Mathematical Models as a Basis for Digital Twins. Adv. Biochem. Eng. Biotechnol. 2021, 176, 133–180. [Google Scholar] [CrossRef]

- Beschkov, V.; Marc, A.; Engasser, J.M. A kinetic model for the hydrolysis and synthesis of maltose, isomaltose, and maltotriose by glucoamylase. Biotechnol. Bioeng. 1984, 26, 22–26. [Google Scholar] [CrossRef] [PubMed]

- Kusunoki, K.; Kawakami, K.; Shiraishi, F.; Kato, K.; Kai, M. A kinetic expression for hydrolysis of soluble starch by glucoamylase. Biotechnol. Bioeng. 1982, 24, 347–354. [Google Scholar] [CrossRef] [PubMed]

- Beaubier, S.; Framboisier, X.; Fournier, F.; Galet, O.; Kapel, R. A new approach for modelling and optimizing batch enzymatic proteolysis. Chem. Eng. J. 2021, 405, 126871. [Google Scholar] [CrossRef]

- Hass, V.C. Verbesserung der bioverfahrenstechnischen Ausbildung durch einen “Virtuellen Bioreaktor”. Chem. Ing. Tech. 2005, 77, 161–167. [Google Scholar] [CrossRef]

- Hass, V.C.; Knutzsch, S.; Gerlach, I.; Kühn, K.; Winterhalter, M. Towards the Development of a Training Simulator for Biorefineries. Chem. Eng. Trans. 2012, 247–252. [Google Scholar] [CrossRef]

- Gerlach, I.; Hass, V.C.; Brüning, S.; Mandenius, C.-F. Virtual bioreactor cultivation for operator training and simulation: Application to ethanol and protein production. J. Chem. Technol. Biotechnol. 2013, 88, 2159–2168. [Google Scholar] [CrossRef]

- Gerlach, I.; Hass, V.; Mandenius, C.-F. Conceptual Design of an Operator Training Simulator for a Bio-Ethanol Plant. Processes 2015, 3, 664–683. [Google Scholar] [CrossRef] [Green Version]

- Hass, V.C.; Kuhnen, F.; Schoop, K.-M. Rapid Design of interactive operator-training simulators for training and education. In Proceedings of the 7th World Congress of Chemical Engineering, WCCE, Glasgow, Scotland, 10–14 July 2005. [Google Scholar]

- Hass, V.C. Operator Training Simulators for Bioreactors. In Bioreactors: Design, Operation and Novel Applications; Mandenius, C.-F., Ed.; Wiley: Weinheim, Germany, 2016; pp. 453–486. ISBN 9783527683369. [Google Scholar]

- Isimite, J.; Baganz, F.; Hass, V.C. Operator training simulators for biorefineries: Current position and future directions. J. Chem. Technol. Biotechnol. 2018, 93, 1529–1541. [Google Scholar] [CrossRef]

- Hirschmann, R.; Borodkin, N.; Baganz, F.; Hass, V.C. Towards the Integration of the Anaerobic Ethyl (S)-3-Hydroxybutyrate Production Process into a Biorefinery Concept. Chem. Eng. Trans. 2018, 70, 559–564. [Google Scholar]

- Hass, V.C.; Kuhnen, F.; Schoop, K.-M. An environment for the development of operator training systems (OTS) from chemical engineering models. Comput. Aided Chem. Eng. 2005, 289–293. [Google Scholar] [CrossRef]

- Moser, A.; Kuchemüller, K.B.; Deppe, S.; Hernández Rodríguez, T.; Frahm, B.; Pörtner, R.; Hass, V.C.; Möller, J. Model-assisted DoE software: Optimization of growth and biocatalysis in Saccharomyces cerevisiae bioprocesses. Bioprocess Biosyst. Eng. 2021, 44, 683–700. [Google Scholar] [CrossRef]

- Nelder, J.A.; Mead, R. A Simplex Method for Function Minimization. Comput. J. 1965, 7, 308–313. [Google Scholar] [CrossRef]

- R Core Team. The R Project for Statistical Computing. Available online: www.R-project.org (accessed on 27 September 2021).

- Ingenieurbüro Dr.-Ing.Schoop GmbH. WinErs. Process control and automation system on PC under Windows. Available online: www.schoop.de (accessed on 27 September 2021).

- Illanes, A. Enzyme Biocatalysis: Principles and Applications; Springer: Dordrecht, The Netherlands, 2008; ISBN 1402083610. [Google Scholar]

- Chutipongtanate, S.; Watcharatanyatip, K.; Homvises, T.; Jaturongkakul, K.; Thongboonkerd, V. Systematic comparisons of various spectrophotometric and colorimetric methods to measure concentrations of protein, peptide and amino acid: Detectable limits, linear dynamic ranges, interferences, practicality and unit costs. Talanta 2012, 98, 123–129. [Google Scholar] [CrossRef]

- Buckow, R.; Heinz, V.; Knorr, D. Two Fractional Model for Evaluating the Activity of Glucoamylase from Aspergillus Niger Under Combined Pressure and Temperature Conditions. Food Bioprod. Process. 2005, 83, 220–228. [Google Scholar] [CrossRef]

- Buckow, R.; Weiss, U.; Heinz, V.; Knorr, D. Stability and catalytic activity of alpha-amylase from barley malt at different pressure-temperature conditions. Biotechnol. Bioeng. 2007, 97, 1–11. [Google Scholar] [CrossRef]

- Nebesny, E. Kombinierte enzymatische Stärkehydrolyse. Starch/Stärke 1989, 41, 266–270. [Google Scholar] [CrossRef]

- Rao, M.B.; Tanksale, A.M.; Ghatge, M.S.; Deshpande, V.V. Molecular and biotechnological aspects of microbial proteases. Microbiol. Mol. Biol. Rev. 1998, 62, 597–635. [Google Scholar] [CrossRef] [Green Version]

- Lee, C.-G.; Kim, C.H.; Rhee, S.K. A kinetic model and simulation of starch saccharification and simultaneous ethanol fermentation by amyloglucosidase and Zymomonas mobilis. Bioprocess Eng. 1992, 7, 335–341. [Google Scholar] [CrossRef]

- Kuntzsch, S. Energy Efficiency Investigations with a New Operator Training Simulator for Biorefineries. Ph.D. Thesis, Jacobs University, Bremen, Germany, 2014. [Google Scholar]

- Brüning, S. Development of a Generalized Process Model for Optimization of Biotechnological Processes. Ph.D. Thesis, Jacobs University, Bremen, Germany, 2016. [Google Scholar]

- Novozymes A/S. Novozymes Spirizyme® Products for use in saccharification and fermentation: Application Sheet 2010. Available online: https://docplayer.net/20898529-Application-sheet-novozymes-spirizyme-products-for-use-in-saccharification-and-fermentation.html (accessed on 27 September 2021).

- Novozymes A/S. Product Sheet: Termamyl SC 2004. Available online: http://www.ebiosis.co.kr/Novozymes%20Product%20Sheet/Termamyl%20SC.pdf (accessed on 27 September 2021).

- Ziegler, J.G.; Nichols, N.B. Optimum Settings for Automatic Controllers. J. Dyn. Syst. Meas. Control. 1993, 115, 220–222. [Google Scholar] [CrossRef]

- Witte, V.C.; Munack, A.; Märkl, H. Mathematische Modellierung und Adaptive Prozeßsteuerung der Kultivierung von Cyathus Striatus; Zugl.: Hamburg-Harburg, Techn. Univ., Arbeitsbereich Regelungstechnik und Systemdynamik [i.e. Arbeitsbereich Regelungstechnik] und Arbeitsbereich Bioprozess- und Bioverfahrenstechnik, Diss., Als Ms. gedr; VDI-Verl.: Düsseldorf, Germany, 1996; ISBN 3183144174. [Google Scholar]

| Abbreviations | Description |

|---|---|

| rSIP,E1 | Degradation rate of substrate to intermediate product. |

| rSP,E1 | Degradation rate of substrate to product. |

| rIPP,E2 | Degradation rate of intermediate product to product. |

| rmax,SIP,E1 | Maximum degradation rate of substrate to intermediate product. |

| rmax,SP,E1 | Maximum degradation rate of substrate to product. |

| rmax,IPP,E2 | Maximum degradation rate of intermediate product to product. |

| KM,SIP,E1 | Half-saturation constant for degradation of substrate to intermediate product. |

| KM,SP,E1 | Half-saturation constant for degradation of substrate to product. |

| KM,IPP,E2 | Half-saturation constant for degradation of intermediate product to product. |

| fT,act,E1 | Factor for temperature-dependent activity of enzyme 1. |

| fT,act,E2 | Factor for temperature-dependent activity of enzyme 2. |

| fpH,act,E1 | Factor for pH-dependent activity of enzyme 1. |

| fpH,act,E2 | Factor for pH-dependent activity of enzyme 2. |

| rIPS,E1 | Conversation rate of intermediate product from substrate. |

| rPS,E1 | Conversation rate of product from substrate. |

| rPIP,E2 | Conversation rate of product from intermediate product. |

| YIPS,E1 | Yield coefficient for conversation of intermediate product from substrate. |

| YPS,E1 | Yield coefficient for conversation of product from substrate. |

| YPIP,E2 | Yield coefficient for conversation of product from intermediate product. |

| rden,E1 | Denaturation rate of enzyme 1. |

| rden,E2 | Denaturation rate of enzyme 2. |

| rmax,den,E1 | Maximum denaturation rate of enzyme 1. |

| rmax,den,E2 | Maximum denaturation rate of enzyme 2. |

| fT,sta,E1 | Factor for temperature-dependent stability of enzyme 1. |

| fT,sta,E2 | Factor for temperature-dependent stability of enzyme 2. |

| fpH,sta,E1 | Factor for pH-dependent stability of enzyme 1. |

| fpH,sta,E2 | Factor for pH-dependent stability of enzyme 2. |

| VB | Volume of broth in the reactor. |

| S1 | Concentration of starch in the reactor. |

| SH1 | Concentration of the hydrolysable components of the substrate in the reactor. |

| SNH1 | Concentration of the non-hydrolysable components of the substrate in the reactor. |

| E11 | Concentration of enzyme 1 in the reactor. |

| E21 | Concentration of enzyme 2 in the reactor. |

| IP1 | Concentration of the intermediate product in the reactor. |

| P1 | Concentration of the product in the reactor. |

| FS,0 | Inflow of substrate solution to the reactor. |

| FE1,0 | Inflow of enzyme 1 to the reactor. |

| FE2,0 | Inflow of enzyme 2 to the reactor. |

| SH0 | Concentration of the hydrolysable components of the substrate in FS,0. |

| SNH0 | Concentration of the non-hydrolysable components of the substrate in FS,0. |

| E10 | Concentration of enzyme 1 in FE1,0. |

| E20 | Concentration of enzyme 2 in FE2,0. |

| IP0 | Concentration of the intermediate product in FS,0. |

| P0 | Concentration of the product in FS,0. |

| Fin | Absolute inflow into the reactor. |

| Fout | Absolute outflow from the reactor. |

| Parameter | Description | Value |

|---|---|---|

| YLS,T,act,E1,P1 | DSig value at low temperature. | 0.0 |

| Ymid,T,act,E1,P1 | DSig value between rmax,Tlow,E1,P1 and rmaxT,high,E1,P1. | 1.0 |

| YRS,T,act,E1,P1 | DSig value at high temperature. | 1.0 |

| KLS,T,act,E1,P1 | Slope on the low side of the DSig function. | 0.1 |

| KRS,T,act,E1,P1 | Slope on the high side of the DSig function. | 0.1 |

| rmax,Tlow,act,E1,P1 | Location parameter of the low side of the DSig function. | 56.0 °C |

| rmax,Thigh,act,E1,P1 | Location parameter of the high side of the DSig function. | 56.0 °C |

| YLS,pH,act,E1,P1 | DSig value at low pH. | 0.0 |

| Ymid,pH,act,E1,P1 | DSig value between rmax,pHlow,act,E1,P1 and rmax,pHhigh,act,E1,P1. | 1.4 |

| YRS,pH,act,E1,P1 | DSig value at high pH. | 0.0 |

| KLS,pH,act,E1,P1 | Slope on the low side of the DSig function. | 3.5 |

| KRS,pH,act,E1,P1 | Slope on the high side of the DSig function. | 1.6 |

| rmax,pHlow,act,E1,P1 | Location parameter of the low side of the DSig function. | 4.5 |

| rmax,pHhigh,act,E1,P1 | Location parameter of the high side of the DSig function. | 6.0 |

| YLS,T,act,E2,P1 | DSig value at low temperature. | 0.0 |

| Ymid,T,act,E2,P1 | DSig value between rmax,Tlow,E2,P1 and rmaxT,high,E2,P1. | 1.0 |

| YRS,T,act,E2,P1 | DSig value at high temperature. | 1.0 |

| KLS,T,act,E2,P1 | Slope on the low side of the DSig function. | 0.1 |

| KRS,T,act,E2,P1 | Slope on the high side of the DSig function. | 0.1 |

| rmax,Tlow,act,E2,P1 | Location parameter of the low side of the DSig function. | 45.0 °C |

| rmax,Thigh,act,E2,P1 | Location parameter of the high side of the DSig function. | 45.0 °C |

| YLS,pH,act,E2,P1 | DSig value at low pH. | 0.0 |

| Ymid,pH,act,E2,P1 | DSig value between rmax,pHlow,act,E2,P1 and rmax,pHhigh,act,E2,P1. | 1.0 |

| YRS,pH,act,E2,P1 | DSig value at high pH. | 0.0 |

| KLS,pH,act,E2,P1 | Slope on the low side of the DSig function. | 3.0 |

| KRS,pH,act,E2,P1 | Slope on the high side of the DSig function. | 3.0 |

| rmax,pHlow,act,E2,P1 | Location parameter of the low side of the DSig function. | 4.0 |

| rmax,pHhigh,act,E2,P1 | Location parameter of the high side of the DSig function. | 8.5 |

| Parameter | Description | Value |

|---|---|---|

| YLS,T,act,E1,P2 | DSig value at low temperature. | 0.0 |

| Ymid,T,act,E1,P2 | DSig value between rmax,Tlow,E1,P2 and rmaxT,high,E1,P2. | 1.5 |

| YRS,T,act,E1,P2 | DSig value at high temperature. | 0.0 |

| KLS,T,act,E1,P2 | Slope on the low side of the DSig function. | 0.1 |

| KRS,T,act,E1,P2 | Slope on the high side of the DSig function. | 0.2 |

| rmax,Tlow,act,E1,P2 | Location parameter of the low side of the DSig function. | 43.0 °C |

| rmax,Thigh,act,E1,P2 | Location parameter of the high side of the DSig function. | 65.0 °C |

| YLS,pH,act,E1,P2 | DSig value at low pH. | 0.0 |

| Ymid,pH,act,E1,P2 | DSig value between rmax,pHlow,act,E1,P2 and rmax,pHhigh,act,E1,P2. | 1.1 |

| YRS,pH,act,E1,P2 | DSig value at high pH. | 0.0 |

| KLS,pH,act,E1,P2 | Slope on the low side of the DSig function. | 2.5 |

| KRS,pH,act,E1,P2 | Slope on the high side of the DSig function. | 2.0 |

| rmax,pHlow,act,E1,P2 | Location parameter of the low side of the DSig function. | 5.8 |

| rmax,pHhigh,act,E1,P2 | Location parameter of the high side of the DSig function. | 8.6 |

| YLS,T,act,E2,P2 | DSig value at low temperature. | 0.0 |

| Ymid,T,act,E2,P2 | DSig value between rmax,Tlow,E2,P2 and rmaxT,high,E2,P2. | 1.1 |

| YRS,T,act,E2,P2 | DSig value at high temperature. | 0.0 |

| KLS,T,act,E2,P2 | Slope on the low side of the DSig function. | 0.1 |

| KRS,T,act,E2,P2 | Slope on the high side of the DSig function. | 0.2 |

| rmax,Tlow,act,E2,P2 | Location parameter of the low side of the DSig function. | 28.0 °C |

| rmax,Thigh,act,E2,P2 | Location parameter of the high side of the DSig function. | 64.0 °C |

| YLS,pH,act,E2,P2 | DSig value at low pH. | 0.0 |

| Ymid,pH,act,E2,P2 | DSig value between rmax,pHlow,act,E2,P2 and rmax,pHhigh,act,E2,P2. | 1.8 |

| YRS,pH,act,E2,P2 | DSig value at high pH. | 0.0 |

| KLS,pH,act,E2,P2 | Slope on the low side of the DSig function. | 1.2 |

| KRS,pH,act,E2,P2 | Slope on the high side of the DSig function. | 1.0 |

| rmax,pHlow,act,E2,P2 | Location parameter of the low side of the DSig function. | 6.4 |

| rmax,pHhigh,act,E2,P2 | Location parameter of the high side of the DSig function. | 8.4 |

| Parameter | Description | Initial | Adjusted |

|---|---|---|---|

| rmax,SIP,E1,P1 | Maximum degradation rate of substrate to intermediate product. | 1.10 s−1 | 2.00 s−1 |

| rmax,SP,E1,P1 | Maximum degradation rate of substrate to product. | 1.30 s−1 | 0.10 s−1 |

| rmax,IPP,E2,P1 | Maximum degradation rate of intermediate product to product. | 1.80 s−1 | 1.99 s−1 |

| KM,SIP,E1,P1 | Half-saturation constant for degradation of substrate to intermediate product. | 1.40 g L−1 | 15.04 g L−1 |

| KM,SP,E1,P1 | Half-saturation constant for degradation of substrate to product. | 9.00 g L−1 | 20.00 g L−1 |

| KM,IPP,E2,P1 | Half-saturation constant for degradation of intermediate product to product. | 9.00 g L−1 | 8.32 g L−1 |

| Parameter | Description | Initial | Adjusted |

|---|---|---|---|

| rmax,SIP,E1,P2 | Maximum degradation rate of substrate to intermediate product. | 0.70 s−1 | 0.10 s−1 |

| rmax,SP,E1,P2 | Maximum degradation rate of substrate to product. | 0.16 s−1 | 0.16 s−1 |

| rmax,IPP,E2,P2 | Maximum degradation rate of intermediate product to product. | 0.15 s−1 | 0.15 s−1 |

| KM,SIP,E1,P2 | Half-saturation constant for degradation of substrate to intermediate product. | 6.94 g L−1 | 5.94 g L−1 |

| KM,SP,E1,P2 | Half-saturation constant for degradation of substrate to product. | 7.80 g L−1 | 9.80 g L−1 |

| KM,IPP,E2,P2 | Half-saturation constant for degradation of intermediate product to product. | 2.10 g L−1 | 0.10 g L−1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Appl, C.; Baganz, F.; Hass, V.C. Development of a Digital Twin for Enzymatic Hydrolysis Processes. Processes 2021, 9, 1734. https://0-doi-org.brum.beds.ac.uk/10.3390/pr9101734

Appl C, Baganz F, Hass VC. Development of a Digital Twin for Enzymatic Hydrolysis Processes. Processes. 2021; 9(10):1734. https://0-doi-org.brum.beds.ac.uk/10.3390/pr9101734

Chicago/Turabian StyleAppl, Christian, Frank Baganz, and Volker C. Hass. 2021. "Development of a Digital Twin for Enzymatic Hydrolysis Processes" Processes 9, no. 10: 1734. https://0-doi-org.brum.beds.ac.uk/10.3390/pr9101734