The Use of Phosphate Washing Sludge to Recover by Composting the Leachate from the Controlled Landfill

Abstract

:1. Introduction

2. Material and Methods

2.1. Composting Materials and Process Operation

- a

- Olive mill wastewater is recovered from Bouchane oil mill, Morocco.

- b

- Green waste (grass) was collected from the garden of the Faculty of Science Semlalia Cadi Ayyad University of Marrakesh, Morocco. This type of green waste was chosen to ensure better absorption of the leachate.

- c

- The phosphate washing sludge was obtained from the Youssoufia region, Morocco.

- d

- Leachate was sampled from the ECOMED landfill in Marrakech, Morocco on 2 March 2020.

- e

- Sugar lime sludge was from the Doukkala sugar industry, Morocco.

2.2. Monitoring Composting

2.3. Physicochemical Analysis

2.4. Determination of the Bacterial Population

2.5. Humification Process

2.6. Statistical Analysis

3. Results and Discussion

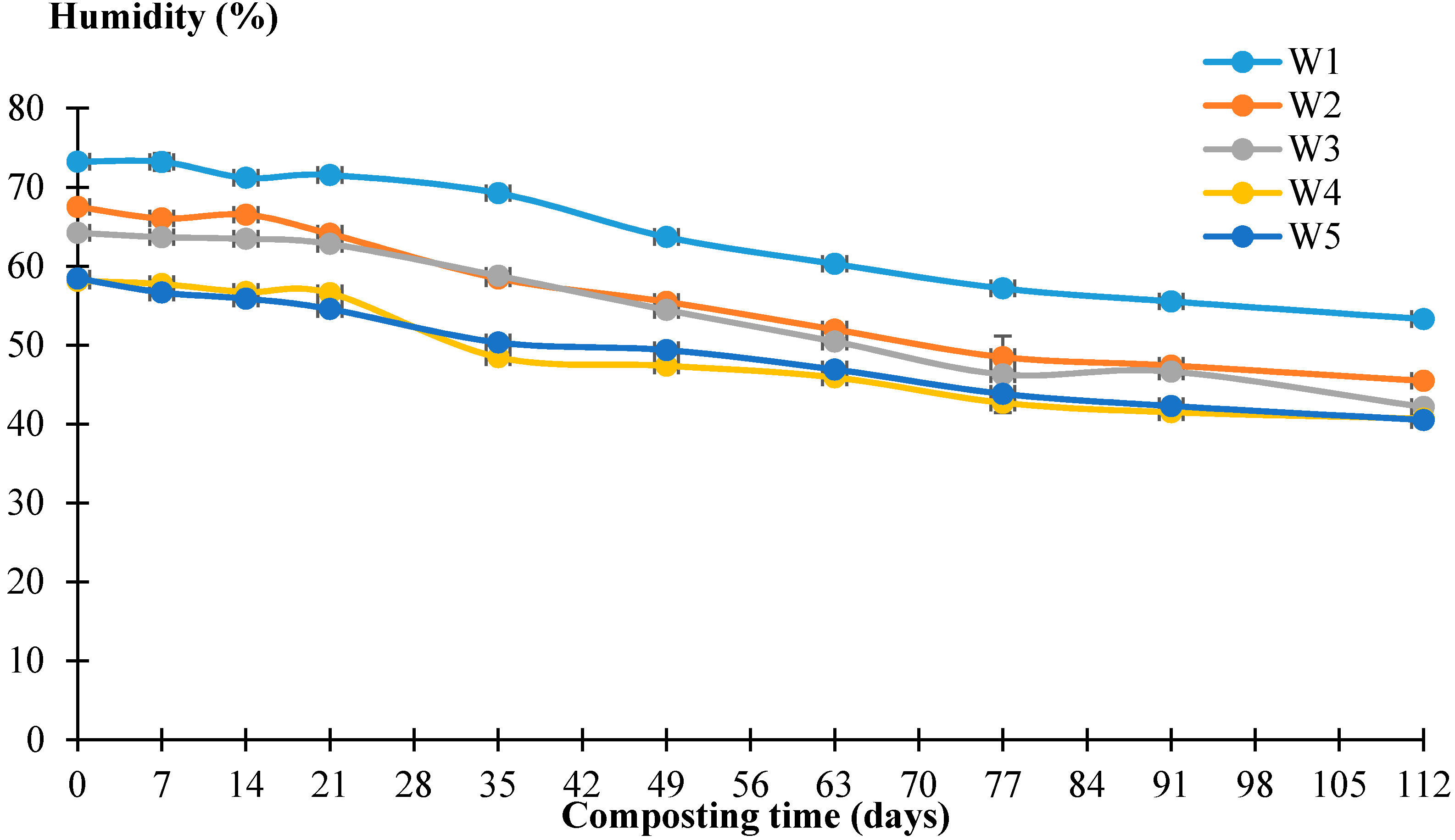

3.1. Moisture Content

3.2. Temperature Evolution

3.3. Evolution of the pH

3.4. C/N Ratio Evolution and Organic Matter Degradation

3.5. Monitoring of Microbiological Parameters

3.5.1. Microbiological Characteristics of the Raw Leachate

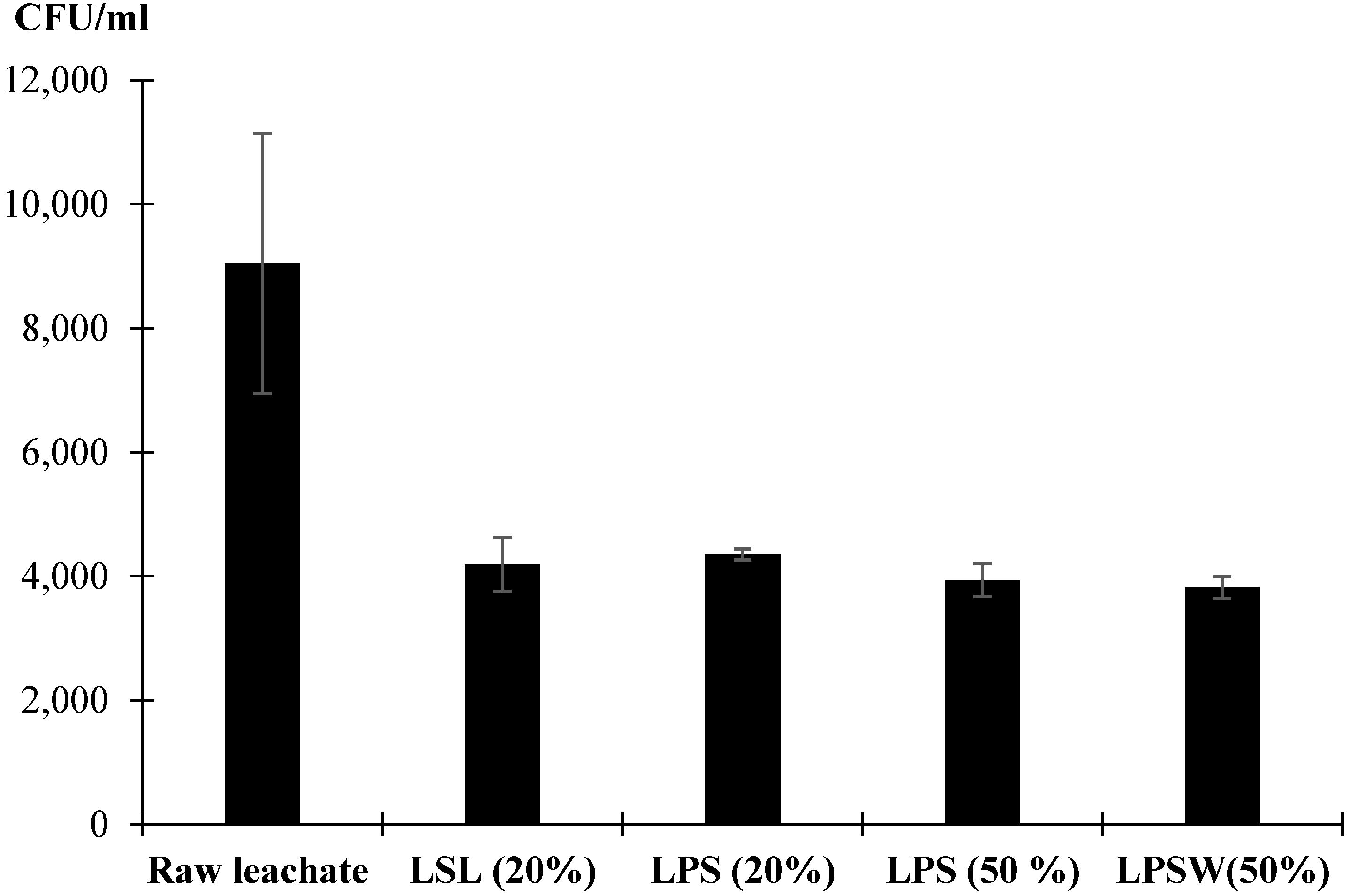

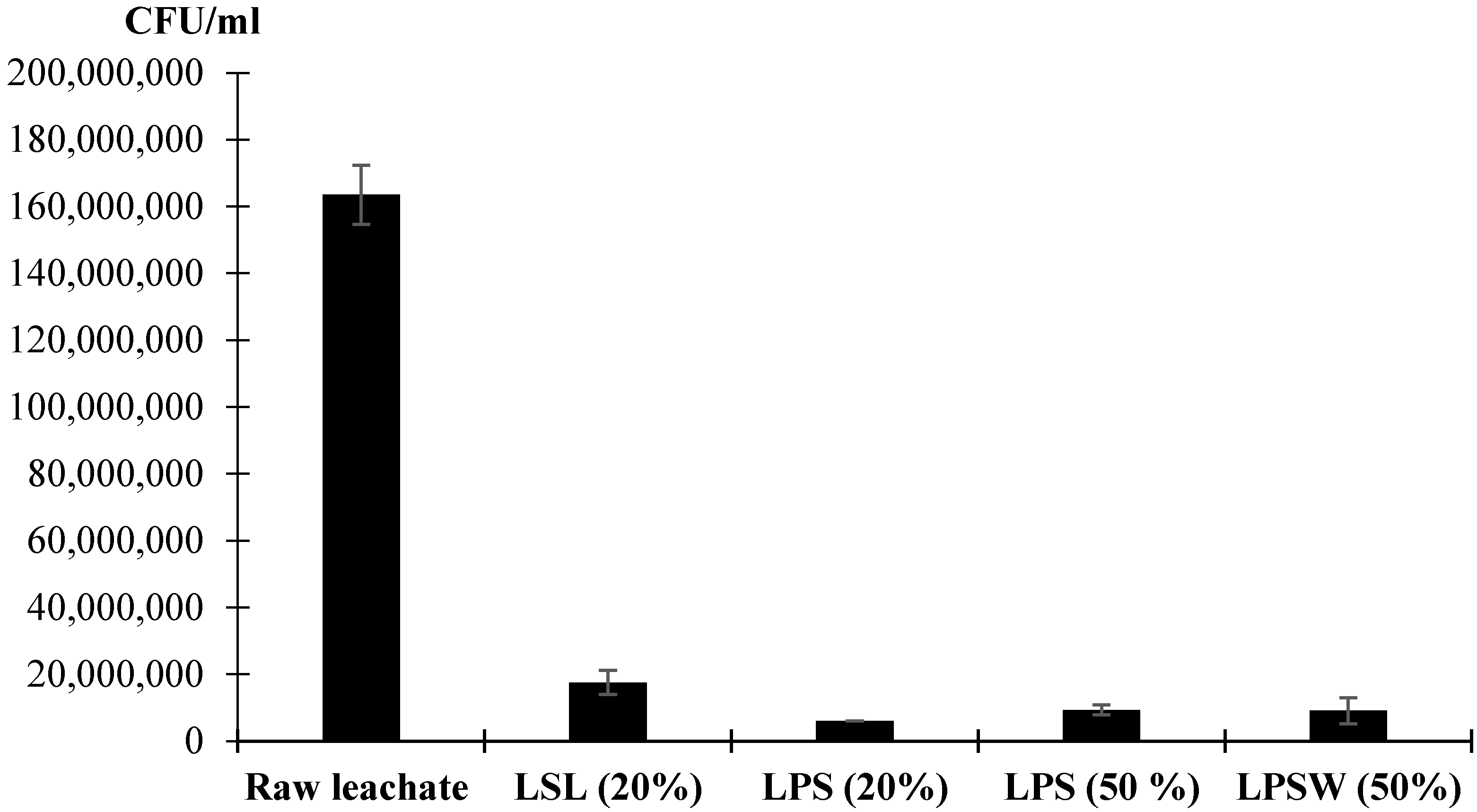

3.5.2. The impact of Adding Phosphate Sludge on the Content of Microorganisms in the Leachate

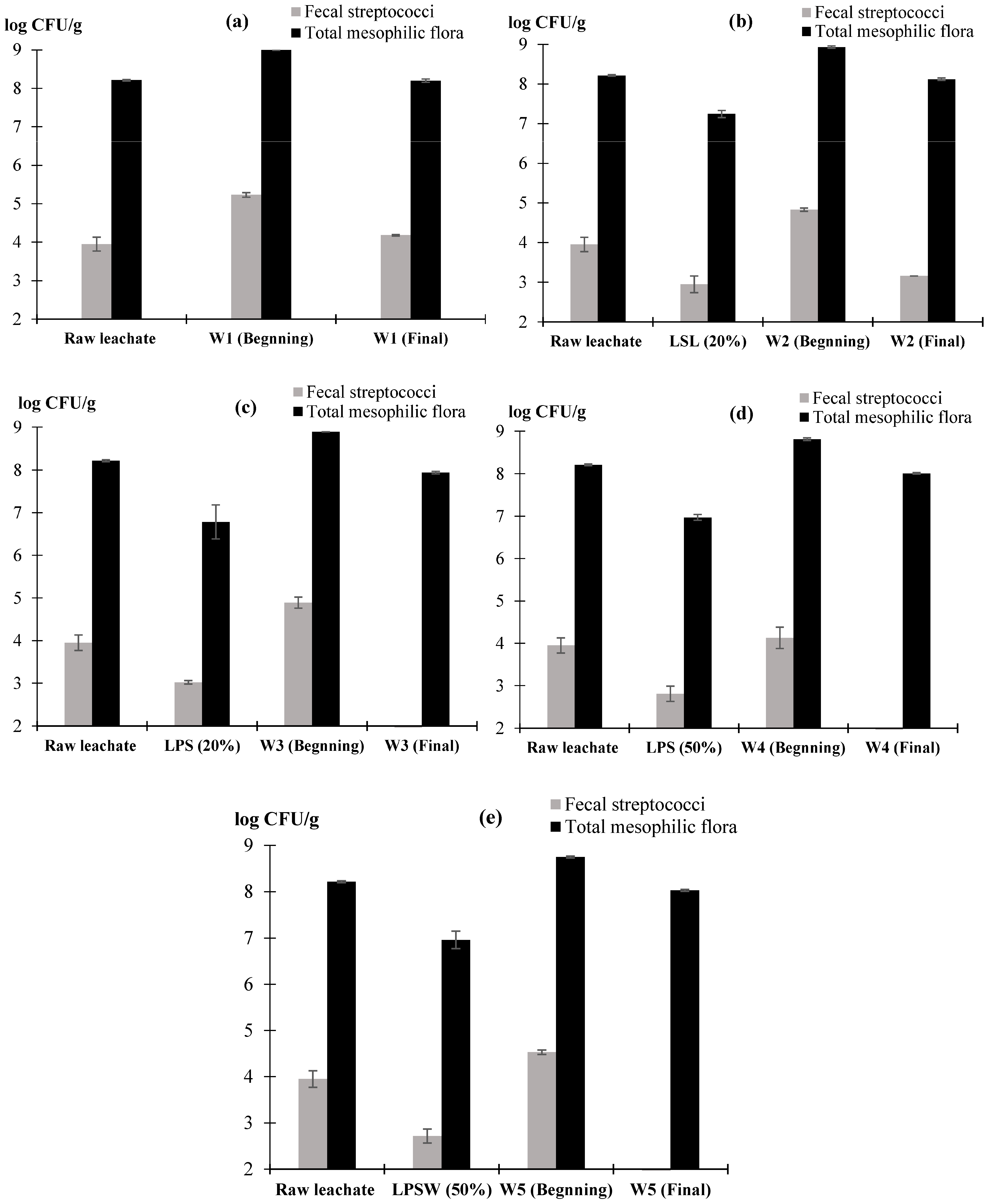

3.5.3. The Effect of Composting on the Hygienization

3.6. Humification Process during Composting

3.7. Effect of the Composting Process on Available Phosphorus Content

3.8. Visual Quality of the Final Composts

3.9. Heavy Metals Concentration

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Charnay, F. Compostage des Déchets Urbains dans les Pays en Développement: Élaboration d’une Démarche Méthodologique Pour une Production Pérenne de Compost. Ph.D. Thesis, Université de Limoges, Limoges, France, 2005. Ecole Doctorale Science—Technique—Santé. p. 5, 277p. [Google Scholar]

- Hakkou, R.; Wahbi, M.; Bachnou, A.; El Amari, K.; Hanich, L.; Hibti, M. Impact of Marrakech (Morocco) municipal landfill on water resources. Bull. Eng. Geol. Environ. 2001, 60, 325–336. [Google Scholar] [CrossRef]

- Hakkou, R.; Benzaazoua, M.; Bussière, B. Valorization of Phosphate Waste Rocks and Sludge from the Moroccan Phosphate Mines: Challenges and Perspectives. Procedia Eng. 2016, 138, 110–118. [Google Scholar] [CrossRef] [Green Version]

- Loutou, M.; Hajjaji, M.; Mansori, M.; Favotto, C.; Hakkou, R. Phosphate sludge: Thermal transformation and use as lightweight aggregate material. J. Environ. Manag. 2013, 130, 354–360. [Google Scholar] [CrossRef] [PubMed]

- Saadani Hassani, O.; Saadaoui, N.; Loqman, S.; Rida, S.; Soraa, N.; R’zina, Q.; Fares, K. Impact of carbonatation lime addition on composting of vegetable oil refining sludge. Sugar Ind. 2019, 144, 139–146. [Google Scholar] [CrossRef]

- Asadi, M. Beet-Sugar Handbook; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Kestioğlua, K.; Yonar, T.; Azbar, N. Feasibility of physicochemical treatment and Advanced Oxidation Processes (AOPs) as a means of pretreatment of olive mill effluent (OME). Process Biochem. 2005, 40, 2409–2416. [Google Scholar] [CrossRef]

- Haug, R.T. The Practical Handbook of Compost Engineering; Lewis Publishers: Boca Raton, FL, USA, 1993. [Google Scholar]

- Schnitzer, M. Organic matter characterization. In Methods of Soil Analysis, Part 2. Chemical and Microbiological Properties, 2nd ed.; Page, A.L., Miller, R.H., Keeney, D.R., Eds.; Agronomy Monograph, N°9; American Society of Agronomy: Madison, WI, USA, 1982; pp. 581–595. [Google Scholar]

- Ciavatta, C.; Antisari, L.V.; Sequi, P. A 1st approach to the characterization of the presence of humified materials in organic fertilizers. Agrochimica 1988, 32, 510–517. [Google Scholar]

- Sequi, P.; De Nobili, M.; Leita, L.; Cercignani, G. A new index of humification. Agrochimica 1986, 30, 175–180. [Google Scholar]

- Sugahara, K.; Inoko, A. Composition analysis of humus and characterization of humic acid obtained from city refuse compost. Soil Sci. Plant Nutr. 1981, 27, 213–224. [Google Scholar] [CrossRef]

- Zorpas, A.A.; Loizidou, M. Sawdust and natural zeolite as a bulking agent for improving quality of a composting product from anaerobically stabilized sewage sludge. Bioresour. Technol. 2008, 99, 7545–7552. [Google Scholar] [CrossRef] [PubMed]

- Chowdhury, A.K.M.M.B.; Akratos, C.S.; Vayenas, D.V.; Pavlou, S. Olive mill waste composting: A review. Int. Biodeterior. Biodegrad. 2013, 85, 108–119. [Google Scholar] [CrossRef]

- Khalib, S.N.B.; Zakarya, I.A.; Tengku Izhar, T.N. Composting of Garden Waste using Indigenous Microorganisms (IMO) as Organic Additive. Int. J. Integr. Eng. 2018, 10, 140–145. [Google Scholar] [CrossRef] [Green Version]

- Goyal, S.; Dhull, S.; Kapoor, K. Chemical and biological changes during composting of different organic wastes and assessment of compost maturity. Bioresour. Technol. 2005, 96, 1584–1591. [Google Scholar] [CrossRef]

- Bustamante, M.A.; Paredes, C.; Marhuenda-Egea, F.C.; Pérez-Espinosa, A.; Bernal, M.P.; Moral, R. Co-composting of distillery wastes with animal manures: Carbon and nitrogen transformations in the evaluation of compost stability. Chemosphere 2008, 72, 551–557. [Google Scholar] [CrossRef]

- Nolan, T.; Troy, S.M.; Healy, M.G.; Kwapinski, W.; Leahy, J.J.; Lawlor, P.G. Characterization of compost produced from separated pig manure and a variety of bulking agents at low initial C/N ratios. Bioresour. Technol. 2011, 102, 7131–7138. [Google Scholar] [CrossRef]

- Li, H.; Meng, F.; Duan, W.; Lin, Y.; Zheng, Y. Biodegradation of phenol in saline or hypersaline environments by bacteria: A review. Ecotoxicol. Environ. Saf. 2019, 184, 109658. [Google Scholar] [CrossRef]

- Ait Baddi, G.; Antonio Alburquerque, J.; Gonzálvez, J.; Cegarra, J.; Hafidi, M. Chemical and spectroscopic analyses of organic matter transformations during composting of olive mill wastes. Int. Biodeterior. Biodegrad. 2004, 54, 39–44. [Google Scholar] [CrossRef]

- Mustin, M. Le Compost, Gestion de la Matière Organique; François Dubux: Paris, France, 1987. [Google Scholar]

- El Fels, L.; Zamama, M.; El Asli, A.; Hafidi, M. Assessment of biotransformation of organic matter during co-composting of sewage sludge-lignocelullosic waste by chemical, FTIR analyses, and phytotoxicity tests. Int. Biodeterior. Biodegrad. 2014, 87, 128–137. [Google Scholar] [CrossRef]

- Vergnoux, A.; Guiliano, M.; Le Dréau, Y.; Kister, J.; Dupuy, N.; Doumenq, P. Monitoring of the evolution of an industrial compost and prediction of some compost properties by NIR spectroscopy. Sci. Total Environ. 2009, 407, 2390–2403. [Google Scholar] [CrossRef] [PubMed]

- McKinley, V.L.; Vestal, J.R. Biokinetic analyses of adaptation and succession: Microbial activity in composting municipal sewage sludge. Appl. Environ. Microbiol. 1985, 47, 933–941. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sasaki, N.; Suehara, K.; Kohda, J.; Nakano, Y.; Yano, T. Effects of C/N ratio and pH of raw materials on oil degradation, efficiency in a compost fermentation process. J. Biosci. Bioeng. 2003, 96, 47–52. [Google Scholar] [CrossRef]

- Espinosa-Valdemar, R.M.; Sotelo-Navarro, P.X.; Quecholac-Piña, X.; García-Rivera, M.A.; Beltrán-Villavicencio, M.; Ojeda-Benítez, S.; Vázquez-Morillas, A. Biological recycling of used baby diapers in a small-scale composting system. Resour. Conserv. Recycl. 2014, 87, 153–157. [Google Scholar] [CrossRef]

- Raj, D.; Antil, R.S. Evaluation of maturity and stability parameters of composts prepared from agroindustrial wastes. Bioresour. Technol. 2011, 102, 2868–2873. [Google Scholar] [CrossRef]

- AFNOR; NFU 44-051. Amendements Organiques—Dénomination, Spécifications et Marquage. 2006. Available online: https://www.boutique.afnor.org/fr-fr/norme/nf-u44051/amendements-organiques-denominations-specifications-et-marquage/fa125064/754 (accessed on 26 September 2021).

- Yosr, S.; Jalel, B.; Sami, S. Combination of air stripping and biological processes for landfill leachate treatment. Environ. Eng. Res. 2019, 25, 80–87. [Google Scholar] [CrossRef]

- Abed, H.; Esamil, A.; Barrahi, M.; Chahboun, N.; Khadmaoui, A.; Ouhssine, M. Analytical evaluation of the microbiological water quality of landfill leachate Kenitra. Int. J. Innov. Appl. Stud. 2014, 7, 1225–1231. [Google Scholar]

- Belle, E.; Genevois, V.; Mudry, J.; Aleya, L. Distribution annuelle de bactéries indicatrices au niveau de la décharge d’ordures ménagères d’Etueffont (France). Environ. Technol. 2008, 29, 207–216. [Google Scholar] [CrossRef] [PubMed]

- Bolta, S.V.; Mihelic, R.; Lobnik, F.; Lestan, D. Microbial community structure during composting with and without mass inocula. Compost Sci. Util. 2003, 11, 6–15. [Google Scholar] [CrossRef]

- Wong, J.W.C.; Selvam, A. Reduction of indicator and pathogenic microorganisms in pig manure through fly ash and lime addition during alkaline stabilization. J. Hazard. Mater. 2009, 169, 882–889. [Google Scholar] [CrossRef]

- López, M.; Elorrieta, M.; Vargas-García, M.; Suárez-Estrella, F.; Moreno, J. The effect of aeration on the biotransformation of lignocellulosic wastes by white-rot fungi. Bioresour. Technol. 2002, 81, 123–129. [Google Scholar] [CrossRef]

- Domeizel, M.; Khalil, A.; Prudent, P. UV spectroscopy: A tool for monitoring humification and for proposing an index of the maturity of compost. Bioresour. Technol. 2004, 94, 177–184. [Google Scholar] [CrossRef] [PubMed]

- Ciavatta, C.; Francioso, O.; Montecchio, D.; Cavani, L.; Grigatti, M. Use of organic wastes of agroindustrial and municipal origin for soil fertilisation: Quality criteria for organic matter. In Proceedings of the First International Encounter, Management of Organic Wastes in Rural Mediterranean Areas, Pamplona, Spain, 22–23 February 2001; pp. 1–17. [Google Scholar]

- Jimenez, E.I.; Garcia, V.P. Composting of domestic refuse and sewage sludge. II. Evolution of carbon and some “humification” indexes. Resour. Conserv. Recycl. 1992, 6, 243–257. [Google Scholar] [CrossRef]

- Flaig, W.; Beutelspacher, H.; Rietz, E. Chemical Composition and Physical Properties of Humic Substances. In Soil Components; Springer: Berlin/Heidelberg, Germany, 1975; pp. 1–211. [Google Scholar] [CrossRef]

- Chen, Y.; Senesi, N.; Schnitzer, M. Information Provided on Humic Substances by E4/E6 Ratios1. Soil Sci. Soc. Am. J. 1977, 41, 352. [Google Scholar] [CrossRef]

- Wei, Y.; Zhao, Y.; Xi, B.; Wei, Z.; Li, X.; Cao, Z. Changes in phosphorus fractions during organic wastes composting from different sources. Bioresour. Technol. 2015, 189, 349–356. [Google Scholar] [CrossRef]

- Tibu, C.Y.; Annang, T.; Solomon, N.; Yirenya-Tawiah, D. Effect of the composting process on physicochemical properties and concentration of heavy metals in market waste with additive materials in the Ga West Municipality, Ghana. Int. J. Recycl. Organ. Waste Agric. 2019, 8, 393–403. [Google Scholar] [CrossRef] [Green Version]

- Lazzari, L.; Sperni, L.; Bertin, P.; Pavoni, B. Correlation between inorganic (PCBs and PAHs) micropollutant concentrations during sewage sludge composting process. Chemosphere 2000, 41, 427–435. [Google Scholar] [CrossRef]

- Amir, S.; Hafidi, M.; Merlina, G.; Revel, J.C. Sequential extraction of heavy metals during composting of sewage sludge. Chemosphere 2005, 59, 801–810. [Google Scholar] [CrossRef] [PubMed]

- Canaruttto, S.; Petruzzelli, G.; Lubrano, L.; Guidi, G.V. How composting affects heavy metal content. BioCycle 1991, 32, 48–50. [Google Scholar]

- Businelli, M.; Gigliotti, G.; Guisquiani, I. Trace element fate in soil profile and corn plant after massive application of urban waste compost: A six-year study. Agrochimica 1996, 40, 145–152. [Google Scholar]

- Pascual, J.A.; Ayuso, M.; Garcia, C.; Hernández, T. Characterization of urban wastes according to fertility and phytotoxicity parameters. Waste Manag. Res. 1997, 15, 103–112. [Google Scholar] [CrossRef]

| Characteristics | L | GW | OMW | PS | SL |

|---|---|---|---|---|---|

| pH | 8.0 ± 0.04 | 7.9 ± 0.03 | 5.1 ± 0.01 | 7.9 ± 0.1 | 8.1 ± 0.05 |

| TKN (% DM) | 0.4 ± 0.1 | 2.8 ± 0.1 | 0.4 ± 0.1 | 0.04 ± 0.1 | 0.3 ± 0.1 |

| Organic matter (% DM) | nd | 81.2 ± 0.6 | nd | 10.7 ± 2.1 | 12.7 ± 0.2 |

| TOC (% DM) | nd | 45.1 ± 0.3 | nd | 5.9 ± 1.2 | 7.1 ± 0.1 |

| Humidity (%) | 95.7 ± 0.1 | 12.1 ± 0.6 | 90.5 ± 0.1 | 2.4 ± 0.1 | 4.7 ± 0.06 |

| BOD5 (mg O2 /L) | 1400 ± 0.0 | nd | nd | Nd | nd |

| COD (mg O2 /L) | 25,750 ± 403.7 | nd | 190,550 ± 14,131.3 | Nd | nd |

| BOD5/COD | 0.05 | nd | nd | Nd | nd |

| Ni | 0.07 ± 0.01 | 0.9 ± 0.3 | 0.01 ± 0.0 | 27.7 ± 1.1 | 0.8 ± 0.2 |

| Cu | 0.0 | 12.6 ± 0.1 | 0.0 | 32.4 ± 0.6 | 10.0 ± 0.2 |

| Pb | 0.01 ± 0.0 | 1.4 ± 0.1 | 0.01 ± 0.0 | 1.1 ± 0.01 | 0.7 ± 0.02 |

| Zn | 0.04 ± 0.0 | 55.8 ± 0.7 | 0.3 ± 0.01 | 302.2 ± 6.2 | 23.0 ± 0.6 |

| Cr | 0.07 ± 0.0 | 0.7 ± 0.04 | 0.0 | 51.4 ± 1.0 | 0.9 ± 0.02 |

| As | 0.5 ± 0.1 | 0.4 ± 0.1 | 0.0 | 19.6 ± 0.4 | 1.9 ± 0.02 |

| Barrels | Treatments | % of Sludge (w/v) |

|---|---|---|

| Barrel 1 | L | 0 |

| Barrel 2 | L + SL | 20 |

| Barrel 3 | L + PS | 20 |

| Barrel 4 | L + PS | 50 |

| Barrel 5 | L + PSW | 50 |

| Windrows | GW (kg) | PS (kg) | L (L) | SL (kg) |

|---|---|---|---|---|

| W1 | 33 | 0 | 80 | 0 |

| W2 | 33 | 0 | 80 | 16 |

| W3 | 33 | 16 | 80 | 0 |

| W4 | 33 | 40 | 80 | 0 |

| W5 | 33 | 40 | 80 | 0 |

| Microorganismes | CFU/mL |

|---|---|

| Fecal streptococci | 9050 |

| Fecal coliforms | 0 |

| Total coliforms | 0 |

| Total mesophilic flora | 163,500,000 |

| Pseudomonas aeruginosa | 0 |

| Salmonella spp. | 0 |

| Composts | C1 | C2 | C3 | C4 | C5 |

|---|---|---|---|---|---|

| Humification index (IH) | 0.9 ± 0.1 | 1.3 ± 0.2 | 1.9 ± 0.2 | 3.5 ± 0.6 | 3.0 ± 0.2 |

| Humification rate (HR%) | 27.0 ± 0.7 | 41.7 ± 0.6 | 53.9 ± 0.6 | 78.1 ± 2.4 | 76.6 ± 0.2 |

| Humification degree (HD%) | 43.6 ± 0.0 | 59.2 ± 5.5 | 78.4 ± 2.4 | 95.7 ± 0.3 | 97.8 ± 2.7 |

| E4/E6 | 11.8 ± 0.6 | 3.5 ± 0.3 | 2.7 ± 0.1 | 3.5 ± 0.2 | 3.7 ± 0.1 |

| Compost 1 (C1) | Compost 2 (C2) | Compost 3 (C3) | Compost 4 (C4) | Compost 5 (C5) | |

|---|---|---|---|---|---|

| Texture | Fine to coarse | Fine to coarse | Fine to coarse | Fine to coarse to mostly fine | |

| Color | Dark brown | Brown | Brown | Light brown | Brown |

| Bad odor | Absent | Absent | Absent | Absent | Absent |

| Hevay Metals | Windrows | Begnning | Final | NF U44-051 Range |

|---|---|---|---|---|

| As | W1 | 3.8 ± 0.02 | 8.9 ± 0.02 | 18 mg/kg DM |

| W2 | 3.4 ± 0.04 | 5.3 ± 0.01 | ||

| W3 | 6.5 ± 0.04 | 7.7 ± 0.1 | ||

| W4 | 5.2 ± 0.1 | 7.3 ± 0.04 | ||

| W5 | 4.0 ± 0.03 | 6.6 ± 0.3 | ||

| Cr | W1 | 1.5 ± 0.2 | 5.4 ± 1.9 | 120 mg/kg DM |

| W2 | 1.6 ± 0.3 | 2.2 ± 0.1 | ||

| W3 | 13.1 ± 1.2 | 10.7 ± 1.8 | ||

| W4 | 13.8 ± 2.0 | 14.9 ± 1.3 | ||

| W5 | 10.4 ± 0.7 | 13.8 ± 0.8 | ||

| Zn | W1 | 48.6 ± 0.6 | 95.9 ± 5.5 | 600 mg/kg DM |

| W2 | 39.8 ± 1.0 | 50.5 ± 1.6 | ||

| W3 | 103.5 ± 1.0 | 125.6 ± 1.6 | ||

| W4 | 98.3 ± 3.4 | 132.7 ± 2.4 | ||

| W5 | 79.8 ± 1.2 | 121.6 ± 10.5 | ||

| Cu | W1 | 12.7 ± 0.1 | 26.2 ± 1.0 | 300 mg/kg DM |

| W2 | 8.5 ± 0.2 | 12.9 ± 0.1 | ||

| W3 | 18.5 ± 0.2 | 17.7 ± 0.1 | ||

| W4 | 12.9 ± 0.6 | 16.8 ± 0.3 | ||

| W5 | 10.2 ± 0.1 | 16.4 ± 0.6 | ||

| pb | W1 | 2.3 ± 0.2 | 1.4 ± 0.1 | 180 mg/kg DM |

| W2 | 0.5 ± 0.04 | 0.9 ± 0.04 | ||

| W3 | 0.4 ± 0.05 | 0.7 ± 0.03 | ||

| W4 | 1.9 ± 0.1 | 0.6 ± 0.02 | ||

| W5 | 2.4 ± 0.1 | 0.8 ± 0.04 | ||

| Ni | W1 | 1.8 ± 0.1 | 6.3 ± 0.8 | 60 mg/kg DM |

| W2 | 2.2 ± 0.3 | 2.9 ± 0.2 | ||

| W3 | 11.0 ± 0.5 | 7.3 ± 0.2 | ||

| W4 | 10.3 ± 1.5 | 8.9 ± 0.3 | ||

| W5 | 7.1 ± 0.2 | 9.2 ± 1.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mobaligh, M.; Meddich, A.; Imziln, B.; Fares, K. The Use of Phosphate Washing Sludge to Recover by Composting the Leachate from the Controlled Landfill. Processes 2021, 9, 1735. https://0-doi-org.brum.beds.ac.uk/10.3390/pr9101735

Mobaligh M, Meddich A, Imziln B, Fares K. The Use of Phosphate Washing Sludge to Recover by Composting the Leachate from the Controlled Landfill. Processes. 2021; 9(10):1735. https://0-doi-org.brum.beds.ac.uk/10.3390/pr9101735

Chicago/Turabian StyleMobaligh, Meriem, Abdelilah Meddich, Boujamaa Imziln, and Khalid Fares. 2021. "The Use of Phosphate Washing Sludge to Recover by Composting the Leachate from the Controlled Landfill" Processes 9, no. 10: 1735. https://0-doi-org.brum.beds.ac.uk/10.3390/pr9101735