Background, Applications and Issues of the Experimental Designs for Mixture in the Food Sector

Abstract

:1. Introduction

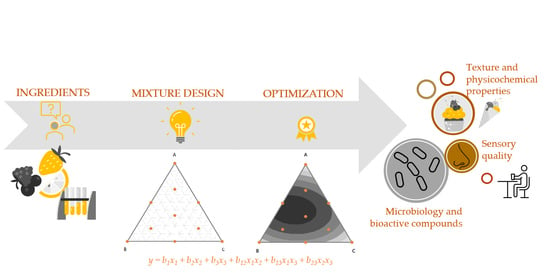

1.1. The Mixture Context

1.2. Designs for Mixtures

2. Materials and Methods

3. Results

3.1. Study and Optimization of Product Formulation

3.1.1. Case Studies on Bakery Products and Pasta

3.1.2. Case Studies on Meat and Meat Products

3.1.3. Case Studies on Emulsions, Creams, Dessert

3.1.4. Case Studies on Juice, Beverages and Jam

3.2. Mixture Design for Extraction Applications

3.3. Mixture Design for the Study of Shelf-Life and Stability

3.4. Applications on Food Microbiology

3.5. Applications on Food Engineering, Packaging and Related Topics

3.6. Criticism

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shiby, V.K.; Radhakrishna, K.; Bawa, A.S. Development of whey-fruit-based energy drink mixes using D-optimal mixture design. Int. J. Food Sci. Technol. 2013, 48, 742–748. [Google Scholar] [CrossRef]

- Lawless, L.J.R.; Threlfall, R.T.; Meullenet, J.F.; Howard, L.R. Applying a Mixture Design for Consumer Optimization of Black Cherry, Concord Grape and Pomegranate Juice Blends. J. Sens. Stud. 2013, 28, 102–112. [Google Scholar] [CrossRef]

- Brandelero, R.P.H.; Yamashita, F.; Zanela, J.; Brandelero, E.M.; Caetano, J.G. Mixture design applied to evaluating the effects of polyvinyl alcohol (PVOH) and alginate on the properties of starch-based films. Starch-Staerke 2015, 67, 191–199. [Google Scholar] [CrossRef]

- Dogan, M.; Toker, O.S.; Aktar, T.; Goksel, M. Optimization of Gum Combination in Prebiotic Instant Hot Chocolate Beverage Model System in Terms of Rheological Aspect: Mixture Design Approach. Food Bioprocess Technol. 2013, 6, 783–794. [Google Scholar] [CrossRef]

- de Souza, V.R.; Pereira, P.A.P.; Pinheiro, A.C.M.; Nunes, C.A.; Silva, T.L.T.; Borges, S.V.; Queiroz, F. Multivariate Approaches for Optimization of the Acceptance: Optimization of a Brazilian Cerrado Fruit Jam Using Mixture Design and Parallel Factor Analysis. J. Sens. Stud. 2012, 27, 417–424. [Google Scholar] [CrossRef]

- Pierlot, C.; Leprêtre, A.; Aubry, J.M. Experimental design, sensorial and principal components analysis: Three complementary tools for cocktail optimization. Analusis 1998, 26, 71–78. [Google Scholar] [CrossRef]

- Lundstedt, T.; Seifert, E.; Abramo, L.; Thelin, B.; Nystrom, A.; Pettersen, J.; Bergmanä Bergman, R. Experimental Design and Optimization. Chemom. Intell. Lab. Syst. 1998, 42, 3–40. [Google Scholar] [CrossRef]

- Oehlert, G.W. A First Course in Design and Analysis of Experiments; W.H. Freeman: New York, NY, USA, 2000; ISBN 0716735105. [Google Scholar]

- Belay, Z.A.; Caleb, O.J.; Mahajan, P.V.; Opara, U.L. Application of simplex lattice mixture design for optimization of active modified atmosphere for pomegranate arils (cv. Wonderful) based on microbial criteria. Food Packag. Shelf Life 2017, 14, 12–17. [Google Scholar] [CrossRef]

- Dooley, L.; Threlfall, R.T.; Meullenet, J.F. Optimization of blended wine quality through maximization of consumer liking. Food Qual. Prefer. 2012, 24, 40–47. [Google Scholar] [CrossRef]

- Leardi, R. Experimental Design. In Chemometrics in Food Chemistry; Elsevier Inc.: Amsterdam, The Netherlands, 2013; Volume 28. [Google Scholar]

- Benedetti, B.; Caponigro, V.; Ardini, F. Experimental Design Step by Step: A Practical Guide for Beginners. Crit. Rev. Anal. Chem. 2020. [Google Scholar] [CrossRef]

- Einax, J.W. Paul Gemperline (Ed.): Practical guide to chemometrics, 2nd Ed. Anal. Bioanal. Chem. 2007, 388, 511–512. [Google Scholar] [CrossRef]

- Hibbert, D.B. Vocabulary of concepts and terms in chemometrics (IUPAC Recommendations 2016). Pure Appl. Chem. 2016, 88, 407–443. [Google Scholar] [CrossRef]

- Brereton, R.G. Applied Chemometrics for Scientists; John Wiley & Sons: Hoboken, NJ, USA, 2007; ISBN 9780470016862. [Google Scholar]

- McNaught, M.; Wilkinson, A. Mixture. In IUPAC Compendium of Chemical Terminology; IUPAC: Research Triagle Park, NC, USA, 1997; Available online: https://goldbook.iupac.org/ (accessed on 30 April 2021).

- Cambridge English Dictionary. Available online: https://dictionary.cambridge.org/dictionary/english/mixture (accessed on 29 April 2021).

- Marrubini, G.; Dugheri, S.; Cappelli, G.; Arcangeli, G.; Mucci, N.; Appelblad, P.; Melzi, C.; Speltini, A. Experimental designs for solid-phase microextraction method development in bioanalysis: A review. Anal. Chim. Acta 2020, 1119, 77–100. [Google Scholar] [CrossRef]

- Shaviklo, A.R.; Kargari Dehkordi, A.; Zangeneh, P. Interactions and effects of the seasoning mixture containing fish protein powder/omega-3 fish oil on children’s liking and stability of extruded corn snacks using a mixture design approach. J. Food Process. Preserv. 2014, 38, 1097–1105. [Google Scholar] [CrossRef]

- Larrosa, V.; Lorenzo, G.; Zaritzky, N.; Califano, A. Optimization of rheological properties of gluten-free pasta dough using mixture design. J. Cereal Sci. 2013, 57, 520–526. [Google Scholar] [CrossRef]

- Tontul, I.; Topuz, A. Production of pomegranate fruit leather (pestil) using different hydrocolloid mixtures: An optimization study by mixture design. J. Food Process. Eng. 2018, 41. [Google Scholar] [CrossRef]

- Yu, J.; Gleize, B.; Zhang, L.; Caris-Veyrat, C.; Renard, C.M.G.C. A D-optimal mixture design of tomato-based sauce formulations: Effects of onion and EVOO on lycopene isomerization and bioaccessibility. Food Funct. 2019, 10, 3589–3602. [Google Scholar] [CrossRef] [PubMed]

- Spanemberg, F.E.M.; Korzenowski, A.L.; Sellitto, M.A. Effects of sugar composition on shelf life of hard candy: Optimization study using D-optimal mixture design of experiments. J. Food Process Eng. 2019, 42. [Google Scholar] [CrossRef]

- Hong, H.D.; Kim, J.C.; Lim, T.G.; Song, Y.R.; Cho, C.W.; Jang, M. Mixing ratio optimization for functional complex extracts of Rhodiola crenulata, Panax quinquefolius, and Astragalus membranaceus using mixture design and verification of immune functional efficacy in animal models. J. Funct. Foods 2018, 40, 447–454. [Google Scholar] [CrossRef]

- Anarjan, N.; Fahimdanesh, M.; Jafarizadeh-Malmiri, H. β-Carotene nanodispersions synthesis by three-component stabilizer system using mixture design. J. Food Sci. Technol. 2017, 54, 3731–3736. [Google Scholar] [CrossRef]

- Kim, M.B.; Ko, J.Y.; Lim, S. Bin Formulation Optimization of Antioxidant-Rich Juice Powders Based on Experimental Mixture Design. J. Food Process. Preserv. 2017, 41. [Google Scholar] [CrossRef]

- Noghabi, M.S.; Molaveisi, M. Microencapsulation optimization of cinnamon essential oil in the matrices of gum Arabic, maltodextrin, and inulin by spray-drying using mixture design. J. Food Process. Eng. 2020, 43. [Google Scholar] [CrossRef]

- Dingstad, G.I.; Westad, F.; Næs, T. Three case studies illustrating the properties of ordinary and partial least squares regression in different mixture models. Chemom. Intell. Lab. Syst. 2004, 71, 33–45. [Google Scholar] [CrossRef]

- Drava, G.; Leardi, R.; Portesani, A.; Sales, E. Application of chemometrics to the production of friction materials: Analysis of previous data and search of new formulations. Chemom. Intell. Lab. Syst. 1996, 32, 245–255. [Google Scholar] [CrossRef]

- Wüstenberg, T. General overview of food hydrocolloids. In Cellulose and Cellulose Derivatives in the Food Industry Fundamentals and Applications; Wiley-VCH Verlag GmbH & Co.: Weinheim, Germany, 2015; pp. 1–68. [Google Scholar]

- Difonzo, G.; Squeo, G.; Pasqualone, A.; Summo, C.; Paradiso, V.M.; Caponio, F. The challenge of exploiting polyphenols from olive leaves: Addition to foods to improve their shelf-life and nutritional value. J. Sci. Food Agric. 2020. [Google Scholar] [CrossRef]

- Difonzo, G.; Troilo, M.; Squeo, G.; Pasqualone, A.; Caponio, F. Functional compounds from olive pomace to obtain high-added value foods—A review. J. Sci. Food Agric. 2021, 101, 15–26. [Google Scholar] [CrossRef]

- Gullón, P.; Gullón, B.; Romaní, A.; Rocchetti, G.; Lorenzo, J.M. Smart advanced solvents for bioactive compounds recovery from agri-food by-products: A review. Trends Food Sci. Technol. 2020, 101, 182–197. [Google Scholar] [CrossRef]

- Encina-Zelada, C.R.; Cadavez, V.; Teixeira, J.A.; Gonzales-Barron, U. Optimization of quality properties of gluten-free bread by a mixture design of xanthan, guar, and hydroxypropyl methyl cellulose gums. Foods 2019, 8, 156. [Google Scholar] [CrossRef] [Green Version]

- Mancebo, C.M.; Merino, C.; Martínez, M.M.; Gómez, M. Mixture design of rice flour, maize starch and wheat starch for optimization of gluten free bread quality. J. Food Sci. Technol. 2015, 52, 6323–6333. [Google Scholar] [CrossRef] [Green Version]

- Rößle, C.; Ktenioudaki, A.; Gallagher, E. Inulin and oligofructose as fat and sugar substitutes in quick breads (scones): A mixture design approach. Eur. Food Res. Technol. 2011, 233, 167–181. [Google Scholar] [CrossRef]

- Santos, F.G.; Fratelli, C.; Muniz, D.G.; Capriles, V.D. Mixture Design Applied to the Development of Chickpea-Based Gluten-Free Bread with Attractive Technological, Sensory, and Nutritional Quality. J. Food Sci. 2018, 83, 188–197. [Google Scholar] [CrossRef]

- Ammar, I.; Gharsallah, H.; Ben Brahim, A.; Attia, H.; Ayadi, M.A.; Hadrich, B.; Felfoul, I. Optimization of gluten-free sponge cake fortified with whey protein concentrate using mixture design methodology. Food Chem. 2021, 343. [Google Scholar] [CrossRef]

- Nukabadi, F.A.; Hojjatoleslamy, M.; Abbasi, H. Optimization of fortified sponge cake by nettle leaves and milk thistle seed powder using mixture design approach. Food Sci. Nutr. 2021, 9, 757–771. [Google Scholar] [CrossRef]

- Masmoudi, M.; Besbes, S.; Bouaziz, M.A.; Khlifi, M.; Yahyaoui, D.; Attia, H. Optimization of acorn (Quercus suber L.) muffin formulations: Effect of using hydrocolloids by a mixture design approach. Food Chem. 2020, 328. [Google Scholar] [CrossRef]

- Bravo-Núñez, Á.; Sahagún, M.; Bravo-Núñez, A.; Gómez, M. Optimisation of protein-enriched gluten-free layer cakes using a mixture design. Int. J. Food Sci. Technol. 2020, 55, 2171–2178. [Google Scholar] [CrossRef]

- Franklin, M.E.E.; Pushpadass, H.A.; Kamaraj, M.; Muthurayappa, M.; Battula, S.N. Application of D-optimal mixture design and fuzzy logic approach in the preparation of chhana podo (baked milk cake). J. Food Process. Eng. 2019, 42. [Google Scholar] [CrossRef]

- Loubes, M.A.; Flores, S.K.; Tolaba, M.P. Effect of formulation on rice noodle quality: Selection of functional ingredients and optimization by mixture design. LWT Food Sci. Technol. 2016, 69, 280–286. [Google Scholar] [CrossRef]

- Rousta, L.K.; Yazdi, A.P.G.; Amini, M. Optimization of athletic pasta formulation by D-optimal mixture design. Food Sci. Nutr. 2020, 8, 4546–4554. [Google Scholar] [CrossRef]

- Cajas Locke, J.E.; González, L.C.; Loubes, M.A.; Tolaba, M.P. Optimization of rice bread formulation by mixture design and relationship of bread quality to flour and dough attributes. LWT Food Sci. Technol. 2019, 113. [Google Scholar] [CrossRef]

- Yuksel, F.; Campanella, O.H. Textural, rheological and pasting properties of dough enriched with einkorn, cranberry bean and potato flours, using simplex lattice mixture design. Qual. Assur. Saf. Crop. Foods 2018, 10, 389–398. [Google Scholar] [CrossRef]

- Tormena, M.M.L.; de Medeiros, L.T.; de Lima, P.C.; Possebon, G.; Fuchs, R.H.B.; Bona, E. Application of multi-block analysis and mixture design with process variable for development of chocolate cake containing yacon (Smallanthus sonchifolius) and maca (Lepidium meyenii). J. Sci. Food Agric. 2017, 97, 3559–3567. [Google Scholar] [CrossRef] [PubMed]

- Coker, O.J.; Sobukola, O.P.; Sanni, L.O.; Bakare, H.A.; Kajihausa, O.E.; Adebowale, A.R.A.; Tomlins, K. Quality attributes of cassava-fish crackers enriched with different flours: An optimization study by a simplex centroid mixture design. J. Food Process. Eng. 2017, 40. [Google Scholar] [CrossRef]

- Sahnoun, M.; Kriaa, M.; Besbes, S.; Jardak, M.; Bejar, S.; Kammoun, R. Optimization of Aspergillus oryzae S2 α-amylase, ascorbic acid, and glucose oxidase combination for improved French and composite Ukrainian wheat dough properties and bread quality using a mixture design approach. Food Sci. Biotechnol. 2016, 25, 1291–1298. [Google Scholar] [CrossRef] [PubMed]

- Lee, Y.J.; Kim, D.B.; Lee, O.H.; Yoon, W.B. Characterizing Texture, Color and Sensory Attributes of Cookies Made with Jerusalem Artichoke (Helianthus tuberosus L.) Flour Using a Mixture Design and Browning Reaction Kinetics. Int. J. Food Eng. 2016, 12, 107–126. [Google Scholar] [CrossRef]

- Brito, I.L.; de Souza, E.L.; Felex, S.S.S.; Madruga, M.S.; Yamashita, F.; Magnani, M. Nutritional and sensory characteristics of gluten-free quinoa (Chenopodium quinoa Willd)-based cookies development using an experimental mixture design. J. Food Sci. Technol. 2015, 52, 5866–5873. [Google Scholar] [CrossRef]

- Yilmaz, M.T.; Yildiz, Ö.; Yurt, B.; Toker, O.S.; Karaman, S.; Baştürk, A. A mixture design study to determine interaction effects of wheat, buckwheat, and rice flours in an aqueous model system. LWT Food Sci. Technol. 2015, 61, 583–589. [Google Scholar] [CrossRef]

- Karaman, S.; Yilmaz, M.T.; Kayacier, A. Simplex lattice mixture design approach on the rheological behavior of glucomannan based salep-honey drink mixtures: An optimization study based on the sensory properties. Food Hydrocoll. 2011, 25, 1319–1326. [Google Scholar] [CrossRef]

- Totosaus, A.; López, H.; Güemes-Vera, N. Effect of Lupinus (Lupinus albus) and Jatropha (Jatropha curcas) Protein Concentrates on Wheat Dough Texture and Bread Quality: Optimization by a D-Optimal Mixture Design. J. Texture Stud. 2013, 44, 424–435. [Google Scholar] [CrossRef]

- Sahu, C.; Patel, S. Optimization of maize–millet based soy fortified composite flour for preparation of RTE extruded products using D-optimal mixture design. J. Food Sci. Technol. 2020, 1–10. [Google Scholar] [CrossRef]

- Afshari, R.; Hosseini, H.; Khaksar, R.; Mohammadifar, M.A.; Amiri, Z.; Komeili, R.; Khaneghah, A.M. Investigation of the effects of inulin and β-glucan on the physical and sensory properties of low-fat beef burgers containing vegetable oils: Optimisation of the formulation using D-optimal mixture design. Food Technol. Biotechnol. 2015, 53, 436–445. [Google Scholar] [CrossRef]

- Keenan, D.F.; Resconi, V.C.; Kerry, J.P.; Hamill, R.M. Modelling the influence of inulin as a fat substitute in comminuted meat products on their physico-chemical characteristics and eating quality using a mixture design approach. Meat Sci. 2014, 96, 1384–1394. [Google Scholar] [CrossRef]

- Zouari, N.; Ayadi, M.A.; Hadj-Taieb, S.; Frikha, F.; Attia, H. Whey powder, ι -carrageenan, and fat interactions and their influence on instrumental texture and sensory properties of Turkey meat sausage using a mixture design approach. Int. J. Food Prop. 2012, 15, 1233–1246. [Google Scholar] [CrossRef] [Green Version]

- Safaei, F.; Abhari, K.; Khosroshahi, N.K.; Hosseini, H.; Jafari, M. Optimisation of functional sausage formulation with konjac and inulin: Using D-Optimal mixture design. Foods Raw Mater. 2019, 7, 177–184. [Google Scholar] [CrossRef]

- Sarteshnizi, R.A.; Hosseini, H.; Bondarianzadeh, D.; Colmenero, F.J.; Khaksar, R. Optimization of prebiotic sausage formulation: Effect of using β-glucan and resistant starch by D-optimal mixture design approach. LWT Food Sci. Technol. 2015, 62, 704–710. [Google Scholar] [CrossRef] [Green Version]

- Nurain, A.; Noriham, A.; Zainon, M.N. Optimisation of mechanically deboned chicken meat (MDCM) aromatic herbal sausage formulations using simplex-lattice mixture design. Int. Food Res. J. 2018, 25, 1799–1807. [Google Scholar]

- Marchetti, L.; Argel, N.; Andrés, S.C.; Califano, A.N. Sodium-reduced lean sausages with fish oil optimized by a mixture design approach. Meat Sci. 2015, 104, 67–77. [Google Scholar] [CrossRef]

- Baugreet, S.; Kerry, J.P.; Allen, P.; Hamill, R.M. Optimisation of protein-fortified beef patties targeted to the needs of older adults: A mixture design approach. Meat Sci. 2017, 134, 111–118. [Google Scholar] [CrossRef]

- Los, P.R.; Marson, G.V.; Dutcosky, S.D.; Nogueira, A.; Marinho, M.T.; Simões, D.R.S. Optimization of beef patties produced with vegetable oils: A mixture design approach and sensory evaluation. Food Sci. Technol. 2020, 40, 12–20. [Google Scholar] [CrossRef]

- Delgado-Pando, G.; Allen, P.; Kerry, J.P.; O’Sullivan, M.G.; Hamill, R.M. Optimising the acceptability of reduced-salt ham with flavourings using a mixture design. Meat Sci. 2019, 156, 1–10. [Google Scholar] [CrossRef]

- Momchilova, M.; Gradinarska, D.; Petrova, T.; Zsivanovits, G.; Bakalov, I.; Penov, N.; Yordanov, D. Inulin and lentil flour as fat replacers in meat-vegetable pâté-a mixture design approach. Carpathian J. Food Sci. Technol. 2019, 11, 5–14. [Google Scholar] [CrossRef]

- Guedes-Oliveira, J.M.; Costa-Lima, B.R.C.; Oliveira, D.; Neto, A.; Deliza, R.; Conte-Junior, C.A.; Guimarães, C.F.M. Mixture design approach for the development of reduced fat lamb patties with carboxymethyl cellulose and inulin. Food Sci. Nutr. 2019, 7, 1328–1336. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Velioglu, H.M. Low-fat beef patties with cold-pressed oils optimized by mixture design. J. Food Nutr. Res. 2016, 55, 89–100. [Google Scholar]

- Nikzade, V.; Tehrani, M.M.; Saadatmand-Tarzjan, M. Optimization of low-cholesterol-low-fat mayonnaise formulation: Effect of using soy milk and some stabilizer by a mixture design approach. Food Hydrocoll. 2012, 28, 344–352. [Google Scholar] [CrossRef]

- Rahbari, M.; Aalami, M.; Kashaninejad, M.; Maghsoudlou, Y.; Aghdaei, S.S.A. A mixture design approach to optimizing low cholesterol mayonnaise formulation prepared with wheat germ protein isolate. J. Food Sci. Technol. 2015, 52, 3383–3393. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Toker, O.S.; Dogan, M.; Canıyılmaz, E.; Ersöz, N.B.; Kaya, Y. The Effects of Different Gums and Their Interactions on the Rheological Properties of a Dairy Dessert: A Mixture Design Approach. Food Bioprocess Technol. 2013, 6, 896–908. [Google Scholar] [CrossRef]

- Nejatian, M.; Jonaidi-Jafari, N.; Abbaszadeh, S.; Saberian, H.; Darabzadeh, N.; Ghanizadeh, G. Using the mixture design approach to predict the rheological properties of low-calorie dairy desserts containing gum tragacanth exuded by three Iranian Astragalus species. Food Sci. Biotechnol. 2019, 28, 405–412. [Google Scholar] [CrossRef]

- Kashaninejad, M.; Razavi, S.M.A. The effects of different gums and their interactions on the rheological properties of instant camel yogurt: A mixture design approach. J. Food Meas. Charact. 2019, 13, 1299–1309. [Google Scholar] [CrossRef]

- BahramParvar, M.; Tehrani, M.M.; Razavi, S.M.A.; Koocheki, A. Application of simplex-centroid mixture design to optimize stabilizer combinations for ice cream manufacture. J. Food Sci. Technol. 2015, 52, 1480–1488. [Google Scholar] [CrossRef] [Green Version]

- Ribeiro, M.N.; Rodrigues, D.M.; Rocha, R.A.R.; Silveira, L.R.; Condino, J.P.F.; Júnior, A.C.; de Souza, V.R.; Nunes, C.A.; Pinheiro, A.C.M. Optimising a stevia mix by mixture design and napping: A case study with high protein plain yoghurt. Int. Dairy J. 2020, 110. [Google Scholar] [CrossRef]

- Waldrop, M.E.; Ross, C.F. Sweetener Blend Optimization by Using Mixture Design Methodology and the Electronic Tongue. J. Food Sci. 2014, 79, S1782–S1794. [Google Scholar] [CrossRef]

- Homayouni Rad, A.; Pirouzian, H.R.; Toker, O.S.; Konar, N. Application of simplex lattice mixture design for optimization of sucrose-free milk chocolate produced in a ball mill. LWT Food Sci. Technol. 2019, 115. [Google Scholar] [CrossRef]

- Homayouni Rad, A.; Pirouzian, H.R. Optimization of prebiotic sucrose-free milk chocolate formulation by mixture design. J. Food Sci. Technol. 2021, 58, 244–254. [Google Scholar] [CrossRef] [PubMed]

- Zahedi, Y.; Mazaheri-Tehrani, M. Development of Spreadable Halva Fortified with Soy Flour and Optimization of Formulation Using Mixture Design. J. Food Qual. 2012, 35, 390–400. [Google Scholar] [CrossRef]

- Gama, A.P.; Hung, Y.C.; Adhikari, K. Optimization of emulsifier and stabilizer concentrations in a model peanut-based beverage system: A mixture design approach. Foods 2019, 8, 116. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zendeboodi, F.; Yeganehzad, S.; Sadeghian, A. Optimizing the formulation of a natural soft drink based on biophysical properties using mixture design methodology. J. Food Meas. Charact. 2018, 12, 763–769. [Google Scholar] [CrossRef]

- Aslan, M.; Ertaş, N. Foam drying of aquafaba: Optimization with mixture design. J. Food Process. Preserv. 2021, 45. [Google Scholar] [CrossRef]

- Dogan, M.; Ersoz, N.B.; Toker, O.S.; Kaya, Y.; Canıyılmaz, E. Optimization of gum combination for instant pudding based on creep and recovery parameters by mixture design approach. Eur. Food Res. Technol. 2014, 238, 47–58. [Google Scholar] [CrossRef]

- Dogan, M.; Aktar, T.; Toker, O.S.; Tatlisu, N.B. Combination of the Simple Additive (SAW) Approach and Mixture Design to Determine Optimum Cocoa Combination of the Hot Chocolate Beverage. Int. J. Food Prop. 2015, 18, 1677–1692. [Google Scholar] [CrossRef]

- Rezende, N.V.; Benassi, M.T.; Vissotto, F.Z.; Augusto, P.P.C.; Grossmann, M.V.E. Mixture design applied for the partial replacement of fat with fibre in sucrose-free chocolates. LWT Food Sci. Technol. 2015, 62, 598–604. [Google Scholar] [CrossRef]

- Ozgur, A.; Dogan, M.; Karaman, S. Rheological interactions of the xanthan gum and carboxymethyl cellulose as alternative to pectin in organic acid–sucrose model system: Simplex lattice mixture design approach. Eur. Food Res. Technol. 2017, 243, 1041–1056. [Google Scholar] [CrossRef]

- Schiassi, M.C.E.V.; Salgado, D.L.; Meirelles, B.S.; Lago, A.M.T.; Queiroz, F.; Curi, P.N.; Pio, R.; de Souza, V.R. Berry Jelly: Optimization Through Desirability-Based Mixture Design. J. Food Sci. 2019, 84, 1522–1528. [Google Scholar] [CrossRef] [PubMed]

- Curi, P.N.; de Almeida, A.B.; Pio, R.; Lima, L.C.d.O.; Nunes, C.A.; de SOUZA, V.R. Optimization of native Brazilian fruit jelly through desirability-based mixture design. Food Sci. Technol. 2019, 39, 388–395. [Google Scholar] [CrossRef] [Green Version]

- de Moraes Filho, M.L.; Busanello, M.; Prudencio, S.H.; Garcia, S. Soymilk with okara flour fermented by Lactobacillus acidophilus: Simplex-centroid mixture design applied in the elaboration of probiotic creamy sauce and storage stability. LWT Food Sci. Technol. 2018, 93, 339–345. [Google Scholar] [CrossRef]

- Razak, A.; Rahman, A.; Baharuddin, N.A.; Amin, M.; Parid, M. Optimisation of stabiliser combinations in instant ice cream mix powder formulation via mixture design methodology. Int. Food Res. J. 2019, 26, 1689–1698. [Google Scholar]

- Anastácio, A.; de Carvalho, I.S. Development of a beverage benchtop prototype based on sweet potato peels: Optimization of antioxidant activity by a mixture design. Int. J. Food Sci. Nutr. 2016, 67, 496–506. [Google Scholar] [CrossRef]

- Baú, T.R.; Garcia, S.; Ida, E.I. Optimization of a fermented soy product formulation with a kefir culture and fiber using a simplex-centroid mixture design. Int. J. Food Sci. Nutr. 2013, 64, 929–935. [Google Scholar] [CrossRef] [PubMed]

- Siefarth, C.; Tyapkova, O.; Beauchamp, J.; Schweiggert, U.; Buettner, A.; Bader, S. Mixture design approach as a tool to study in vitro flavor release and viscosity interactions in sugar-free polyol and bulking agent solutions. Food Res. Int. 2011, 44, 3202–3211. [Google Scholar] [CrossRef]

- Jang, M.S.; Park, J.E.; Park, H.Y. Formulation optimization of salad dressing added with Chinese quince (Chaenomelis sinensis) juice by mixture design. Food Sci. Biotechnol. 2011, 20, 409–417. [Google Scholar] [CrossRef]

- Yoshiara, L.Y.; Madeira, T.B.; Delaroza, F.; Da Silva, J.B.; Ida, E.I. Optimization of soy isoflavone extraction with different solvents using the simplex-centroid mixture design. Int. J. Food Sci. Nutr. 2012, 63, 978–986. [Google Scholar] [CrossRef] [PubMed]

- Ozturk, I.; Karaman, S.; Baslar, M.; Cam, M.; Caliskan, O.; Sagdic, O.; Yalcin, H. Aroma, Sugar and Anthocyanin Profile of Fruit and Seed of Mahlab (Prunus mahaleb L.): Optimization of Bioactive Compounds Extraction by Simplex Lattice Mixture Design. Food Anal. Methods 2014, 7, 761–773. [Google Scholar] [CrossRef]

- Smaoui, S.; Ben Hlima, H.; Fourati, M.; Elhadef, K.; Ennouri, K.; Mellouli, L. Multiobjective optimization of Phoenix dactylifera L. seeds extraction: Mixture design methodology for phytochemical contents and antibacterial activity. J. Food Process. Preserv. 2020, 44. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Y.; Wang, M.; Jiang, L.; Sui, X. Simplex-centroid mixture design applied to the aqueous enzymatic extraction of fatty acid-balanced oil from mixed seeds. JAOCS J. Am. Oil Chem. Soc. 2013, 90, 349–357. [Google Scholar] [CrossRef]

- da Silva Oliveira, W.; de Souza, T.C.L.; Padula, M.; Godoy, H.T. Development of an Extraction Method Using Mixture Design for the Evaluation of Migration of Non-target Compounds and Dibutyl Phthalate from Baby Bottles. Food Anal. Methods 2017, 10, 2619–2628. [Google Scholar] [CrossRef]

- Saoudi, S.; Chammem, N.; Sifaoui, I.; Jiménez, I.A.; Lorenzo-Morales, J.; Piñero, J.E.; Bouassida-Beji, M.; Hamdi, M.; L Bazzocchi, I. Combined effect of carnosol, rosmarinic acid and thymol on the oxidative stability of soybean oil using a simplex centroid mixture design. J. Sci. Food Agric. 2017, 97, 3300–3311. [Google Scholar] [CrossRef] [PubMed]

- Meinhart, A.D.; da Silveira, T.F.F.; de Moraes, M.R.; Petrarca, M.H.; Silva, L.H.; Oliveira, W.S.; Wagner, R.; Bolini, H.M.A.; Bruns, R.E.; Teixeira, J.; et al. Optimization of frying oil composition rich in essential fatty acids by mixture design. LWT Food Sci. Technol. 2017, 84, 795–803. [Google Scholar] [CrossRef]

- Hosseini, H.; Bolourian, S.; Shahidi, F. Extending the shelf-life of sponge cake by an optimized level of jujube fruit flour determined using custom mixture design. Br. Food J. 2019, 121, 3208–3232. [Google Scholar] [CrossRef]

- Maher, P.G.; Fenelon, M.A.; Zhou, Y.; Kamrul Haque, M.; Roos, Y.H. Optimization of β-Casein Stabilized Nanoemulsions Using Experimental Mixture Design. J. Food Sci. 2011, 76. [Google Scholar] [CrossRef]

- Yolmeh, M.; Khomeiri, M.; Ahmadi, Z. Application of mixture design to introduce an optimum cell-free supernatant of multiple-strain mixture (MSM) for Lactobacillus against food-borne pathogens. LWT Food Sci. Technol. 2017, 83, 298–304. [Google Scholar] [CrossRef]

- Falleh, H.; Ben Jemaa, M.; Djebali, K.; Abid, S.; Saada, M.; Ksouri, R. Application of the mixture design for optimum antimicrobial activity: Combined treatment of Syzygium aromaticum, Cinnamomum zeylanicum, Myrtus communis, and Lavandula stoechas essential oils against Escherichia coli. J. Food Process. Preserv. 2019, 43. [Google Scholar] [CrossRef]

- Mahdhi, A.; Bahi, A.; Mzah, D.; Bakhrouf, A. Use of mixture design to construct a consortium of date palm (Phoenix dactylifera L.) fruit extract and potentially probiotic Bacillus strain to confer protection against vibriosis in Artemia culture. J. Sci. Food Agric. 2013, 93, 3850–3855. [Google Scholar] [CrossRef]

- De Castro, R.J.S.; Sato, H.H. Functional properties and growth promotion of bifidobacteria and lactic acid bacteria strains by protein hydrolysates using a statistical mixture design. Food Biosci. 2014, 7, 19–30. [Google Scholar] [CrossRef]

- Pelissari, F.M.; Yamashita, F.; Garcia, M.A.; Martino, M.N.; Zaritzky, N.E.; Grossmann, M.V.E. Constrained mixture design applied to the development of cassava starch-chitosan blown films. J. Food Eng. 2012, 108, 262–267. [Google Scholar] [CrossRef]

- Özbek, Z.A.; Ergönül, P.G. Optimisation of wall material composition of freeze–dried pumpkin seed oil microcapsules: Interaction effects of whey protein, maltodextrin, and gum Arabic by D–optimal mixture design approach. Food Hydrocoll. 2020, 107. [Google Scholar] [CrossRef]

- Davidov-Pardo, G.; Arozarena, I.; Marín-Arroyo, M.R. Optimization of a Wall Material Formulation to Microencapsulate a Grape Seed Extract Using a Mixture Design of Experiments. Food Bioprocess Technol. 2013, 6, 941–951. [Google Scholar] [CrossRef]

- Barnett, S.M.; Diako, C.; Ross, C.F. Identification of a Salt Blend: Application of the Electronic Tongue, Consumer Evaluation, and Mixture Design Methodology. J. Food Sci. 2019, 84, 327–338. [Google Scholar] [CrossRef] [PubMed]

| # | Simplex-Lattice Design | Simplex-Centroid Design | ||||

|---|---|---|---|---|---|---|

| X1 | X2 | X3 | X1 | X2 | X3 | |

| 1 | 1 | 0 | 0 | 1 | 0 | 0 |

| 2 | 0 | 1 | 0 | 0 | 1 | 0 |

| 3 | 0 | 0 | 1 | 0 | 0 | 1 |

| 4 | 2/3 | 1/3 | 0 | 0.5 | 0.5 | 0 |

| 5 | 2/3 | 0 | 1/3 | 0.5 | 0 | 0.5 |

| 6 | 1/3 | 2/3 | 0 | 0 | 0.5 | 0.5 |

| 7 | 0 | 2/3 | 1/3 | 1/3 | 1/3 | 1/3 |

| 8 | 1/3 | 0 | 2/3 | - | - | - |

| 9 | 0 | 1/3 | 2/3 | - | - | - |

| 10 | 1/3 | 1/3 | 1/3 | - | - | - |

| q | Simplex-Lattice Design | Simplex-Centroid Design | ||

|---|---|---|---|---|

| Linear | Quadratic | Special Cubic | ||

| 2 | 2 | 3 | 4 | 3 |

| 3 | 3 | 6 | 10 | 7 |

| 4 | 4 | 10 | 20 | 15 |

| 5 | 5 | 15 | 35 | 31 |

| 6 | 6 | 21 | 56 | 63 |

| 7 | 7 | 28 | 84 | 127 |

| Web of Science Categories | Records | % of 2169 |

|---|---|---|

| Materials Science Multidisciplinary | 507 | 23 |

| Engineering Civil | 488 | 22 |

| Construction Building Technology | 454 | 21 |

| Food Science Technology | 330 | 15 |

| Pharmacology Pharmacy | 174 | 8 |

| Engineering Chemical | 167 | 8 |

| Environmental Sciences | 121 | 6 |

| Biotechnology Applied Microbiology | 90 | 4 |

| Engineering Environmental | 90 | 4 |

| Energy Fuels | 89 | 4 |

| Reference | Food Product/Application | Components | No. Components | Model a | Design | No. Experiments b | Model Fitting c | Validation d | Surface Plots e | Optimization f |

|---|---|---|---|---|---|---|---|---|---|---|

| Bakery Products and Pasta | ||||||||||

| [34] | Bread | Hydroxypropyl methyl cellulose, xanthan and guar gums | 3 | Quadratic | D-optimal | 11 | Anova of regression, R2, R2 adj, R2 pred, Lack of fit, PRESS | No | Yes | Yes |

| [35] | Bread | Rice flour, maize starch and wheat starch | 3 | Special cubic | Simplex-centroid | 7 | Anova of regression, R2 | No | Yes | Yes |

| [36] | Quick breads (scones) | Margarine, oligofructose, caster sugar and inulin | 4 | Special cubic | D-optimal | 24 | Anova of regression, R2 | Yes | Yes | Yes |

| [37] | Bread | Chickpea flour, cassava starch, maize starch, potato starch and rice flour | 3 | Linear, quadratic, special cubic | Simplex-centroid | 9 (×6 designs) | Anova of regression, R2 adj, Lack of fit | Yes | Yes | Yes |

| [38] | Gluten-free sponge cake | Whey protein concentrate, maize and rice flours | 3 | Linear, quadratic, special cubic | Not reported | 15 | Anova of regression, R2, R2 adj | No | No | Yes |

| [39] | Sponge cake | Powdered nettle leaf and milk thistle | 2 | Linear, quadratic, cubic, quartic | Not reported | 9 | Anova of regression, R2, R2 adj | Yes | Yes | Yes |

| [40] | Muffin | Xathan, carboxymethylcellulose and κ-carrageenan | 3 | Linear, quadratic, special cubic and cubic | Augmented simplex-centroid | 10 | R2, R2 pred | No | Yes | Yes |

| [41] | Gluten-free layer cakes | Pea, whey and egg white proteins | 3 | Cubic | Simplex-lattice | 10 | R2 | No | Yes | No |

| [42] | Cake | Chhana, tikhur starch and semolina | 3 | Linear, quadratic, special cubic, cubic | D-optimal | 14 | R2, R2 adj, Lack of fit, PRESS | Yes | Yes | Yes |

| [20] | Pasta | Water, proteins and gums | 3 | Quadratic | Augmented simplex-centroid | 13 | Anova of regression, Lack of fit | No | Yes | Yes |

| [43] | Rice noodle | Gelatinized corn starch, guar gum and xanthan gum | 3 | Special cubic | Simplex-centroid | 7 | R2 | No | Yes | Yes |

| [44] | Pasta | Semolina, pea protein isolate 80%, whey protein isolate 80%, soy protein isolate 90%, oat flour and gluten | 6 | Linear, quadratic and special cubic | D-optimal | 31 | R2 pred, Lack of fit, Cook’s distance, DFFITS | No | No | Yes |

| [45] | Bread | Xanthan gum, sodium alginate and guar gum | 3 | Quadratic, cubic | Simplex-centroid | 7 | R2 | No | Yes | Yes |

| [46] | Dough | Einkorn, cranberry bean and potato flours | 3 | Quadratic | Simplex-lattice | 15 | Anova of regression, R2, RMSE | No | No | No |

| [47] | Cake | Wheat flour, yacon flour and maca flour | 3 | Special cubic | Simplex-centroid | 7 (21 considering the mixture-process design) | Anova of regression, R2 adj, Relative error | No | Yes | Yes |

| [48] | Crackers | Cassava starch, high quality cassava flour and fish flour | 3 | Quadratic, special cubic, cubic | Simplex-centroid | 14 | R2 | No | Yes | Yes |

| [49] | Breadmaking improvers | Aspergillus oryzae S2 α-amylase, ascorbic acid and glucoseoxidase | 3 | Special cubic | Simplex-centroid | 7 | R2 | Yes | Yes | Yes |

| [50] | Cookies | Wheat flour, Jerusalem artichoke flour and sugar | 3 | Quadratic | Simplex-centroid | 7 | R2 | No | Yes | Yes |

| [51] | Cookies | Quinoa flour, quinoa flakes and corn starch | 3 | Cubic | Simplex-lattice | 14 | R2, R2 adj | No | Yes | Yes |

| [52] | Aqueous model system | Wheat, buckwheat and rice flours | 3 | Linear, quadratic | Simplex-lattice | 14 | R2 | No | Yes | No |

| [53] | Wheat chips | Chickpea flour, pea flour and soy flour | 3 | Quadratic | Simplex-lattice | 15 | Anova of regression, R2, RMSE | No | Yes | Yes |

| [19] | Extruded corn snacks | Fish protein, cheddar cheese powder and vegetable oil; omega-3 fish oil, vegetable oil and cheese powder | 3 | Not reported | D-optimal | 14 | Not reported | No | Yes | Yes |

| [54] | Dough | Wheat flour, WF, Lupinus protein concentrate and Jatropha protein concentrate | 3 | Special cubic | D-optimal | 8 | Anova of regression, R2 | Yes | Yes | Yes |

| [55] | Extruded product | Maize, finger millet and defatted soy flours | 3 | Linear, quadratic, cubic, special cubic | D-optimal | 16 | Anova of regression, R2, R2 adj, Lack of fit | Yes | Yes | Yes |

| Meat products | ||||||||||

| [56] | Beef burgers | Inulin, β-glucan and breadcrumbs | 3 | Linear, quadratic, special cubic | D-optimal | 14 | R2 | Yes | Yes | Yes |

| [57] | Sausage | Pork back fat, inulin (two types) | 3 | Linear, quadratic, special cubic | D-optimal | 17 | Anova of regression, R2, Lack of fit | No | Yes | Yes |

| [58] | Sausage | Whey powder, ι-carrageenan and turkey fat | 3 | Special cubic | Simplex-lattice | 14 | R2, R2 adj | No | Yes | Yes |

| [59] | Sausage | Inulin, konjac and starch | 3 | Linear, quadratic, special cubic | D-optimal | 13 | R2 pred | No | Yes | Yes |

| [60] | Sausage | β -glucan, resistant starch and starch | 3 | Linear, quadratic, special cubic | D-optimal | 13 | R2 pred | No | No | Yes |

| [61] | Sausage | Persicaria hydropiper, Murraya koenigii and Etlingera elatior dried aromatic herbs | 3 | Linear, quadratic, special cubic | Simplex-lattice | 13 | Anova of regression, R2, Lack of fit | Yes | Yes | Yes |

| [62] | Sausage | NaCl, KCl and sodium tripolyphosphate | 3 | Cubic | Augmented simplex-centroid | 13 | Anova of regression, Lack of fit | Yes | Yes | Yes |

| [63] | Beef patties | Meat, lentil flour and rice protein | 3 | Linear, quadratic, special cubic | D-optimal | 17 | Anova of regression, R2, Lack of fit | Yes | Yes | Yes |

| [64] | Beef patties | Pork fat, pomace olive oil and canola oil | 3 | Special cubic | Augmented simplex-centroid | 10 | R2 adj | No | Yes | No |

| [65] | Ham | NaCl, glycine and yeast extract | 3 | Linear, quadratic | I-optimal | 12 | Anova of regression, R2 adj, Lack of fit | Yes | Yes | Yes |

| [66] | Canned meat | Pork bacon, inulin and lentil flour | 3 | Special cubic | Simplex-centroid | 10 | R2 | No | Yes | No |

| [19] | Fish strudel | Fish mince, onion and curry powder | 3 | Not reported | D-optimal | 14 | Not reported | No | Yes | Yes |

| [67] | Lamb patties | Fat, carboxymethyl cellulose and inulin | 3 | Special cubic | Simplex-lattice | 13 | Not reported | No | Yes | No |

| [68] | Beef patties | Grape seed oil, pomegranate seed oil and animal fat | 3 | Quadratic | Simplex-lattice | 15 | R2 | No | No | No |

| Emulsions, creams, desserts, juices, beverages, jams | ||||||||||

| [69] | Mayonnaise-like product | Xanthan gum, guar gum and mono-diglycerides emulsifier | 3 | Linear, qudratic, special cubic | Augmented simplex-centroid | 10 | R2 | No | Yes | Yes |

| [70] | Mayonnaise | Germ protein isolate, xanthan gum and egg yolk | 3 | Linear, quadratic, special cubic | Undefined optimal design | 10 | R2 | No | Yes | Yes |

| [71] | Dairy dessert | Carrageenan, alginate, guar and xanthan gums | 4 | Cubic | Simplex-lattice | 30 | R2 | No | Yes | Yes |

| [72] | Dairy dessert | A. gossypinus, A. fluccosus and A. rahensis tragacanth gums | 3 | Linear, quadratic, special cubic, cubic | Not reported | 17 | R2 | No | No | No |

| [73] | Camel yogurt | Carboxymethyl cellulose, konjac gum and sage seed gum | 3 | Quadratic | Simplex-centroid | 14 | Anova of regression analysis, R2, Lack of fit | No | Yes | Yes |

| [74] | Ice cream | Basil seed gum, carboxymethyl cellulose and guar gum | 3 | Quadratic, full quartic | Augmented simplex-centroid | 10 (x2 different total amount) | Anova of regression, R2, R2 adj | Yes | Yes | Yes |

| [75] | Yogurt | Steviol glycoside sweeteners | 3 | Linear, special cubic | Simplex-lattice | 10 | Anova of regression, R2 | No | Yes | Yes |

| [76] | Sweeteners blend | Coconut sugar, agave and stevia | 3 | Linear, quadratic, special cubic | Augmented simplex-centroid | 10 | R2 adj | No | Yes | Yes |

| [77] | Milk chocolate | Maltitol, xylitol and isomalt | 3 | Linear, quadratic, special cubic | Simplex-lattice | 15 | Anova of regression, R2, R2 adj, Lack of fit | Yes | Yes | Yes |

| [78] | Chocolate | Maltitol, xylitol and galactooligosaccharide | 3 | Linear, quadratic | Simplex-lattice | 14 | Anova of regression, R2, R2 adj, Lack of fit | Yes | Yes | Yes |

| [79] | Spreadable halva | Soy flour, sesame paste and emulsifier | 3 | Linear, quadratic, special quartic | Undefined optimal design | 12 | Anova of regression, R2 | No | No | Yes |

| [80] | Peanut-based beverage | Lecithin, xanthan gum, propylene glycol alginate | 3 | Linear plus two interaction terms | Simplex-centroid | 7 | R2, R2 adj, RMSE | No | Yes | Yes |

| [1] | Energy drink | Whey and grape juice; whey and pomegranate juice | 2 | Quadratic | D-optimal | 13 | R2 | Yes | Yes | Yes |

| [81] | Soft drink | Whey protein concentrate, date syrup and persian gum | 3 | Quadratic | Not reported | 9 | R2 | No | Yes | Yes |

| [26] | Juice powders | Broccoli, cabbage and carrot powders | 3 | Linear, quadratic | Augmented simplex-lattice | 13 | Anova of regression, R2 | No | Yes | Yes |

| [2] | Juice | Black cherry, Concord grape and pomegranate juices | 3 | Not reported | Simplex-centroid | 7 | Not reported | No | Yes | Yes |

| [10] | Wine blends | Cabernet Sauvignon, Merlot and Zinfandel | 3 | Linear | Augmented simplex-centroid | 10 | Not reported | Yes | Yes | Yes |

| [82] | Aquafaba | Carboxymethylcellulose, Na-alginate, polydextrose and whey powder | 4 | Quadratic | D-optimal | 25 | Anova, R2, R2 adj, Lack of fit, PRESS | No | Yes | Yes |

| [83] | Chocolate | Xanthan gum, guar gum, alginate and locust bean gum | 4 | Quadratic | Simplex-centroid | 15 | R2 | No | Yes | Yes |

| [84] | Chocolate | Usta cocoa, Gerkens cocoa and Ulker Gold cocoa | 3 | Quadratic | Augmented simplex-lattice | 9 | R2 | No | Yes | Yes |

| [85] | Chocolate | Cocoa butter, inulin and β-glucan | 3 | Quadratic | Simplex-centroid | 8 | Anova of regression, R2 adj, Lack of fit | No | Yes | No |

| [21] | Pestil (fruit leather) | Xanathan gum, locust bean gum and pregelitinized starch | 3 | Linear, quadratic, special cubic, cubic, quartic and special quartic | D-optimal | 16 | R2, Lack of fit | Yes | Yes | Yes |

| [86] | Jam/jelly-like model system | Xanthan gum, pectin and carboxymethyl cellulose | 3 | Not reported | Simplex-lattice | 13 | R2 | No | Yes | Yes |

| [5] | Jam | Jenipapo, marolo, murici, soursop and sweet passion fruit pulps | 5 | Quadratic | Simplex-lattice | 21 | Anova of regression, R2 | Yes | Yes | Yes |

| [22] | Tomato sauce | Hot-break tomato puree, onion puree and extra virgin olive oil; Cold-break tomato puree, onion puree and extra virgin olive oil | 3 | Linear, quadratic, special cubic | D-optimal | 14 | Anova of regression, R2, R2 adj, Lack of fit | No | Yes | No |

| [87] | Berry jelly | Blackberry, blueberry and strawberry fruit juices | 3 | Linear, quadratic | Simplex-centroid | 7 | Anova of regression, R2, Lack of fit | No | Yes | Yes |

| [88] | Fruit jelly | Jabuticaba, pitanga and cambuci fruit juices | 3 | Linear | Simplex-centroid | 7 | R2, Lack of fit | No | Yes | Yes |

| [89] | Soy-based sauce | Guar gum, xanthan gum and pregelatinized cassava starch | 3 | Linear, quadratic, cubic | Simplex-centroid | 9 | R2, Lack of fit | No | Yes | Yes |

| [90] | Instant ice cream mix powder | Carboxymethyl cellulose, carrageenan and sodium alginate | 3 | Cubic | D-optimal | 14 | R2, R2 adj | No | Yes | Yes |

| [91] | Beverage | Sweet potato peel water extract, sweet potato leaves water extract and honey solution | 3 | Cubic | I-optimal | 24 | Anova of regression, R2, R2 adj, Lack of fit, RMSE | No | Yes | Yes |

| [83] | Dairy dessert | Carrageenan, alginate, guar and xanthan gums | 4 | Reduced cubic, reduced special cubic, reduced special quartic | Simplex-lattice | 30 | R2 | No | Yes | Yes |

| [92] | Soy-based fermented product | Soy, oat and wheat fibers | 3 | Linear, quadratic, special cubic | Simplex-centroid | 9 | R2, Lack of fit | No | Yes | Yes |

| [93] | In vitro flavor release | Maltitol, erythritol, polydextrose and oligofructose | 4 | Quadratic | D-optimal | 20 | R2 | No | Yes | No |

| [53] | Beverage | Pine, flower and highland honeys | 3 | Quadratic | Simplex-lattice | 15 | R2 | No | Yes | Yes |

| [94] | Salad dressing | Chinese quince juice, oil and vinegard | 3 | Linear, quadratic | D-optimal | 14 | Anova of regression, R2 | No | Yes | Yes |

| Extraction applications | ||||||||||

| [95] | Isoflavone extraction from soy flour | Water, acetone, acetonitrile and ethanol | 4 | Linear, quadratic, special cubic | Simplex-centroid | 15 | Anova of regression, R2, Lack of fit | Yes | Yes | Yes |

| [96] | Bioactive extraction from fruits | Acetone, methanol and water | 3 | Quadratic | Simplex-lattice | 15 | Anova of regression, R2, R2 adj, R2 pred, Lack of fit | Yes | Yes | Yes |

| [97] | Bioactive extraction from seeds | Ethanol, acetone and water | 3 | Linear, quadratic, special cubic | Augmented simplex-centroid | 10 | Anova of regression, R2 | No | Yes | Yes |

| [24] | Extraction from herbs | Rhodiola crenulata, Panax quinquefolius and Astragalus membranaceus | 3 | Linear, quadratic | Augmented simplex-centroid | 10 | Anova of regression, R2, R2 adj | No | Yes | Yes |

| [98] | Oil extraction | Soybeans, peanuts, linseeds and tea seeds | 4 | Linear, quadratic, cubic, special cubic | Augmented simplex centroid | 24 | Anova of regression, R2, R2 adj, R2 pred, Lack of fit | Yes | Yes | Yes |

| [99] | Migration from baby bottles | Toluene–hexane, dichloromethane–hexane and ethyl acetate–hexane | 3 | Linear, quadratic, cubic | Augmented simplex-centroid | 13 | Anova of regression, Lack of fit | Yes | No | Yes |

| Study of shelf-life and stability | ||||||||||

| [100] | Stability of soybean oil | Carnosol, rosmarinic acid and thymol | 3 | Special cubic | Augmented simplex centroid | 10 | R2 | No | Yes | No |

| [101] | Frying oil | Soybean, safflower and flaxseed oils | 3 | Linear, cubic | Simplex-lattice | 185 | Anova of regression | Yes | No | Yes |

| [102] | Shelf life of sponge cake | Refined wheat flour, sugar, jujube fruit flour | 3 | Linear, quadratic, special cubic | Undefined optimal design | 16 | Anova of regression, R2, R2 adj, R2 pred, Lack of fit | Yes | Yes | Yes |

| [23] | Shelf life of hard candy | Sucrose, 40 DE corn syrup and 20 DE high-maltose corn syrup | 3 | Linear, quadratic, cubic | D-optimal | 36 | Anova of regression, R2, R2 adj, Lack of fit, residuals analysis | Yes | Yes | Yes |

| [103] | Nanoemulsion | Lactose, trehalose and β-casein | 3 | Quadratic, special cubic, cubic | D-optimal | 17 | Anova of regression, R2 adj | No | Yes | Yes |

| [25] | β-carotene nanoparticles | Tween 80, gelatine and pectin | 3 | Special cubic | Augmented simplex-centroid | 10 | Anova of regression, R2 | Yes | Yes | Yes |

| [9] | Gas mixture | O2, CO2, N2 | 3 | Linear, special cubic | Simplex-lattice | 7 | R2 | Yes | Yes | Yes |

| Food microbiology | ||||||||||

| [104] | Microbiology | Cell-free supernatants of L. brevis and L. plantarum | 3 | Linear, quadratic, special cubic, cubic | Simplex-centroid | 14 | Anova of regression, R2, R2 adj, R2 pred, Lack of fit | Yes | Yes | Yes |

| [105] | Antimicrobial activity | Clove, cinnamon, lavender and myrtle essential oils | 4 | Cubic | Simplex-centroid | 15 | Anova of regression, Residuals | Yes | Yes | Yes |

| [106] | Microbiology | Deglet Nour extract, Deglat extract and Bacillus strain | 3 | Linear, quadratic | D-optimal | 10 | Anova of regression, Lack of fit | No | Yes | Yes |

| [107] | Microbiology | Soy protein isolate, bovine whey protein and egg white protein | 3 | Quadratic, special cubic | Simplex-centroid | 7 | Anova of regression, R2 adj | Yes | Yes | No |

| Food engineering, packaging and related topics | ||||||||||

| [108] | Film production by blown extrusion | Cassava starch, chitosan and glycerol | 3 | Special cubic | Not reported | 11 | R2, Lack of fit | No | Yes | No |

| [3] | Starch-based films | Cassava starch, alginate and polyvinyl alcohol | 3 | Cubic | Augmented simplex-lattice | 10 | Anova of regression, R2 | No | Yes | Yes |

| [109] | Microencapsulation | Whey protein concentrate, maltodextrin and arabic gum | 3 | Linear, reduced quadratic, quadratic, reduced cubic, special cubic, reduced special quartic, special quartic | D-optimal | 18 | Anova of regression, R2 | No | Yes | Yes |

| [27] | Microencapsulation | Arabic gum, maltodextrin and inulin | 3 | Cubic | Augmented simplex-centroid | 16 | Anova of regression, R2 | Yes | Yes | Yes |

| [110] | Extract microencapsulation | Maltodextrin, mesquite gum and zein | 3 | Not reported | Augmented simplex-centroid | 10 | Not reported | No | No | Yes |

| [111] | Salt reduction | NaCl, KCl and CaCl2 | 3 | Linear, quadratic, special cubic | Not reported | 10 | R2 adj | No | Yes | Yes |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Squeo, G.; De Angelis, D.; Leardi, R.; Summo, C.; Caponio, F. Background, Applications and Issues of the Experimental Designs for Mixture in the Food Sector. Foods 2021, 10, 1128. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10051128

Squeo G, De Angelis D, Leardi R, Summo C, Caponio F. Background, Applications and Issues of the Experimental Designs for Mixture in the Food Sector. Foods. 2021; 10(5):1128. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10051128

Chicago/Turabian StyleSqueo, Giacomo, Davide De Angelis, Riccardo Leardi, Carmine Summo, and Francesco Caponio. 2021. "Background, Applications and Issues of the Experimental Designs for Mixture in the Food Sector" Foods 10, no. 5: 1128. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10051128