Transformational Steam Infusion Processing for Resilient and Sustainable Food Manufacturing Businesses

Abstract

:1. Introduction

2. Materials and Methods

2.1. The Steam Infusion Process

- Liquid food material is recirculated through the Steam Infusion Vaction™ pump, where steam is accelerated to a high velocity before entering into the liquid food stream via an annular nozzle (Figure 2). This process is conducted repeatedly with controllable temperature changes (∆t) between 1 °C and 30 °C, which are dependent on steam pressure. Through multiple cycles, an overall temperature gradient, typically up to 95 °C within the atmospheric kettle, is achieved. The product can be held at this temperature using an insulated covering so that the food materials are typically pasteurised and are cooked through to the required texture/consistency. Steam Infusion is designed to cook the liquid food extremely quickly and efficiently using steam that is under pressure and is in direct contact with food materials instead of through a heated jacketed kettle wall. It also provides options for using traditional kettle cooking to provide a ‘jacket and Steam Infusion’ production process. The trials for Steam Infusion were tested in this reported research using the steam infusion technologies developed by OAL (reported on-line through personal communication to W Martindale by OAL, Steam Infusion Test Centre, 2020). Profiling within the steam chamber can accelerate the velocity of the steam to 1000 m s−1 (3280 feet s−1), which is above the speed of sound. The steam passes into the mixing chamber through an annular nozzle disrupting the liquid food flow to form small droplets, referred to as the vapour phase. The momentum transfers from the steam to the food material and creates a partial vacuum of −0.7 barg (−10.1 psig) within the unit.

- As the steam condenses into the liquid food droplets, the pressure rises. This is referred to as the condensation shockwave, and it generates a pumping effect. The small droplets within the low-pressure vapour phase offer a significantly increased product surface area for the steam to condense into, typically resulting in a near instantaneous temperature gradient of 10–15 °C (50–59 °F).

- The very short residence times and partial vacuum within the unit prevent exposure to excessive temperatures. There are no hot contact surface areas/hot spots, and therefore, the Steam Infusion process prevents Maillard reactions and the resulting burn-on.

- An unrestricted Vaction™ Pump pumps at a rate of 50,000 kg/h (55 US t/h) in water at 20 °C (68 °F), and the turbulent mixing conditions in the low-pressure vapour area enhance the transfer of flavours. The Vaction™ Pump has an uninhibited bore of 47 mm (1.85 in), enabling particulates to freely pass through the unit with no damage.

2.2. Data Collection during Processing

- (1)

- The processing energy and GHG balance trial processed batches of vegetable soup that had the following ingredients (specific recipe amounts are protected due to commercial sensitivity): butter, cream, milk, cabbage, mushroom, onion, potato, spinach, and tomato. As guidance, recipe typical amounts for a vegetable soup will be 35–45% w/v vegetables, 5% w/v butter, 5% w/v cream, 10% w/v milk, and processed to 100% volume with water. The soup was cooked using the Steam Infusion Vaction™ Pump and using a steam jacket vessel method separately to compare performance.

- (2)

- The processing time trial provided further temperature assessments and demonstrations of the Steam Infusion Vaction™ Pump data collection for water and a chocolate custard product. These were used as typical examples to show the diversity of products that can be processed with respect to time required to reach 90 C. These are reported to demonstrate both the data collection and the Steam Infusion Vaction™ Pump processing times achieved under trial conditions.

- (3)

- The volatile compounds in the product trials processed batches of a curry sauce that contained water (27% w/v), onion (7% w/v), tomato (15% w/v), rapeseed oil (5% w/v), tomato purée (10% w/v), ground spices (15% w/v), which comprised paprika, coriander, mustard, fenugreek leaf, and coriander leaf. The recipe used contained a modified maize starch (3% w/v), sugar (3% w/v), garlic purée (7% w/v), salt (3% w/v), and yeast extract powder (5% w/v).

2.3. Analysis of Food Volatiles for Steam Infusion Cooking

3. Results

3.1. The Energy and CO2e Balance for Steam Infusion Processes

3.2. The Operational Efficiencies of Steam Infusion

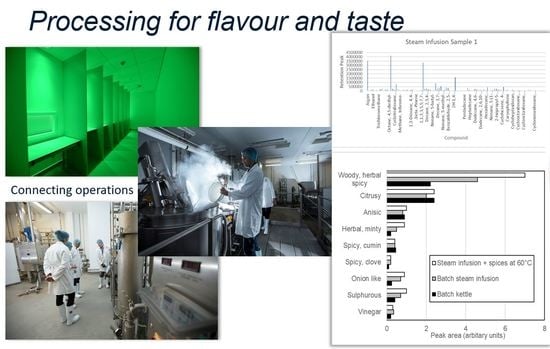

3.3. Analysis of Volatiles in Steam Infusion

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ladha-Sabur, A.; Bakalis, S.; Fryer, P.J.; Lopez-Quiroga, E. Mapping energy consumption in food manufacturing. Trends Food Sci. Technol. 2019, 86, 270–280. [Google Scholar] [CrossRef]

- Bayona-Saez, C.; Cruz-Cázares, C.; García-Marco, T.; Sánchez García, M. Open innovation in the food and beverage industry. Manag. Decis. 2017, 55, 526–546. [Google Scholar] [CrossRef] [Green Version]

- Notarnicola, B.; Tassielli, G.; Renzulli, P.A.; Castellani, V.; Sala, S. Environmental impacts of food consumption in Europe. J. Clean. Prod. 2017, 140, 753–765. [Google Scholar] [CrossRef]

- Martindale, W.; Swainson, M.; Choudhary, S. The Impact of Resource and Nutritional Resilience on the Global Food Supply System. Sustainability 2020, 12, 751. [Google Scholar] [CrossRef] [Green Version]

- de Sousa Jabbour, A.B.L.; Jabbour, C.J.C.; Hingley, M.; Vilalta-Perdomo, E.L.; Ramsden, G.; Twigg, D. Sustainability of supply chains in the wake of the coronavirus (COVID-19/SARS-CoV-2) pandemic: Lessons and trends. Mod. Supply Chain Res. Appl. 2020, 2, 117–122. [Google Scholar] [CrossRef]

- Jagtap, S.; Duong, L.N.K. Improving the new product development using big data: A case study of a food company. Br. Food J. 2019, 121, 2835–2848. [Google Scholar] [CrossRef] [Green Version]

- Griggs, D.; Stafford-Smith, M.; Gaffney, O.; Rockström, J.; Öhman, M.C.; Shyamsundar, P.; Steffen, W.; Glaser, G.; Kanie, N.; Noble, I. Policy: Sustainable development goals for people and planet. Nature 2013, 495, 305. [Google Scholar] [CrossRef]

- Martindale, W. The potential of food preservation to reduce food waste. Proc. Nutr. Soc. 2016, 76, 28–33. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Martindale, W.; Finnigan, T.; Needham, L. Current Concepts and Applied Research in Sustainable Food Processing; Wiley Blackwell: Oxford, UK, 2013; pp. 9–38. ISBN 9781118634301. [Google Scholar]

- Lozano, J.; Saenz-Díez, J.C.; Martínez, E.; Jiménez, E.; Blanco, J. Methodology to improve machine changeover performance on food industry based on SMED. Int. J. Adv. Manuf. Technol. 2017, 90, 3607–3618. [Google Scholar] [CrossRef]

- Kelleher, C.M.; Tobin, J.T.; O’Mahony, J.A.; Kelly, A.L.; O’Callaghan, D.J.; McCarthy, N.A. A comparison of pilot-scale supersonic direct steam injection to conventional steam infusion and tubular heating systems for the heat treatment of protein-enriched skim milk-based beverages. Innov. Food Sci. Emerg. Technol. 2019, 52, 282–290. [Google Scholar] [CrossRef] [Green Version]

- ASHRAE Handbook—Refrigeration. Thermal Properties of Food. Copyrighted Materials. American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc., 2006. Available online: www.knovel.com (accessed on 21 January 2021).

- Defra 2021 UK Greenhouse Gas Conversion Factors for Company Reporting 2019. Available online: https://www.gov.uk/government/collections/government-conversion-factors-for-company-reporting (accessed on 12 July 2021).

- Acree, T. Discrete mathematic analysis of the Dravnieks and Flavornet data bases. Flavour 2014, 3, K1. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Capone, D.L.; Wilkinson, K.L.; Jeffery, D.W. Chemical and sensory profiles of rosé wines from Australia. Food Chem. 2016, 196, 682–693. [Google Scholar] [CrossRef] [PubMed]

- Rauh, V.M.; Sundgren, A.; Bakman, M.; Ipsen, R.; Paulsson, M.; Larsen, L.B.; Hammershøj, M. Plasmin activity as a possible cause for age gelation in UHT milk produced by direct steam infusion. Int. Dairy J. 2014, 38, 199–207. [Google Scholar] [CrossRef]

- Bowser, T.J. Steam Basics for Food Processors; Oklahoma Cooperative Extension Service: Stillwater, OK, USA, 2006; Available online: http://osufacts.okstate.edu/docushare/dsweb/Get/Document-3042/FAPC-142web.pdf (accessed on 21 January 2021).

- Johnson, L.A.; Hoover, W.J.; Deyoe, C.W.; Erickson, L.E.; Johnson, W.H.; Schwenke, J.R. Modeling the kinetics of heat inactivation of trypsin inhibitors during steam-infusion cooking of soymilk. Trans. ASAE 1980, 23, 1326–1329. [Google Scholar] [CrossRef]

- Chen, S.H.; Li, X.-F.; Shih, P.-T.; Pai, S.-M. Preparation of thermally stable and digestive enzyme resistant flour directly from Japonica broken rice by combination of steam infusion, enzymatic debranching, and heat moisture treatment. Food Hydrocoll. 2020, 108, 106022. [Google Scholar] [CrossRef]

- Fayle, S.E.; Gerrard, J.A. The Maillard Reaction; RSC Publishing: Cambridge, UK, 2002; Volume 5, ISBN 0854045813. [Google Scholar]

- Drewnowski, A.; Rehm, C.D.; Martin, A.; Verger, E.O.; Voinnesson, M.; Imbert, P. Energy and nutrient density of foods in relation to their carbon footprint. Am. J. Clin. Nutr. 2015, 101, 184–191. [Google Scholar] [CrossRef] [PubMed]

- Clune, S.; Crossin, E.; Verghese, K. Systematic review of greenhouse gas emissions for different fresh food categories. J. Clean. Prod. 2017, 140, 766–783. [Google Scholar] [CrossRef] [Green Version]

| Steam Infusion Operational Efficiency | |

|---|---|

| Energy reduction at point of use compared to steam jacket vessel cooking (% reduction) | 17.3 |

| Production time saved by Steam Infusion cooking method related CIP reduction (cleaning time hours reduced per year) | 277.8 |

| GHG reduction due to decreased energy use (CO2e reduction per year) | 8.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brooks, C.; Swainson, M.; Beauchamp, I.; Campelos, I.; Ishak, R.; Martindale, W. Transformational Steam Infusion Processing for Resilient and Sustainable Food Manufacturing Businesses. Foods 2021, 10, 1763. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10081763

Brooks C, Swainson M, Beauchamp I, Campelos I, Ishak R, Martindale W. Transformational Steam Infusion Processing for Resilient and Sustainable Food Manufacturing Businesses. Foods. 2021; 10(8):1763. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10081763

Chicago/Turabian StyleBrooks, Christopher, Mark Swainson, Ian Beauchamp, Isabel Campelos, Ruzaina Ishak, and Wayne Martindale. 2021. "Transformational Steam Infusion Processing for Resilient and Sustainable Food Manufacturing Businesses" Foods 10, no. 8: 1763. https://0-doi-org.brum.beds.ac.uk/10.3390/foods10081763