Acceptable Inclusion Levels for Selected Brown and Red Irish Seaweed Species in Pork Sausages

Abstract

:1. Introduction

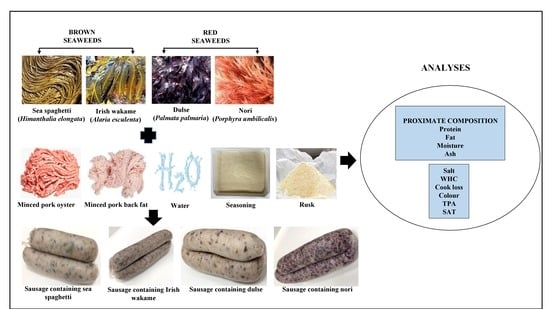

2. Materials and Methods

2.1. Chemicals and Reagents

2.2. Raw Materials

2.3. Sausage Production

2.4. Proximate Composition

2.5. Salt Analysis

2.6. Water-Holding Capacity (WHC)

2.7. Cook Loss

2.8. Instrumental Colour Analysis

2.9. Texture Profile Analysis (TPA)

2.10. Sensory Acceptance Testing (SAT)

2.11. Statistical Analysis

3. Results and Discussion

3.1. Proximate Composition, Salt, WHC, and Cook Loss

3.2. Colour

3.3. Texture Profile Analysis (TPA) of Cooked Pork Sausages

3.4. Sensory Analysis of Cooked Pork Sausages

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sloan, E. The new market: Foods for the not-so-healthy. Food Technol. 1999, 53, 54–60. [Google Scholar]

- Bocanegra, A.; Bastida, S.; Benedi, J.; Rodenas, S.; Sanchez-Muniz, F.J. Characteristics and nutritional and cardiovascular-health properties of seaweeds. J. Med. Food 2009, 12, 236–258. [Google Scholar] [CrossRef] [PubMed]

- Hur, J. Dong-Ui-Bo-Gam; Bupin Publishing Co.: Seoul, Korea, 1999; pp. 5–10. [Google Scholar]

- López-López, I.; Cofrades, S.; Jiménez-Colmenero, F. Low-fat frankfurters enriched with n− 3 PUFA and edible seaweed: Effects of olive oil and chilled storage on physicochemical, sensory and microbial characteristics. Meat Sci. 2009, 83, 148–154. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fernández-Martín, F.; López-López, I.; Cofrades, S.; Colmenero, F.J. Influence of adding Sea Spaghetti seaweed and replacing the animal fat with olive oil or a konjac gel on pork meat batter gelation. Potential protein/alginate association. Meat Sci. 2009, 83, 209–217. [Google Scholar] [CrossRef]

- Jaswir, I.; Tope, A.H.T.; Raus, R.A.; Monsur, H.A.; Ramli, N. Study on anti-bacterial potentials of some Malaysian brown seaweeds. Food Hydrocoll. 2014, 42, 275–279. [Google Scholar] [CrossRef]

- Jiménez-Escrig, A.; Sánchez-Muniz, F.J. Dietary fibre from edible seaweeds: Chemical structure, physicochemical properties and effects on cholesterol metabolism. Nutr. Res. 2000, 20, 585–598. [Google Scholar] [CrossRef]

- Kumar, M.; Sharma, B.D. The storage stability and textural, physico-chemical and sensory quality of low-fat ground pork patties with Carrageenan as fat replacer. Int. J. Food Sci. Technol. 2004, 39, 31–42. [Google Scholar] [CrossRef]

- Cierach, M.; Modzelewska-Kapituła, M.; Szaciło, K. The influence of carrageenan on the properties of low-fat frankfurters. Meat Sci. 2009, 82, 295–299. [Google Scholar] [CrossRef]

- Totosaus, A.; Alfaro-Rodriguez, R.H.; Pérez-Chabela, M.L. Fat and sodium chloride reduction in sausages using κ-carrageenan and other salts. Int. J. Food Sci. Nutr. 2004, 55, 371–380. [Google Scholar] [CrossRef]

- Cao, C.; Feng, Y.; Kong, B.; Xia, X.; Liu, M.; Chen, J.; Zhang, F.; Liu, Q. Textural and gel properties of frankfurters as influenced by various κ-carrageenan incorporation methods. Meat Sci. 2021, 176, 108483. [Google Scholar] [CrossRef]

- Qin, Y.; Zhang, G.; Chen, H. The Applications of Alginate in Functional Food Products. J. Nutr. Food Sci. 2020, 3, 100013. [Google Scholar]

- Kang, Z.L.; Wang, T.T.; Li, Y.P.; Li, K.; Ma, H.J. Effect of sodium alginate on physical-chemical, protein conformation and sensory of low-fat frankfurters. Meat Sci. 2020, 162, 108043. [Google Scholar] [CrossRef] [PubMed]

- Selby, H.H.; Whistler, R.L. Agar. In Industrial Gums; Academic Press: Cambridge, MA, USA, 1993; pp. 87–103. [Google Scholar]

- Mabeau, S.; Cavaloc, E.; Fleurence, J.; Lahaye, M. New seaweed based ingredients for the food industry. Int. Food Ingred. 1992, 3, 38–45. [Google Scholar]

- Cox, S.; Abu-Ghannam, N. Enhancement of the phytochemical and fibre content of beef patties with Himanthalia elongata seaweed. Int. J. Food Sci. Technol. 2013, 48, 2239–2249. [Google Scholar]

- Kim, H.W.; Kim, J.H.; Kim, Y.S.; Han, D.J.; Kim, H.Y.; Lee, M.A.; Kim, S.Y.; Kim, C.J. Effects of sea tangle (Lamina japonica) powder on quality characteristics of breakfast sausages. Food Sci. Anim. Resour. 2010, 30, 55–61. [Google Scholar] [CrossRef] [Green Version]

- Jeon, M.R.; Kim, S.H. Quality characteristics of pork patties added with seaweed powder. Food Sci. Anim. Resour. 2012, 32, 77–83. [Google Scholar] [CrossRef]

- Mohammed, H.O.; O’Grady, M.N.; O’Sullivan, M.G.; Hamill, R.M.; Kilcawley, K.N.; Kerry, J.P. An Assessment of Selected Nutritional, Bioactive, Thermal and Technological Properties of Brown and Red Irish Seaweed Species. Foods 2021, 10, 2784. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of AOAC International, 16th ed.; Association of Official Analytical Chemists: Rockville, MD, USA, 1999. [Google Scholar]

- Kirk, R.S.; Sawyer, R. Pearson’s Composition and Analysis of Foods, 9th ed.; Longman Scientific & Technical: Har-low, UK, 1991. [Google Scholar]

- Lianji, M.; Chen, N. Research in improving the water holding capacity of meat in sausage products. In Proceedings of the 35th International Congress on Meat Science and Technology, Copenhagen, Denmark, 20–25 August 1989; pp. 781–786. [Google Scholar]

- Bourne, M.C. Texture profile analysis. Food Technol. 1978, 32, 62–66. [Google Scholar]

- Stone, H.; Bleibaum, R.; Thomas, H. Sensory Evaluation Practices; Elsevier: Amsterdam, The Netherlands, 2012; Volume 4, pp. 117–157. [Google Scholar]

- ISO 11136:2014; Sensory Analysis-Methodology-General Guidance for Conducting Hedonic Tests with Consumers in a Controlled Area. International Organisation for Standardisation: Geneva, Switzerland, 2014. Available online: https://www.iso.org/standard/50125.html (accessed on 31 August 2021).

- Stengel, D.B.; Connan, S.; Popper, Z.A. Algal chemo diversity and bioactivity: Sources of natural variability and implications for commercial application. Biotechnol. Adv. 2011, 29, 483–501. [Google Scholar] [CrossRef]

- Shannon, E.; Abu-Ghannam, N. Optimisation of fucoxanthin extraction from Irish seaweeds by response surface methodology. J. Appl. Phycol. 2017, 29, 1027–1036. [Google Scholar] [CrossRef] [Green Version]

- Kraan, S. Pigments and minor compounds in algae. In Functional Ingredients from Algae for Foods and Nutraceuticals; Woodhead Publishing: Cambridge, England, 2013; pp. 205–251. [Google Scholar]

- Brownlee, I.; Fairclough, A.; Hall, A.; Paxman, J. The potential health benefits of seaweed and seaweed extract. In Seaweed: Ecology, Nutrient Composition and Medicinal Uses. Marine Biology: Earth Sciences in the 21st Century; Nova Science Publishers: New York, NY, USA, 2012; pp. 119–136. [Google Scholar]

- Thebaudin, J.Y.; Lefebvre, A.C.; Harrington, M.; Bourgeois, C.M. Dietary fibres: Nutritional and technological interest. Trends Food Sci. Technol. 1997, 8, 41–48. [Google Scholar] [CrossRef]

- Chun, S.S.; Park, J.R.; Park, J.C.; Suh, J.S.; Ahn, C.B. Quality characteristics of hamburger patties added with seaweed powder. J. Korean Soc. Food Sci. Nutr. 1999, 28, 140–144. [Google Scholar]

- Kwon, E.A.; Chang, M.J.; Kim, S.H. Quality characteristics of bread containing Laminaria powder. J. Korean Soc. Food Sci. Nutr. 2003, 32, 406–412. [Google Scholar]

| Sample | Control | Seaweed Inclusion Levels | ||

|---|---|---|---|---|

| 1% | 2.5% | 5% | ||

| Pork oyster | 45.00 | 44.00 | 42.50 | 40.00 |

| Pork back fat | 20.00 | 20.00 | 20.00 | 20.00 |

| Water | 20.00 | 20.00 | 20.00 | 20.00 |

| Rusk | 12.50 | 12.50 | 12.50 | 12.50 |

| Seasoning | 2.50 | 2.50 | 2.50 | 2.50 |

| Seaweed | 0.00 | 1.00 | 2.50 | 5.00 |

| Treatment | Protein | Moisture | Fat | Ash | Salt | WHC | Cook Loss | |

|---|---|---|---|---|---|---|---|---|

| Control | 14.09 ± 0.47 a | 54.46 ± 0.89 abc | 20.02 ± 0.58 a | 2.23 ± 0.04 a | 1.47 ± 0.10 a | 63.73 ± 1.62 ab | 29.45 ± 0.79 abc | |

| SS | 1% | 13.14 ± 0.29 a | 55.71 ± 0.75 c | 19.65 ± 0.19 a | 2.40 ± 0.07 a | 1.61 ± 0.03 a | 69.25 ± 1.96 bdef | 30.27 ± 1.72 abc |

| 2.5% | 13.72 ± 0.51 a | 55.63 ± 0.22 bc | 19.14 ± 0.53 a | 2.85 ± 0.05 bc | 1.77 ± 0.16 abc | 70.96 ± 3.48 def | 28.57 ± 0.80 abc | |

| 5% | 14.31 ± 1.21 a | 54.02 ± 1.65 abc | 18.79 ± 0.33 a | 3.39 ± 0.23 de | 2.10 ± 0.01 bcd | 74.95 ± 1.36 f | 25.05 ± 2.37 a | |

| IW | 1% | 13.61 ± 0.17 a | 55.03 ± 0.41 abc | 19.55 ± 0.29 a | 2.50 ± 0.02 ab | 1.61 ± 0.05 a | 67.47 ± 1.50 bde | 31.98 ± 2.01 bc |

| 2.5% | 13.48 ± 0.36 a | 54.32 ± 0.71 abc | 19.29 ± 0.42 a | 3.02 ± 0.10 cd | 1.86 ± 0.13 abcd | 71.18 ± 0.48 def | 30.52 ± 5.48 abc | |

| 5% | 13.84 ± 0.63 a | 54.89 ± 1.00 abc | 18.99 ± 0.42 a | 3.66 ± 0.02 e | 2.26 ± 0.19 d | 73.20 ± 2.58 ef | 29.97 ± 2.49 abc | |

| PP | 1% | 13.38 ± 0.13 a | 53.82 ± 1.34 abc | 19.69 ± 0.70 a | 2.48 ± 0.04 ab | 1.60 ± 0.29 a | 55.05 ± 1.92 c | 33.23 ± 0.45 c |

| 2.5% | 14.38 ± 0.62 a | 53.52 ± 0.64 abc | 19.25 ± 0.20 a | 2.90 ± 0.06 bc | 1.80 ± 0.19 abc | 60.66 ± 0.46 ac | 31.04 ± 0.72 abc | |

| 5% | 14.51 ± 1.01 a | 53.13 ± 0.42 ab | 18.79 ± 0.22 a | 3.67 ± 0.44 e | 2.21 ± 0.10 cd | 64.98 ± 2.43 ab | 27.38 ± 0.69 abc | |

| Nori | 1% | 14.04 ± 0.34 a | 53.43 ± 0.29 abc | 19.88 ± 0.20 a | 2.38 ± 0.04 a | 1.47 ± 0.08 a | 66.14 ± 2.66 abd | 28.29 ± 2.25 abc |

| 2.5% | 14.43 ± 0.36 a | 52.81 ± 0.74 a | 19.45 ± 0.69 a | 2.54 ± 0.13 ab | 1.62 ± 0.19 a | 69.30 ± 1.04 bdef | 26.14 ± 0.73 ab | |

| 5% | 15.60 ± 0.88 a | 53.09 ± 0.86 ab | 18.90 ± 0.12 a | 3.17 ± 0.10 cd | 1.73 ± 0.17 ab | 73.36 ± 2.06 ef | 25.76 ± 1.74 ab | |

| Treatment | L* | a* | b* | |

|---|---|---|---|---|

| Control | 70.45 ± 0.25 a | 6.25 ± 0.16 a | 13.87 ± 0.29 a | |

| SS | 1% | 66.54 ± 3.33 abc | 4.29 ± 1.08 bc | 13.35 ± 0.53 ab |

| 2.5% | 64.90 ± 1.96 abcd | 2.97 ± 0.15 cde | 13.16 ± 0.30 ab | |

| 5% | 61.73 ± 3.39 bcde | 1.42 ± 1.05 e | 12.77 ± 1.12 abc | |

| IW | 1% | 66.15 ± 0.90 abc | 2.05 ± 0.96 de | 12.39 ± 0.71 abc |

| 2.5% | 59.71 ± 2.22 de | −0.65 ± 0.26 f | 10.90 ± 0.71 bcd | |

| 5% | 53.29 ± 2.44 fg | −2.01 ± 0.20 f | 9.55 ± 0.93 de | |

| PP | 1% | 67.78 ± 2.64 ab | 3.94 ± 0.58 bcd | 11.62 ± 0.94 abcd |

| 2.5% | 62.21 ± 0.47 bcd | 3.04 ± 0.46 cde | 9.44 ± 0.65 de | |

| 5% | 59.13 ± 1.64 def | 2.54 ± 1.00 cde | 8.03 ± 1.54 ef | |

| Nori | 1% | 61.09 ± 1.71 cde | 5.29 ± 0.37 ab | 10.34 ± 1.53 cde |

| 2.5% | 56.05 ± 1.72 ef | 4.19 ± 0.59 bc | 8.22 ± 0.63 ef | |

| 5% | 48.96 ± 2.02 g | 2.70 ± 0.33 cde | 6.19 ± 0.70 f | |

| Treatment | Hardness (N) | Adhesiveness (N) | Springiness (mm) | Cohesiveness | Chewiness (N*mm) | |

|---|---|---|---|---|---|---|

| Control | 42.81 ± 3.47 ab | −0.022 ± 0.02 a | 0.862 ± 0.02 abc | 0.664 ± 0.04 abc | 24.41 ± 2.05 abc | |

| SS | 1% | 35.67 ± 1.83 ab | −0.009 ± 0.01 a | 0.893 ± 0.03 ab | 0.686 ± 0.01 ab | 21.80 ± 1.09 ab |

| 2.5% | 45.23 ± 6.11 ab | −0.012 ± 0.01 a | 0.903 ± 0.00 a | 0.669 ± 0.01 abc | 27.32 ± 3.94 bc | |

| 5% | 46.62± 9.07 ab | −0.011 ± 0.00 a | 0.843 ± 0.04 abcd | 0.704 ± 0.02 a | 27.76 ± 6.34 bc | |

| IW | 1% | 41.49 ± 1.62 ab | −0.009 ± 0.00 a | 0.891 ± 0.02 ab | 0.671 ± 0.01 abc | 24.89 ± 1.26 abc |

| 2.5% | 44.95 ± 3.36 ab | −0.010 ± 0.00 a | 0.852 ± 0.01 abc | 0.664 ± 0.03 abc | 25.38 ± 3.05 abc | |

| 5% | 64.13± 3.62 cd | −0.021 ± 0.01 a | 0.813 ± 0.04 bcd | 0.620 ± 0.03 c | 32.13± 3.24 cd | |

| PP | 1% | 50.07 ± 6.32 bc | −0.012 ± 0.01 a | 0.819 ± 0.03 abcd | 0.618 ± 0.01 c | 25.11 ± 2.59 abc |

| 2.5% | 41.18 ± 4.76 ab | −0.022 ± 0.02 a | 0.783 ± 0.03 cd | 0.639 ± 0.03 bc | 20.58 ± 2.07 ab | |

| 5% | 34.20 ± 2.21 a | −0.035 ± 0.01 a | 0.759 ± 0.03 d | 0.650 ± 0.02 abc | 16.91 ± 0.78 a | |

| Nori | 1% | 46.20 ± 2.18 ab | −0.020 ± 0.01 a | 0.871 ± 0.02 ab | 0.672 ± 0.02 abc | 27.10 ± 2.14 bc |

| 2.5% | 48.29 ± 5.74 ab | −0.022 ± 0.01 a | 0.825 ± 0.05 abcd | 0.682 ± 0.01 abc | 27.20 ± 3.62 bc | |

| 5% | 68.60 ± 6.61 d | −0.013 ± 0.00 a | 0.880 ± 0.02 ab | 0.623 ± 0.01 bc | 37.42 ± 2.82 d | |

| Treatment | Appearance | Aroma | Texture | Flavour | Overall Acceptability | |

|---|---|---|---|---|---|---|

| Control | 6.78 ± 1.76 ab | 6.87 ± 1.46 ab | 5.72 ± 2.07 ab | 6.70 ± 1.69 ab | 6.78 ± 1.76 ab | |

| SS | 1% | 7.18 ± 1.20 a | 6.89 ± 1.48 ab | 6.53 ± 1.46 a | 7.39 ± 1.59 a | 7.27 ± 1.45 a |

| 2.5% | 6.63 ± 1.02 ab | 5.23 ± 2.03 bcd | 5.71 ± 1.51 ab | 5.04 ± 2.09 bcd | 5.23 ± 1.71 bcde | |

| 5% | 5.78 ± 2.03 abc | 4.12 ± 2.41 d | 5.07 ± 2.01 ab | 3.14 ± 2.69 d | 3.81 ± 2.50 e | |

| IW | 1% | 6.37 ± 1.13 ab | 6.82 ± 1.22 ab | 5.76 ± 1.96 ab | 6.68 ± 1.28 ab | 6.26 ± 1.30 abc |

| 2.5% | 5.24 ± 1.87 bc | 5.38 ± 1.85 bcd | 5.65 ± 1.96 ab | 5.32 ± 1.84 abc | 5.55 ± 1.63 abcde | |

| 5% | 3.19 ± 1.99 d | 4.42 ± 1.97 cd | 4.37 ± 1.58 b | 4.38 ± 2.41 cd | 4.12 ± 2.08 de | |

| PP | 1% | 6.96 ± 1.65 ab | 7.23 ± 1.16 a | 5.84 ± 1.98 ab | 5.83 ± 2.08 abc | 5.91 ± 1.77 abcd |

| 2.5% | 6.03 ± 1.82 abc | 6.05 ± 1.67 abc | 5.29 ± 2.20 ab | 4.34 ± 0.61 cd | 4.78 ± 2.79 cde | |

| 5% | 5.44 ± 1.37 abc | 4.79 ± 2.25 cd | 5.01 ± 2.05 ab | 3.23 ± 2.28 d | 4.17 ± 2.14 de | |

| Nori | 1% | 7.01 ± 1.36 a | 6.87 ± 1.40 ab | 5.71 ± 1.63 ab | 7.08 ± 1.57 ab | 6.98 ± 1.60 ab |

| 2.5% | 6.23 ± 2.00 abc | 6.87 ± 1.23 ab | 5.35 ± 2.25 ab | 6.82 ± 1.63 ab | 6.23 ± 1.71 abc | |

| 5% | 4.60 ± 2.22 cd | 6.02 ± 1.17 abc | 5.44 ± 1.73 ab | 6.58 ± 1.99 ab | 6.18 ± 1.84 abc | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammed, H.O.; O’Grady, M.N.; O’Sullivan, M.G.; Hamill, R.M.; Kilcawley, K.N.; Kerry, J.P. Acceptable Inclusion Levels for Selected Brown and Red Irish Seaweed Species in Pork Sausages. Foods 2022, 11, 1522. https://0-doi-org.brum.beds.ac.uk/10.3390/foods11101522

Mohammed HO, O’Grady MN, O’Sullivan MG, Hamill RM, Kilcawley KN, Kerry JP. Acceptable Inclusion Levels for Selected Brown and Red Irish Seaweed Species in Pork Sausages. Foods. 2022; 11(10):1522. https://0-doi-org.brum.beds.ac.uk/10.3390/foods11101522

Chicago/Turabian StyleMohammed, Halimah O., Michael N. O’Grady, Maurice G. O’Sullivan, Ruth M. Hamill, Kieran N. Kilcawley, and Joseph P. Kerry. 2022. "Acceptable Inclusion Levels for Selected Brown and Red Irish Seaweed Species in Pork Sausages" Foods 11, no. 10: 1522. https://0-doi-org.brum.beds.ac.uk/10.3390/foods11101522