The Effect of Roast Development Time Modulations on the Sensory Profile and Chemical Composition of the Coffee Brew as Measured by NMR and DHS-GC–MS

Abstract

:1. Introduction

2. Materials and Methods

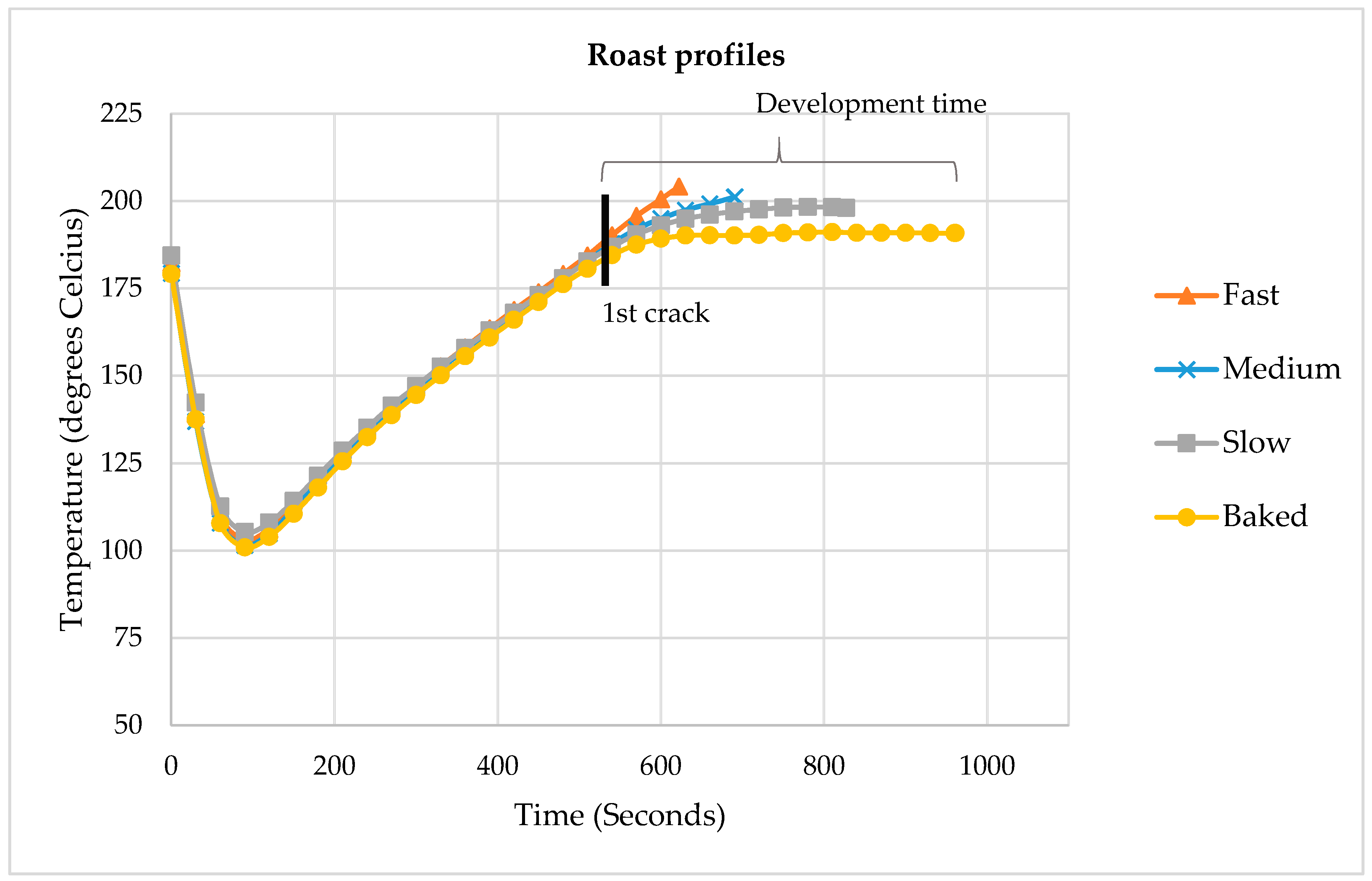

2.1. Coffee Sample Preparation

2.2. Sensory Evaluation

2.2.1. Brewing

2.2.2. Panel Evaluation

2.3. NMR Methodology

2.4. Dynamic Headspace Sampling and GC–MS Methodology

3. Results

3.1. Sensory Evaluation

3.2. NMR

3.3. DHS-GC–MS

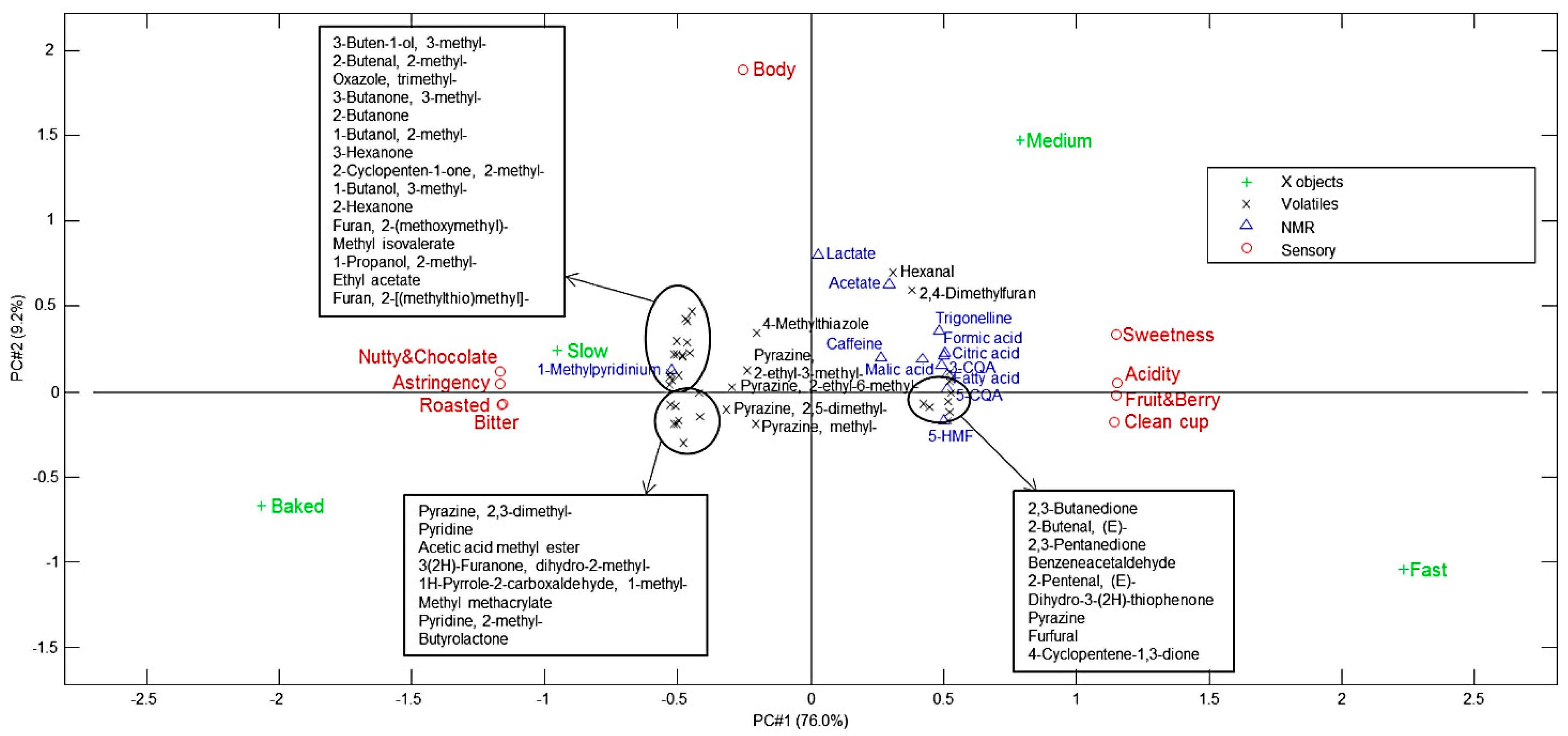

3.4. Correlation between Sensory and Instrumental Variables

3.5. Overall

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Category | Descriptor | Definition | Reference |

|---|---|---|---|

| Basic tastes | Sweetness | The sweet sensation associated with sucrose solution | Sucrose solution of 24 g/L |

| Acidity | The sour sensation associated with citric acid solution | Citric acid solution of 1.2 g/L | |

| Bitterness | The bitter sensation associated with caffeine solution | Bitter solution of 0.54 g/L caffeine. | |

| Mouthfeel | Body | The sensation of thickness, viscosity, and heaviness of the beverage. | Pure water Solution of 0.05% xanthan gum in water. Solution of 0.1% xanthan gum in water. |

| Astringency | The dry sensation on the tongue associated with over extracted earl grey tea. | - | |

| Aroma | Roasted | The aroma associated with dark roasted coffee and rye bread crust. | Mix of dark roasted whole coffee beans and rye bread crust. |

| Nutty+Chocolate | The aroma associated with a mix of nuts and dark chocolate. | Mix of nuts (almonds, hazelnuts, walnuts) and 80% dark chocolate | |

| Fruit+Berry | The aroma associated with citrus fruits and dark berries. | - | |

| Quality | Clean cup | The absence of negative off-flavours from initial tasting of the beverage to swallowing (Speciality Coffee Association, 2019). |

References

- CBI. What is the Demand for Coffee in the European Market? Available online: https://www.cbi.eu/market-information/coffee/trade-statistics/ (accessed on 9 December 2019).

- Eggers, R.; Pietsch, A. Technology I: Roasting. In Coffee: Recent Developments; Clarke, R.J., Vitzthum, O.G., Eds.; Blackwell Sciences Ltd.: London, UK, 2001; pp. 90–107. [Google Scholar]

- van der Merwe, K.; Maree, T. The Behavioural Intentions of Specialty Coffee Consumers in South Africa. Int. J. Consum. Stud. 2016, 40, 501–508. [Google Scholar] [CrossRef]

- Münchow, M.; Alstrup, J.; Steen, I.; Giacalone, D. Roasting Conditions and Coffee Flavor: A Multi-Study Empirical Investigation. Beverages 2020, 6, 29. [Google Scholar] [CrossRef]

- Bonnländer, B.; Eggers, R.; Engelhardt, U.H.; Maier, H.G. Roasting. In Espresso Coffee: The Science of Quality; Illy, A., Viani, R., Eds.; Elsevier Academic Press: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Ahmed, J.; Dolan, K.; Mishra, D. Chemical Reaction Kinetics Pertaining to Foods. In Handbook of Food Process Design; Ahmed, J., Shafiur Rahman, M., Eds.; Wiley-Blackwell: Oxford, UK, 2012. [Google Scholar]

- Bicho, N.C.; Leitão, A.E.; Ramalho, J.C.; Bartolomeu de Alvarenga, N.; Lidon, F.C. Impact of Roasting Time on the Sensory Profile of Arabica and Robusta Coffee. Ecol. Food Nutr. 2013, 52, 163–177. [Google Scholar] [CrossRef] [PubMed]

- Wang, N.; Lim, L.T. Fourier Transform Infrared and Physicochemical Analyses of Roasted Coffee. J. Agric. Food Chem. 2012, 60, 5446–5453. [Google Scholar] [CrossRef]

- Blumberg, S.; Frank, O.; Hofmann, T. Quantitative Studies on the Influence of the Bean Roasting Parameters and Hot Water Percolation on the Concentrations of Bitter Compounds in Coffee Brew. J. Agric. Food Chem. 2010. [Google Scholar] [CrossRef]

- Lyman, D.J.; Benck, R.; Dell, S.; Merle, S.; Murray-Wijelath, J. FTIR-ATR Analysis of Brewed Coffee: Effect of Roasting Conditions. J. Agric. Food Chem. 2003, 51, 3268–3272. [Google Scholar] [CrossRef]

- Gloess, A.N.; Vietri, A.; Wieland, F.; Smrke, S.; Schönbächler, B.; López, J.A.S.; Petrozzi, S.; Bongers, S.; Koziorowski, T.; Yeretzian, C. Evidence of Different Flavour Formation Dynamics by Roasting Coffee from Different Origins: On-Line Analysis with PTR-ToF-MS. Int. J. Mass Spectrom. 2014, 365–366, 324–337. [Google Scholar] [CrossRef] [Green Version]

- Baggenstoss, J.; Poisson, L.; Kaegi, R.; Perren, R.; Escher, F. Coffee Roasting and Aroma Formation: Application of Different Time-Temperature Conditions. J. Agric. Food Chem. 2008, 56, 5836–5846. [Google Scholar] [CrossRef]

- Schenker, S. Investigations on the Hot Air Roasting of Coffee Beans; Dissertation No. 13620; Eidgenoessische Technische Hochschule Zuerich (ETH): Zürich, Switzerland, 2000. [Google Scholar]

- Ruosi, M.R.; Cordero, C.; Cagliero, C.; Rubiolo, P.; Bicchi, C.; Sgorbini, B.; Liberto, E. A Further Tool to Monitor the Coffee Roasting Process: Aroma Composition and Chemical Indices. J. Agric. Food Chem. 2012, 60, 11283–11291. [Google Scholar] [CrossRef]

- Liberto, E.; Ruosi, M.R.; Cordero, C.; Rubiolo, P.; Bicchi, C.; Sgorbini, B. Non-Separative Headspace Solid Phase Microextraction-Mass Spectrometry Profile as a Marker to Monitor Coffee Roasting Degree. J. Agric. Food Chem. 2013, 61, 1652–1660. [Google Scholar] [CrossRef]

- Giacalone, D.; Kreuzfeldt, T.; Yang, N.; Liu, C.; Fisk, I.; Münchow, M. Common Roasting Defects in Co Ff Ee: Aroma Composition, Sensory Characterization and Consumer Perception. Food Qual. Prefer. 2018, 71, 463–474. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Lim, L.T. A Kinetics and Modeling Study of Coffee Roasting Under Isothermal Conditions. Food Bioprocess Technol. 2014, 7, 621–632. [Google Scholar] [CrossRef]

- SCAA. Protocols & Best Practices. Available online: https://sca.coffee/research/protocols-best-practices/ (accessed on 4 December 2019).

- Stokes, C.N.; O’Sullivan, M.G.; Kerry, J.P. Assessment of Black Coffee Temperature Profiles Consumed from Paper-Based Cups and Effect on Affective and Descriptive Product Sensory Attributes. Int. J. Food Sci. Technol. 2016, 51, 2041–2048. [Google Scholar] [CrossRef]

- Borchgrevink, C.P.; Susskind, A.M.; Tarras, J.M. Consumer Preferred Hot Beverage Temperatures. Food Qual. Prefer. 1999, 10, 117–121. [Google Scholar] [CrossRef] [Green Version]

- Steen, I.; Waehrens, S.S.; Petersen, M.A.; Münchow, M.; Bredie, W.L.P. Influence of Serving Temperature on Flavour Perception and Release of Bourbon Caturra Coffee. Food Chem. 2017, 219, 61–68. [Google Scholar] [CrossRef]

- Lawless, H.T.; Heymann, H. Sensory Evaluation of Food—Principles and Practices, 2nd ed.; Heldman, D.R., Ed.; Springer Science+Business Media LLC.: New York, NY, USA, 2010. [Google Scholar]

- Bax, A. A Spatially Selective Composite 90 Radiofrequency Pulse. J. Magn. Reson. 1985, 65, 142–145. [Google Scholar] [CrossRef]

- Campo, G.; Caracena, R.; Zuriarrain, J. Talanta Quantitative Determination of Caffeine, Formic Acid, Trigonelline and 5- (Hydroxymethyl) Furfural in Soluble Coffees by 1 H NMR Spectrometry. Talanta 2010, 81, 367–371. [Google Scholar] [CrossRef]

- Wei, F.; Furihata, K.; Koda, M.; Hu, F.; Miyakawa, T.; Tanokura, M. Roasting Process of Coffee Beans as Studied by Nuclear Magnetic Resonance: Time Course of Changes in Composition. J. Agric. Food Chem. 2012, 60, 1005–1012. [Google Scholar] [CrossRef]

- Meilgaard, M.; Civille, G.V.; Carr, B.T. Sensory Evaluation Techniques, 4th ed.; Taylor and Francis Group, LLC.: Boca Raton, FL, USA, 2007. [Google Scholar]

- Folmer, B. The Craft and Science of Coffee; Elsevier Science & Technology: San Diego, CA, USA, 2017. [Google Scholar]

- Giacalone, D.; Steen, I.; Alstrup, J.; Münchow, M. Inter-Rater Reliability of “Clean Cup” Scores by Coffee Experts. J. Sens. Stud. 2020. [Google Scholar] [CrossRef]

- Belitz, H.D.; Grosch, W.; Schieberle, P. Food Chemistry; 4th revise; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar] [CrossRef]

- Toci, A.T.; Azevedo, D.A.; Farah, A. Effect of Roasting Speed on the Volatile Composition of Coffees with Different Cup Quality. Food Res. Int. 2020, 137. [Google Scholar] [CrossRef]

- Yang, N.; Liu, C.; Liu, X.; Degn, T.K.; Munchow, M.; Fisk, I. Determination of Volatile Marker Compounds of Common Coffee Roast Defects. Food Chem. 2016, 211, 206–214. [Google Scholar] [CrossRef] [PubMed]

- Schenker, S.; Heinemann, C.; Huber, M.; Pompizzi, R.; Perren, R.; Escher, F. Impact of Roasting Conditions on the Formation of Aroma Compounds in Coffee Beans. J. Food Sci. 2002, 67, 60–66. [Google Scholar] [CrossRef]

- Bradbury, A.G.W. Chemistry. In Coffee: Recent Developments; Clarke, R., Vitzthum, O.G., Eds.; Blackwell Sciences Ltd.: Boston, MA, USA, 2001. [Google Scholar]

- Clark, S.; Winter, C.K. Diacetyl in Foods: A Review of Safety and Sensory Characteristics. Compr. Rev. Food Sci. Food Saf. 2015, 14, 634–643. [Google Scholar] [CrossRef]

- Martyny, J.W.; Van Dyke, M.V.; Arbuckle, S.; Towle, M.; Rose, C.S. Diacetyl Exposures in the Flavor Manufacturing Industry. J. Occup. Environ. Hyg. 2008, 5, 679–688. [Google Scholar] [CrossRef]

| Sample | Fast | Medium | Slow | Baked | p-Values |

|---|---|---|---|---|---|

| Sweetness | 8.7 C | 8.3 C | 7.2 B | 6.3 A | <0.001 |

| Acidity | 8.5 C | 7.6 B | 5.8 A | 5.4 A | <0.001 |

| Bitter | 5.7 A | 6.5 A | 8.0 B | 8.6 B | <0.001 |

| Body | 6.9 A | 7.4 A | 7.2 A | 7.1 A | 0.37 |

| Astringency | 5.4 A | 6.0 AB | 6.7 BC | 7.1 C | <0.001 |

| Roasted | 5.4 A | 6.3 B | 8.3 C | 8.8 C | <0.001 |

| Nutty+Chocolate | 6.0 A | 6.9 B | 7.9 C | 8.4 C | <0.001 |

| Fruit+Berry | 7.3 C | 6.4 B | 4.6 A | 4.4 A | <0.001 |

| Clean cup | 7.5 C | 6.7 B | 5.5 A | 5.5 A | <0.001 |

| Compound | Fast | Medium | Slow | Baked |

|---|---|---|---|---|

| Acetate | 9.26 | 9.67 | 9.39 | 8.63 |

| Formic acid | 5.53 | 5.40 | 4.75 | 4.16 |

| Trigonelline | 4.45 | 4.53 | 4.05 | 3.78 |

| Citric acid | 4.33 | 4.26 | 4.01 | 3.73 |

| Caffeine | 3.35 | 3.40 | 3.22 | 3.34 |

| 5-CQA * | 3.52 | 3.24 | 2.33 | 2.44 |

| Fatty acid | 2.00 | 1.83 | 1.58 | 1.29 |

| Malic acid | 1.22 | 1.17 | 1.16 | 0.95 |

| 3-CQA | 1.24 | 1.23 | 0.96 | 1.00 |

| Lactate | 0.89 | 0.95 | 0.94 | 0.88 |

| 1-methylpyridinium | 0.32 | 0.37 | 0.43 | 0.43 |

| 5-HMF | 0.10 | 0.08 | 0.05 | 0.06 |

| Retention Index (RI) | Mean Relative Peak Area (n = 3) | |||||||

|---|---|---|---|---|---|---|---|---|

| Exp | Auth | Lit (1) | Fast | Medium | Slow | Baked | ANOVA, p | |

| -Alcohols | ||||||||

| 1-Propanol, 2-methyl- | 1114 | 1110 | 16 A | 20 AB | 21 AB | 24 B | 0.019 | |

| 1-Butanol, 2-methyl- | 1228 | 1207 | 15 A | 18 B | 17 B | 19 C | 0.000 | |

| 1-Butanol, 3-methyl- | 1229 | 1224 | 80 A | 88 AB | 88 AB | 94 B | 0.025 | |

| 3-Buten-1-ol, 3-methyl- | 1272 | 1249 | 102 A | 115 B | 115 B | 117 B | 0.003 | |

| -Aldehydes | ||||||||

| 2-Butenal, (E)- | 1036 | 1040 | 55 B | 49 B | 35 A | 30 A | 0.000 | |

| Hexanal | 1085 | 1087 | 149 B | 192 C | 136 AB | 125 A | 0.000 | |

| 2-Butenal, 2-methyl-, (E)- | 1092 | 1092 | 112 A | 129 B | 133 B | 133 B | 0.001 | |

| 2-Pentenal, (E)- | 1134 | 1129 | 29 B | 25 AB | 23 B | 20 B | 0.006 | |

| 1H-Pyrrole-2-carboxaldehyde, 1-methyl- | 1625 | 1628 | 181 A | 193 A | 214 AB | 249 B | 0.008 | |

| Benzeneacetaldehyde | 1656 | 1659 | 48 B | 41 AB | 32 AB | 28 A | 0.017 | |

| -Esters | ||||||||

| Acetic acid, methyl ester | 828 | 826 | 516 A | 587 AB | 670 AB | 789 B | 0.027 | |

| Ethyl Acetate | 894 | 887 | 26 A | 37 B | 44 BC | 52 C | 0.000 | |

| Methyl methacrylate | 1008 | 1006 | 21 A | 22 AB | 26 BC | 29 C | 0.001 | |

| Methyl isovalerate | 1020 | 1019 | 19 A | 23 AB | 26 B | 28 B | 0.008 | |

| -Furans | ||||||||

| 2,4-Dimethylfuran | 963 | 949 | 16 AB | 17 A | 15 AB | 14 B | 0.025 | |

| Furan, 2-(methoxymethyl)- | 1253 | 1243 | 203 A | 260 B | 306 C | 330 D | 0.000 | |

| 3(2H)-Furanone, dihydro-2-methyl- | 1279 | 1267 | 1487 A | 1521 A | 1518 A | 1629 B | 0.000 | |

| Furfural | 1477 | 1476 | 2701 C | 2487 B | 2246 A | 2222 A | 0.000 | |

| Furan, 2-[(methylthio)methyl]- | 1499 | 1491 | 129 A | 170 AB | 222 BC | 241 C | 0.001 | |

| -Ketones | ||||||||

| 2-Butanone | 905 | 906 | 995 A | 1154 AB | 1146 AB | 1239 B | 0.017 | |

| 2-Butanone, 3-methyl- | 927 | 943 | 5 A | 6 AB | 7 AB | 7 B | 0.034 | |

| 2,3-Butanedione | 984 | 985 | 1213 B | 1146 B | 892 A | 838 A | 0.000 | |

| 3-Hexanone | 1051 | 1055 | 92 A | 102 AB | 112 B | 110 B | 0.026 | |

| 2,3-Pentanedione | 1071 | 1073 | xx | 2434 B | 2020 A | 1991 A | 0.000 | |

| 2-Hexanone | 1085 | 1086 | 28 A | 30 AB | 33 A | 32 AB | 0.028 | |

| 2-Cyclopenten-1-one, 2-methyl- | 1381 | 1369 | 33 A | 36 B | 38 B | 39 B | 0.001 | |

| Dihydro-3-(2H)-thiophenone | 1577 | 1560 | 3 B | 3 AB | 2 AB | 2 A | 0.019 | |

| 4-Cyclopentene-1,3-dione | 1598 | 1567 | 48 B | 41 AB | 33 A | 33 A | 0.028 | |

| -Pyrazines | ||||||||

| Pyrazine | 1220 | 1214 | 93 C | 90 BC | 80 A | 86 AB | 0.002 | |

| Pyrazine, methyl- | 1283 | 1267 | 1302 A | 1317 AB | 1272 A | 1380 B | 0.004 | |

| Pyrazine, 2,5-dimethyl- | 1347 | 1340 | 225 A | 235 AB | 224 A | 259 B | 0.027 | |

| Pyrazine, 2,3-dimethyl- | 1363 | 1343 | 46 A | 49 AB | 48 A | 55 B | 0.010 | |

| Pyrazine, 2-ethyl-6-methyl- | 1399 | 1385 | 160 A | 170 AB | 160 A | 182 B | 0.018 | |

| Pyrazine, 2-ethyl-3-methyl- | 1419 | 1404 | 71 AB | 77 AB | 70 A | 81 B | 0.029 | |

| -Pyridines | ||||||||

| Pyridine | 1190 | 1188 | 2011 A | 2177 B | 2505 C | 2689 D | 0.000 | |

| Pyridine, 2-methyl- | 1232 | 1222 | 6 A | 6 A | 9 B | 10 B | 0.004 | |

| -Lactones | ||||||||

| Butyrolactone | 1645 | 1652 | 30 A | 28 A | 43 A | 43 A | 0.035 | |

| -Other | ||||||||

| Oxazole, trimethyl- | 1209 | 1199 | 22 A | 25 B | 25 B | 26 B | 0.000 | |

| 4-Methylthiazole | 1299 | 1283 | 47 A | 50 B | 47 A | 50 B | 0.002 | |

| Characteristics of the ‘Baked’ Roast | ||||

| Sensory Attribute | NMR | Taste Qualities | GC–MS | Odour Qualities |

| Nutty+Chocolate Astringency Roasted Bitter | Methylpyridinium | Furan, 2-[(methylthio)methyl]- Methyl isovalerate Furan, 2-(methoxymethyl)- Pyridine Ethyl Acetate 2-Cyclopenten-1-one, 2-methyl- Pyridine, 2-methyl- Acetic acid, methyl ester Methyl methacrylate 3-Hexanone 2-Butanone, 3-methyl- 1-Propanol, 2-methyl- 1H-Pyrrole-2-carboxaldehyde, 1-methyl- 2-Hexanone 1-Butanol, 3-methyl- Butyrolactone 2-Butenal, 2-methyl-, (E)- 2-Butanone Oxazole, trimethyl- 1-Butanol, 2-methyl- 3-Buten-1-ol, 3-methyl- Pyrazine, 2,3-dimethyl- 3(2H)-Furanone, dihydro-2-methyl- Pyrazine, 2,5-dimethyl- Pyrazine, 2-ethyl-6-methyl- Pyrazine, 2-ethyl-3-methyl- Pyrazine, methyl- 4-Methylthiazole | onion, garlic fruity coffee, roasted fishy, coffee ethereal, fruity - nutty ethereal, fruity plastic fruity, waxy camphor fusel roasted acetone fusel creamy, caramel nutty acetone nut, roasted roasted, fusel sweet, fruity nutty, coffee brown, nutty nutty, cocoa roasted, hazelnut nutty, peanut nutty, cocoa nutty, green | |

| Characteristics of the ‘Fast’ roast | ||||

| Sensory attribute | NMR | Taste qualities | GC–MS | Odour qualities |

| Sweetness Acidity Fruit+Berry Clean cup | Acetate Malic Acid Trigonelline#1 Trigonelline 3-CQA 5-HMF Citric acid Formic acid 5-CQA Fatty acid | Sour Bitter | Hexanal 2,4-Dimethylfuran Dihydro-3-(2H)-thiophenone Pyrazine 2-Pentenal, (E)- 4-Cyclopentene-1,3-dione 2,3-Pentanedione 2,3-Butanedione Furfural 2-Butenal, (E)- Benzeneacetaldehyde | Grass, apple garlic, meaty, green roasted, nut green, fruitysweet, creamy butter, caramel sweet, woody flower honey, rose |

| No systematic effect | ||||

| Sensory | NMR | GC–MS | ||

| Body | Lactate Caffeine | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alstrup, J.; Petersen, M.A.; Larsen, F.H.; Münchow, M. The Effect of Roast Development Time Modulations on the Sensory Profile and Chemical Composition of the Coffee Brew as Measured by NMR and DHS-GC–MS. Beverages 2020, 6, 70. https://0-doi-org.brum.beds.ac.uk/10.3390/beverages6040070

Alstrup J, Petersen MA, Larsen FH, Münchow M. The Effect of Roast Development Time Modulations on the Sensory Profile and Chemical Composition of the Coffee Brew as Measured by NMR and DHS-GC–MS. Beverages. 2020; 6(4):70. https://0-doi-org.brum.beds.ac.uk/10.3390/beverages6040070

Chicago/Turabian StyleAlstrup, Jesper, Mikael Agerlin Petersen, Flemming Hofmann Larsen, and Morten Münchow. 2020. "The Effect of Roast Development Time Modulations on the Sensory Profile and Chemical Composition of the Coffee Brew as Measured by NMR and DHS-GC–MS" Beverages 6, no. 4: 70. https://0-doi-org.brum.beds.ac.uk/10.3390/beverages6040070