Calculating the Emissions Impacts of Waste Electronics Recycling in Ontario, Canada

Abstract

:1. Introduction

Literature Review

2. Results and Discussion

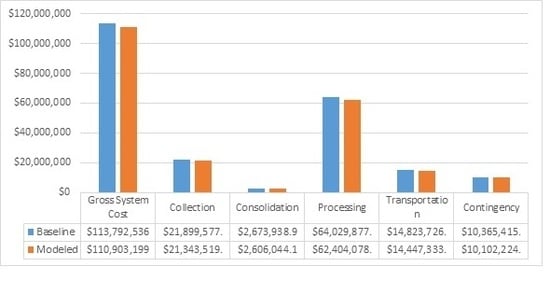

Quantifying the Emissions Impacts of the Waste Electronics Program (Baseline Scenario vs. Modeled Scenario)

3. Materials and Methods

3.1. Data Sources

3.2. Description of Study Site

3.3. Description of Waste Electronics Materials

- Computer Monitors

- Display Devices (18”–45”)

- Desktop Computers

- Portable Laptop Computers

- Desktop and portable printing, copying machines

- Telephones and telephone answering machines

- Cellular Devices and Pagers

- Computer Peripherals

- Personal/Portable (CD Players, MP3 Players, etc.)

- Home/Non Portable

- Home Theatre in a Box

- Aftermarket Vehicle Radio

- Floor Standing Printing Devices

- Floor Standing Copying Devices

3.4. Description of Environment Canada Greenhouse Gase (GHG) Calculator

- Using Canadian GHG emissions factors for materials commonly found in the Canadian waste stream

- Includes anaerobic digestion as a waste management treatment option

- Expands the list of materials included in the calculator to better reflect Canada’s waste stream, i.e., inclusion of white goods and waste electronics

- The use of province specific fuel generation to reflect regional differences in the energy grid mix.

3.5. Description of Model

- Users can alter material tonnes recovered or material revenues to re-calculate impact on WEEE system costs, diversion levels and emissions impacts.

- Users can set a WEEE system goal emissions target (currently set at 215,000 CO2/e). The model calculates the impact on Waste Electronics system costs and recycling rates (To achieve the goal emissions target) by increasing diversion for the materials with the lowest net cost and highest emissions credits.

- Users can select the value of a proposed carbon credit and calculate the potential value of carbon offsets for the WEEE program (by material type).

3.6. Key Model Assumptions

4. Conclusions and Policy Implications

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ministry of the Environment and Climate Change (MOECC). Climate Change Strategy. Available online: https://www.ontario.ca/page/climate-change-strategy (accessed on 6 December 2015).

- Ontario Waste Management Association. Greenhouse Gas Emissions and the Ontario Waste Management Industry White Paper. 2015. Available online: http://www.owma.org/About/tabid/120/ctl/DisplayAttachment/mid/511/AnnotationId/0752ab47-a9a9-e511-8dc5-00155d607900/ShowOpenSaveDlg/1/Default.aspx (accessed on 11 December 2015).

- Unruh, J. Recycle Everything: Why We Must, How We Can; CreateSpace Independent Publishing Platform: New York, NY, USA, 2010. [Google Scholar]

- Conference Board of Canada. Opportunities for Ontario’s Waste: Economic Impacts of Waste Diversion in North America. 2014. Available online: http://www.conferenceboard.ca/e-library/abstract.aspx?did=6233 (accessed on 15 December 2015).

- Corrections to Published Carbon Storage Factors for Mixed Municipal Waste. Memorandum to Parties Interested in Carbon Sequestration from Municipal Solid Waste. Available online: https://www3.epa.gov/warm/pdfs/Sequestration_Correction2_102708.pdf (accessed on 4 January 2016).

- ICF. Determination of the Impact of Waste Management Activities on Greenhouse Gas Emissions. Available online: http://www.rcbc.ca/files/u3/ICF-final-report.pdf (accessed on 8 April 2016).

- Mabee, W.E.; Calvert, K.; Manion, N.C.; Stephen, J.D.; Earley, S. Circular economies and Canada’s forest sector. In Proceedings of the Greening Work in a Chilly World Conference, University of Toronto/York University, Toronto, ON, Canada, 18 November 2011.

- Sachs, N. Planning the funeral at the birth: Extended producer responsibility in the European union and the Unites States. Harv. Environ. Law Rev. 2006, 30, 51–98. [Google Scholar]

- Highfill, J.; Mcasey, M. Municipal waste management: Recycling and landfill space constraints. J. Urban Econ. 1997, 41, 118–136. [Google Scholar] [CrossRef]

- Lox, F. Waste Management—Life Cycle Analysis of Packaging; Final Report; Belgian Packaging Institute: Zellik, Belgium, 1994. [Google Scholar]

- Measuring the Environmental Benefits of Ontario’s Blue Box, MHSW and WEEE Diversion. Available online: https://www.ontario.ca/document/measuring-environmental-benefits-ontarios-blue-box-mhsw-and-weee-diversion-final-report (accessed on 17 December 2015).

- United States Environmental Protection Agency. Documentation for Greenhouse Gas Emission and Energy Factors Used in the Waste Reduction Model. Available online: http://www3.epa.gov/warm/SWMGHGreport.html (accessed on 26 December 2015).

- Sheehan, B.; Spiegelman, H. EPR in the US and Canada. Resour. Recycl. 2005, 3, 18–21. [Google Scholar]

- National Recycling Coalition Inc. U.S. Recycling Economic Information Study. Available online: http://www.epa.gov/osw/conserve/tools/rmd/rei-rw/pdf/n_report.pdf (accessed on 19 January 2016).

- United States Environmental Protection Agency. Municipal Solid Waste in the United States 2007 Facts and Figures; USEPA: Washington, DC, USA, 2007. [Google Scholar]

- Mayers, K.; Butler, S. Producer responsibility organizations development and operations. J. Ind. Ecol. 2013, 17, 277–289. [Google Scholar] [CrossRef]

- Pollin, R.; Peltier-Garrett, H. Building a Green Economy: Employment Effects of Green Energy Investments for Ontario; Political Economy Research Institute, University of Massachusetts: Amherst, MA, USA, 2009. [Google Scholar]

- Ontario Electronic Stewardship. Annual Program Plan. Available online: http://ontarioelectronicstewardship.ca/wp-content/uploads/2014/02/program_plan_jul10_2009.pdf (accessed on 19 December 2015).

- Waste Diversion Ontario. About WDO. Available online: http://www.wdo.ca/content/?path=page81+item35937 (accessed on 19 December 2015).

- Ministry of the Environment and Climate Change. Ontario Environmental Protection Act: Ontario Regulation 320/09. Available online: http://www.e-laws.gov.on.ca/html/source/regs/english/2009/elaws_src_regs_r04274_e.htm (accessed on 4 January 2016).

- Ontario Electronic Stewardship. Final Revised Waste Electrical and Electronic Equipment Program Plan. Available online: http://ontarioelectronicstewardship.ca/wp-content/uploads/2014/02/program_plan_jul10_2009.pdf (accessed on 19 December 2015).

- (GHG) Calculator for Waste Management. Available online: https://www.ec.gc.ca/gdd-mw/default.asp?lang=En&n=D6A8B05A-1 (accessed on 20 December 2015).

- Boyce, J. Recycling of Non Renewable Resource and the Least Cost First Principle; Department of Economics, University of Calgary: Calgary, AB, USA, 2012. [Google Scholar]

| Change in Individual Material Tonnages | ||

|---|---|---|

| Display Devices | −4013 T | 36,776 |

| Computers | 2190 T | 10,475 |

| Printers and Peripherals | 159 T | 22,482 |

| Big Printers/Copiers | 140 T | 1285 |

© 2016 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lakhan, C. Calculating the Emissions Impacts of Waste Electronics Recycling in Ontario, Canada. C 2016, 2, 11. https://0-doi-org.brum.beds.ac.uk/10.3390/c2020011

Lakhan C. Calculating the Emissions Impacts of Waste Electronics Recycling in Ontario, Canada. C. 2016; 2(2):11. https://0-doi-org.brum.beds.ac.uk/10.3390/c2020011

Chicago/Turabian StyleLakhan, Calvin. 2016. "Calculating the Emissions Impacts of Waste Electronics Recycling in Ontario, Canada" C 2, no. 2: 11. https://0-doi-org.brum.beds.ac.uk/10.3390/c2020011