One-Step Densification of Carbon/Carbon Composites Impregnated with Pyrolysis Fuel Oil-Derived Mesophase Binder Pitches

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation of Mesophase Binder Pitches

2.3. Preparation of C/C Composites

2.4. Characterizations

2.4.1. Density and Porosity

2.4.2. Structural Characteristics

2.4.3. Mechanical Properties

2.4.4. Morphology

3. Results and Discussion

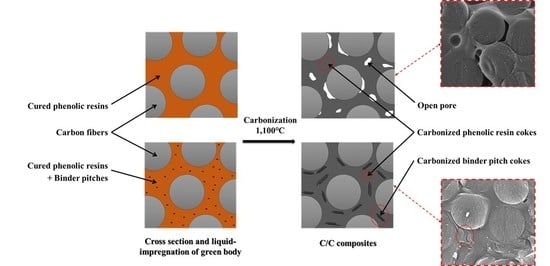

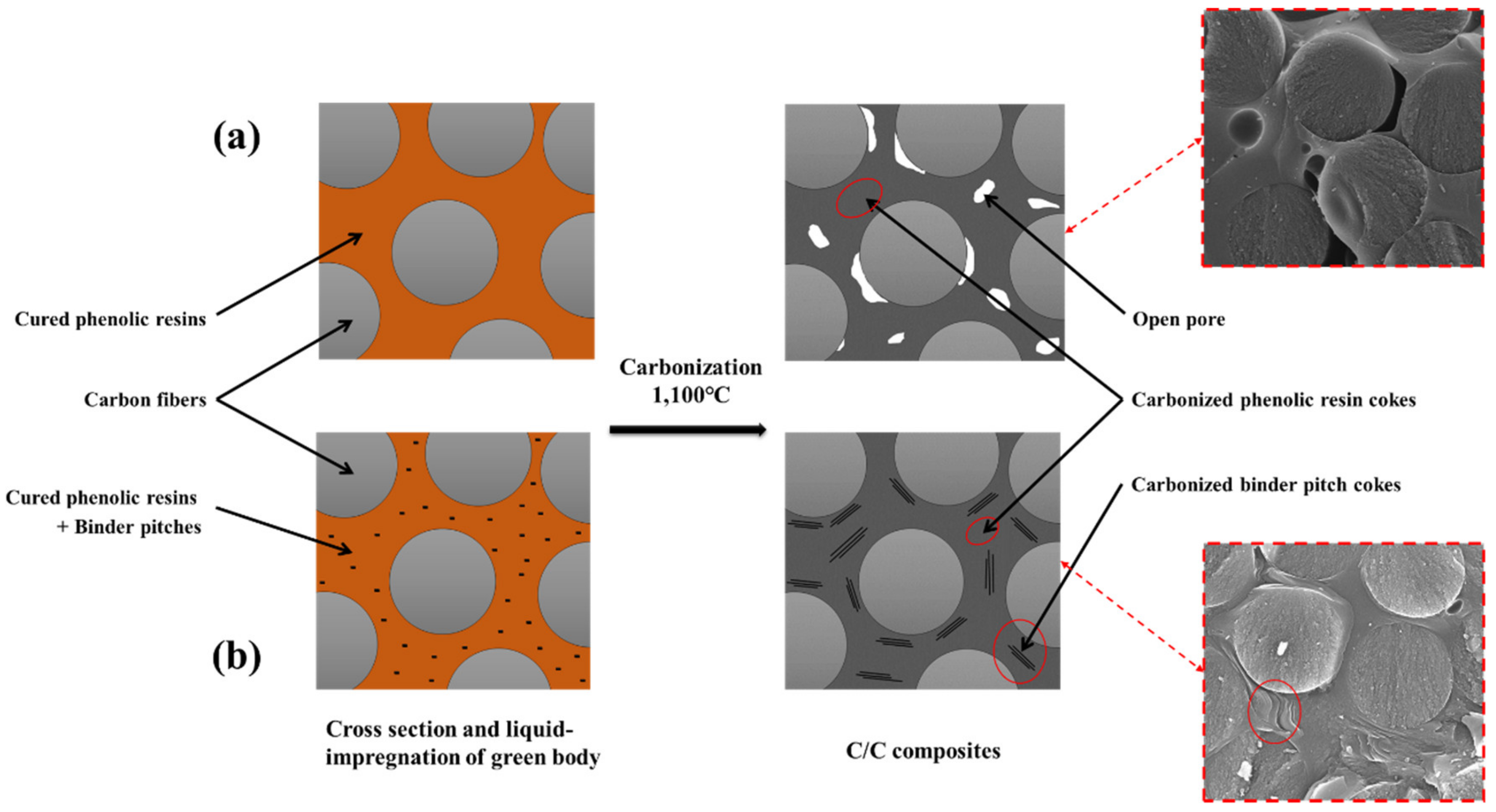

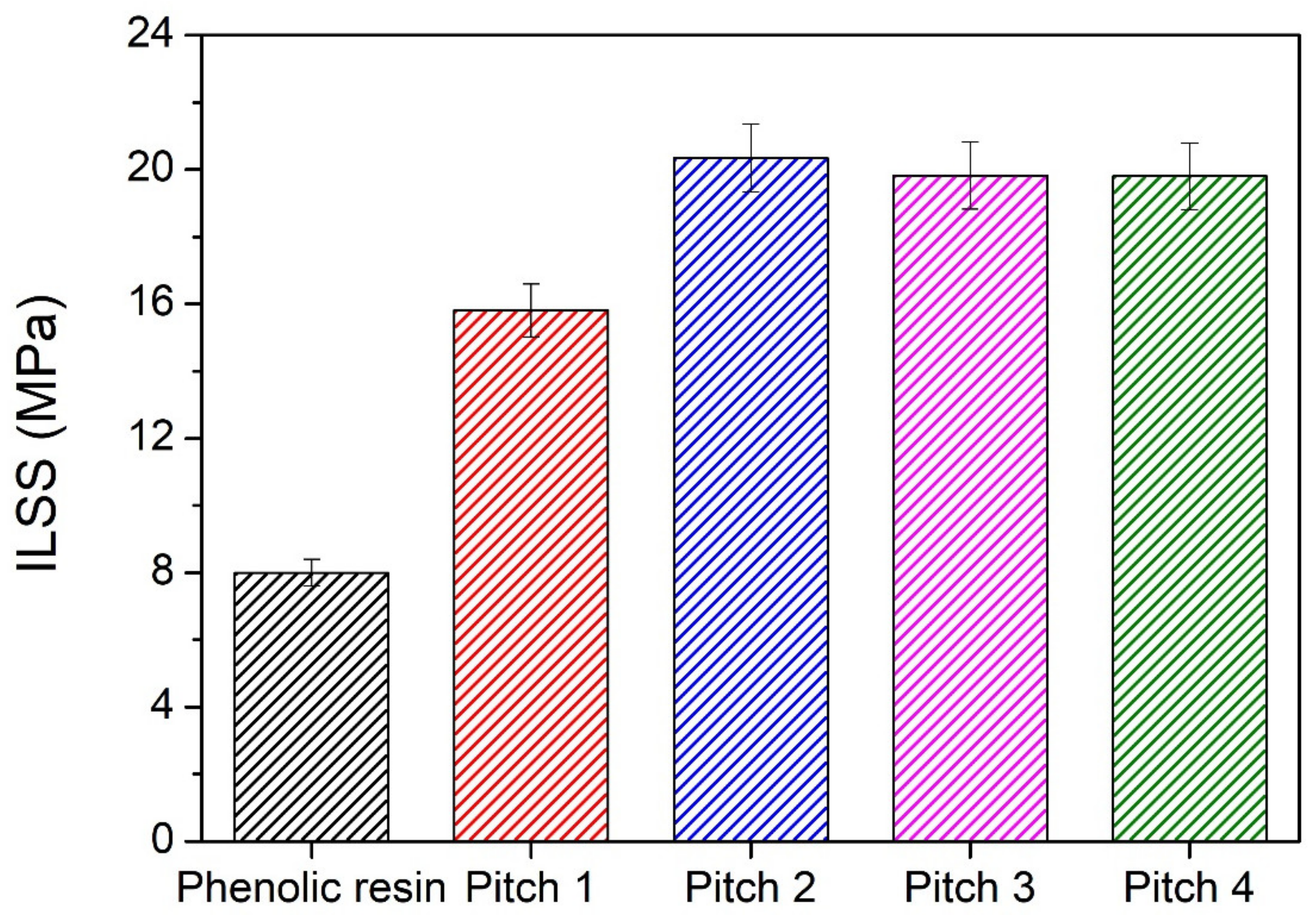

3.1. Effect of Mesophase Binder Pitches on C/C Composites

3.2. Effect of Binder Pitch Content on C/C Composites

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Park, S.J.; Seo, M.K.; Park, M.L.; Kim, H.Y. Carbon Materials; MyoungMoon Publishing Co.: Jawa Barat, Indonesia, 2015. [Google Scholar]

- Granda, M.; Patrick, J.; Walker, A.; Casal, E.; Bermejo, J.; Menendez, R. Densification of unidirectional C/C composites by melted pitch impregnation. Carbon 1998, 36, 943–952. [Google Scholar] [CrossRef]

- Xu, B.; Du, Y.; Wang, P.; Yan, L.; Sun, B.; Du, B.; Cheng, Y.; Hong, C. Microstructure, surface emissivity and ablation resistance of multilayer coating for lightweight and porous carbon–bonded carbon fiber composites. J. Alloy. Compd. 2016, 685, 799–805. [Google Scholar] [CrossRef]

- Xuefeng, L.; Jie, Z.; Kun, Q. Densification rate and mechanical properties of carbon/carbon composites with layer-designed preform. Ceram. Int. 2019, 45, 4167–4175. [Google Scholar] [CrossRef]

- Ehrburger, P.; Sanseigne, E.; Tahon, B. Formation of porosity and change in binder pitch properties during thermal treatment of green carbon materials. Carbon 1996, 34, 1493–1499. [Google Scholar] [CrossRef]

- Wu, X.; Langhof, N.; Krenkel, W.; Habath, R.; Lenz, F. Effect of pyrolysis temperature on the microstructure and capillary infiltration behavior of carbon/carbon composites. Ceram. Int. 2018, 44, 16325–16332. [Google Scholar] [CrossRef]

- Xie, W.H.; Meng, S.H.; Ding, L.; Jin, H.; Han, G.K.; Wang, L.B.; Scarpa, F.; Chi, R.Q. High velocity impact tests on high temperature carbon-carbon composites. Compos. Part B 2016, 98, 30–38. [Google Scholar] [CrossRef] [Green Version]

- Hu, Y.; Luo, R.; Zhang, Y.; Zhang, J.; Li, J. Effect of preform density on densification rate and mechanical properties of carbon/carbon composites. Mater. Sci. Eng. A 2010, 527, 797–801. [Google Scholar] [CrossRef]

- Matzinos, P.; Patrick, J.; Walker, A. The efficiency and mechanism of densification of 2-D C/C composites by coal-tar pitch impregnation. Carbon 2000, 38, 1123–1128. [Google Scholar] [CrossRef]

- Chollon, G.; Siron, O.; Takahashi, J.; Yamauchi, H.; Maeda, K.; Kosaka, K. Microstructure and mechanical properties of coal tar pitch-based 2D-C/C composites with a filler addition. Carbon 2001, 39, 2065–2075. [Google Scholar] [CrossRef]

- Lan, F.; Li, K.; Li, H.; Guo, L.; He, Y.; Zhang, L. High-temperature property of carbon/carbon composite joints bonded with ternary Ti–Si–C compound. J. Alloy. Compd. 2009, 480, 747–749. [Google Scholar] [CrossRef]

- Dimitrienko, Y.I. Modelling of carbon-carbon composites manufacturing processes. Compos. Part A 1999, 30, 221–230. [Google Scholar] [CrossRef]

- Kuo, H.; Lin, J.C.; Ju, C. Effect of carbonization rate on the properties of a PAN/phenolic-based carbon/carbon composite. Carbon 2005, 43, 229–239. [Google Scholar] [CrossRef]

- Yang, H.; Luo, R. Effect of coal tar pitch modified by sulfur as a binder on the mechanical and tribological properties of bronze-impregnated carbon-matrix composites. Mater. Sci. Eng. A 2011, 528, 2929–2935. [Google Scholar] [CrossRef]

- Yang, J.-Y.; Park, S.-H.; Park, S.-J.; Seo, M.-K. Preparation and Characteristic of Carbon/Carbon Composites with Coal-tar and Petroleum Binder Pitches. Appl. Chem. Eng. 2015, 26, 406–412. [Google Scholar] [CrossRef]

- Yang, J.Y.; Kim, B.S.; Park, S.J.; Rhee, K.Y.; Seo, M.K. Preparation and characterization of mesophase formation of pyrolysis fuel oil-derived binder pitches for carbon composites. Compos. Part B 2019, 165, 467–472. [Google Scholar] [CrossRef]

- Park, S.-J.; Seo, M.-K.; Lee, D.-R. Studies on the mechanical and mechanical interfacial properties of carbon–carbon composites impregnated with an oxidation inhibitor. Carbon 2003, 41, 2991–3002. [Google Scholar] [CrossRef]

- Park, S.J.; Cho, M.S.; Lee, J.R. Influence of oxidation inhibitor on carbon-carbon composites: 1. Degree of graphitization and mechanical behavior. Polymer (Korea) 1998, 22, 972–978. [Google Scholar]

- Kowbel, W.; Chellapa, V.; Withers, J. Properties of C/C composites produced in one low cost manufacturing step. Carbon 1996, 34, 819–821. [Google Scholar] [CrossRef]

- Park, S.J.; Cho, M.S.; Lee, J.R. Influence of oxidation inhibitor on carbon-carbon composites: 4. Gibbs surface free energy and ILSS improvement. Polymer (Korea) 1999, 23, 717–723. [Google Scholar]

- Park, S.J.; Cho, M.S.; Lee, J.R. Influence of oxidation inhibitor on carbon-carbon composites: 3. Effect of molybdenum disilicide on thermal stability of the composites. Polymer (Korea) 1999, 23, 305–311. [Google Scholar]

- Kanno, K.; Koike, N.; Korai, Y.; Mochida, I. Densification of carbons prepared from mesophase pitch and phenolic resin blend. Carbon 1998, 36, 869–874. [Google Scholar] [CrossRef]

- Ko, T.H.; Kuo, W.S.; Chang, Y.H. Influence of carbon-fiber felts on the development of carbon-carbon composites. Compos. Part A 2003, 34, 393–401. [Google Scholar] [CrossRef]

- Braga, C.P.; Dutra, C.H.M.D.C.; De Castro, L.D.; De Andrade, C.T. Influence of heat and pressure treatment on the rheological behavior of petroleum pitches. Fuel 2009, 88, 853–860. [Google Scholar] [CrossRef]

- Ungár, T.; Gubicza, J.; Ribárik, G.; Pantea, C.; Zerda, T. Microstructure of carbon blacks determined by X-ray diffraction profile analysis. Carbon 2002, 40, 929–937. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.B.; Kim, C.; Yang, K.S.; Kook, Y.H. Chemical modification of coal tar pitch. J. Korean Fiber Soc. 1995, 32, 403–411. [Google Scholar]

- Li, X.; Yu, S.; Li, Y.; Wu, Q.; Li, Z.; Xiao, T.; Liu, L.; Guo, X. Effect of pre-fatigue on bending behavior of 2.5D C/C composites. Mater. Sci. Eng. A 2017, 682, 290–295. [Google Scholar] [CrossRef]

- Xue, L.-Z.; Li, K.-Z.; Jia, Y.; Zhang, S.-Y.; Cheng, J.; Guo, J. Flexural fatigue behavior of 2D cross-ply carbon/carbon composites at room temperature. Mater. Sci. Eng. A 2015, 634, 209–214. [Google Scholar] [CrossRef]

- Fathollahi, B.; Chau, P.C.; White, L. Injection and stabilization of mesophase pitch in the fabrication of carbon-carbon composites. Part Ι. Injection process. Carbon 2005, 43, 125–133. [Google Scholar] [CrossRef]

- Casal, E.; Granda, M.; Bermejo, J.; Bonhomme, J.; Menéndez, R. Influence of porosity on the apparent interlaminar shear strength of pitch-based unidirectional C–C composites. Carbon 2001, 39, 73–82. [Google Scholar] [CrossRef]

- Kim, J.I.; Oh, I.S.; Joo, H.J. Mechanical properties & ablation mechanism of SiC coated carbon/carbon composites by pack-cementation method. Carbon Sci. 2001, 2, 27–36. [Google Scholar]

- Park, S.-J.; Cho, M.-S.; Lee, J.-R. Studies on the Surface Free Energy of Carbon–Carbon Composites: Effect of Filler Addition on the ILSS of Composites. J. Colloid Interface Sci. 2000, 226, 60–64. [Google Scholar] [CrossRef] [PubMed]

- Mora, E.; Santamarıa, R.; Blanco, C.; Granda, M.; Menéndez, R. Mesophase development in petroleum and coal-tar pitches and their blends. J. Anal. Appl. Pyrolysis 2003, 68, 409–424. [Google Scholar] [CrossRef]

- Li, K.-Z.; Jing, X.; Qian-Gang, F.; He-Jun, L.; Ling-Jun, G. Effects of porous C/C density on the densification behavior and ablation property of C/C–ZrC–SiC composites. Carbon 2013, 57, 161–168. [Google Scholar] [CrossRef]

- Matzinos, P.D.; Patick, J.W.; Walker, A. Coal-tar pitch as a matrix precursor for 2-D C/C composites. Carbon 2017, 34, 639–644. [Google Scholar] [CrossRef]

- Chung, J.K.; Lim, Y.S. Preparation and characterization of mesophase pitches as matrix precursor of carbon fiber reinforced carbon composite. J. Kor. Ceram. Soc. 1996, 33, 1387–1393. [Google Scholar]

- An, D.H.; Kim, K.H.; Kim, J.G.; Lee, Y.S. Structural analysis of volatile matters and heavy oil fractions from pyrolysis fuel oil by the heat treatment temperature. Appl. Chem. Eng. 2019, 30, 297–302. [Google Scholar]

- Seo, S.W.; Kim, J.H.; Lee, Y.S.; Im, J.S. Identification of synthesized pitch derived from pyrolyzed fuel oil (PFO) by pressure. Appl. Chem. Eng. 2018, 29, 652–656. [Google Scholar]

- Kil, H.-S.; Oh, K.; Kim, Y.-J.; Ko, S.; Jeon, Y.P.; Joh, H.-I.; Kim, Y.-K.; Lee, S. Structural evolution of pitch fibers during low temperature carbonization. J. Anal. Appl. Pyrolysis 2018, 136, 153–159. [Google Scholar] [CrossRef]

- March, H.; Martınez-Escandell, M.; Rodr´ıguez-Reinoso, F. Semicokes from pitch pyrolysis: Mechanisms and kinetics. Carbon 1999, 37, 363–390. [Google Scholar]

- Lee, J.S.; Kim, Y.K.; Hwang, J.Y.; Joh, H.I.; Park, C.R.; Lee, S.H. Carbon nanosheets by the graphenization of ungrahpitizable isotropic pitch molecules. Carbon 2017, 121, 479–489. [Google Scholar] [CrossRef]

- Chioujones, K.; Ho, W.; Fathollahi, B.; Chau, P.; Wapner, P.; Hoffman, W. Microstructural analysis of in situ mesophase transformation in the fabrication of carbon–carbon composites. Carbon 2006, 44, 284–292. [Google Scholar] [CrossRef]

- Fitzer, E.; Manocha, L.M. Carbon Reinforcements and Carbon/Carbon Composites; Springer Science and Business Media LLC: Berlin, Germany, 1998; pp. 97–187. [Google Scholar]

- Wang, A.; Chung, D. First report of fumed alumina incorporation in carbon–carbon composite and the consequent improvement of the oxidation resistance and mechanical properties. Carbon 2016, 101, 281–289. [Google Scholar] [CrossRef]

| Product | Number of Filaments | Tensile Strength (MPa) | Tensile Modulus (GPa) | Density (g/cm3) | Elongation (%) | Diameter (μm) |

|---|---|---|---|---|---|---|

| Carbon fibers | 12,000 | 4410 | 245 | 1.78 | 1.8 | 7 |

| Samples | 1st Heating Rate (°C/min) | 1st Heat Treatment (°C) | Holding Time (h) | 2nd Heating Rate (°C/min) | 2nd Heat Treatment (°C) | Holding Time (h) | Amount of Gas (L/min) |

|---|---|---|---|---|---|---|---|

| Pitch 1 | 2 | 200 | 0.5 | 2 | 360 | 4 | N2, 1 |

| Pitch 2 | 2 | 360 | 4 | 2 | 380 | 3 | |

| Pitch 3 | 2 | 360 | 4 | 2 | 400 | 3 | |

| Pitch 4 | 2 | 360 | 4 | 2 | 420 | 1 |

| Samples | SP (°C) | QI (%) | Carbon Yield (%) | Elemental Analysis (%) | C/H Ratio | |||

|---|---|---|---|---|---|---|---|---|

| C | H | N | S | |||||

| Pitch 1 | 135 | 0 | 35 | 93.73 | 6.00 | 0.11 | 0.75 | 1.30 |

| Pitch 2 | 168 | 10.74 | 50 | 94.30 | 5.41 | 0.09 | 0.27 | 1.45 |

| Pitch 3 | 227 | 35.93 | 67 | 94.78 | 4.75 | 0.11 | 0.28 | 1.66 |

| Pitch 4 | 250 | 50.19 | 68 | 94.71 | 4.72 | 0.10 | 0.28 | 1.67 |

| Samples | d002 (Å) | Lc (Å) |

|---|---|---|

| Pitch 1 | 3.58 | 13.66 |

| Pitch 2 | 3.57 | 14.41 |

| Pitch 3 | 3.56 | 16.26 |

| Pitch 4 | 3.56 | 16.49 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.-Y.; Park, J.-H.; Kuk, Y.-S.; Kim, B.-S.; Seo, M.-K. One-Step Densification of Carbon/Carbon Composites Impregnated with Pyrolysis Fuel Oil-Derived Mesophase Binder Pitches. C 2020, 6, 5. https://0-doi-org.brum.beds.ac.uk/10.3390/c6010005

Yang J-Y, Park J-H, Kuk Y-S, Kim B-S, Seo M-K. One-Step Densification of Carbon/Carbon Composites Impregnated with Pyrolysis Fuel Oil-Derived Mesophase Binder Pitches. C. 2020; 6(1):5. https://0-doi-org.brum.beds.ac.uk/10.3390/c6010005

Chicago/Turabian StyleYang, Jae-Yeon, Jong-Hyun Park, Yun-Su Kuk, Byoung-Suhk Kim, and Min-Kang Seo. 2020. "One-Step Densification of Carbon/Carbon Composites Impregnated with Pyrolysis Fuel Oil-Derived Mesophase Binder Pitches" C 6, no. 1: 5. https://0-doi-org.brum.beds.ac.uk/10.3390/c6010005