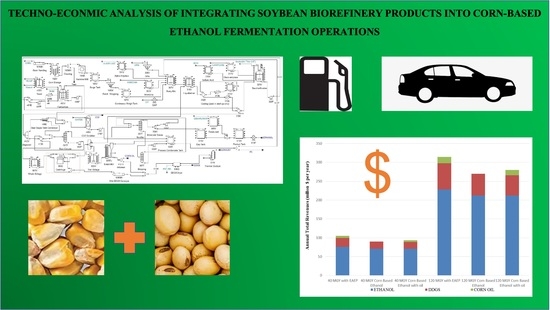

Techno-Economic Analysis of Integrating Soybean Biorefinery Products into Corn-Based Ethanol Fermentation Operations

Abstract

:1. Introduction

2. Materials and Methods

2.1. Computer Model

2.2. Simulation Scenarios

- Integrated EAEP with corn-based ethanol process producing 40 million gallons ethanol per year with distillers corn oil removal vs. no oil separation.

- Integrated EAEP with corn-based ethanol process producing 120 million gallons ethanol per year with distillers corn oil removal vs. no oil separation.

3. Results

3.1. Capital Costs

3.2. Annual Operating Costs

3.2.1. Facility and Labor Costs

3.2.2. Material Costs

3.2.3. Utility Costs

3.3. Annual Revenues

3.3.1. Ethanol

3.3.2. Distillers Dried Grains with Solubles (DDGS)

3.3.3. Distillers Corn Oil (DCO)

3.4. Gross Operating Margins and Payback Time

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alinia, R.; Zabihi, S.; Esmaeilzadeh, F.; Kalajahi, J.F. Pretreatment of wheat straw by supercritical CO2 and its enzymatic hydrolysis for sugar production. Biosyst. Eng. 2010, 107, 61–66. [Google Scholar] [CrossRef]

- Lamsal, B.P.; Murphy, P.A.; Johnson, L.A. Flaking and extrusion as mechanical treatments for enzyme-assisted aqueous extraction of oil from soybeans. J. Am. Oil Chem. Soc. 2006, 83, 973–979. [Google Scholar] [CrossRef]

- Chabrand, R.M.; Glatz, C.E. Destabilization of the emulsion formed during the enzyme-assisted aqueous extraction of oil from soybean flour. Enzyme Microb. Technol. 2009, 45, 28–35. [Google Scholar] [CrossRef]

- Yao, L.; Wang, T.; Wang, H. Effect of soy skim from soybean aqueous processing on the performance of corn ethanol fermentation. Bioresour. Technol. 2011, 120, 9199–9205. [Google Scholar] [CrossRef] [PubMed]

- Yao, L.; Lee, S.L.; Wang, T.; de Moura, J.M.; Johnson, L.A. Effects of fermentation substrate conditions on corn-soy co-fermentation for fuel ethanol production. Bioresour. Technol. 2012, 120, 140–148. [Google Scholar] [CrossRef] [PubMed]

- Sekhon, J.K.; Jung, S.; Wang, T.; Rosentrater, K.A.; Johnson, L.A. Effect of co-products of enzyme-assisted aqueous extraction of soybeans on ethanol production in dry-grind corn fermentation. Bioresour. Technol. 2015, 192, 451–460. [Google Scholar] [CrossRef] [PubMed]

- Ngo, H.L.; Yee, W.C.; McAloon, A.J.; Haas, M.J. Techno-economic analysis of an improved process for producing saturated branched-chain fatty acids. J. Agric. Sci. 2014, 6, 158. [Google Scholar] [CrossRef] [Green Version]

- McAloon, A.; Yee, W. Ethanol Plant Model; USDA, ARS: Wyndmoor, PA, USA, 2011. [Google Scholar]

- Wood, C.; Rosentrater, K.A.; Muthukumarappan, K. Techno-economic modeling of a corn based ethanol plant in 2011/2012. Ind. Crops Prod. 2014, 56, 145–155. [Google Scholar] [CrossRef] [Green Version]

- Cheng, M.H.; Rosentrater, K.A.; Sekhon, J.; Wang, T.; Jung, S.; Johnson, L.A. Economic feasibility of soybean oil production by enzyme-assisted aqueous extraction processing. Food Bioprocess Technol. 2019, 12, 539–550. [Google Scholar] [CrossRef]

- USDA (United States Department of Agriculture). Fuel Ethanol, Corn and Gasoline Prices, Marketing Year. Available online: http://marketnews.usda.gov/portal/lg (accessed on 21 May 2021).

- Alibaba. Alibaba.com. Retrieved from Untreated Insoluble Fiber. 2016. Available online: http://www.alibaba.com/showroom/untreatedinsolublefiber.html (accessed on 21 May 2021).

- EIA (U.S. Energy Information Administration). U.S. Natural Gas Wellhead Price. 2016. Available online: http://www.eia.gov/dnav/ng/hist/n9190us3a.htm (accessed on 21 May 2021).

- EIA (U.S. Energy Information Administration). Average Retail Price of Electricity to Ultimate Customers. 2016. Available online: http://www.eia.gov/electricity/data.cfm#traderel (accessed on 21 May 2021).

- Damodaran, A. Investment Valuation: Tools and Techniques for Determining the Value of Any Asset; John Wiley & Sons: Hoboken, NJ, USA, 2012; Volume 666. [Google Scholar]

- Index, C.P. Bureau of Labor Statistics, U.S. Department of Labor. Washington, DC. 2012. Available online: http://data.bls.gov/cgi-bin/surveymost/ (accessed on 21 May 2021).

- Jacobsen. (2016, July). Distillers Corn Oil. Retrieved from The Jacobsen Research Database. Available online: https://thejacobsen.com (accessed on 21 May 2021).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rosentrater, K.A.; Zhang, W. Techno-Economic Analysis of Integrating Soybean Biorefinery Products into Corn-Based Ethanol Fermentation Operations. Fermentation 2021, 7, 82. https://0-doi-org.brum.beds.ac.uk/10.3390/fermentation7020082

Rosentrater KA, Zhang W. Techno-Economic Analysis of Integrating Soybean Biorefinery Products into Corn-Based Ethanol Fermentation Operations. Fermentation. 2021; 7(2):82. https://0-doi-org.brum.beds.ac.uk/10.3390/fermentation7020082

Chicago/Turabian StyleRosentrater, Kurt A., and Weitao Zhang. 2021. "Techno-Economic Analysis of Integrating Soybean Biorefinery Products into Corn-Based Ethanol Fermentation Operations" Fermentation 7, no. 2: 82. https://0-doi-org.brum.beds.ac.uk/10.3390/fermentation7020082