Thermophysical Characterization of a Layered P2 Type Structure Na0.53MnO2 Cathode Material for Sodium Ion Batteries

Abstract

:1. Introduction

2. Results and Discussion

2.1. Elemental Analysis, Morphology, and Particle Size Distribution

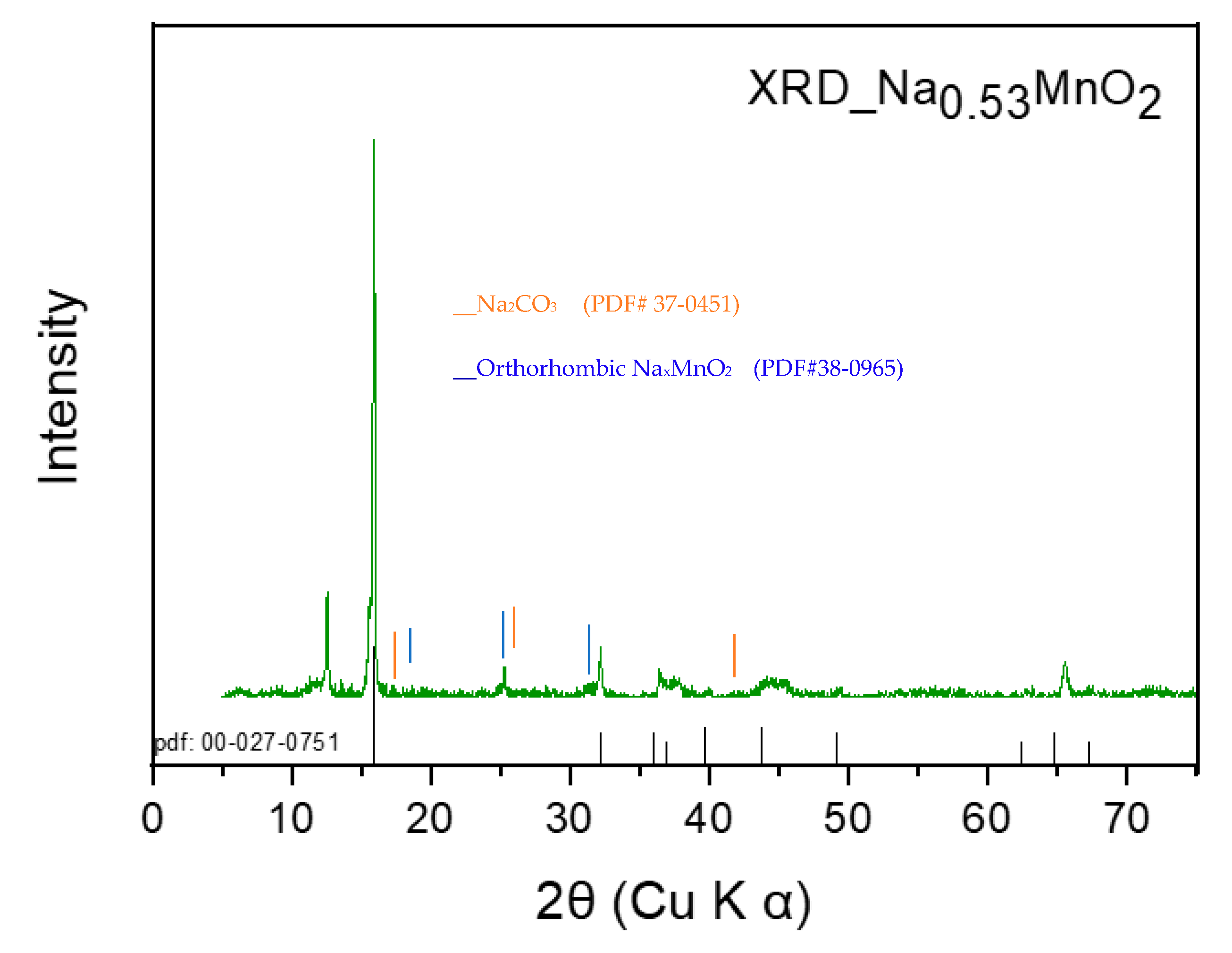

2.2. X-Ray Diffraction (XRD)

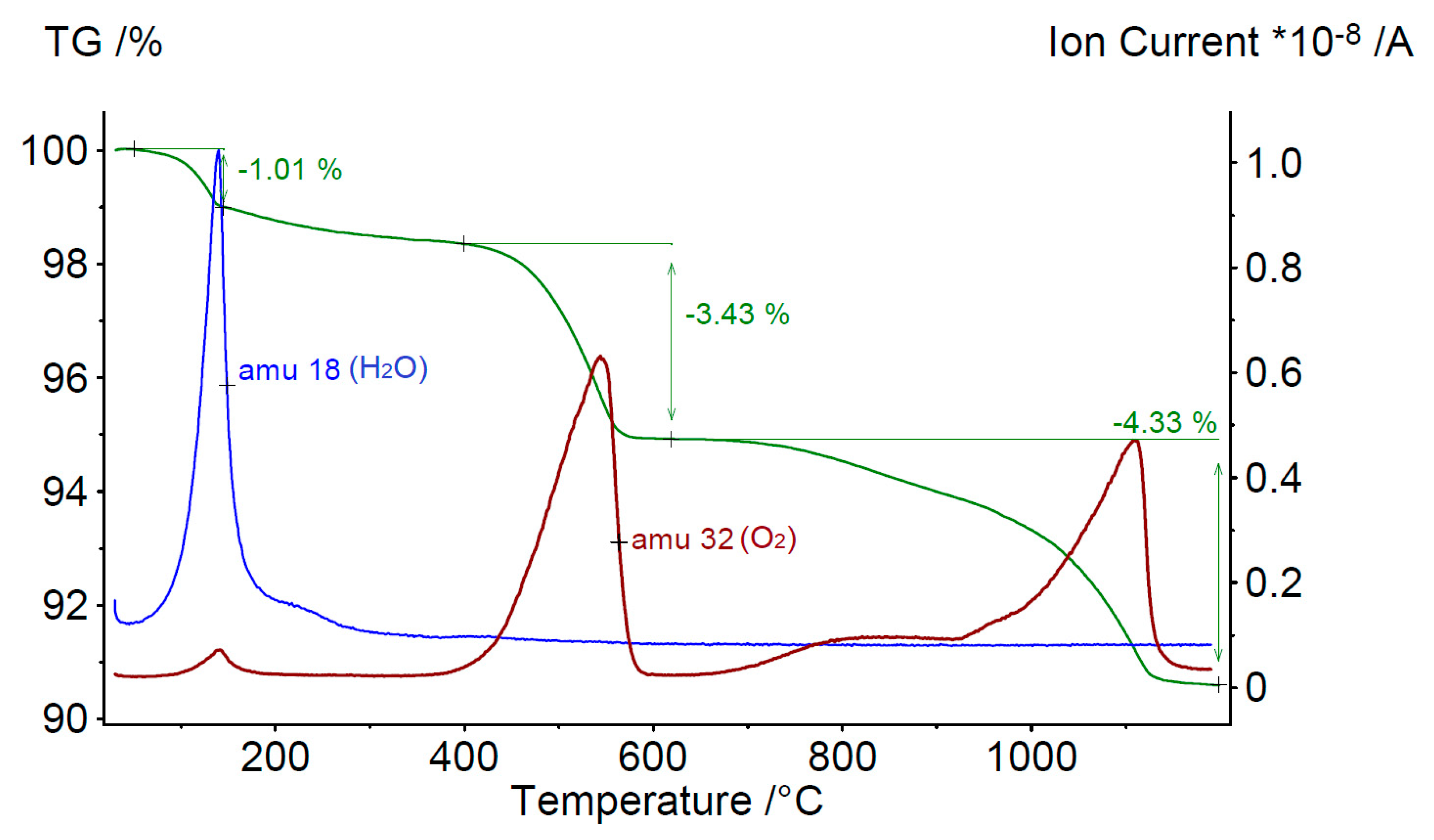

2.3. Thermal Stability and Evolved Gas Analysis

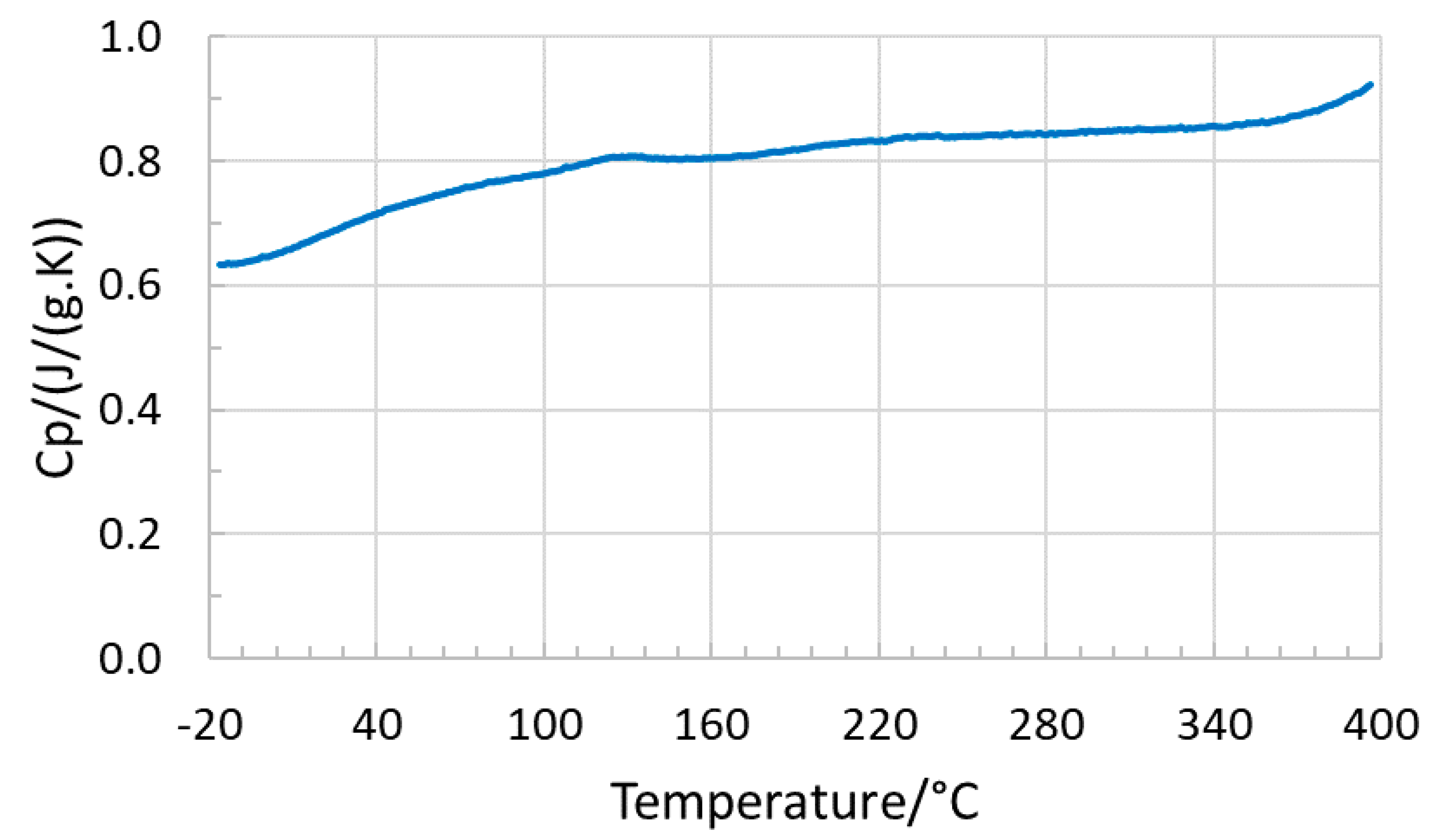

2.4. Specific Heat Capacity (Cp)

2.5. Dimensional Change (Dilatometry)

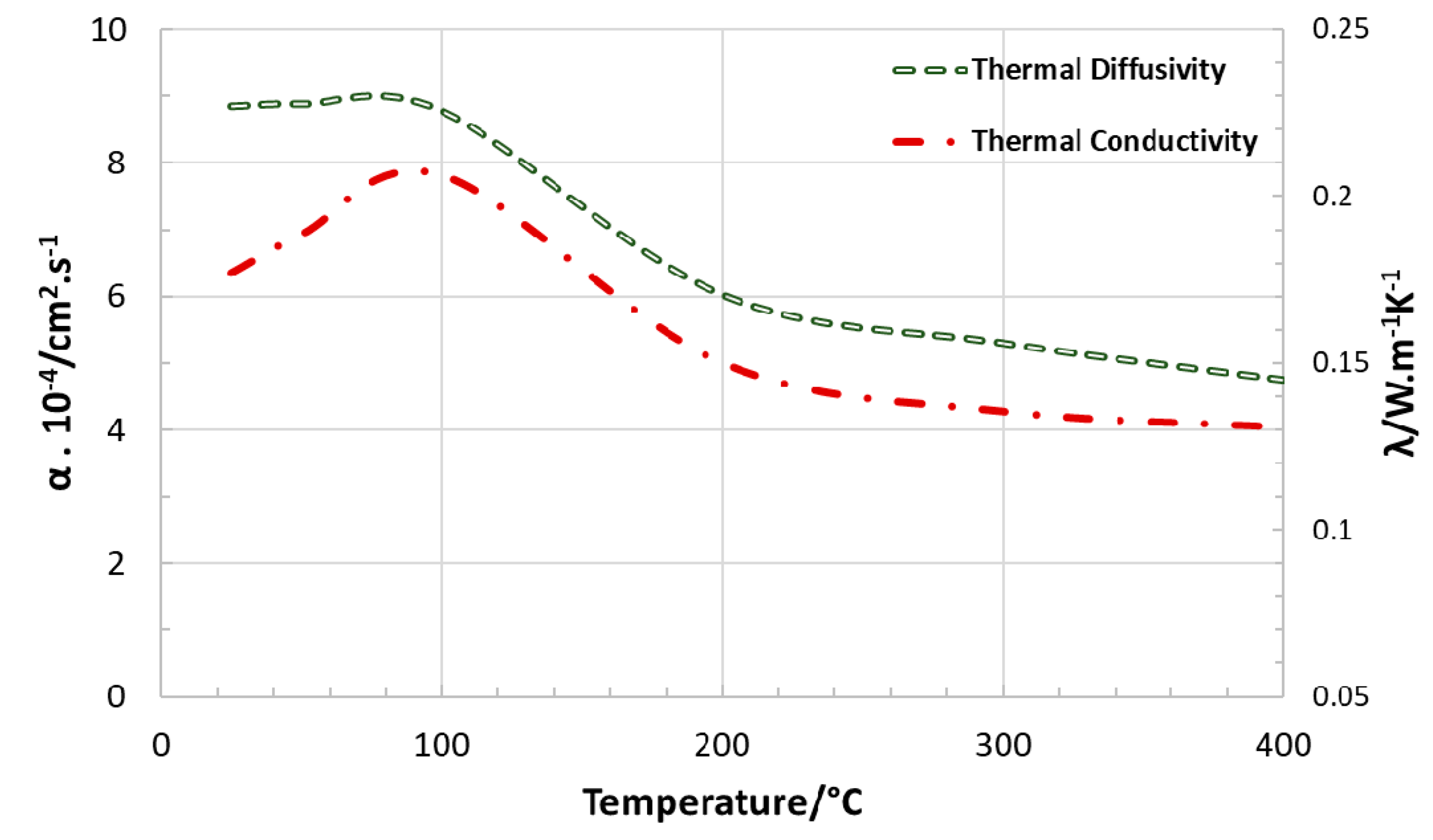

2.6. Thermal Diffusivity and Conductivity

3. Materials and Methods

4. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Berthelot, R.; Carlier, D.; Delmas, C. Electrochemical investigation of the P2–NaxCoO2 phase diagram. Nat. Mater. 2011, 10, 74–80. [Google Scholar] [CrossRef] [PubMed]

- Yoshida, H.; Yabuuchi, N.; Komaba, S. NaFe0.5Co0.5O2 as high energy and power positive electrode for Na-ion batteries. Electrochemistry 2012, 80, 716–719. [Google Scholar] [CrossRef]

- Ma, X.; Chen, H.; Ceder, G. Electrochemical Properties of Monoclinic NaMnO2. J. Electrochem. Soc. 2011, 158, A1307–A1312. [Google Scholar] [CrossRef]

- Li, Z.-Y.; Gao, R.; Zhang, J.; Zhang, X.; Hu, Z.; Liu, X. New insights into designing high-rate performance cathode materials for sodium ion batteries by enlarging the slab-spacing of the Na-ion diffusion layer. J. Mater. Chem. A 2016, 4, 3453–3461. [Google Scholar] [CrossRef]

- Li, F.; Zhou, Z. Micro/nanostructured materials for sodium ion batteries and capacitors. Small 2018, 14, 1702961. [Google Scholar] [CrossRef]

- Terayama, K.; Ikeda, M. Study on Thermal Decomposition of MnO2 and Mn2O3 by Thermal Analysis. Trans. Jpn. Inst. Met. 1983, 24, 754–758. [Google Scholar] [CrossRef] [Green Version]

- Braconnier, J.-J.; Delmas, C.; Fouassier, C.; Hagenmuller, P. Comportement electrochimique des phases NaxCoO2. Mater. Res. Bull. 1980, 15, 1797. [Google Scholar] [CrossRef]

- Gotcu, P.; Pfleging, W.; Smyrek, P.; Seifert, H.J. Thermal behaviour of LixMeO2 (Me = Co or Ni + Mn + Co) cathode materials. Phys. Chem. Chem. Phys. 2017, 19, 11920–11930. [Google Scholar] [CrossRef]

- Gotcu, P.; Seifert, H.J. Thermophysical properties of LiCoO2–LiMn2O4 blended electrode materials for Li-ion batteries. Phys. Chem. Chem. Phys. 2016, 18, 10550–10562. [Google Scholar] [CrossRef]

- Williford, R.E.; Viswanathan, V.V.; Zhang, J.G. Effects of entropy changes in anodes and cathodes on the thermal behavior of lithium ion batteries. J. Power Sources 2009, 189, 101–107. [Google Scholar] [CrossRef]

- Chen, S.C.; Wan, C.C.; Wang, Y.Y. Thermal analysis of lithium-ion batteries. J. Power Sources 2005, 140, 111–124. [Google Scholar] [CrossRef]

- Mathewson, S. Experimental Measurements of LiFePO4 Battery Thermal Characteristics. Master’s Thesis, University of Waterloo, Waterloo, ON, Canada, 2014. [Google Scholar]

- Hautier, G.; Jain, A.; Ong, S.P.; Kang, B.; Moore, C.; Doe, R.; Ceder, G. Phosphates as Lithium-Ion Battery Cathodes: An Evaluation Based on High-Throughput ab Initio Calculations. Chem. Mater. 2011, 12, 3495–3508. [Google Scholar] [CrossRef]

- Lim, S.Y.; Kim, H.; Shakoor, R.A.; Jung, Y.; Choi, J.W. Electrochemical and thermal properties of NASICON structured Na3V2(PO4)3 as a sodium rechargeable battery cathode: A combined experimental and theoretical study. J. Electrochem. Soc. 2012, 159, A1393–A1397. [Google Scholar] [CrossRef]

- Jin, T.; Li, H.; Zhu, K.; Wang, P.-F.; Liu, P.; Jiao, L. Polyanion-type cathode materials for sodium-ion batteries. Chem. Soc. Rev. 2020, 49, 2342–2377. [Google Scholar] [CrossRef] [PubMed]

- Zang, H. Polyanionic Cathode Materials for Sodium-Ion Batteries. Ph.D. Thesis, Karlsruhe Institute of Technology (KIT), Karlsruhe, Germany, 2018. Available online: https://publikationen.bibliothek.kit.edu/1000091096/23082781 (accessed on 1 March 2018).

- Zhao, J.; Zhao, L.; Dimov, N.; Okada, S.; Nishida, T. Electrochemical and Thermal Properties of α-NaFeO2 Cathode for Na-Ion Batteries. J. Electrochem. Soc. 2013, 160, A3077–A3081. [Google Scholar] [CrossRef]

- Kobayashi, W.; Yanagita, A.; Akaba, T.; Shimono, T.; Tanabe, D.; Moritomo, Y. Thermal Expansion in Layered NaxMO2. Sci. Rep. 2018, 8, 3988–3997. [Google Scholar] [CrossRef] [Green Version]

- Bak, S.; Zhou, Y.; Hu, E.; Yu, X.; Yang, X. Thermal Stability Studies in Charged Layered Sodium Transition Metal Oxide Cathode Materials for Na-Ion Batteries. ECS Meet. Abstr. A04-Battery Saf. 2015, MA2015-02, 338. [Google Scholar]

- Sun, Y.; Guo, S.; Zhou, H. Adverse effects of interlayer-gliding in layered transition-metal oxides on electrochemical sodium-ion storage. Energy Environ. Sci. 2019, 12, 825–840. [Google Scholar] [CrossRef]

- Yabuuchi, N.; Ikeuchi, I.; Kubota, K.; Komaba, S. Thermal Stability of NaxCrO2 for Rechargeable Sodium Batteries; Studies by High-Temperature Synchrotron X-ray Diffraction. ACS Appl. Mater. Interfaces 2016, 47, 32292–32299. [Google Scholar] [CrossRef] [PubMed]

- Hwang, S.; Lee, Y.; Jo, E.; Chung, Y.; Choi, W.; Kim, S.M.; Chang, W. Investigation of Thermal Stability of P2-NaxCoO2 Cathode Materials for Sodium Ion Batteries Using Real-Time Electron Microscopy. ACS Appl. Mater. Interfaces 2017, 9, 18883–18888. [Google Scholar] [CrossRef]

- Yang, C.; Xin, S.; Mai, L.; You, Y. Materials Design for High-Safety Sodium-Ion Battery. Adv. Energy Mater. 2021, 11, 2000974. [Google Scholar] [CrossRef]

- Vaalma, C.; Buchholz, D.; Weil, M.; Passerini, S. A cost and resource analysis of sodium-ion batteries. Nat. Rev. Mater. 2018, 3, 18013. [Google Scholar] [CrossRef]

- Peng, P.; Sun, Y.; Jiang, F. Thermal analyses of LiCoO2 lithium-ion battery during oven tests. Int. J. Heat Mass Transf. 2014, 50, 1405–1416. [Google Scholar] [CrossRef]

- Balandin, A. Thermal properties of graphene and nanostructured carbon materials. Nat. Mater. 2011, 10, 569–581. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shahil, K.; Balandin, A. Thermal properties of graphene and multilayer graphene: Applications in thermal interface materials. Solid State Commun. 2012, 152, 1331–1340. [Google Scholar] [CrossRef]

- Mohsin, I.U.; Lager, D.; Gierl, C.; Hohenauer, W.; Danninger, H. Thermo-kinetics study of MIM thermal de-binding using TGA coupled with FTIR and mass spectrometry. Thermochim. Acta 2010, 503, 40–45. [Google Scholar] [CrossRef]

- Della Gatta, G.; Richardson, M.J.; Sarge, S.M.; Stolen, S. Standards, Calibration, and Guidelines in Microcalorimetry Part 2. Calibration Standards For Differential Scanning IUPAC Technical Report. Pure Appl. Chem. 2006, 78, 1455–1476. [Google Scholar] [CrossRef] [Green Version]

- Dusza, L. Heat transport models for determining the thermal diffusivity of substances with the transient laser flash method. High Temp. High Press. 1995, 27, 467–473. [Google Scholar] [CrossRef]

- Blumm, J.; Opferman, J. Improvement of the mathematical modeling of flash measurements. High Temp. High Press. 2002, 34, 515–521. [Google Scholar] [CrossRef]

- Mohsin, I.U.; Lager, D.; Hohenauer, W.; Gierl, C.; Danninger, H. Finite element sintering analysis of metal injection molded copper brown body using thermo-physical data and kinetics. Comput. Mater. Sci. 2012, 53, 6–11. [Google Scholar] [CrossRef]

| Element | Cathode Material (Sodium Manganese Oxide) | |

|---|---|---|

| Mean Value (wt %) | SD | |

| C | 0.08 | 0.00 |

| O | 33.5 | 0.2 |

| Na | 12.2 | 0.1 |

| Mn | 52.2 | 0.2 |

| Temperature °C | Specific Heat Capacity (Cp) (J/(g.K)) | Thermal Diffusivity α × 10−4 cm2 s−1 | Thermal Conductivity W/mK |

|---|---|---|---|

| 25 | 0.68934 | 8.85 | 0.177079 |

| 50 | 0.73144 | 8.89 | 0.188572 |

| 100 | 0.78022 | 8.79 | 0.206430 |

| 200 | 0.82630 | 6.03 | 0.150026 |

| 300 | 0.84821 | 5.30 | 0.135520 |

| 400 | 0.92262 | 4.75 | 0.130734 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohsin, I.U.; Ziebert, C.; Rohde, M.; Seifert, H.J. Thermophysical Characterization of a Layered P2 Type Structure Na0.53MnO2 Cathode Material for Sodium Ion Batteries. Batteries 2021, 7, 16. https://0-doi-org.brum.beds.ac.uk/10.3390/batteries7010016

Mohsin IU, Ziebert C, Rohde M, Seifert HJ. Thermophysical Characterization of a Layered P2 Type Structure Na0.53MnO2 Cathode Material for Sodium Ion Batteries. Batteries. 2021; 7(1):16. https://0-doi-org.brum.beds.ac.uk/10.3390/batteries7010016

Chicago/Turabian StyleMohsin, Ijaz Ul, Carlos Ziebert, Magnus Rohde, and Hans Jürgen Seifert. 2021. "Thermophysical Characterization of a Layered P2 Type Structure Na0.53MnO2 Cathode Material for Sodium Ion Batteries" Batteries 7, no. 1: 16. https://0-doi-org.brum.beds.ac.uk/10.3390/batteries7010016