How COVID-19 Could Change the Economics of the Plastic Recycling Sector

Abstract

:1. Introduction

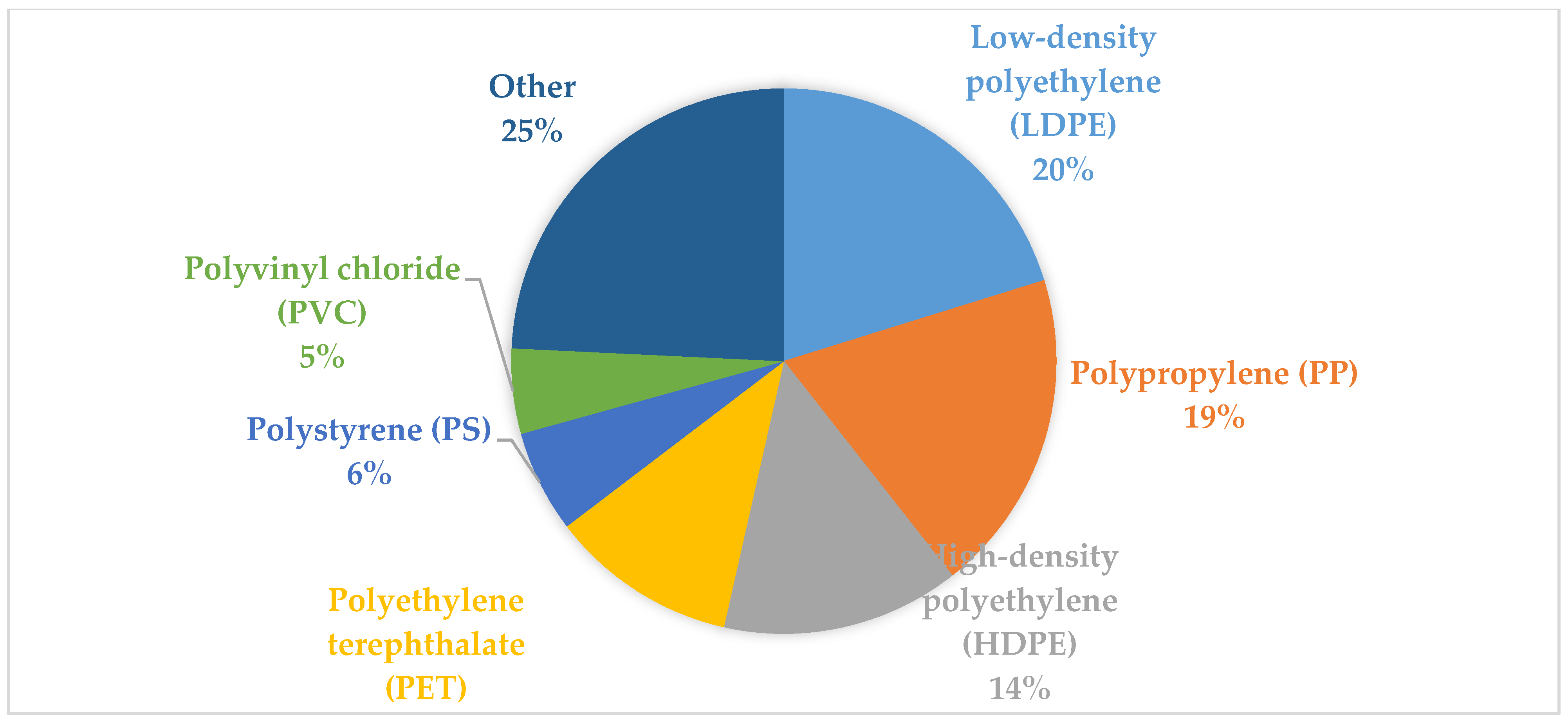

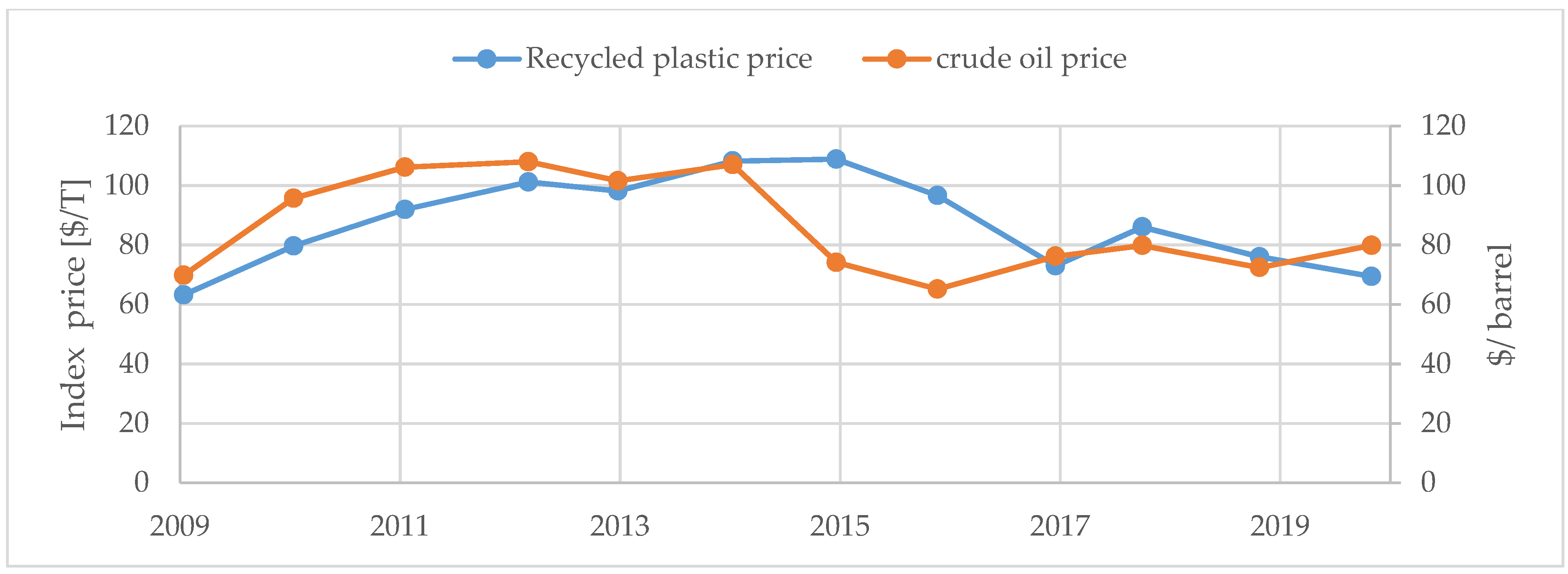

2. COVID-19-Induced Oil Shock and Its Impact on Plastic Recycling Sector

3. Methods

3.1. Type of Data and Sources

3.2. Description of Variables

3.3. Unit Root Test

3.4. The Johansen Approach Cointegration Test

3.5. Results and Discussion

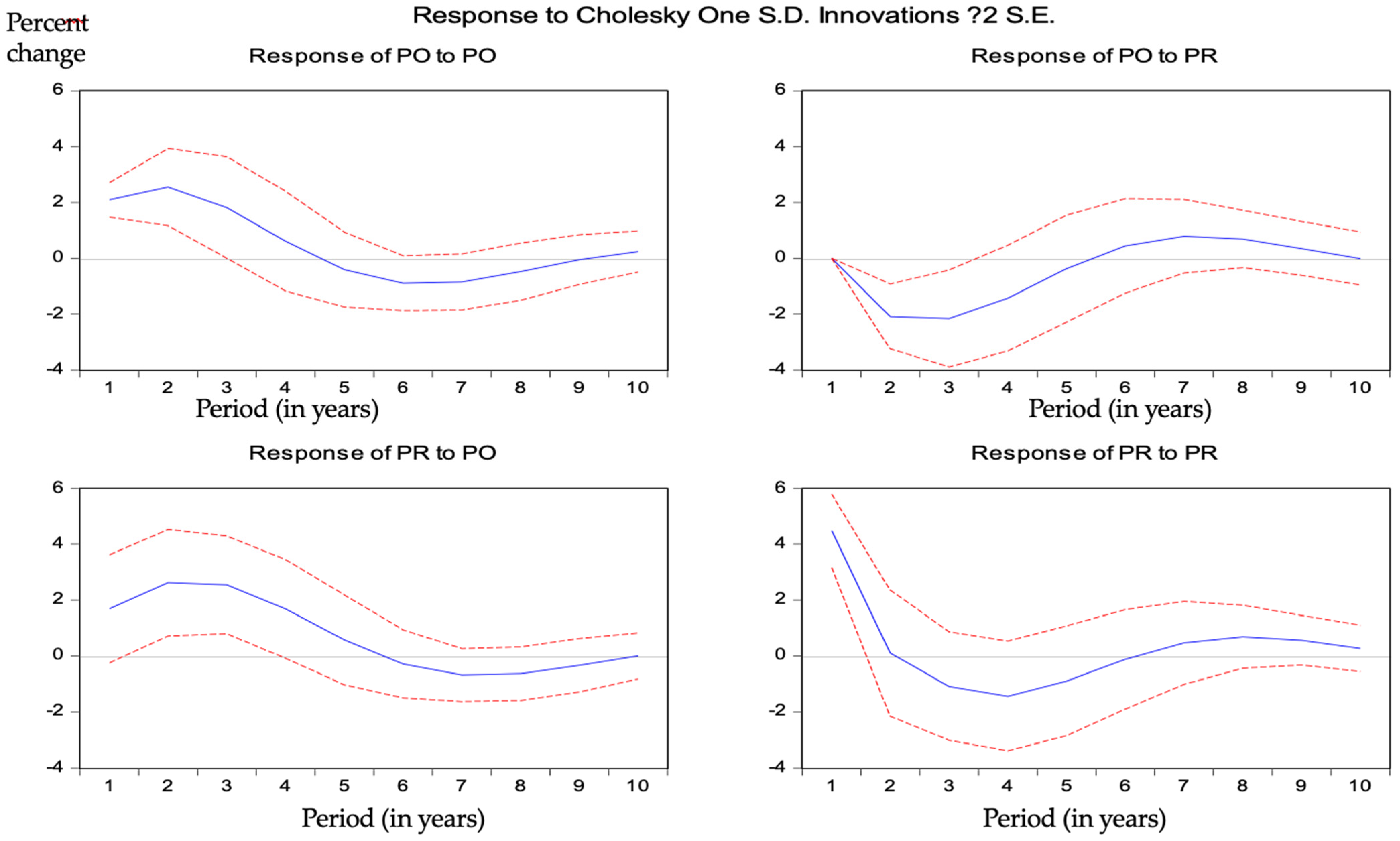

3.6. Impulse Response Functions

3.7. Variance Decompositions

3.8. Navigating beyond Current Global Commitments to Address Plastic Recycling

3.9. What Has Been the History of Coordinated Efforts to Managed Plastic Waste?

- Deposit-refund schemes

- Subsidies and fiscal incentives

- Price differentiation

- Business commitments

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Andrady, A.L. Microplastics in the marine environment. Mar. Pollut. Bull. 2011, 62, 1596–1605. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [Green Version]

- Bermingham, F.; Tan, S.L. Coronavirus: China’s mask-making juggernaut cranks into gear, sparking fears of over-reliance on world’s workshop. South China Morning Post, 12 March 2020. Available online: www.scmp.com/economy/global-economy/article/3074821/coronavirus-chinas-mask-making-juggernaut-cranks-gear (accessed on 20 August 2020).

- McKinsey. The New Plastics Economy—Rethinking the Future of Plastics 2016. Available online: http://www.ellenmacarthurfoundation.org/publications (accessed on 22 August 2020).

- Lebreton, L.; Andrady, A. Future scenarios of global plastic waste generation and disposal. Palgrave Commun. 2019, 5, 6. [Google Scholar] [CrossRef] [Green Version]

- Jambeck, J.R.; Geyer, R.; Wilcox, C.; Siegler, T.R.; Perryman, M.; Andrady, A.; Narayan, R.; Law, K.L. Plastic waste inputs from land into the ocean. Science 2015, 347, 768–771. [Google Scholar] [CrossRef]

- Czigány, T.; Ronkay, F. Editorial corner—A personal view the coronavirus and plastics. eXPRESS Polym. Lett. 2020, 14, 510–511. [Google Scholar]

- Lebreton, L.C.M.; van der Zwet, J.; Damsteeg, J.W.; Slat, B.; Andrady, A.; Reisser, J. River plastic emissions to the world’s ocean. Nat. Commun. 2017, 8, 15611. [Google Scholar] [CrossRef]

- Rudolph, N.; Kiesel, R.; Aumnate, C. Understanding Plastics Recycling: Economic, Ecological, and Technical Aspects of Plastic Waste Handling; Carl Hanser Verlag: Munich, Germany, 2017; pp. 15–114. [Google Scholar]

- World Bank. Commodity Markets Outlook: Implications for COVID-19 for Commodities; The World Bank: Washington, DC, USA, 2020. [Google Scholar]

- Stromberg, P. Market imperfections in recycled markets: Conceptual issues and empirical study of price volatility in plastics. Resour. Conserv. Recycl. 2004, 41, 339–364. [Google Scholar] [CrossRef]

- OECD. Improving Markets for Recycled Plastics: Trends, Prospects and Policy Response; OECD Publishing: Paris, France, 2018. [Google Scholar] [CrossRef]

- Angus, A.; Casado, M.R.; Fitzsimons, D. Exploring the usefulness of a simple linear regression model for understanding price movements of selected recycled materials in the UK. Resour. Conserv. Recycl. 2012, 60, 10–19. [Google Scholar] [CrossRef] [Green Version]

- WRAP. UK’s Recovered Plastic Prices 2008. Available online: www//wrap.org.uk/content/plastic (accessed on 2 July 2020).

- Weinhagen, J.C. Price transmission: From crude petroleum to plastics products. Mon. Labor Rev. 2006, 4, 46–55. [Google Scholar]

- Dickey, D.A.; Fuller, W.A. Distribution of the estimators for autoregressive time series with a unit root. J. Am. Stat. Assoc. 1979, 74, 427–431. [Google Scholar]

- Granger, C.; Newbold, P. Spurious regressions in econometrics. J. Econom. 1974, 2, 111–120. [Google Scholar] [CrossRef] [Green Version]

- Johansen, S.; Juselius, K. Maximum likelihood estimation and inference on cointegration—with applications to the demand for money. Oxf. Bull. Econ. Stat. 1990, 2, 169–210. [Google Scholar] [CrossRef]

- Johansen, S.; Juselius, K. Testing structural hypotheses in a multivariate cointegration analysis of the PPP and the UIP for UK. J. Econom. 1992, 1, 211–244. [Google Scholar] [CrossRef]

- Campos, J.; Ericsson, N.R. Constructive data mining: Modeling consumers’ expenditures in Venezuela. Econom. J. 1999, 2, 226–240. [Google Scholar] [CrossRef]

- Johnston, J.; Dinardo, J. Econometric Methods, 4th ed.; McGraw Hill: New York, NY, USA, 1997; pp. 299–300. [Google Scholar]

- Acuff, K.; Kaffine, D. Greenhouse gas emissions, waste and recycling policy. J. Environ. Econ. Manag. 2013, 65, 74–86. [Google Scholar] [CrossRef]

- McIlgorm, A.; Campbell, H.F.; Rule, M.J. The economic cost and control of marine debris damage in the Asia-Pacific region. Oc. Coast. Manag. 2011, 54, 643–651. [Google Scholar] [CrossRef]

- Ferrara, I.; Plourde, C. Refillable versus non-refillable containers: The impact of regulatory measures on packaging mix and quality choices. Resour. Policy 2003, 29, 1–13. [Google Scholar] [CrossRef]

- Williams, C. Combating marine pollution from land-based activities: Australian initiatives. Ocean Coast. Manag. 1996, 33, 87–112. [Google Scholar] [CrossRef]

- Lane, S.B.; Ahamada, S.; Gonzalves, C.; Lukambuzi, L.; Ochiewo, J.; Pereira, M.; Rasolofojaona, H.; Ryan, P.; and Seewoobaduth, J. Regional Overview and Assessment of Marine Litter Related Activities in the West Indian Ocean Region (WIOMSA Report to the United Nations Environment Programme). 2007. Available online: https://wedocs.unep.org/bitstream/handle/20.500.11822/8764/-A%20Regional%20Overview%20%26%20Assessment%20of%20Marine%20Litter%20Related%20Activities%20in%20the%20%20Western%20Indian%20Ocean%20Region-2007Regional_assessment_of_marine_litter_WIO_Region.PDF?sequence=3&isAllowed=y (accessed on 14 February 2020).

- Anstine, J. Consumers’ willingness to pay for recycled content in plastic kitchen garbage bags: A hedonic price approach. Appl. Econ. Lett. 2000, 7, 35–39. [Google Scholar] [CrossRef]

- Ellen MacArthur Foundation. Global Commitment 2019 Progress Report (2019). Available online: https://www.newplasticseconomy.org/about/publications/global-commitment-2019-progress-report (accessed on 15 December 2020).

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B 2009, 364, 2115–2126. [Google Scholar] [CrossRef] [Green Version]

- Abbott, J.K.; Sumaila, U.R. Reducing marine plastic pollution: Policy insights from economics. Rev. Environ. Econ. Policy 2019, 13, 327–336. [Google Scholar] [CrossRef] [Green Version]

- Issifu, I.; Sumaila, U.R. A review of the production, recycling and management of marine plastic pollution. J. Mar. Sci. Eng. 2020, 8, 945. [Google Scholar] [CrossRef]

| Industry Focus | Data | Method | Results | Reference |

|---|---|---|---|---|

| UK recycled plastic market | Recycled price data from letsrecycle.com | Regression model | Since 2004, the prices of crude oil and recycled plastics are linked | [13] |

| UK’s recovered plastic prices | Virgin, recycled PET, and HDPE data | Scenarios analysis | Recycled plastic is closely linked to the price of virgin plastic | [14] |

| US’s crude oil and plastic products markets | US’s producer price indexes for crude oil and plastics products | Vector autoregression model | Changes in crude oil prices are passed on to prices of plastics products | [15] |

| US’s price volatility in recyclables markets | Recyclables price data in Seattle (US) | Regression analysis | The supply of recycled materials is price inelastic because they are driven by law or taste | [11] |

| Variable | Mean | Range | Standard Deviation |

|---|---|---|---|

| Recyclates price index (PR) | 102 | (±12.9) | 10 |

| Crude oil price (PO) | 68 | (±14.0) | 8 |

| N = 25 | |||

| Variable | Augmented Dickey–Fuller | Probability | |

| Recyclates price index (PR) | −3.8359 | 0.0083 | |

| Crude oil price (PO) | −5.0305 | 0.0005 | |

| Lag | LogL | LR | FPE | AIC | SC | HQ |

|---|---|---|---|---|---|---|

| 0 | −112.9128 | NA | 335.5231 | 11.49128 | 11.59085 | 11.51072 |

| 1 | −72.14838 | 69.29948 | 8.530479 | 7.814838 | 8.113558 | 7.873151 |

| 2 | −58.64135 | 20.26054 * | 3.353593 * | 6.864135 * | 7.362001 * | 6.961324 * |

| 3 | −56.17281 | 3.209110 | 4.068610 | 7.017281 | 7.714293 | 7.153345 |

| 4 | −53.49429 | 2.946372 | 5.015211 | 7.149429 | 8.045588 | 7.324368 |

| 5 | −49.61086 | 3.495081 | 5.805800 | 7.161086 | 8.256392 | 7.374901 |

| Null Hypothesis: | Obs | F-Statistic | Prob |

|---|---|---|---|

| PR does not Granger Cause PO | 23 | 9.03292 | 0.0019 |

| PO does not Granger Cause PR | 23 | 6.33788 | 0.0082 |

| S.E. | PO | PR | |

|---|---|---|---|

| PO | 3.91101 | 71.5169 | 28.4830 |

| PR | 5.45317 | 32.5859 | 67.4141 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Issifu, I.; Deffor, E.W.; Sumaila, U.R. How COVID-19 Could Change the Economics of the Plastic Recycling Sector. Recycling 2021, 6, 64. https://0-doi-org.brum.beds.ac.uk/10.3390/recycling6040064

Issifu I, Deffor EW, Sumaila UR. How COVID-19 Could Change the Economics of the Plastic Recycling Sector. Recycling. 2021; 6(4):64. https://0-doi-org.brum.beds.ac.uk/10.3390/recycling6040064

Chicago/Turabian StyleIssifu, Ibrahim, Eric Worlanyo Deffor, and Ussif Rashid Sumaila. 2021. "How COVID-19 Could Change the Economics of the Plastic Recycling Sector" Recycling 6, no. 4: 64. https://0-doi-org.brum.beds.ac.uk/10.3390/recycling6040064