Boron-Based Neutron Scintillator Screens for Neutron Imaging

Abstract

:1. Introduction

1.1. Background

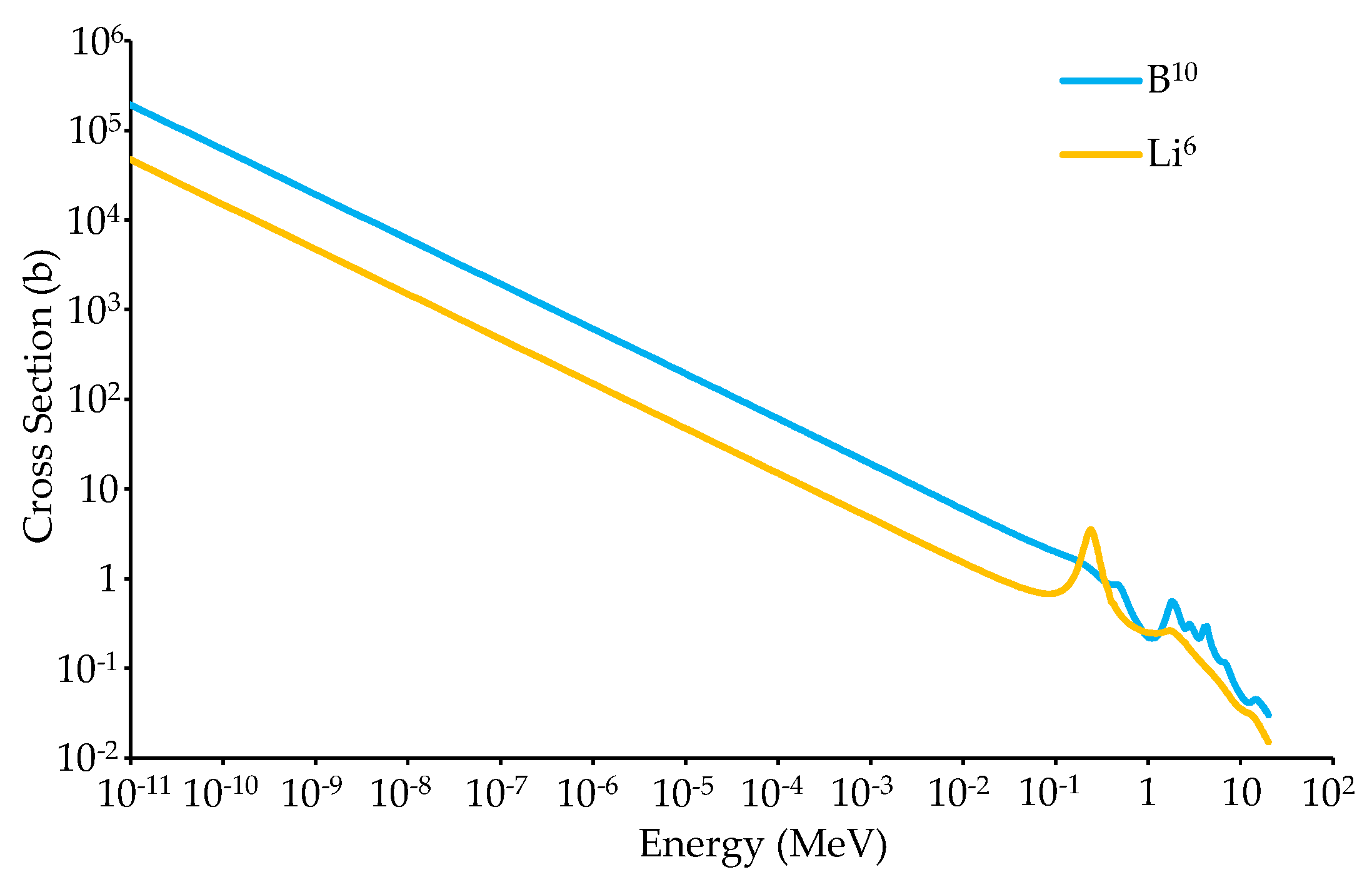

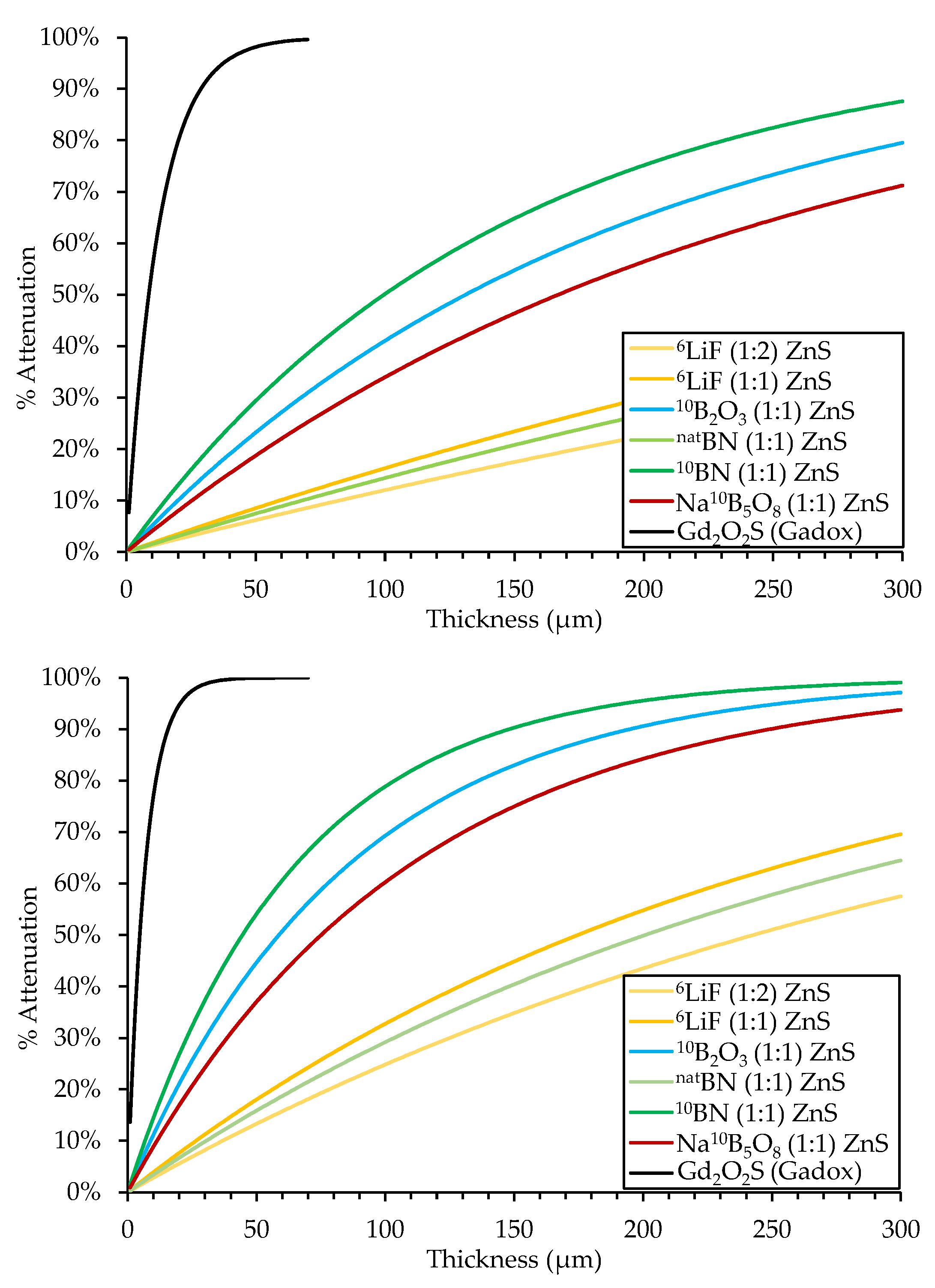

1.2. Theory of Boron-Based Scintillator Screens

2. Materials and Methods

2.1. Scintillator Screens

2.1.1. Scintillator Screen Compositions

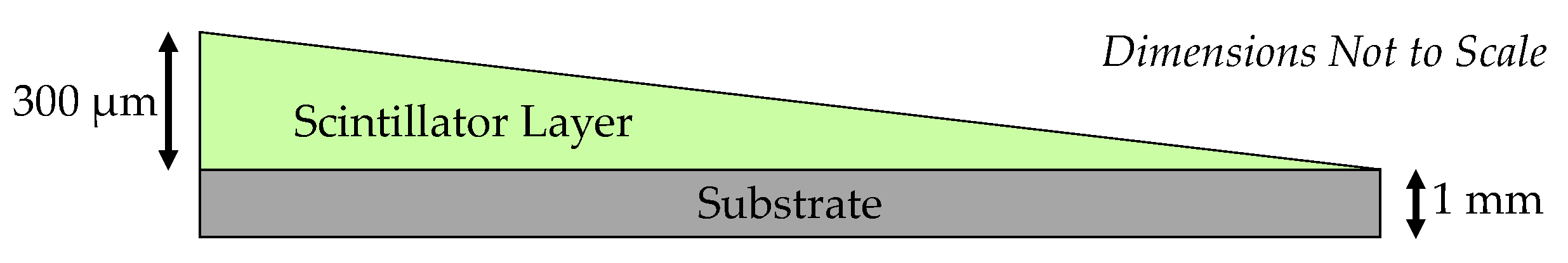

2.1.2. Wedged Scintillator Screens

2.1.3. Double-Wedged Scintillator Screens

2.1.4. High-Resolution Scintillator Screens

2.2. Neutron Source and Instrumentation

2.3. Testing Methodology

2.4. Data Processing

3. Results

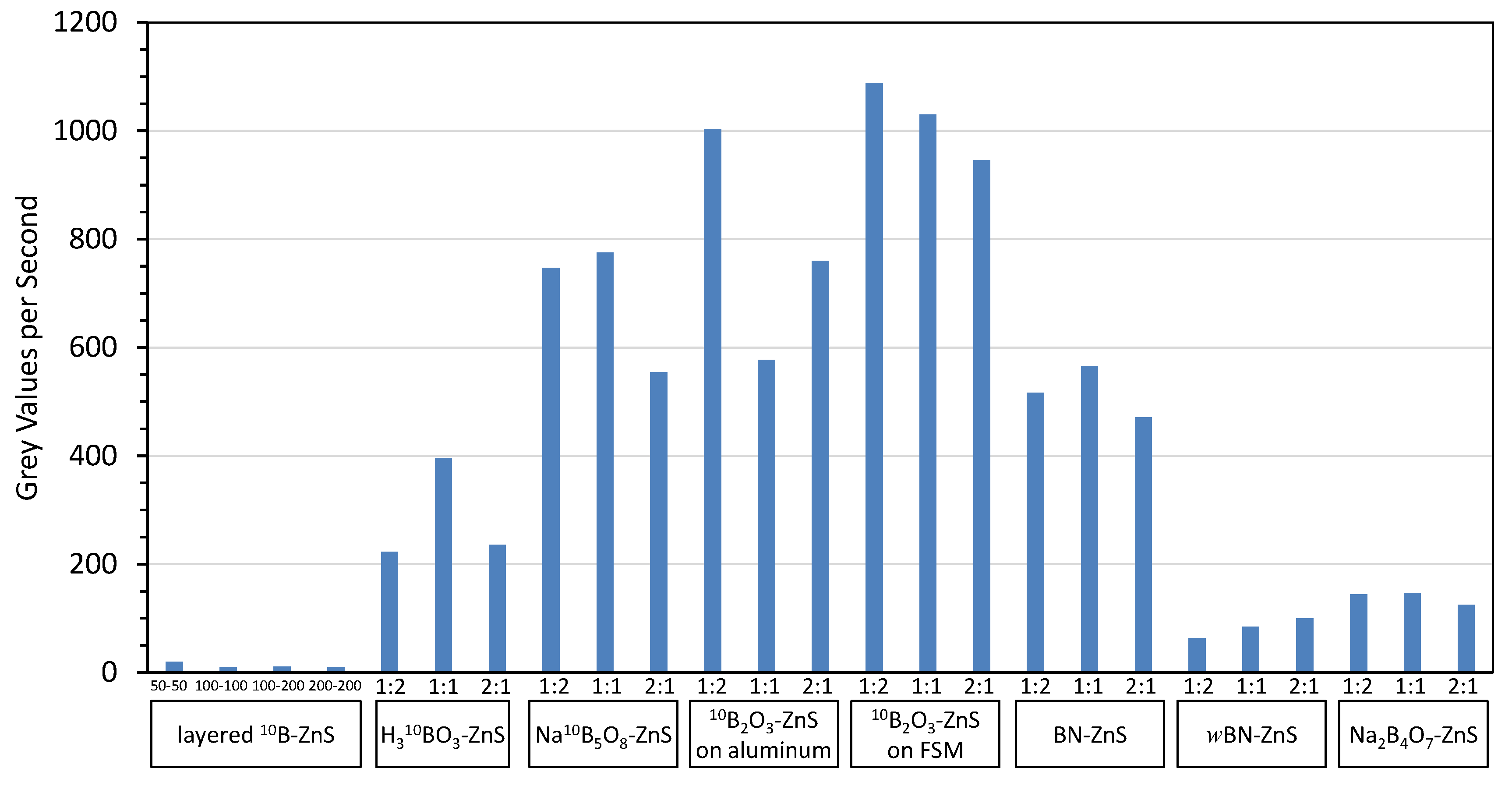

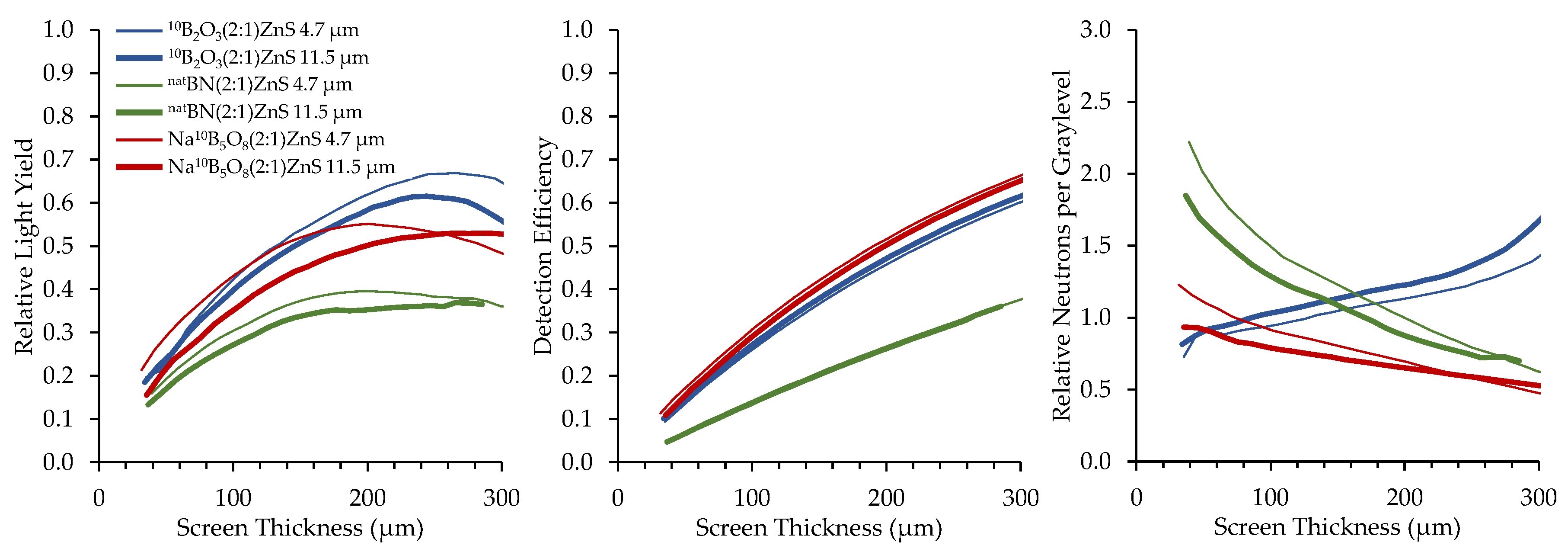

3.1. Results of Initial Scoping Studies

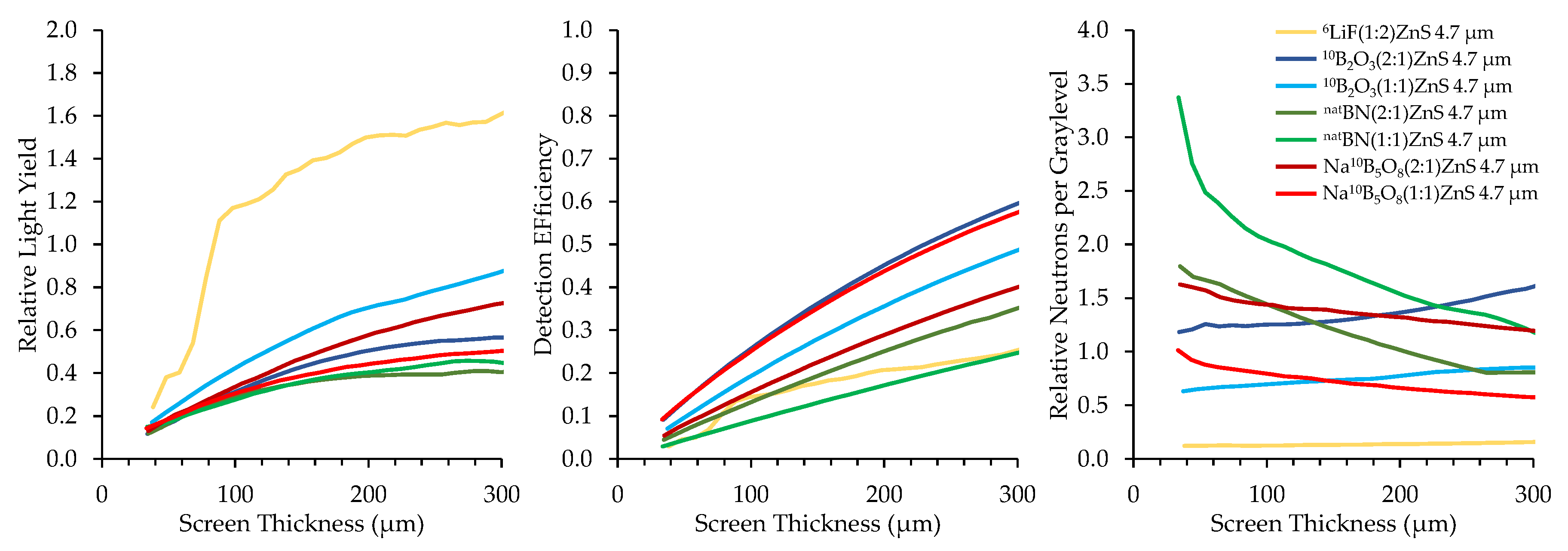

3.2. Additional Testing

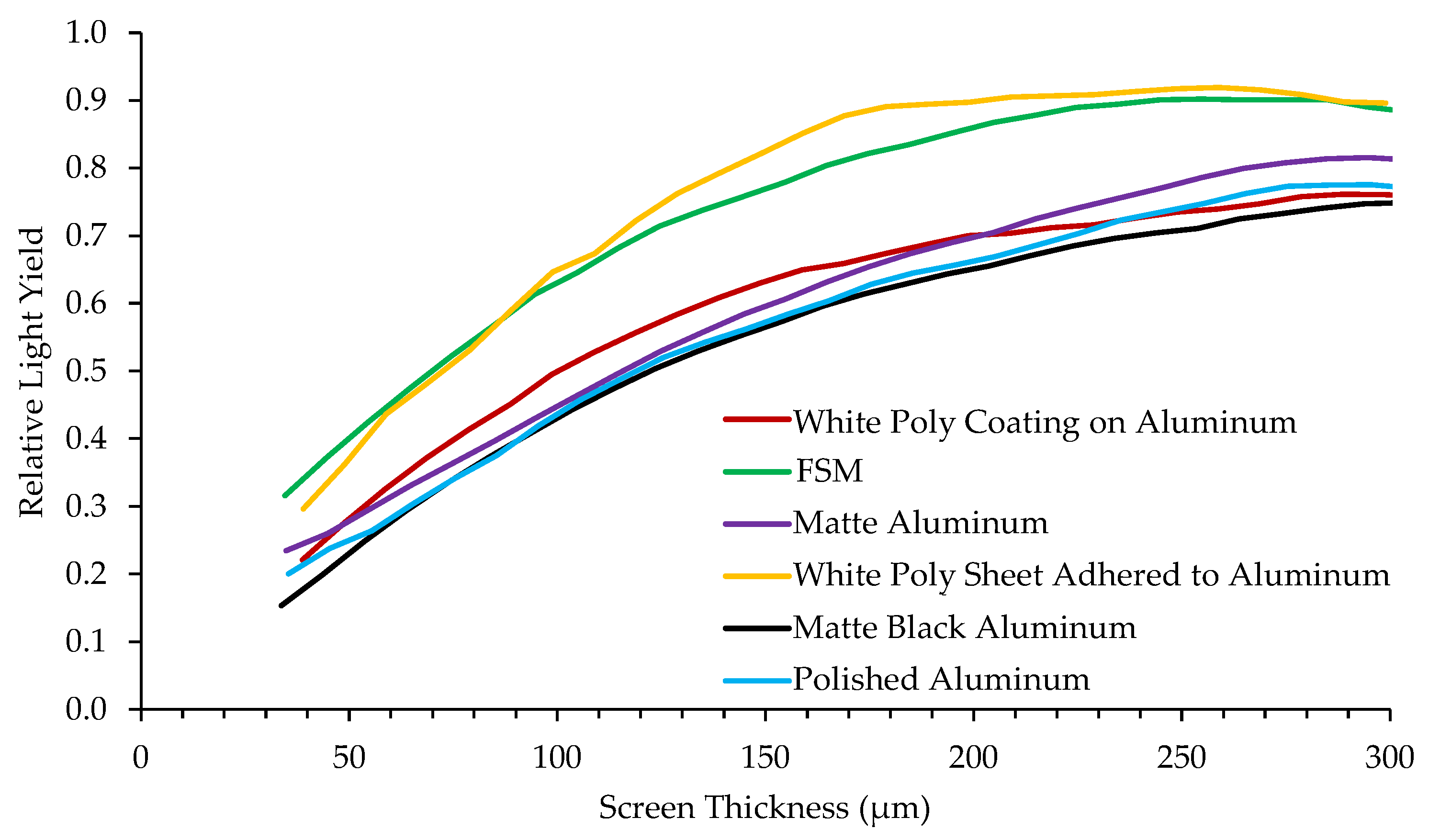

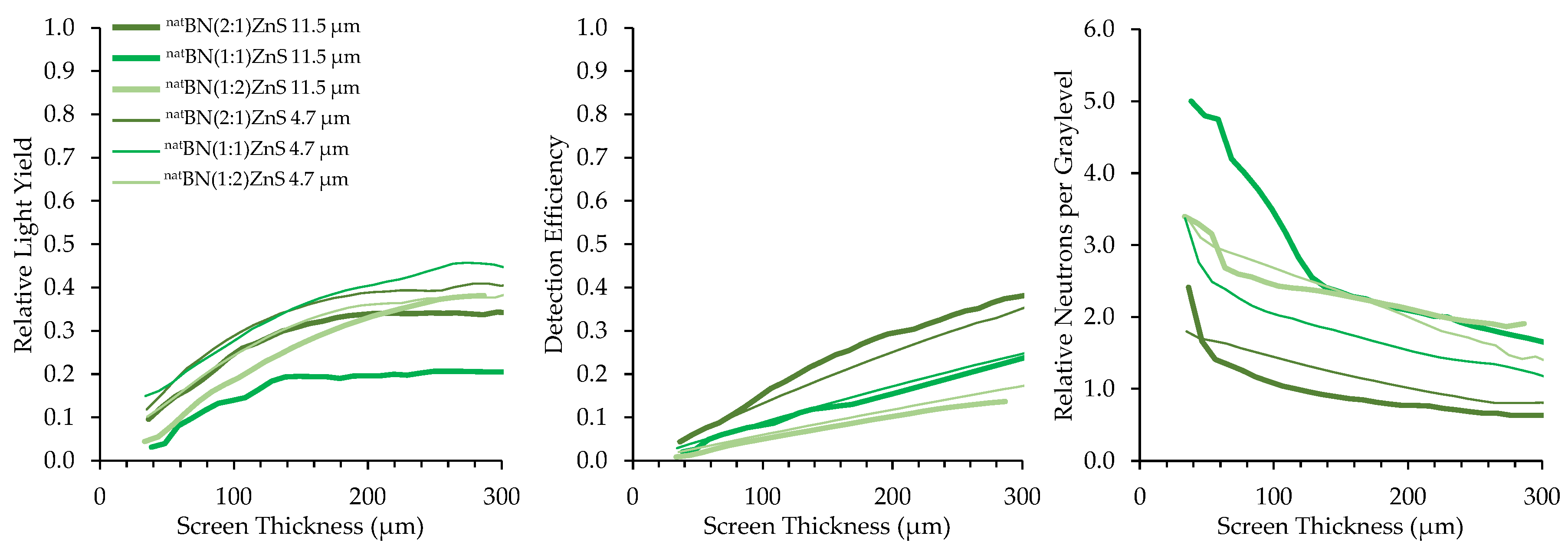

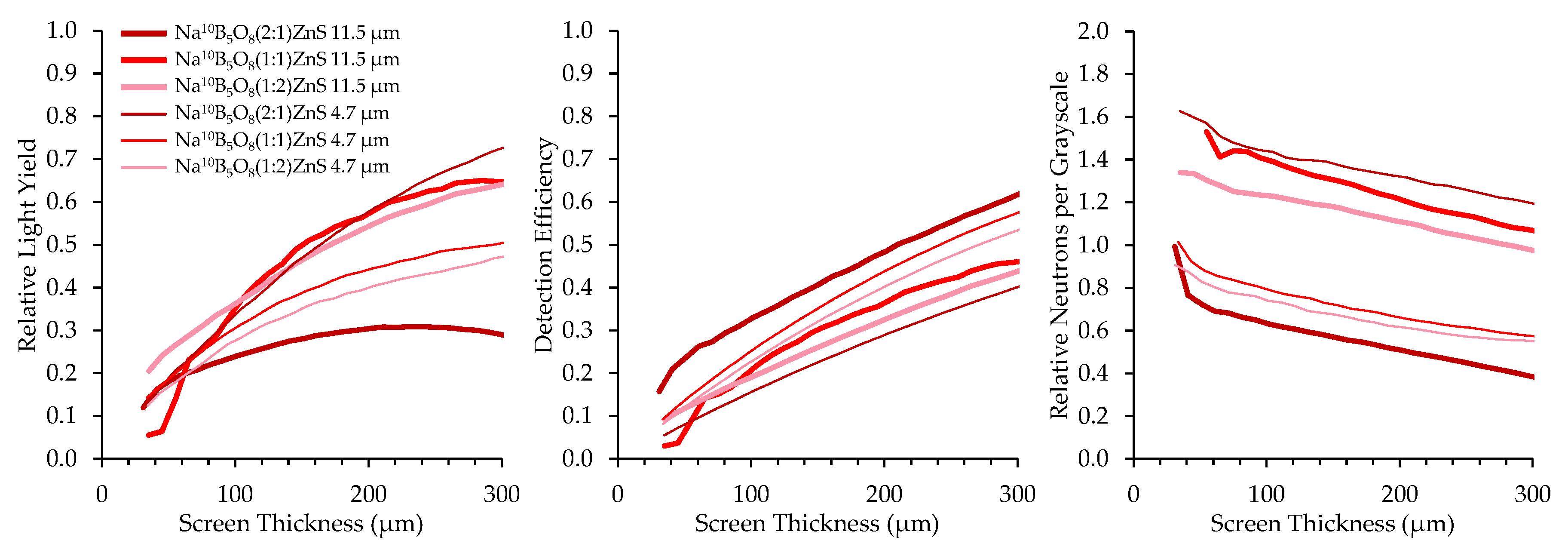

3.2.1. Cold Neutron Results

3.2.2. Epithermal Neutron Results

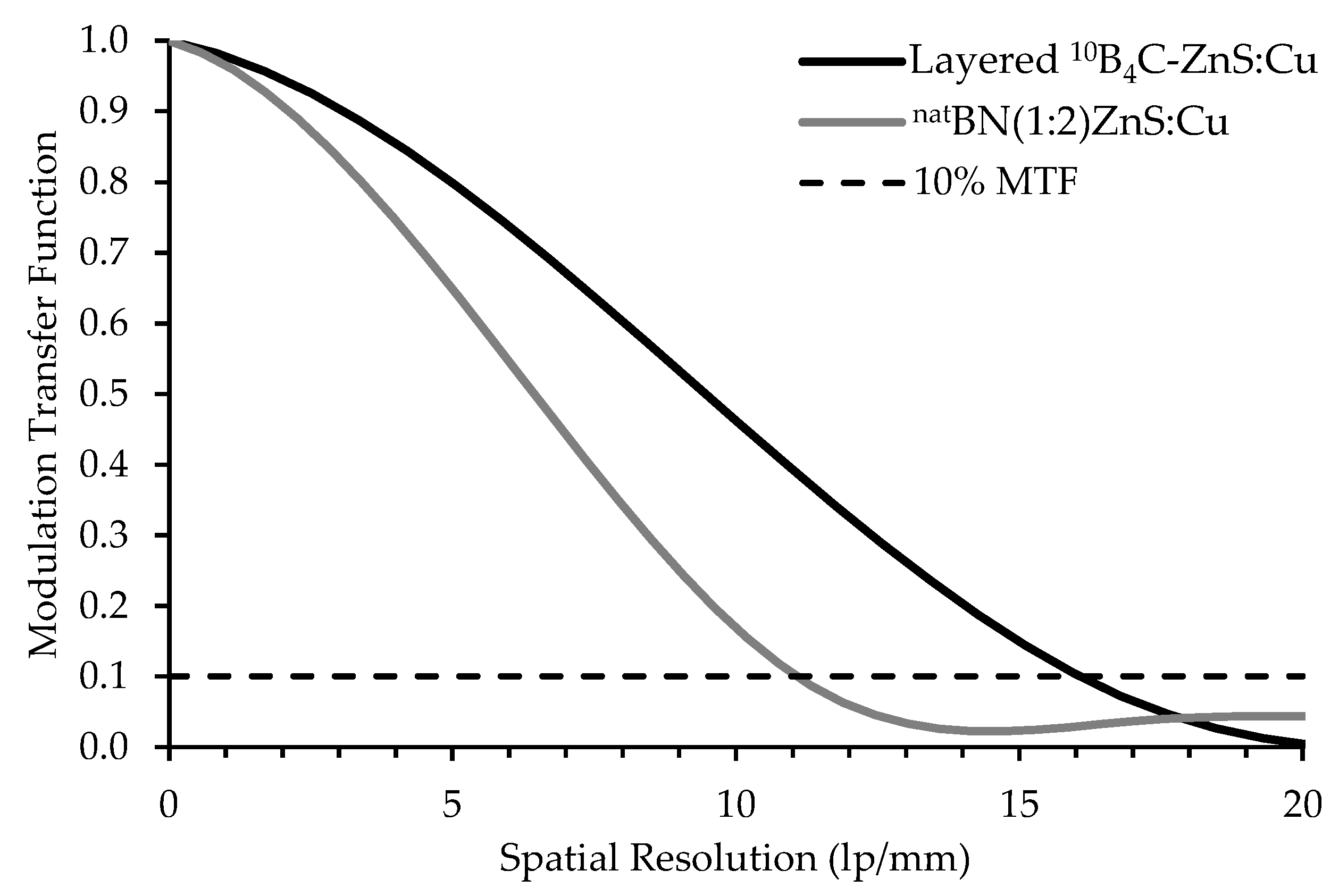

3.2.3. Spatial Resolution

3.2.4. Neutron Computed Tomography

4. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lehmann, E.H.; Vontobel, P.; Hermann, A. Non-destructive analysis of nuclear fuel by means of thermal and cold neutrons. Nucl. Instrum. Methods Phys. Res. A 2003, 515, 745–759. [Google Scholar] [CrossRef]

- Sim, C.-M.; Kim, T.; Oh, H.S.; Kim, J.C. Measurement of Ballooning Gap Size of Irradiated Fuels Using Neutron Radiography Transfer Method and HV Image Filter. J. Korean Soc. Nondestruct. Test. 2013, 33, 212–218. [Google Scholar] [CrossRef] [Green Version]

- Tremsin, A.S.; Vogel, S.C.; Mocko, M.; Bourke, M.A.M.; Yuan, V.; Nelson, R.O.; Brown, D.W.; Feller, W.B. Non-destructive studies of fuel pellets by neutron resonance absorption radiography and thermal neutron radiography. J. Nucl. Mater. 2013, 440, 633–646. [Google Scholar] [CrossRef]

- Craft, A.E.; Wachs, D.M.; Okuniewski, M.A.; Chichester, D.L.; Williams, W.J.; Papaioannou, G.C.; Smolinski, A.T. Neutron Radiography of Irradiated Nuclear Fuel at Idaho National Laboratory. Phys. Procedia 2015, 69, 483–490. [Google Scholar] [CrossRef] [Green Version]

- Tremsin, A.S.; Craft, A.E.; Papaioannou, G.C.; Smolinski, A.T.; Boulton, N.M.; Ruddell, M.A.; Littell, B.J.; Riley, K.D. On the possibility to investigate irradiated fuel pins non-destructively by digital neutron radiography with a neutron-sensitive microchannel plate detector with Timepix readout. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2019, 927, 109–118. [Google Scholar] [CrossRef]

- Schulthess, J.; Woolstenhulme, N.; Craft, A.; Kane, J.; Boulton, N.; Chuirazzi, W.; Winston, A.; Smolinski, A.; Jensen, C.; Kamerman, D.; et al. Non-Destructive Post-irradiation Examination Results of the First Modern Fueled Experiments in TREAT. J. Nucl. Mater. 2020, 541, 152442. [Google Scholar] [CrossRef]

- Lehmann, E.H.; Vontobel, P.; Deschler-Erb, E.; Soares, M. Non-invasive studies of objects from cultural heritage. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2005, 42, 68–75. [Google Scholar] [CrossRef]

- Rant, J.; Milič, Z.; Istenič, J.; Knific, T.; Lengar, I.; Rant, A. Neutron radiography examination of objects belonging to the cultural heritage. Appl. Radiat. Isot. 2006, 64, 7–12. [Google Scholar] [CrossRef]

- Mannes, D.; Schmid, F.; Frey, J.; Schmidt-Ott, K.; Lehmann, E. Combined Neutron and X-ray Imaging for Non-invasive Investigations of Cultural Heritage Objects. Phys. Procedia 2015, 69, 653–660. [Google Scholar] [CrossRef] [Green Version]

- Iranzo, A.; Boillat, P.; Rosa, F. Validation of a three dimensional PEM fuel cell CFD model using local liquid water distributions measured with neutron imaging. Int. J. Hydrogen Energy 2014, 39, 7089–7099. [Google Scholar] [CrossRef]

- Makowska, M.G.; Strobl, M.; Lauridsen, E.M.; Frandsen, H.L.; Tremsin, A.S.; Kardjilov, N.; Manke, I.; Kelleher, J.F.; Theil Kuhn, L. Effect of stress on NiO reduction in solid oxide fuel cells: A new application of energy-resolved neutron imaging. J. Appl. Crystallogr. 2015, 48, 401–408. [Google Scholar] [CrossRef] [Green Version]

- Cochet, M.; Forner-Cuenca, A.; Manzi, V.; Siegwart, M.; Scheuble, D.; Boillat, P. Novel Concept for Evaporative Cooling of Fuel Cells: An Experimental Study Based on Neutron Imaging. Fuel Cells 2018, 18, 619–626. [Google Scholar] [CrossRef]

- Cho, J.I.S.; Neville, T.P.; Trogadas, P.; Meyer, Q.; Wu, Y.; Ziesche, R.; Boillat, P.; Cochet, M.; Manzi-Orezzoli, V.; Shearing, P.; et al. Visualization of liquid water in a lung-inspired flow-field based polymer electrolyte membrane fuel cell via neutron radiography. Energy 2019, 170, 14–21. [Google Scholar] [CrossRef]

- Kulkarni, N.; Meyer, Q.; Hack, J.; Jervis, R.; Iacoviello, F.; Ronaszegi, K.; Adcock, P.; Shearing, P.R.; Brett, D.J.L. Examining the effect of the secondary flow-field on polymer electrolyte fuel cells using X-ray computed radiography and computational modelling. Int. J. Hydrogen Energy 2019, 44, 1139–1150. [Google Scholar] [CrossRef]

- Koerner, S.; Schillinger, B.; Vontobel, P.; Rauch, H. A neutron tomography facility at a low power research reactor. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2001, 471, 69–74. [Google Scholar] [CrossRef]

- Sim, C.M.; Oh, H.S.; Kim, T.J.; Lee, Y.S.; Kim, Y.K.; Kwak, S.S.; Hwang, Y.H. Detecting Internal Hot Corrosion of In-service Turbine Blades Using Neutron Tomography with Gd Tagging. J. Nondestruct. Eval. 2014, 33, 493–503. [Google Scholar] [CrossRef]

- Peetermans, S.; Lehmann, E.H. Simultaneous neutron transmission and diffraction imaging investigations of single crystal nickel-based superalloy turbine blades. NDT E Int. 2016, 79, 109–113. [Google Scholar] [CrossRef]

- Lehmann, E.H. Neutron imaging facilities in a global context. J. Imaging 2017, 3, 52. [Google Scholar] [CrossRef] [Green Version]

- Stedman, R. Scintillator for thermal neutrons using Li6F and ZnS (Ag). Rev. Sci. Instrum. 1960, 31, 1156. [Google Scholar] [CrossRef]

- Mantler-Niederstätter, F.; Bensch, F.; Grass, F. An extremely thin scintillation detector for thermal neutrons. Nucl. Instrum. Methods 1977, 142, 463–466. [Google Scholar] [CrossRef]

- Knoll, G.F. Radiation Detection and Measurements, 3rd ed.; Wiley and Sons: Hoboken, NJ, USA, 2000; ISBN 0471073385. [Google Scholar]

- Katagiri, M.; Sakasai, K.; Matsubayashi, M.; Nakamura, T.; Kondo, Y.; Chujo, Y.; Nanto, H.; Kojima, T. Scintillation materials for neutron imaging detectors. Nucl. Instrum. Methods Phys. Res. A 2004, 529, 274–279. [Google Scholar] [CrossRef]

- Crha, J.; Vila-Comamala, J.; Lehmann, E.; David, C.; Trtik, P. Light Yield Enhancement of 157-Gadolinium Oxysulfide Scintillator Screens for the High-Resolution Neutron Imaging. MethodsX 2019, 6, 107–114. [Google Scholar] [CrossRef] [PubMed]

- Sun, K.H.; Malmberg, P.R.; Pecjak, F.A. High-Efficiency Slow-Neutron Scintillation Counters. Nucleonics 1956, 14, 46–49. [Google Scholar]

- McGonnagle, W.J. Symposium on Physics and Nondestructive Testing; Argonne National Laboratory: Argonne, IL, USA, 1960; ANL-6346.

- Kojima, T.; Katagiri, M.; Tsutsui, N.; Imai, K.; Matsubayashi, M.; Sakasai, K. Neutron scintillators with high detection efficiency. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2004, 529, 325–328. [Google Scholar] [CrossRef]

- Katagiri, M.; Sakasai, K.; Matsubayashi, M.; Kojima, T. Neutron/γ-ray discrimination characteristics of novel neutron scintillators. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2004, 529, 317–320. [Google Scholar] [CrossRef]

- Ishii, M.; Kuwano, Y.; Asai, T.; Asaba, S.; Kawamura, M.; Senguttuvan, N. Boron based oxide scintillation glass for neutron detection. Nucl. Instrum. Methods Phys. Res. A Accel. Spectrometers Detect. Assoc. Equip. 2005, 537, 282–285. [Google Scholar] [CrossRef]

- Czirr, J.B.; Macgillivray, G.M.; Macgillivray, R.R.; Seddon, P.J. Performance and characteristics of a new scintillator. Nucl. Instrum. Methods Phys. Res. Sect. Accel. Spectrometers Detect. Assoc. Equip. 1999, 424, 15–19. [Google Scholar] [CrossRef]

- Williams, A.M.; Beeley, P.A.; Spyrou, N.M. Response of a lithium gadolinium borate scintillator in monoenergetic neutron fields. Radiat. Prot. Dosim. 2004, 110, 497–502. [Google Scholar] [CrossRef]

- Normand, S.; Mouanda, B.; Haan, S.; Louvel, M. Discrimination methods between neutron and gamma rays for boron loaded plastic scintillators. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2002, 484, 342–350. [Google Scholar] [CrossRef]

- Britvich, G.I.; Vasil’chenko, V.G.; Gilitsky, Y.V.; Chubenko, A.P.; Kushnirenko, A.E.; Mamidzhanyan, E.A.; Pavluchenko, V.P.; Pikalov, V.A.; Romakhin, V.A.; Soldatov, A.P.; et al. A neutron detector on the basis of a boron-containing plastic scintillator. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2005, 550, 343–358. [Google Scholar] [CrossRef]

- Mahl, A.; Yemam, H.A.; Stuntz, J.; Remedes, T.; Sellinger, A.; Greife, U. Bis(pinacolato)diboron as an additive for the detection of thermal neutrons in plastic scintillators. Nucl. Instrum. Methods Phys. Res. A 2016, 816, 96–100. [Google Scholar] [CrossRef] [Green Version]

- Mahl, A.; Yemam, H.A.; Fernando, R.; Koubek, J.T.; Sellinger, A. 10B enriched plastic scintillators for application in thermal neutron detection. Nucl. Inst. Methods Phys. Res. A 2018, 880, 1–5. [Google Scholar] [CrossRef]

- Verhaeghe, J.L.; Thielens, G.; Creten, W.L. Preparation and properties of a boron containing scintillator for the detection of slow neutrons. Appl. Sci. Res. Sect. B 1962, 10, 247–256. [Google Scholar] [CrossRef]

- Brenizer, J.S.; Berger, H.; Stebbings, C.T.; Gillies, G.T. Performance characteristics of scintillators for use in an electronic neutron imaging system for neutron radiography. Rev. Sci. Instrum. 1997, 68, 3371–3379. [Google Scholar] [CrossRef]

- McMillan, J.E.; Cole, A.J.; Kirby, A.; Marsden, E. Thermal neutron scintillators using unenriched boron nitride and zinc sulfide. J. Phys. Conf. Ser. 2015, 620, 012011. [Google Scholar] [CrossRef] [Green Version]

- Nakamura, T.; Katagiri, M.; Tsutsui, N.; Toh, K.; Rhodes, N.; Schooneveld, E.; Ooguri, H.; Noguchi, Y.; Sakasai, K.; Soyama, K. Development of a ZnS/10B2O3 scintillator with low- afterglow phosphor Development of a ZnS/10B2O3 scintillator with low-afterglow phosphor. Int. Work. Neutron Opt. Detect. 2014, 528, 1–8. [Google Scholar]

- Miller, S.R.; Marshall, M.S.J.; Wart, M.; Crha, J.; Trtik, P.; Nagarkar, V.V. High Resolution Thermal Neutron Imaging with 10Boron/CsI:Tl Scintillator Screen. IEEE Trans. Nucl. Sci. 2020, 9499, 1–5. [Google Scholar]

- Van Delinder, K.W.; Khan, R.; Gräfe, J.L. Neutron activation of gadolinium for ion therapy: A Monte Carlo study of charged particle beams. Sci. Rep. 2020, 10, 1–11. [Google Scholar] [CrossRef]

- Miller, G.A.; Hertel, N.E.; Wehring, B.W.; Horton, J.L. Gadolinium neutron capture therapy. Nucl. Technol. 1993, 103, 320–331. [Google Scholar] [CrossRef]

- Kandlakunta, P.; Cao, L.R.; Mulligan, P. Measurement of internal conversion electrons from Gd neutron capture. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2013, 705, 36–41. [Google Scholar] [CrossRef]

- Goorley, T.; Nikjoo, H. Electron and photon spectra for three gadolinium-based cancer therapy approaches. Radiat. Res. 2000, 154, 556–563. [Google Scholar] [CrossRef]

- Abdushukurov, D.A.; Abduvokhldov, M.A.; Bondarenko, D.V.; Mumlnov, K.K.; Toshov, T.A.; Chlstyakov, D.Y. Modeling the registration efficiency of thermal neutrons by gadolinium foils. J. Instrum. 2007, 2, 04001. [Google Scholar] [CrossRef] [Green Version]

- Berger, M.J.; Coursey, J.S.; Zucker, M.A.; Chang, J. Stopping-Power and Range Tables For Electrons, Protons, and Helium Ions; NIST Physics Laboratory: Gaithersburg, MD, USA, 2017.

- Ziegler, J.F.; Ziegler, M.D.; Biersack, J.P. SRIM-The stopping and range of ions in matter (2010). Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2010, 268, 1818–1823. [Google Scholar] [CrossRef] [Green Version]

- Salvat, F.; Fernandez-Varea, J.M.; Sempau, J. PENELOPE-2006: A code system for Monte Carlo simulation of electron and photon transport. Work. Proc. 2006, 4, 6222. [Google Scholar]

- Detail Information of NaB5H10O1; Catalyst Hub. Available online: http://www.catalysthub.net/materials.php?id=1830324,2016 (accessed on 27 October 2020).

- Chuirazzi, W.; Craft, A. Measuring Thickness-Dependent Relative Light Yield and Detection Efficiency of Scintillator Screens. J. Imaging 2020, 6, 56. [Google Scholar] [CrossRef]

- Schulz, M.; Schillinger, B. ANTARES: Cold neutron radiography and tomography facility. J. Large-Scale Res. Facil. JLSRF 2015, 1, 8–11. [Google Scholar] [CrossRef] [Green Version]

- Andor, iKon-L Series iKon-L Series. Available online: https://andor.oxinst.com/products/ikon-xl-and-ikon-large-ccd-series/ikon-l-936 (accessed on 12 February 2020).

- Schillinger, B.; Craft, A.E. Epithermal Neutron Radiography and Tomography on Large and Strongly Scattering Samples. Mater. Res. Proc. 2020, 15, 142–148. [Google Scholar]

- Schooneveld, E.M.; Tardocchi, M.; Gorini, G.; Kockelmann, W.; Nakamura, T.; Perelli Cippo, E.; Postma, H.; Rhodes, N.; Schillebeeckx, P. A new position-sensitive transmission detector for epithermal neutron imaging. J. Phys. D Appl. Phys. 2009, 42, 152003. [Google Scholar] [CrossRef]

- Cippo, E.P.; Borella, A.; Gorini, G.; Kockelmann, W.; Moxon, M.; Postma, H.; Rhodes, N.J.; Schillebeeckx, P.; Schoonenveld, E.M.; Tardocchi, M.; et al. Imaging of cultural heritage objects using neutron resonances. J. Anal. At. Spectrom. 2011, 26, 992–999. [Google Scholar] [CrossRef]

- Vogel, S.C. A Review of Neutron Scattering Applications to Nuclear Materials. ISRN Mater. Sci. 2013, 2013, 1–24. [Google Scholar] [CrossRef] [Green Version]

- Vogel, S.C.; Bourke, M.A.M.; Craft, A.E.; Harp, J.M.; Kelsey, C.T.; Lin, J.; Long, A.M.; Losko, A.S.; Hosemann, P.; McClellan, K.J.; et al. Advanced Postirradiation Characterization of Nuclear Fuels Using Pulsed Neutrons. Jom 2020, 72, 187–196. [Google Scholar] [CrossRef]

- Tremsin, A.S.; McPhate, J.B.; Vallerga, J.V.; Siegmund, O.H.W.; Kockelmann, W.; Schooneveld, E.M.; Rhodes, N.J.; Bruce Feller, W. High resolution neutron resonance absorption imaging at a pulsed neutron beamline. IEEE Trans. Nucl. Sci. 2012, 59, 3272–3277. [Google Scholar] [CrossRef]

- Tremsin, A.S.; Kockelmann, W.; Pooley, D.E.; Feller, W.B. Spatially resolved remote measurement of temperature by neutron resonance absorption. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2015, 803, 15–23. [Google Scholar] [CrossRef] [Green Version]

- Dangendorf, V.; Laczko, G.; Kersten, C. Fast neutron resonance radiography in a pulsed neutron beam. arXiv 2003, arXiv:nucl-ex/0301001v1. [Google Scholar]

| Converter | Density (g/cm3) | Daughter Product Range | |||

|---|---|---|---|---|---|

| 7Li (1.01 MeV) | α (1.78 MeV) | 7Li (0.84 MeV) | α (1.47 MeV) | ||

| B2O3 | 2.46 | 2.45 µm | 4.84 µm | 2.19 µm | 3.97 µm |

| NaB5O8 | 2.06 | 2.98 µm | 5.88 µm | 2.66 µm | 4.82 µm |

| BN | 2.10 | 2.61 µm | 5.21 µm | 2.34 µm | 4.24 µm |

| 3H (2.73 MeV) | α (2.05 MeV) | ||||

| LiF | 2.64 | 62.7 µm | 6.04 µm | ||

| ICe− (29 keV) | ICe− (71 keV) | ||||

| 157Gd2O2S:Tb | 7.32 | 1.31 µm | 5.46 µm | ||

| Scintillator Mixture | Σtotal | Mean Free Path (µm) | 20% Absorption Thickness (µm) | |||

|---|---|---|---|---|---|---|

| (cm−1) | ||||||

| Thermal | Cold | Thermal | Cold | Thermal | Cold | |

| 6LiF:ZnS (1:2) | 12.8 | 28.5 | 780 | 350 | 174 | 78 |

| natBN:ZnS (1:1) | 14.3 | 32.0 | 700 | 313 | 156 | 70 |

| 6LiF:ZnS (1:1) | 17.8 | 39.7 | 562 | 252 | 125 | 56 |

| Na10B5O8:ZnS (1:1) | 41.5 | 92.4 | 241 | 108 | 54 | 24 |

| 10B2O3:ZnS (1:1) | 52.9 | 118 | 189 | 85 | 42 | 19 |

| 10BN:ZnS (1:1) | 69.6 | 156 | 144 | 64 | 32 | 14 |

| Gd2O2S (Gadox) | 799 | 1467 | 13 | 6.8 | 2.8 | 1.5 |

| Substrate | Converter Material | Atomic Ratio (B:ZnS) | Thickness (µm) |

|---|---|---|---|

| Aluminum | 10B-enriched boron powder | layered | 5050 |

| Aluminum | 10B-enriched boron powder | layered | 100,100 |

| Aluminum | 10B-enriched boron powder | layered | 200,100 |

| Aluminum | 10B-enriched boron powder | layered | 200,200 |

| Aluminum | 10B-enriched Boric Acid | 2:1 | 200 |

| Aluminum | 10B-enriched Boric Acid | 1:1 | 200 |

| Aluminum | 10B-enriched Boric Acid | 1:2 | 200 |

| Aluminum | 10B-enr. Sodium Pentaborate | 2:1 | 200 |

| Aluminum | 10B-enr. Sodium Pentaborate | 1:1 | 200 |

| Aluminum | 10B-enr. Sodium Pentaborate | 1:2 | 200 |

| Aluminum | Boron Oxide (B2O3) | 2:1 | 200 |

| Aluminum | Boron Oxide (B2O3) | 1:1 | 200 |

| Aluminum | Boron Oxide (B2O3) | 1:2 | 200 |

| 1.9 mm FSM | Boron Oxide (B2O3) | 2:1 | 200 |

| 1.9 mm FSM | Boron Oxide (B2O3) | 1:1 | 200 |

| 1.9 mm FSM | Boron Oxide (B2O3) | 1:2 | 200 |

| Aluminum | Boron Nitride (BN) | 2:1 | 200 |

| Aluminum | Boron Nitride (BN) | 1:1 | 200 |

| Aluminum | Boron Nitride (BN) | 1:2 | 200 |

| Aluminum | Wurtzite-Boron Nitride (w-BN) | 2:1 | 200 |

| Aluminum | Wurtzite-Boron Nitride (w-BN) | 1:1 | 200 |

| Aluminum | Wurtzite-Boron Nitride (w-BN) | 1:2 | 200 |

| Aluminum | Anhydrous Sodium Tetraborate | 2:1 | 200 |

| Aluminum | Anhydrous Sodium Tetraborate | 1:1 | 200 |

| Aluminum | Anhydrous Sodium Tetraborate | 1:2 | 200 |

| Particle Size (µm) | Phosphor Maximum Thickness | Converter Material | Converter Thickness (µm) | Converter to Scintillator At. Ratio (B:ZnS) | Converter to Scintillator Weight Ratio | Substrate Surface Finish | Notes |

|---|---|---|---|---|---|---|---|

| 11.5 | 300 | 10B metal | 100 | - | - | matte black | double Wedge |

| 4.7 | 300 | 10B metal | 100 | - | - | matte black | double Wedge |

| 11.5 | 300 | 10B4C | 100 | - | - | matte black | double Wedge |

| 4.7 | 300 | 10B4C | 100 | - | - | matte black | double Wedge |

| 11.5 | 300 | 10B2O3 | - | 2:1 | 1:2.5 | matte black | single wedge |

| 11.5 | 300 | 10B2O3 | - | 1:1 | 1:4 | matte black | single wedge |

| 11.5 | 300 | 10B2O3 | - | 1:2 | 1:7 | matte black | single wedge |

| 4.7 | 300 | 10B2O3 | - | 2:1 | 1:2.5 | matte black | single wedge |

| 4.7 | 300 | 10B2O3 | - | 1:1 | 1:4 | matte black | single wedge |

| 4.7 | 300 | 10B2O3 | - | 1:2 | 1:7 | matte black | single wedge |

| 11.5 | 300 | Na10B5O8 | - | 2:1 | 1:2.3 | matte black | single wedge |

| 11.5 | 300 | Na10B5O8 | - | 1:1 | 1:3.5 | matte black | single wedge |

| 11.5 | 300 | Na10B5O8 | - | 1:2 | 1:6.1 | matte black | single wedge |

| 4.7 | 300 | Na10B5O8 | - | 2:1 | 1:2.3 | matte black | single wedge |

| 4.7 | 300 | Na10B5O8 | - | 1:1 | 1:3.5 | matte black | single wedge |

| 4.7 | 300 | Na10B5O8 | - | 1:2 | 1:6.1 | matte black | single wedge |

| 11.5 | 300 | natBN | - | 2:1 | 1:3.1 | matte black | single wedge |

| 11.5 | 300 | natBN | - | 1:1 | 1:5.1 | matte black | single wedge |

| 11.5 | 300 | natBN | - | 1:2 | 1:9.2 | matte black | single wedge |

| 4.7 | 300 | natBN | - | 2:1 | 1:3.1 | matte black | single wedge |

| 4.7 | 300 | natBN | - | 1:1 | 1:5.1 | matte black | single wedge |

| 4.7 | 300 | natBN | - | 1:2 | 1:9.2 | matte black | single wedge |

| 11.5 | 300 | 10B2O3 | - | 2:1 | 1:2.5 | polished | single wedge |

| 11.5 | 300 | 10B2O3 | - | 1:1 | 1:4 | polished | single wedge |

| 11.5 | 300 | 10B2O3 | - | 1:2 | 1:7 | polished | single wedge |

| 4.7 | 300 | 10B2O3 | - | 2:1 | 1:2.5 | polished | single wedge |

| 4.7 | 300 | 10B2O3 | - | 1:1 | 1:4 | polished | single wedge |

| 4.7 | 300 | 10B2O3 | - | 1:2 | 1:7 | polished | single wedge |

| 11.5 | 300 | Na10B5O8 | - | 2:1 | 1:2.3 | polished | single wedge |

| 11.5 | 300 | Na10B5O8 | - | 1:1 | 1:3.5 | polished | single wedge |

| 11.5 | 300 | Na10B5O8 | - | 1:2 | 1:6.1 | polished | single wedge |

| 4.7 | 300 | Na10B5O8 | - | 2:1 | 1:2.3 | polished | single wedge |

| 4.7 | 300 | Na10B5O8 | - | 1:1 | 1:3.5 | polished | single wedge |

| 4.7 | 300 | Na10B5O8 | - | 1:2 | 1:6.1 | polished | single wedge |

| 11.5 | 300 | natBN | - | 2:1 | 1:3.1 | polished | single wedge |

| 11.5 | 300 | natBN | - | 1:1 | 1:5.1 | polished | single wedge |

| 11.5 | 300 | natBN | - | 1:2 | 1:9.21 | polished | single wedge |

| 4.7 | 300 | natBN | - | 2:1 | 1:3.1 | polished | single wedge |

| 4.7 | 300 | natBN | - | 1:1 | 1:5.1 | polished | single wedge |

| 4.7 | 300 | natBN | - | 1:2 | 1:9.2 | polished | single wedge |

| 11.5 | 300 | 10B2O3 | - | 1:1 | 1:4 | white poly coating | single wedge |

| 11.5 | 300 | 10B2O3 | - | 1:1 | 1:4 | FSM | single wedge |

| 11.5 | 300 | 10B2O3 | - | 1:1 | 1:4 | matte | single wedge |

| 11.5 | 300 | 6LiF | - | 1:2 | 1:9.2 | matte black | single wedge |

| 6.7 | 300 | 6LiF | - | 1:2 | 1:9.2 | matte black | single wedge |

| 4.7 | 300 | 6LiF | - | 1:2 | 1:9.2 | matte black | single wedge |

| 11.5 | 300 | 6LiF | - | 1:2 | 1:9.2 | matte | single wedge |

| 6.7 | 300 | 6LiF | - | 1:2 | 1:9.2 | matte | single wedge |

| 4.7 | 300 | 6LiF | - | 1:2 | 1:9.2 | matte | single wedge |

| 11.5 | 300 | 10B2O3 | - | 1:1 | 1:4 | white poly sheet | single wedge |

| 4.7 | 20 | 10B2O3 | - | 2:1 | 1:2.5 | matte black | |

| 4.7 | 20 | 10B2O3 | - | 1:1 | 1:4 | matte black | |

| 4.7 | 20 | 10B2O3 | - | 1:2 | 1:7 | matte black | |

| 4.7 | 20 | Na10B5O8 | - | 2:1 | 1:2.3 | matte black | |

| 4.7 | 20 | Na10B5O8 | - | 1:1 | 1:3.5 | matte black | |

| 4.7 | 20 | Na10B5O8 | - | 1:2 | 1:6.1 | matte black | |

| 4.7 | 20 | natBN | - | 2:1 | 1:5.7 | matte black | |

| 4.7 | 20 | natBN | - | 1:1 | 1:10.4 | matte black | |

| 4.7 | 20 | natBN | - | 1:2 | 1:19.9 | matte black | |

| 4.7 | 20 | pure 10B | 10 | - | - | matte black | layered |

| 4.7 | 20 | 10B4C | 10 | - | - | matte black | layered |

| Converter Material | Converter to Scintillator Atomic Ratio (Boron atom to ZnS:Cu) | Resolution at 10% Modulation Transfer Function (MTF) (lp/mm) |

|---|---|---|

| 10B2O3 | 2:1 | 10.6 |

| 10B2O3 | 2:1 | 7.6 |

| 10B2O3 | 1:1 | 9.6 |

| 10B2O3 | 1:1 | 9.6 |

| 10B2O3 | 1:2 | 7.4 |

| 10B2O3 | 1:2 | 7.3 |

| 10NaB5O8 | 2:1 | 10.5 |

| 10NaB5O8 | 2:1 | 8.8 |

| 10NaB5O8 | 1:1 | 10.2 |

| 10NaB5O8 | 1:1 | 9.9 |

| 10NaB5O8 | 1:2 | 7.6 |

| 10NaB5O8 | 1:2 | 8.2 |

| natBN | 2:1 | 4.8 |

| natBN | 2:1 | 9.7 |

| natBN | 1:1 | 8.3 |

| natBN | 1:1 | 6.7 |

| natBN | 1:2 | 6.6 |

| natBN | 1:2 | 15.2 |

| Layered 10B4C | 10 μm 10B4C, 20 μm ZnS:Cu | 16.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chuirazzi, W.; Craft, A.; Schillinger, B.; Cool, S.; Tengattini, A. Boron-Based Neutron Scintillator Screens for Neutron Imaging. J. Imaging 2020, 6, 124. https://0-doi-org.brum.beds.ac.uk/10.3390/jimaging6110124

Chuirazzi W, Craft A, Schillinger B, Cool S, Tengattini A. Boron-Based Neutron Scintillator Screens for Neutron Imaging. Journal of Imaging. 2020; 6(11):124. https://0-doi-org.brum.beds.ac.uk/10.3390/jimaging6110124

Chicago/Turabian StyleChuirazzi, William, Aaron Craft, Burkhard Schillinger, Steven Cool, and Alessandro Tengattini. 2020. "Boron-Based Neutron Scintillator Screens for Neutron Imaging" Journal of Imaging 6, no. 11: 124. https://0-doi-org.brum.beds.ac.uk/10.3390/jimaging6110124