1. Introduction

Safety training on the hazards and tools within a given workplace is a necessity for an employee or general member to receive, so much so that it is a legislative requirement [

1,

2]. It is pivotal to ensure the safety of those working at their respective occupations, while, additionally, helping them become more skilled and prepared at their duties. At the University of Waterloo, this is evident in the policies set down by the administration to ensure the safety of students and faculty [

3]. The guidelines and current training offered by the university is sufficient to providing a basis for safety training [

4]. It cannot, however, fully encompass all of the procedures and operations of the team. In response, the University of Waterloo Alternative Fuels Team (UWAFT) has used systems safety management techniques and the principles of gamification to develop a more appropriate safety training system for the team.

Student teams at universities allow for engineering students to apply the principles that they have learned in the classroom and apply them to real world applications. These applications are often involving design and build phases and as such there can be significant safety risks associated with these activities. The safety risk is increased even higher with the fact that at times, there is limited faculty supervision for such teams in the work areas and laboratory spaces [

5]. This is unlike the labs associated with classes on campus which must have onsite staff, teaching assistants or faculty oversight when the physical work is being executed [

5].

In order to establish the safety training program, though, a formal analysis of the workplace hazards that team members will encounter must be completed to determine what experience level must be obtained before a member can perform a particular job. Systems safety management techniques are utilized to perform this analysis [

2]. These techniques are typically used by a design team in accordance with active safety objectives, determining what hazards a consumer will face and how to mitigate them but these techniques can be extended for use within the workplace [

6]. The management techniques are used to identify workplace hazards, overall classifications of respective risks and subsequently determine mitigation strategies to limit the risks of the hazards [

6].

To ensure the safety of personnel, certain safety objectives have to be established [

4,

7]. They are as follows:

- (1)

To safeguard personnel by preventing loss of life, injury and damage or loss of property;

- (2)

To ensure all UWAFT team members are committed to safety in the workplace; and

- (3)

To provide a process to train personnel on the different systems and operations being completed within the UWAFT facility.

The developed Safety Training Plan shall ensure that safety standards are established and that appropriate evaluation and reviews are accomplished on all facets of operations in UWAFT. Through this plan and its goals, a proper safety training program can be fully developed and implemented. The work being completed here, can then be subsequently extended to other student teams, creating a framework by which they can develop their own safety training program.

2. Background

2.1. Description of Past Safety Practices over Advanced Vehicle Technology Competition (AVTC) Participation

To date the team has participated in 6 Advanced Vehicle Technology competitions (AVTC), including the: Propane Vehicle Challenge, Ethanol Vehicle Challenge, Challenge X, EcoCAR1, EcoCAR2 and EcoCAR3.

In its infancy the team, consisted of only a few team members who largely had mechanical engineering backgrounds. The Propane and Ethanol Vehicle Challenges required members to modify vehicle engines to use alternative fuels and did not require any advanced controls or knowledge of high voltage to perform the necessary tasks. The safety training given to members relied largely on following the safety regimen given by the university, with some minor specialized training for specific tasks.

When participating in ChallengeX, the complexity of the project increased dramatically. The competition involved modifying a vehicle to operate using a hydrogen fuel cell and relied on high voltage batteries for energy storage. As the team was much smaller during this period of time, every person was trained on high voltage, compressed gas safety and vehicle controls. Unfortunately, this process was largely informal, not standardized and relied heavily on the team faculty to detail the safety hazard of using these systems. This posed a difficult problem when trying to schedule safety training sessions, as they had to fit with the particular professor’s schedule.

From EcoCAR1 to EcoCAR3 there was an even greater increase in the scope of the project, incorporating a wide variety of vehicle design aspects. With the number of team members rising, it became abundantly clear that it would be impossible to train everyone in the aspects of mechanical operations, high voltage safety and vehicle operational hazards. When working on projects for the vehicle, team members had to have a more in-depth level of understanding of the entire vehicle and all potential hazards present. In EcoCAR 1, a process was developed for understanding various vehicle hazards associated with mechanical, chemical, electrical and controls. This was expanded upon in EcoCAR2 with the development of High Voltage (HV) Training and the new regulations involved with operating the vehicle. Only team members who had become fully certified and understood all of the different vehicle operations and hazards would be able to drive the vehicle for test runs.

With these changes, though, it required people to attend the safety training lectures to be able to perform work on the vehicle, as opposed to before, which was in-person training on their first day. Safety training became a requirement for students to participate more actively with the team and it was viewed as a negative by the team members. As a result, attendance declined as students joined other teams. The other teams had (and still to this day) fewer requirements to participate in projects for their respective competitions, as they lacked the complexity of projects that UWAFT had to build. Thus, the number of properly trained personnel dwindled and an additional issue arose from a lack of knowledge transfer when the most senior team members graduated university.

In the EcoCAR3 competition, a new safety training program was devised to remedy these issues.

2.2. EcoCAR 3: Hybrid Electric Camaro Case Study

UWAFT has had a long tradition of competing in Advanced Vehicle Technology Competitions (AVTCs). The team has now embarked on participating in the EcoCAR 3 competition, sponsored by the US Department of Energy and General Motors. The task for the university students participating in the challenge is to complete the entire development process, from design to integration, completely re-engineering a stock V6 Camaro into a hybrid-electric vehicle. The goals of this challenge are: to improve fuel economy, reduce emissions and maintain performance of the vehicle. The competition runs over a four-year period, with various milestones having to be completed annually and at the end the teams pursue the goal of having a full operational hybrid electric vehicle.

The architecture chosen by the team and approved by the competition in early 2016, is a split parallel design. To provide torque to the vehicle an 850 cc snowmobile engine and two electric motors are being utilized. The design will also include a custom clutch and coupling systems to connect and disconnect the engine from the driveline when it is required. This is a highly complex design and has a large amount of risk attached to the project, especially when considering the implications of safety for the personnel involved. Working with such complex systems introduces inherent risk into the project, requiring that hazard and risk analyses be completed on the systems and the facility.

In order to best serve UWAFT personnel in completing tasks in a safe and effective manner, a safety training program was developed by Van Lanen et al. [

5]. The program established a series of required safety training activities for students to perform, so as to ensure their safety while working on projects with the team. In addition, the developed safety program provided a more formalized and standardized approach to safety, giving participants a much greater level of understanding of the entire vehicle.

From this initial safety program, additional improvements and revisions have been made to ensure that safety is maintained throughout the competition. This paper will detail the program’s initial development through the application of safety analysis techniques, development and dispersion of information relating to safety training activities, program objectives and revisions made to the program to counteract drawbacks seen from the initial launch.

2.3. Present Day University of Waterloo Alternative Fuels Team (UWAFT) Demographics

Since the beginning of EcoCAR 3, UWAFT has continued to grow its talent base, growing by 19% in year 3 alone. Since the beginning of the competition, 217 students have registered with the team. The bulk of the team is made up of engineering students but the UWAFT team has made strides to gather talented personnel from across both the University of Waterloo and Wilfrid Laurier University, recruiting members from many different faculties and backgrounds.

In terms of education levels, members are enrolled in either undergraduate or Masters-level programs. In former AVTCs, UWAFT has had one or two graduate students capable of taking leadership roles. In year 3 of EcoCAR 3 however, the number of core graduate students has drastically risen to 14, with a total of 17 on the team as a whole. This has allowed the team to now have 59 undergraduates for every 5 graduate students. Allowing for greater leadership, knowledge transfer and providing supervision and guidance to students

Figure 1 details the background of the team based on education level.

The core team has seen an 18% increase in females, with a 22% increase in females overall among team members. Gender percentages for the team can be seen in

Figure 2.

2.4. Occupational Health and Safety Act (OHSA)

The Occupational Health and Safety Act (OHSA) mandates that an employer must provide the necessary safety training to their employees so that they will be able to perform their job safely [

2]. Documentation must also be provided showing that the employee has completed the necessary training to perform their duties [

1,

2]. All workers are covered under the OHSA and must receive proper training. Although a worker is classified as someone who receives monetary compensation [

7], the University has policies which state that students are also classified as workers [

8,

9]. Thus, students are covered under OHSA and require the necessary safety training to perform duties with the team. In Ontario, according to Ontario Regulation 297/13, workers of any type require at the very least a basic safety training that covers the following:

- (1)

The duties and rights of workers under the Act.

- (2)

The duties and rights of employers and supervisors under the Act.

- (3)

The roles of health and safety representatives and joint health and safety committees under the Act.

- (4)

The roles of the Ministry, the Workplace Safety and Insurance Board and so forth, with respect to occupational health and safety.

- (5)

Common workplace hazards.

- (6)

WHMIS safety training with respect to information and instruction on controlled products.

- (7)

In designing a safety program this list forms a basis by which UWAFT can form an effective safety training regimen. The most pertinent task is to identify the common workplace hazards using a variety of systems safety techniques in order to perform a Job Safety Analysis [

7]. The safety analysis will identify the most hazardous tasks and in turn dedicated safety training can be given to personnel so they can become informed and be able to perform those tasks safely. This training will provide additional information in addition to providing an understanding of the broad safety requirements currently in place at facilities.

2.5. Job Safety Analysis

Job Safety Analyses (JSAs), also referred to as job hazard analyses (JHAs) and job hazard breakdowns, are performed in order to integrate, into the daily work life of employees, proper health and safety principles and practices [

7,

8]. This is focused directly on the work completed by personnel in the workplace, as well as, the overall facility. At each step of a particular operation, the goal is to identify potential hazards and to recommend the safest way to do the job [

7].

Safety is an integral part of every job and should be the focus when completing work. Providing personnel with the proper training on equipment and operations reduces the chances of a hazard occurring [

1]. With the team, there are many operations that need to be completed on the vehicle in order to ensure that the goals of the overall project are accomplished. Also, as we can be considered a “small business,” there are only so many resources that the team can draw upon to complete these assessments. Thus, tasks need to be effectively analyzed from the first point of contact.

JSAs are not suitable for jobs defined too broadly, for example, “overhauling an engine” [

8]. Thus, tasks need to be slightly broken down into sub-tasks but as there is not a large number of resources to draw upon and students require training on said tasks. To rectify this a broadly defined task can be better understood by applying a hazards analysis to individual components that make up the entire system. This structure will be beneficial for developing a safety training program [

7]

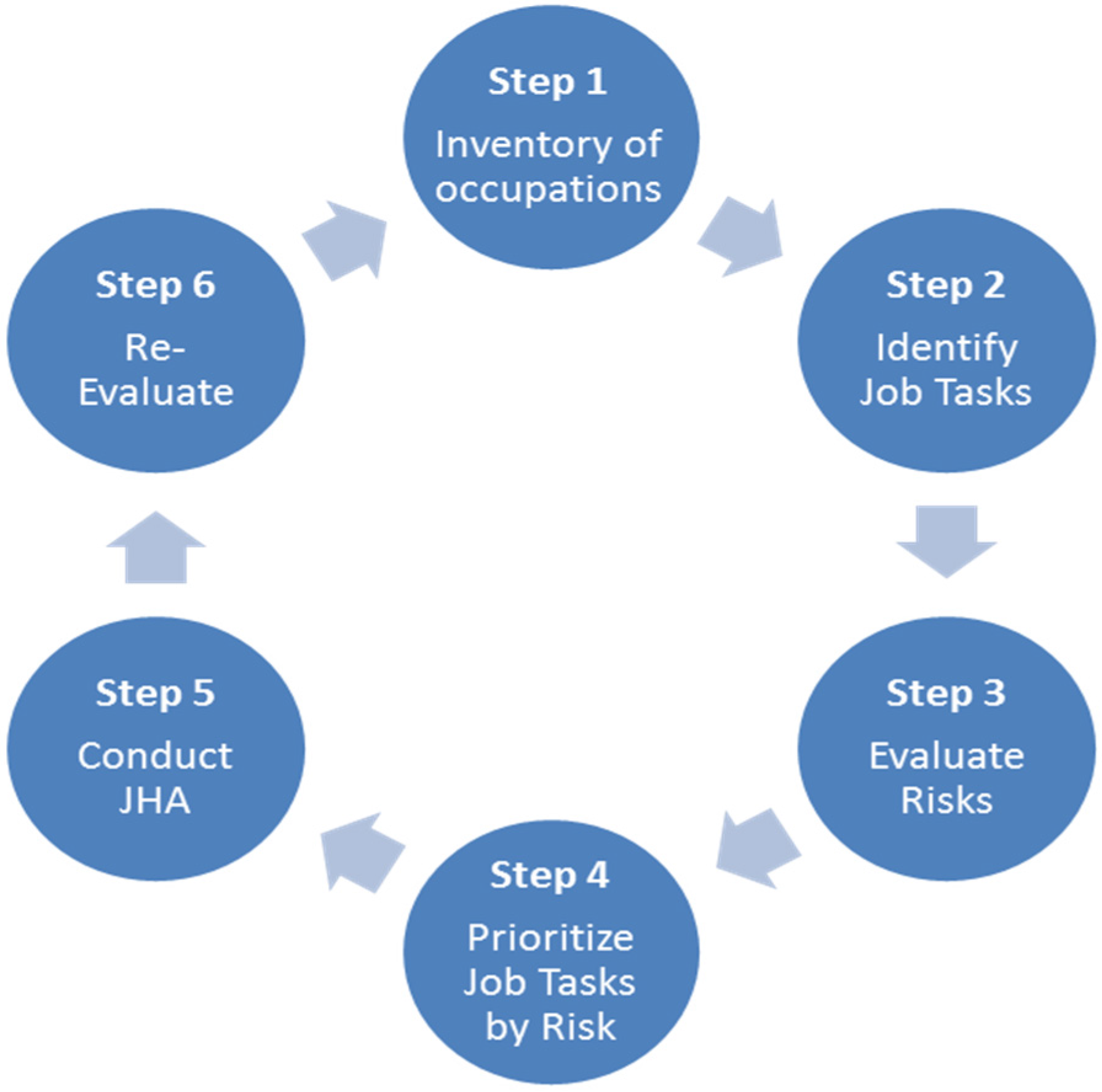

Figure 3 depicts the process for completing a JSA in industry.

2.6. Hierarchal Task Analysis (HTA)

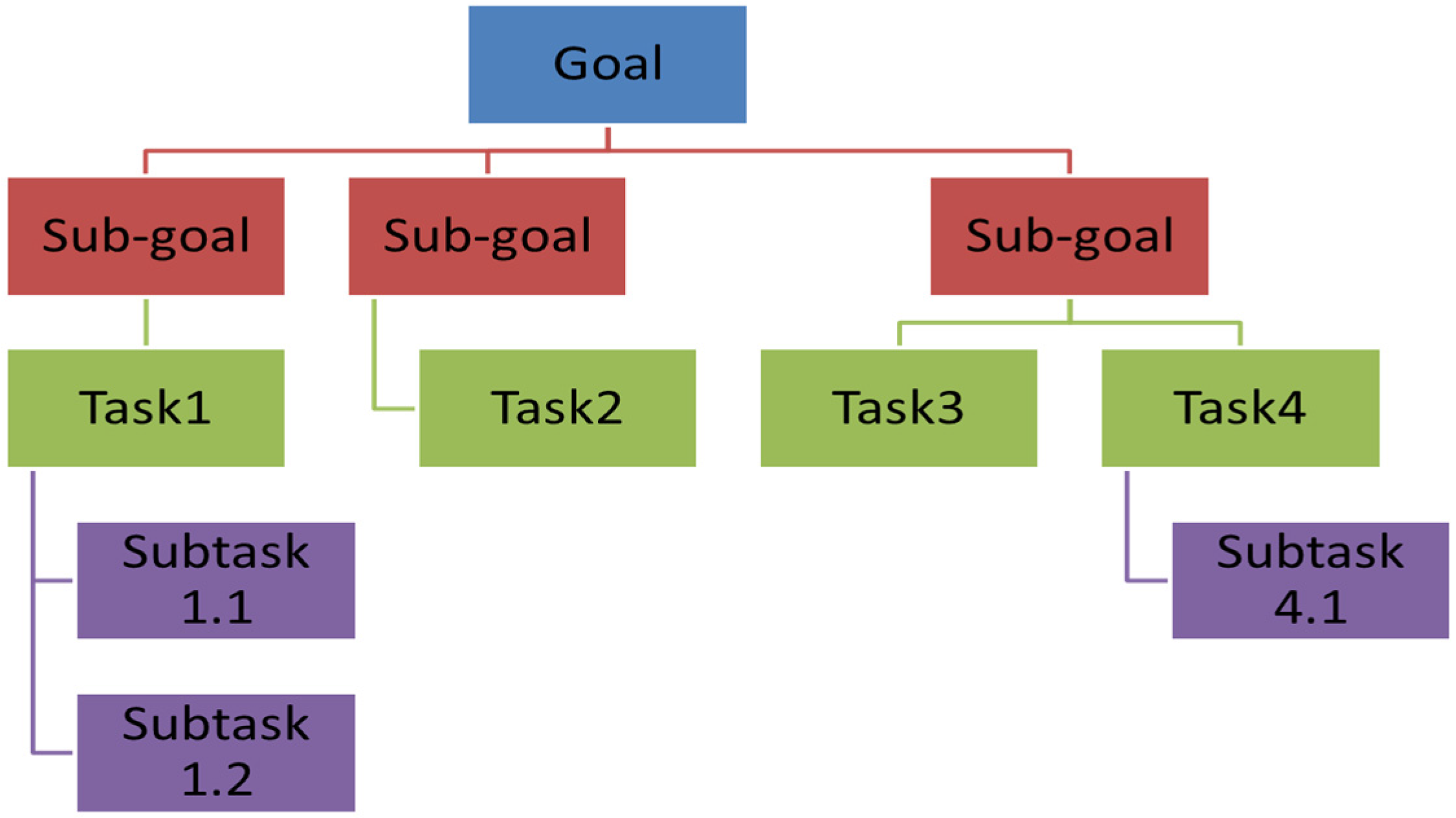

In order to identify the various tasks performed by workers for a particular project or job, a Hierarchical task analysis (HTA) can be utilized. An HTA is one of the most widely used forms of task analysis, breaking down a goal of the job into a hierarchy of sub-goals that are completed by performing a series of tasks and subtasks [

9]. In order to complete an HTA the following steps are performed [

10]:

- (1)

Define the task under investigation;

- (2)

Collect the necessary data for the task;

- (3)

Define the overall task goal;

- (4)

Determine the next level of sub-goals by breaking down the overall goal and continue to do so until all operations are identified;

- (5)

And define plans to describe how to perform the operations in each sub-goal level of the hierarchy.

An example of how an HTA can be developed is provided in

Figure 4:

2.7. Hazard Analysis and Risk Assessment (HARA)

A Hazard Analysis and Risk Assessment (HARA) is a technique that aids in identifying hazards associated with a particular job, operation, or task before they occur. The analysis focuses on the relationship between the worker, the task, the tools and the work environment [

9,

10]. Upon identification, the hazards are given an appropriate risk rating and subsequent steps are taken to eliminate or reduce them to an acceptable risk level [

11].

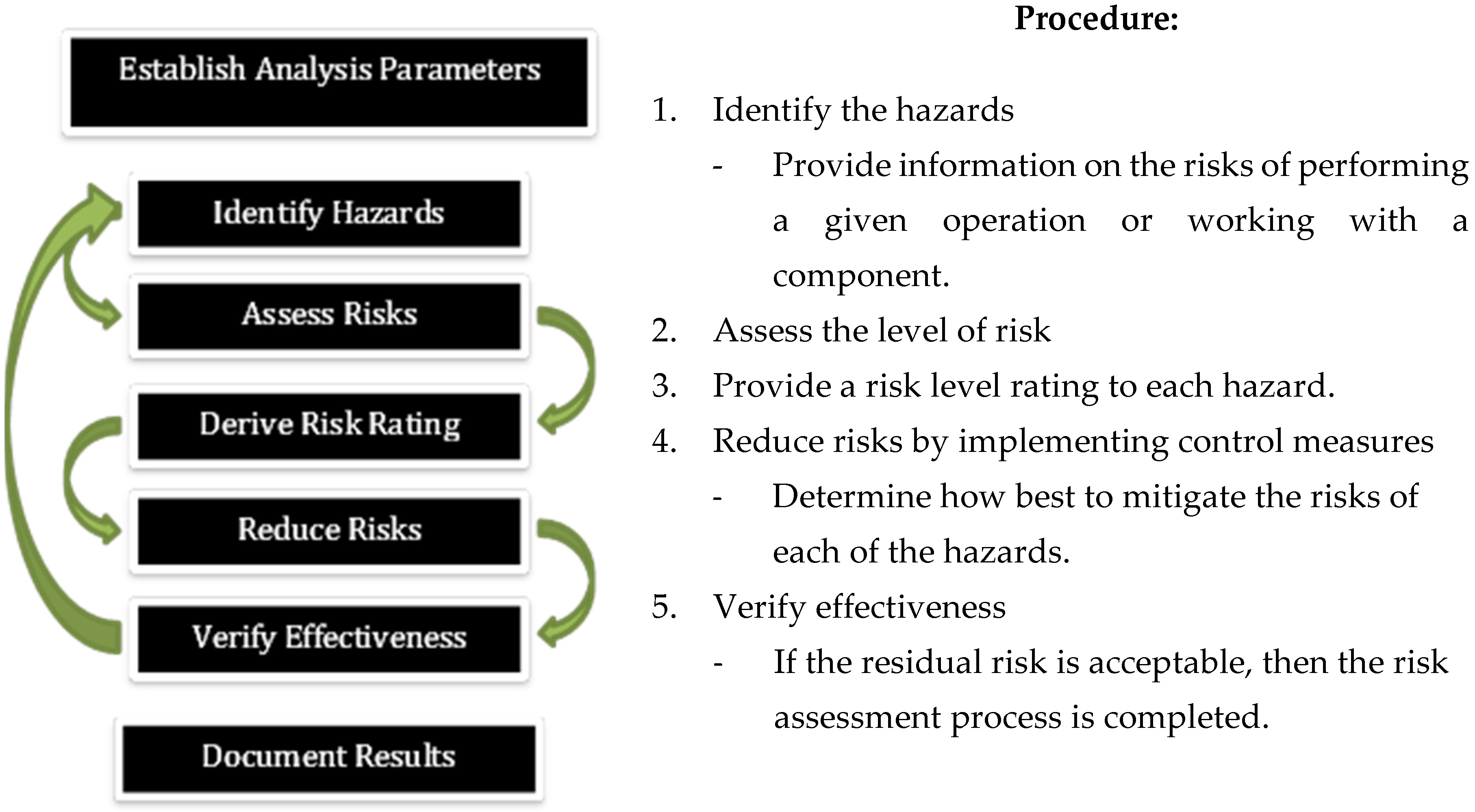

In order to establish proper safety protocols for given operations, the associated hazards need to be determined [

10]. Defining all possible hazards though can be quite difficult to complete, especially if systems are unfamiliar to personnel. This process involves performing research and literature reviews to better understand the hazards associated with each component and operation. The process of performing Hazard Analysis and Risk Assessment is as follows (detailed in

Figure 5) [

10]:

By using this engineering tool, a thorough assessment of the possible hazards and their associated risks can be developed. This will prompt alternative design solutions to mitigate or control the risks to an acceptable level.

It must be noted, though, that any hazard, which is not identified, will not be addressed by safety measures and will not be detected during testing. Hazards not identified during this analysis can create substantial risk to users of the design. Thus, obtaining as much information regarding a system and its components is pivotal to developing the HARA assessment.

2.8. Automotive Safety Integrity Level (ASIL)

Once identified, the hazards in the workplace can be quantified or classified by performing risk assessments, such as an Automotive Safety Integrity (ASIL) assessment [

6,

12]. An ASIL assessment is a risk classification scheme defined by the ISO 26262—Functional Safety for Road Vehicles standard [

3,

12]. The system uses the exposure, controllability and severity ratings determined for a particular hazard and links them to a corresponding ASIL rating [

12]. ASIL ratings are given an alphabetical rating, with A being the least hazardous and D being the most. Although ASIL ratings are typically applied to risks to the driver when operating a vehicle, they can also be applied to risks to a person who is performing a particular job or operation.

Determining the level of exposure, controllability and severity is very similar to the process of determining severity, occurrence and detection for a Design Failure Modes and Effects Analysis (DFMEA). Exposure indicates the probability of a human‘s exposure to a hazard; severity is, again, the extent to how damaging a failure can be; and controllability is the capability of systems to mitigate, or prevent, the hazard from occurring. An associated ranking is given to a hazard based on the conditions.

Table 1 outlines the specifications for each of the levels of individual parameters [

13,

14].

Typically, in order to obtain the exact ASIL rating, a matrix is used to align the three conditions based on their individual specifications [

6,

14]. For this analysis though a numbering system is established to provide a number to the exposure, controllability and severity ratings. The subsequent product of these three values will then give a number that will correspond to a particular ASIL rating.

3. Methodology

The process outlined in this work is to assess current and potential hazards in the UWAFT facility and determine how best to mitigate them, in order to safeguard students working on the project. Utilizing the information collected from the hazard analysis of the various duties to be completed by UWAFT personnel, an effective and informative safety training program can be developed. Also, by determining the highest risk hazards within the team, resources for the project can be appropriately allocated. This is important as they are limited and team must begin work on the vehicle post haste to meet the deadlines of the competition. Although addressing all the possible risks is of importance and will be addressed, specific attention will be dedicated to the higher risk hazards.

3.1. Job Safety Analysis (JSA) for UWAFT Team

Based on UWAFT’s assessment of current resources, the following “refined” JSA procedure, depicted in

Figure 6, is being proposed to assess tasks and their hazards.

The first step in the refined JSA is to distinguish the different types of jobs (Step 1). By doing this, associated hazards can be more easily compiled for a particular job. Job tasks can be grouped under the different occupation types (Step 2). The job tasks should only be an overview of the work being completed and should not go into great detail about every individual detail. Although this is not as beneficial providing a detailed overview of all job tasks and then, subsequently, defining hazards for each job task (Step 3) the risk assessment will be able to address the most hazardous risks (Step 4). The most hazardous risks will then be separated in Step 5, where they are grouped by occupation type and risk level.

3.2. Development of Safety Training Program

The job safety analysis allows for the assessment of workplace operations within UWAFT, providing an effective method for assessing workplace hazards and segregation of tasks based on groups and levels. In order to develop the safety training program, this initial information must be taken and refined using the principles of gamification.

Gamification refers to the process of applying game playing elements to other areas of activity [

1]. UWAFT can apply these principles into the development of an effective safety training program, which uses a level based system. By attaining certain requirements members can move up through the levels to gain the ability to work on more advanced systems. For instance, as a hypothetical example to move from Level 2 to Level 3, a certain number of hours at that level need to be accrued to show that the student gains experience at performing “Level 2” work before he or she can receive training on the next level. This is to ensure experience, on use of a variety of tools and systems, has been obtained by students before beginning Level 3 activities.

In the training system proposed here, students will be able to observe their progress based on the level of training they have reached and be able to understand the requirements they will need to reach subsequent levels in the program. With each level comes more responsibilities and status in the team, increasing the incentive for more members to “level up” in the organization. These levels track students so that as they increase their training level they can increase their hands-on involvement with the design project.

To establish the levels of the safety training program, the information gathered from the job safety analysis and built-in system safety management techniques, must be relied upon [

2].

4. Results and Discussion

In order to ensure teams competing in the competition maintain a safe work environment, the organizers provide safety training and expert advice (in the form of webinars, in person safety talks and access to team mentors from industry partners). Students taking on supervisory roles must learn and understand the content provided so as to ensure they are capable of identifying hazards and instituting mitigation actions. Any of the members can establish risk levels for the tasks, however, this role is largely fulfilled by the systems safety manager who has received the most training in safety awareness by the organizers. The other supervisors then act as overseers who approve the risk level rankings proposed by the manager.

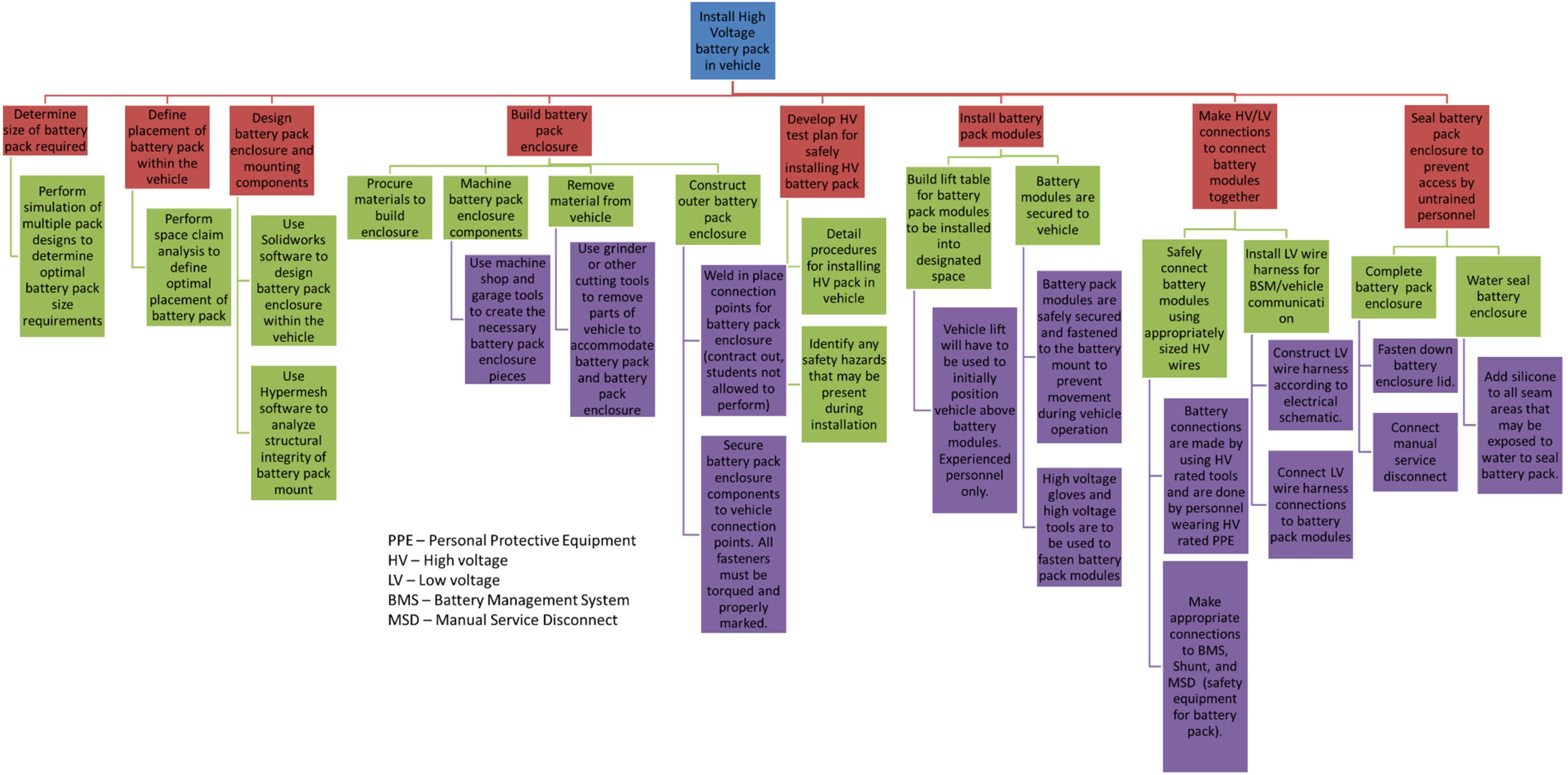

Corresponding to the JSA process depicted in

Figure 6, a generalized list of all tasks performed by UWAFT personnel was developed. The list of tasks depicted in

Figure 7 was generated by performing a hierarchal task analysis (HTA) as described in

Section 2.6. An example of the performed HTA is provided in

Figure A1 in the

Appendix A.

From this list of tasks appropriate hazard analyses were developed based on the task description and potential components involved.

4.1. Establishing Hazard Analysis Documentation

In order to ensure that a thorough hazard analysis is completed to cover all of the necessary steps, a formal HARA document is developed. Establishing a HARA safety document aids in streamlining the process and allows supervisors to maintain consistency when performing analyses on different tasks. This is an important document for the team to have and use as it will effectively document the potential dangers to personnel. The document involves four steps: hazard identification, risk assessment, establishment of control measures and performing a review for current efficacy.

Hazard identification in the document begins with a general identification of potential hazards, such as: chemicals, energy systems, facilities and machinery. Personnel utilize this checklist as a starting point for identifying the potential hazards that may be encountered but can also add additional hazards that are unique to the task. The job is to determine what can go wrong. This is then followed up with a preliminary assessment of the risk level of each of the respective hazards. The “likelihood” of the hazard occurring and the “consequence(s)” of it occurring are estimated and then the two together relate to a subsequent risk level levels [

15].

Table 2 describes the risk level table used to establish the risk levels [

16] and

Table 3 gives the qualifications for each of the risk levels [

15].

It should be noted that the above methodology is very general and relies on a fair amount of subjectivity in the analysis process. For these reasons, it is used mostly to provide an initial risk assessment, with the ASIL assessment proceeding this analysis being the primary establisher of the risk level for a given task.

After establishing an initial assessment of the risks involved in the task and then the subsequent risk level, appropriate mitigation actions. For this paper, the necessary control measures involve developing the safety training program to effectively address the risks and prepare team members for the process on how to mitigate them. Thus, an evaluation of the risks associated with each task is paramount for assessing which ones will require more advanced training and which will not.

Table 4 gives an example of a HARA analysis being utilized for the task of dynamometer testing of the engine system. The hazards/risks of using the system are listed on the left. The associated risk levels for each hazard are determined and finally control measures to ensure the hazards do not occur are listed for implementation during the task to prevent or mitigate the hazards.

4.2. ASIL Analysis

The ASIL analysis yielded the following results as depicted in

Figure 8.

Based on the ASIL classification, activities that were deemed to have low risk levels, class A, were mostly involved with completing design and controls work but not actually having to interact with the vehicle or the design bay. These tasks have very low potentials for hazards to occur resulting in very low ratings across all of the metrics.

At the opposite end, the highest risk activities, class D, were found to be operation of engine, working on HV components and building and testing of chiller system. Many of the tasks associated with these systems involve performing advanced mechanical and electrical work. Improper use of the equipment involved with these systems can easily result in many very severe hazards occurring to personnel. Also, as many of the tasks outlined are similar as those determined in the risk Level C ranking of the ASIL analysis, it is determined that personnel will need to receive specialized training for performing work on tasks risk Level C or higher.

Tasks that involved utilizing basic tools, performing basic installation in the vehicle and working on the low voltage systems were found to be grouped into the B risk level. Most of the tasks are highly controllable through simply providing some basic training or through proper direction by reading the SOPs associated with the tools.

ASIL assessments quantify the severity of the potential hazards faced by UWAFT team members. [

4] By grouping these hazards under individual ratings (using ASIL value ranges), operations involving these hazards can be allocated to the members with the appropriate amount of experience. For instance, an operation with an accompanying hazard ASIL rating of A can be performed by any safety level, whereas an operation with a hazard ASIL rating of C or higher will require a team member to have a safety level close to the top of the hierarchy (or above) to be performed safely.

Based on this segregation, of each of the tasks that can be performed by UWAFT members by their risk levels, the following training hierarchical regimen was developed to match the ASIL ratings and tasks contained within each rating with the appropriate safety level that a member must reach to perform said task

5. Safety Training Program Initial Design

5.1. Development of Tiered Safety Training Program

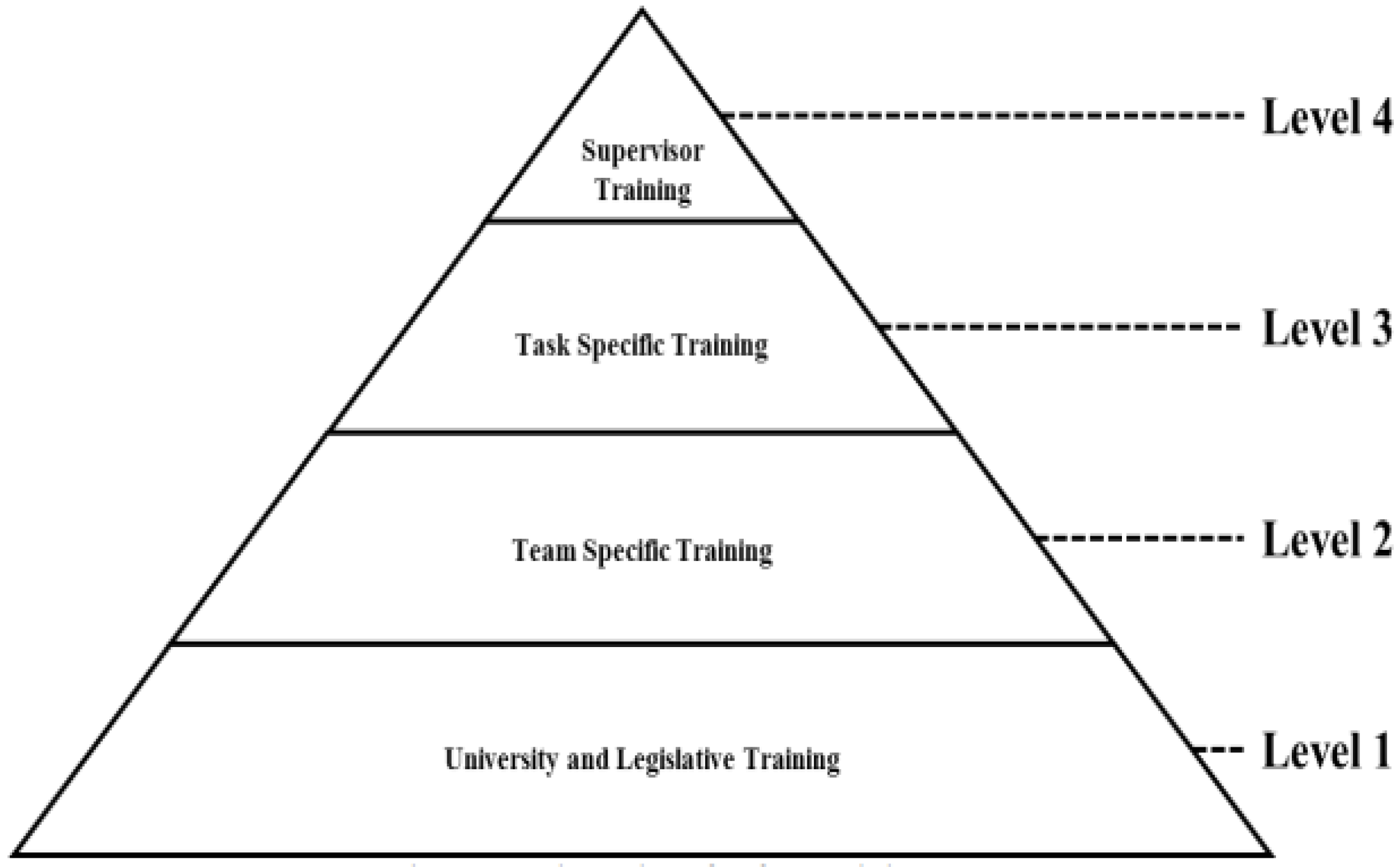

As displayed in

Figure 7, there are a variety of tasks and systems within the UWAFT facility that carry varying degrees of risk of a hazard occurring to personnel. Based on the hazard assessment, a level-based safety training program has been developed using the principles of gamification.

An initial safety program was developed and implemented in Year 1 and Year 2 of the EcoCAR3 competition in the UWAFT facility. The development of the program was based upon the completed JSA, as described in

Figure 6. The program is a progressive multi-tier system that is separated into four levels, which goes from the most basic legislative requirement all the way to the necessary training that a supervisor must receive to be in a “lead” position. At each tier, students are educated on systems that require increasingly more rigorous safety training and mandated to complete a required number of hours working on activities at that tier. This system is designed such that students can be eased into the team while meeting specific safety targets, increasing the overall team safety standard and motivating them to become more involved.

Figure 9 depicts the initial safety program.

5.1.1. Level One Safety Training

As described previously, the University of Waterloo has guidelines to provide a basis for safety training for student groups. As such, Level One training relies on utilizing current university modules pertaining to workers and students, informing students as to a general overview on recognizing hazards in the workplace and their rights as a worker. The training modules are performed online and must be completed by all members before being able to work with the team. New students can become familiarized with the facilities and operations before moving to the next level of training.

In addition to the safety training, students must be aware of all emergency procedures outlined in team documentation, where the documentation exists and sign all Non-Disclosure Agreements. Signing the NDAs allows students access to all information on computer servers and use any team computers that have specific software pertinent to various tasks. At this level, though, the training only covers awareness of hazards and students are not able to perform tasks involving hands-on work with the vehicle systems. It is only after the students have passed Level 2 safety training that they will be able to work safely on specific equipment, nor safe work and operating procedures.

5.1.2. Level Two Safety Training

In order to be able to perform “hands-on” work on the vehicle, team members must complete safety training with regards to the hazards associated with the use of specific tools and equipment that they will be using for the various projects. The training provided is meant to be introductory and the first step to more active team participation.

The training consists of three modules including: general shop safety and facilities, basic electrical safety and general mechanical work and procedures. These training modules are presented to students by team supervisors with the necessary experience to teach them. They provide the foundation for team members to further build upon their training with the team by being able to work on and familiarize themselves with the vehicle and tools. All activities performed by level 2 members are supervised by personnel Level 3 (or higher) team members

The first module is a training session on general shop safety and facilities. This session includes basic training on Personal Protective Equipment (PPE), shop layout, emergency equipment and exits and other pertinent information to day-to-day hands-on activities. The second module is on basic electrical safety. This module covers information for low voltage (12V) electrical work, including best practices and safe operating procedures. The final module is on general mechanical work and procedures, covering commonly used tools and best practices. All modules together form a foundation for team specific training that address risk for common activities on the team.

5.1.3. Level Three Safety Training

After meeting the necessary requirements at Level 2 safety training, personnel can receive Level 3 training. This level of training is meant to give students more in-depth knowledge on specific tasks that are completed on the student team. Level three training becomes much more specialized and is meant for students who have proven their dedication to the team. These students are therefore trusted with higher risk work within UWAFT including advanced mechanical work, engine emissions and hazards and high voltage.

The training involves three aspects: advanced mechanical, engine emissions and hazards and above all High Voltage training. The very nature of the competition involves working with advanced powertrain components (engine, motors, transmissions and so forth) for hybrid drivetrains, as well as, components that utilize voltages that are near or are high voltages. The provided training will allow students to be able to perform more advanced activities, such as: engine dynamometer testing to determine engine efficiencies, as well as, designing and building the battery pack to be integrated into the vehicle to provide the necessary power.

Due to the advanced nature of activities specified under level 3 training, full level 3 certification requires completion of an additional 15 h of practical hands-on work with the team in addition to the training requirements. This safety training level requires both in-person training in the form of presentations and hands-on training to gain the necessary skills to work at this level.

5.1.4. Level Four Safety Training

In order for work on the vehicle to be performed safely and be properly inspected as projects progress, members must be properly supervised by trained personnel. Members who have risen to the level of supervisor must have deep knowledge of the work being performed by members at the lower levels and have completed all the necessary safety training modules. At level four students have reached the highest level of training and are responsible for delegating work and ensuring that it is safely completed. Students who are to become supervisors for the team must first be approved by the faculty advisor in addition to meeting the requirements.

The requirements for Level 4 training are: completion of the safety training modules for supervisors (provided at the university level via online modules), as well as completion of six hours of high voltage work, six hours of mechanical work and eight hours of aiding an already certified level four student in the supervision of group work. These requirements promote the well roundedness of the candidate(s) and ensure that the student(s) understands all of the safety risks involved with the project and the proper protocols for mitigating them.

5.2. Implementation of Safety Training Program

There are three main components required to fully implement this type of safety training program into the team dynamic:

- (1)

Documentation to detail proof of completion of the training, hours and level achieved for each student; and,

- (2)

Documentation of the safety training program modules,

- (3)

Visual representation to aid with the motivation and gamification of the safety program.

Documentation is a very important aspect of the training program as it allows for the monitoring and tracking of a team member’s training. At each tier, there are forms required to be signed by supervisory personnel to ensure that students have completed the necessary safety training modules and the hour requirements. These signoff sheets are stored in a Personnel Training binder detailing the members who have completed safety training at each level. If an incident were to occur on campus, the team will have the supporting documentation to confirm that the student completed the necessary training modules to complete the work.

In accordance with competition procedures, a facilities binder must be created and prominently displayed within the student team’s facilities. The facilities binder contains all of the information pertaining to the safety program. This includes: emergency response plans and procedures, workplace hazards, best practices, safe operating procedures (SOPs), material safety data sheets (MSDSs), as well as, all training documentation. This documentation is only useful for students to use as a reference but also can be used by existing team members for training purposes. To ensure accuracy the documentation must be kept up to date.

While the documentation provides the records for completion of training, the visual representation, of team personnel traversing the tiers of the safety training, is depicted in the safety board,

Figure 10. As part of the gamification integration into the program, students see which level they are and want to improve to attain a higher level. The board, also, serves as a visual identifier for team leads to know what training has been completed by each individual member.

5.3. Successes of the Initial Program

As outlined in a previous case study completed by Van Lanen et al., regarding the development of the safety training program, UWAFT was able to attain a large amount of success [

5]. Over 100 students had participated in varying levels with the team having 29 level one students, 27 level two students, 11 level three students and 6 level four students [

5].

A number of specific benefits have been seen from its initial launch. First, the system allowed for the easy procurement of information by UWAFT administrators and provided a more organized system to track team member progression through the team. The information is all stored in a centralized location, providing ease of access.

Second, training was being conducted on a more frequent basis and there was a much greater push by members to receive training. The system has helped to encourage growth within the team, pushing younger members to get more involved and progress through the safety training levels. This is a significant change from the previous years, in which students deemed safety training as a negative requirement but with the introduction of this new program there has been a psychological shift in the students’ mindsets.

Finally, with a standardized system in place, all members of the team receive the required baseline hazard awareness and educational training on the vehicle. A clearer picture had been defined on what the team wanted to accomplish in terms of safety training and helped to harbor in a swifter method for improving knowledge transfer for training.

5.4. Drawbacks to Initial Safety Training Program

A potential downfall of the programs is that the system allows for students to gain hours from completing even some minor mechanical tasks. If a student simply completes simple tasks and does not immerse themselves in other projects on the vehicle they can still acquire the appropriate number of hours to graduate to the next safety level but only have a narrow understanding of the vehicle as a whole. Thus, it was seen that a number of students were able to attain the level certification with ease. This was a major drawback for both the program and the team as a whole, as a number of untrained personnel could be potentially given tasks that they had little to no understanding of. Lack of experience could then possibly lead to injury or even death depending on the severity of the hazard experienced whilst performing the task.

It has always been difficult for the UWAFT team to define overall student involvement. Separating regular student members from core members can be quite difficult. The safety program provided an initial methodology for doing this. Level 3 and Level 4 team members were considered the core team members because of the training that they had received, which allowed them to work on more difficult systems. As indicated previously, though, some students were able to graduate to the next level by only performing a narrow set of projects and would show minimal initiative as the term progressed. Defining students’ involvement with the team aids in meeting many of the goals of the competition for defining core members and, above all, allowing team leads to have an exact understanding of which personnel can participate in more advanced projects and who would be best suited based on past projects being completed. The safety training system needs to better represent these requirements in this regard.

Finally, additional incentives need to be added to the training program to further increase user interest. Based on the testimonials from the Term End UWAFT Feedback survey, although the skills development in the safety training program has been beneficial, team members are looking for additional criteria to establish their roles on the team. By establishing this path, they better understand their role on the team, besides just being on a particular sub-team and can use the information for their own portfolio when applying to jobs and other such things.

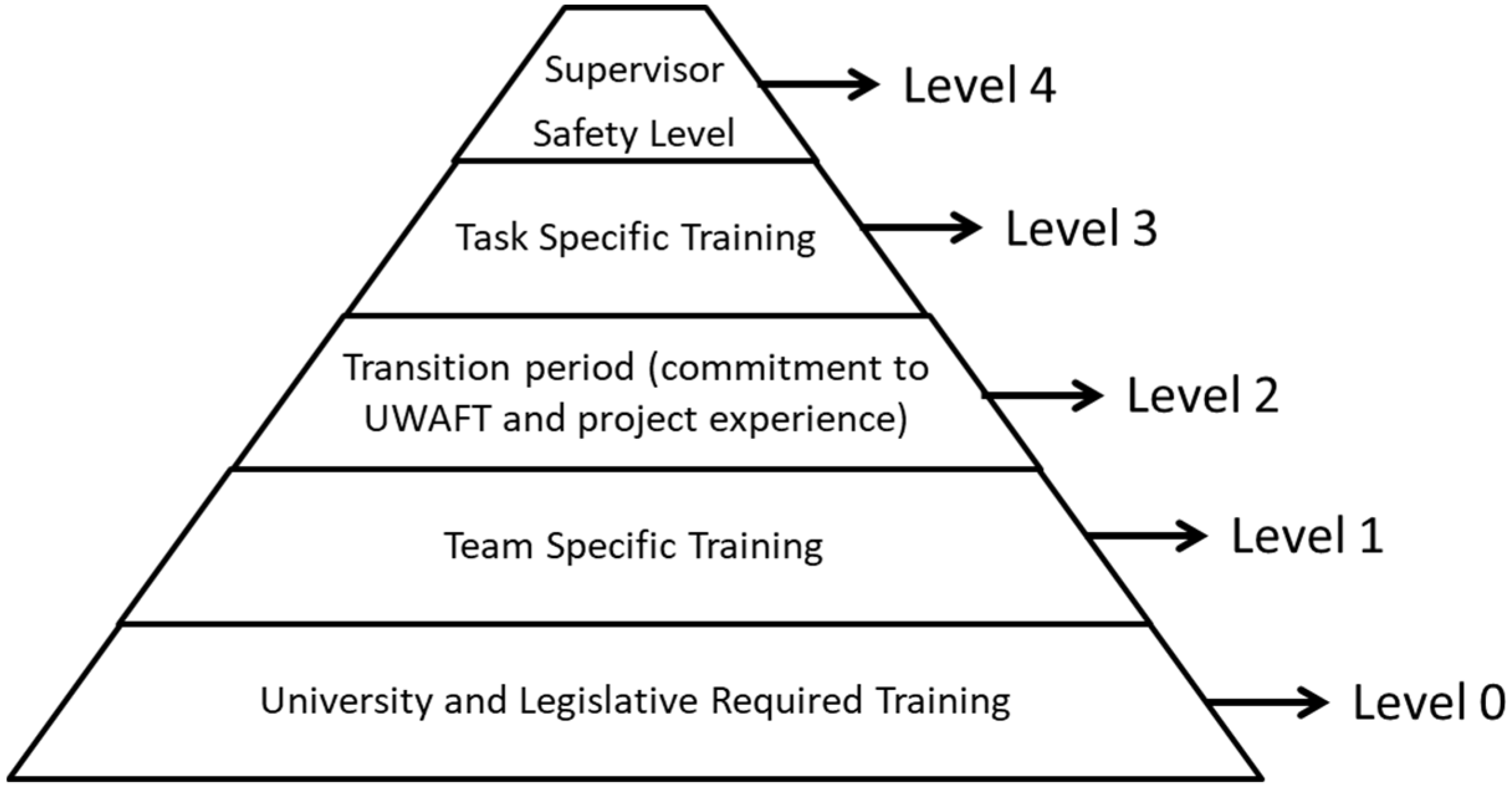

6. Development of New Tier System and Incentive Program

In order to increase the effectiveness of the training program and ensure the maintenance of a safe workplace environment for students a new tier system was developed along with an associated incentive program to increase user involvement. The following modifications to the initial program are described in this section in order to improve upon the previous safety program.

UWAFT will still retain the same leveling up system as that has resulted in greater member interest to excel to the top tier but the levels shall now be changed. A “Level 0” tier has been added to the pyramid. The requirements and tasks outlined in Level 1 will now become a part of Level 0 training. As this forms the basis of the minimum amount of training required by the University, students must have this before anything else. As a result, Level 2 training will shift and become the foundations for Level 1 training. To ensure consistency in providing this training, in-person presentations have been substituted for training videos for the modules. Members looking to work on the vehicle will have to complete the associated modules described previously. Once completed and signed off on by the Safety Manager, the students can begin working on the vehicle but only under direct supervision by a team lead.

The fifteen hour graduation requirement to be able to take Level 3 training will no longer be available. Instead, in order to graduate from Level 1 to Level 2, team members will be recommended by the team leads for advancement based on merits. Once the particular team member has gained enough experience performing basic tasks they will be able to graduate to Level 2, where they will be able to perform more advanced projects with supervisors having to provide less supervision for them to perform the tasks. Team members will be advised to keep a portfolio on completed projects that they had assisted in completing to assist team leads. In addition, as a final requirement the students will have to present the topic that they worked on to qualify for advancement to Level 2 during the team’s general meetings.

Safety levels, Levels 3 and 4 will remain at their current positions in the tier system, however, being able to graduate from Level 2 to Level 3, will require much more rigorous requirements compared to the graduation procedure as from Level 1 to Level 2. Students will have to provide proof of completion of a variety of projects to detail their level of understanding of the vehicle, the powertrain and other key components. The team leads will give the decision as to who will graduate to the next stage based on the students’ merits and expected potential. With this new procedure, another problem will be solved, which the threat of students is being unable to continue providing assistance to the team due to their academic requirements. UWAFT, along with all student teams at the University of Waterloo, promote academics first but team member turnout is a problem when considering the amount of time invested into training them to complete projects with UWAFT. Time and energy to train these students will no longer be wasted.

In addition, as per the competition recommendations High Voltage certification was separated from level three task training. The possibility of too many students learning high voltage design without having a solid knowledge base to draw from can potentially lead to serious injury or death. By instituting this additional program limitation and having control of it given to the supervisors (core team leads) this will limit the number of people with the certification and ensure that safety is maintained at all times with these components.

Figure 11 details the new tier system with the addition of Level 0.

The new tier system will also allow UWAFT to effectively assess, which members are core members. The system will also provide a “ranking” for each student besides just having a number for safety level. Having defined titles will aid students on both the team definition and with career building by having a title that defines them as more than just a “member.” Also, in accordance with the competition deliverables, UWAFT must detail how many of its team members are core members. Under the old system this was not easy to assess. With the ranking system and the requirement of needing to provide a dossier of completed projects, UWAFT team leads can better familiarize themselves with the team members who are more active and can be considered core. The ranking system is defined in

Table 5:

As previously mentioned, the team is largely composed of engineering undergraduate students. In accordance with the requirements of their respective programs, students must obtain and participate in at least five coop placements. Many of the students are coming just out of high school and typically lack experience working in the engineering field. As a result, they struggle to attain coop employment. Joining student teams not only provides a place for students to express their own creativity but it also allows them to gain practical engineering skills to use in the workplace. These skills can be applied to their resume to show prospective employers the applicable skills that they have gained, with more advanced skills being gained as they “level up” in the safety program. Also, the addition of titles to the safety levels present students with additional incentive to level up in the program, as they can add the title to their resume. Thus, instead of just being “a member” of the team they can potentially be seen as a “working” or “core” member if they strive for it. This policy leads back into the gamification potential of the system.

6.1. Updating Procedures on Safety Training and Documentation Maintenance

Documents will now all be kept digitally on the university server to ensure that they are not lost. This will cut down on the number of files that need to be kept in paper format for personnel and cut down on paper requirements. This is both a more economic and a more environmentally sustainable position to take as an AVTC team. Also, Level 1 training will now be given as training videos as opposed to in person training. Team members looking to receive Level 1 training will watch the videos under supervision by UWAFT team lead personnel. This will allow other team leads to give consistent training to each team member even when the Safety Manager is unable to.

6.2. Implementation at UWAFT and Extending to Other Student Teams

The new safety training process has received much praise from its student members and its implementation into UWAFT’s procedures has been quite successful. To date, over 280 students have participated in varying levels. The team currently has 6 level one students, 149 level two students, 5 level three students and 5 level four students. The gamification aspect of the system has led to many students seeking to aspire to climb the safety leadership ladder, with many students inquiring on potential safety training aspects and training dates. Also, as there are new requirements to reach the higher levels of the tiered structure, this has decreased the number of members that have reached them. Team members who are capable of moving to the next stages of training are more aware of the hazards and the vehicle systems as a whole and are better prepared to undertake the work required to be performed at these stages.

Students have shown great adeptness for understanding risks and hazards in the garage and have ensured to take the appropriate measures to protect themselves while performing various tasks. As a result, there have been no major incidents recorded at the UWAFT facility. This is not to suggest that the program itself has resulted in this statistic but the impact of having a well-designed safety program prevalently displayed has ensured that students understand that UWAFT places safety as the highest priority and this has been reflected in their behavior in the garage.

It is not just the students who have been impacted by the safety program. Faculty members have been quite impressed by the team’s safety program and have sought to adopt sections of it into other student teams, siting their own respective gaps in training and the need to accommodate more rigorous safety procedures. With the increase in students participating in student teams, one-on-one knowledge transfer safety training cannot be sustainably implemented. Specialized training programs need to be developed by the respective student teams to provide knowledge of the hazards to a larger audience without causing major disruptions to project work.

6.3. Potential Drawbacks to Consider for Future Development

Due to the increasing complexity of the competitions, safety training is becoming even more detailed and keeping all of the necessary documentation up to date and distributing safety information requires a person full time to maintain the program. The individual must be safety focused and although any of the supervisory personnel meet the necessary requirements to give safety training, ultimately they have other tasks that take precedence. Thus, an individual person is needed, who has a minimum level of safety competence. It can be quite difficult to find a person within the team who is interested in safety management. By having a designated safety manager, though, it displays to individuals UWAFT’s goals of maintaining a safe environment. This increases the implicit value of safety and shows that it is not just something that is done but is important and under constant scrutiny.

The high turnover rate of students from year to year, due to students either graduating or simply phasing out of the team, means that there must be effective information transfer from the exiting leadership to the incoming one, especially when it comes to maintaining the safety program. Although, the team has been maintaining a great safety record so far, future generations of the team may not be as conscientious, putting project deadlines above safety in terms of priority. In order to ensure that the safety training program is maintained, oversight by the faculty advisor is required on each incoming new leadership to ensure that the program and above all safety is maintained. If the advisor believes that there is any lack of understanding among the leadership in the direct role that the training program has in maintaining safety then additional training will be required or possibly removal of the personnel from the team.

The review of the safety program came about as a result of the need to curb students accelerating through the program too quickly but a formal review process should be mandated on a yearly basis. A yearly evaluation of the safety training program can be conducted in the future, with the faculty advisors overseeing the review of current safety protocols with team leads to make potential suggestions on refining the program. A review of past incidents and the effectiveness of corrective actions put in place will establish how the team handles these incidents and find areas for improvement. A yearly review will, also, ensure that the training provided in the modules is kept up-to-date. In addition, the student team leads can develop methodologies to reach out to the team members to enquire about program changes and safety modifications that the respective members see as imperative. Much in the same way UWAFT gathers information about the impact of participation with the team on the students’ lives after graduation, by sending out an online survey, a similar methodology can be used to obtain this safety information from team members as well. Providing this information to faculty during the review will help to shape the program development.

7. Conclusions

This work provides an understanding on the development of a safety training program for a student team. The process relies on the establishment of an effective method of assessing hazards and risks for the tasks that students will be undertaking and the use of gamification to create incentive for team members to participate in the program.

The use of HARA and ASIL risk ratings was imperative for establishing the segregation of the tasks that UWAFT (as a student team) will be undertaking in the EcoCAR3 competition. By grouping tasks based on their risk rating, the most hazardous jobs can receive the necessary attention in terms of dedicated safety training. The tasks are then separated in the hierarchy to ensure team members who do not have the qualifications will not be able to perform them. Graduation to higher levels is then decided upon by the team leads providing a controlled transition for team members and recognizing of merits by the team leads.

In order to create the hierarchal structure the UWAFT team relied upon the establishment of a Job Safety Analysis in the team’s safety process. Introduction of a JSA creates a step by step procedure that UWAFT can follow as it continues to broaden its design scope. As more advanced tools and systems are incorporated into the vehicle, the list of tasks that UWAFT team members will be able to perform will change. The newly introduced tasks will require going through the risk assessment process outlined in the JSA, thus aiding in the further refinement of the team’s safety training.

Developing a simple hierarchal structure based on risk levels of tasks is an effective measure for ensuring the safety of team members. By applying systems safety techniques to safety training programs at UWAFT, allocation of UWAFT personnel can be done effectively and limit the risk of a hazard occurring. Much in the way systems safety analyses risk to drivers with the introduction of designs and innovations, hazards and risk must be analyzed in the workplace to assess when team members can properly perform tasks safely with proper training. Incorporating gamification principals motivates students to become more involved and want to complete the safety training so as to complete additional tasks and to attain higher standing in the team. Thus, the team grows in both numbers and skills.