Gulf of Mexico Seafood Harvesters: Part 3. Potential Occupational Risk Reduction Measures

Abstract

:1. Introduction

2. Method and Materials

3. Results

3.1. Gulf of Mexico Interventions

“Culture refers to a way of life of a group of people: the patterns of behavior among this group, their beliefs, values and symbols they accept, generally without thinking of them.”—Ann K. Carruth et al., 2010 [7]

3.2. Safety Culture

“…safety can be defined as that state for which the risks are judged to be acceptable.”—Fred A. Manuele and Bruce W. Main, 2002 [18]

3.3. Work Process Risk Factors

3.4. Engineering Control

“The most effective means of preventing and controlling occupational injuries, illnesses and fatalities is to “design out” hazards and hazardous exposures from the workplace.”—Paul A. Schulte et al., 2008 [33]

3.4.1. Fall Overboard and Entanglement Control

3.4.2. Vessel Stability

3.4.3. Ergonomics

3.4.4. Fall Prevention

3.4.5. Near Shore Mariculture Innovations

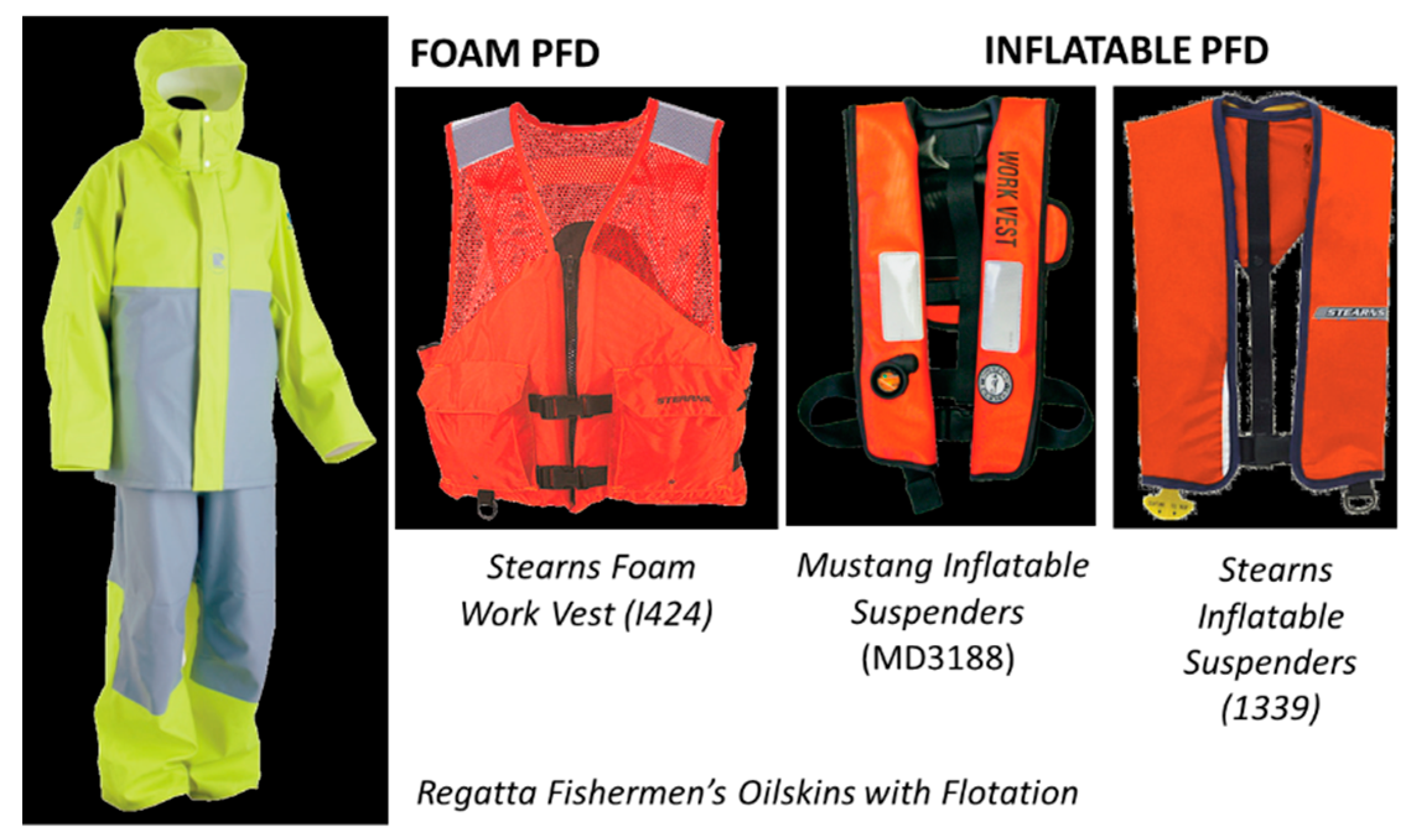

3.5. Personal Protective Equipment: Personal Flotation Devices and Eye UV Protection

“For example, one fisherman told stories about how some of his colleagues from other vessels, in a joking manner, were shouting ‘dog’ to him when he chose to make use of a safety line during periods with rough sea.”—Rolf Bye and Gunnar M. Lamvick, 2007 [24]

3.6. Incentives

3.7. Training

3.8. Narrative Outreach

“This approach basically argues that human beings are natural storytellers and that the exchange of stories permeates our everyday social interaction”—Michael Murray, 2000 [63]

4. Discussion

4.1. Limitations

4.2. The Implications for Countermeasures

4.2.1. Fatality Hazards

4.2.2. Nonfatal Injuries

4.2.3. Musculoskeletal Disorder Hazards

4.2.4. Biological Hazards

4.2.5. Skin and Eye Hazards

4.2.6. Hearing Hazards

4.2.7. Breathing Hazards

4.2.8. Work Process Risk Factors

4.2.9. Safety Culture

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A. Literature Reviewed

| Area | Intervention | Source |

|---|---|---|

| Gulf of Mexico USA, n = 11 | ||

| Fishing | Slip resistant surfaces * | Wallace, 2003 [45] |

| Shrimp | Education/training | Carruth et al., 2010 [7] |

| Shrimp | Demographic factors | Levin et al., 2010 [9] |

| Shrimp | Training partnerships | Levin et al., 2012 [8] |

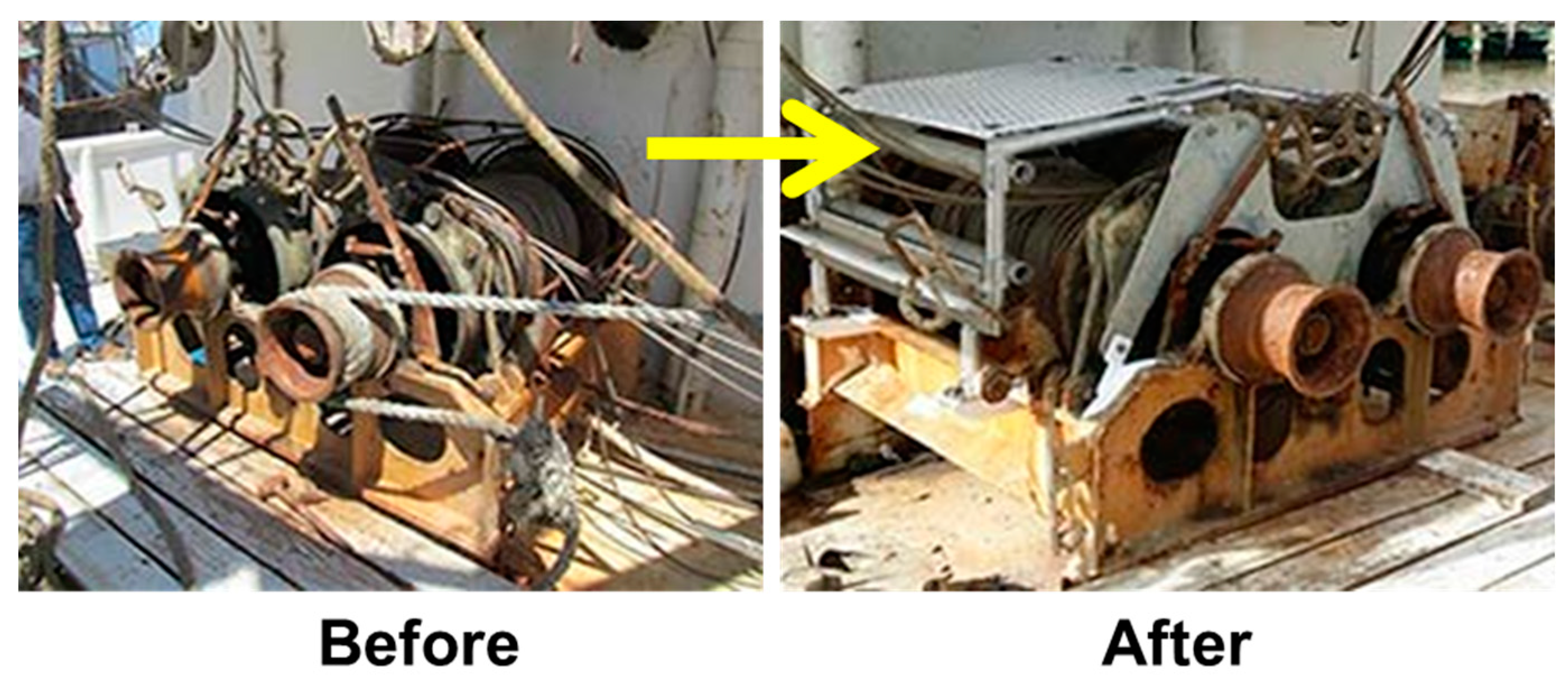

| Fishing | Winch safety | Lucas et al., 2013 [11] |

| Fishing | Ergonomics training | Bloswick and Dzugan, 2014 [15] |

| Fishing | Ergonomics training | Bloswick and Dzugan, 2014 [16] |

| Shrimp | Safety | Levin et al., 2016 [10] |

| Shrimp | Winch guards | Lincoln et al., 2017 [14] |

| Shrimp | PFD acceptance | Carruth et al., 2017 [17] |

| Reef Fish | Individual fishing quotas | Marvasti and Dakhlia, 2017 [58] |

| Atlantic Coast USA, n = 8 | ||

| Fishing | Ergonomics | Fulmer, 2003 [43] |

| Fishing | Entanglement prevention | Backus et al., 2003 [39] |

| Fishing | Culture, insurance | Marshall et al., 2004 [22] |

| Fishing | Training | Hall-Arber and Mrakovcich, 2008 [60] |

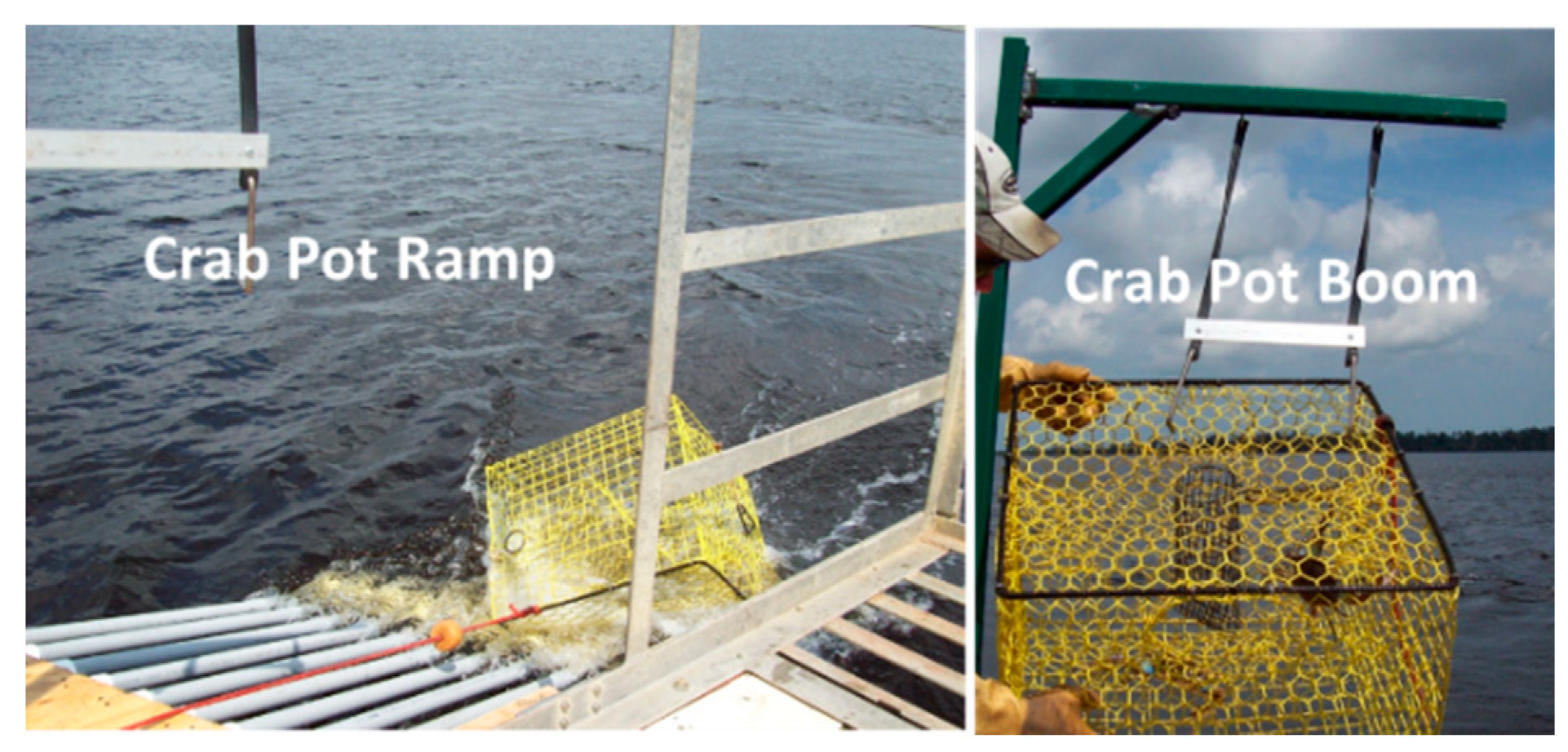

| Crabbing | Ergonomic interventions | Mirka et al., 2011 [42] |

| Lobster (MA) | PFD use | Sorenson, 2015 [53] |

| Lobster (MA) | PFD designs | Weil, 2017 [54] |

| Clam Farming | Innovations | Durborow et al., 2018 [46] |

| Alaska USA, n = 9 | ||

| Fishing | Job hazard analysis | Bloswick et al., 2003 [30] |

| Fishing | Engineering and administrative controls | Lucas and Lincoln, 2007 [38] |

| Fishing | Winch stop switches | Lincoln et al., 2008 [12] |

| Fishing | Training efficacy | Dzugan, 2010 [56] |

| Fishing | Personal flotation device comfort | Lucas et al., 2012 [48] |

| Fishing | Personal flotation device use | Lucas et al., 2013 [50] |

| Fishing | Training efficacy | Dzugan, 2014 [56] |

| Fishing | PFD effectiveness | Lucas et al., 2015 [51] |

| Fishing | Engineering designs | NIOSH, 2016 [13] |

| Fishing | Work process | Syron et al., 2016 [32] |

| Australia, n = 1 | ||

| Fishing | Safety culture | Brooks, 2005 [25] |

| Northern Europe, n = 10 | ||

| Fishing | Safety measures, cost | Törner et al., 1999/2000 [59] |

| Fishing | Roll stabilizers | Webster et al., 2003 [40] |

| Fishing | Rick control attitude | Törner and Eklöf, 2003 [21] |

| Fishing | Process coding | Jensen et al., 2005 [31] |

| Fishing | Safety culture | Bye and Lamvick, 2007 [24] |

| Boaters and Fishers | PFD use | Turner et al., 2009 [47] |

| Fishing | Safety culture | Hávold, 2010 [26] |

| Fishing | Fatality trends | Jensen et al., 2014 [36] |

| Fishing | Interventions, safety culture | Christiansen and Hovmand, 2017 [27] |

| Fishing | Fatigue | Remmen et al., 2017 [44] |

| Other, n = 13 | ||

| Fishing | Vessel age | Meek, 1985 [37] |

| Fishing | Threat perception | Murray et al., 1997 [28] |

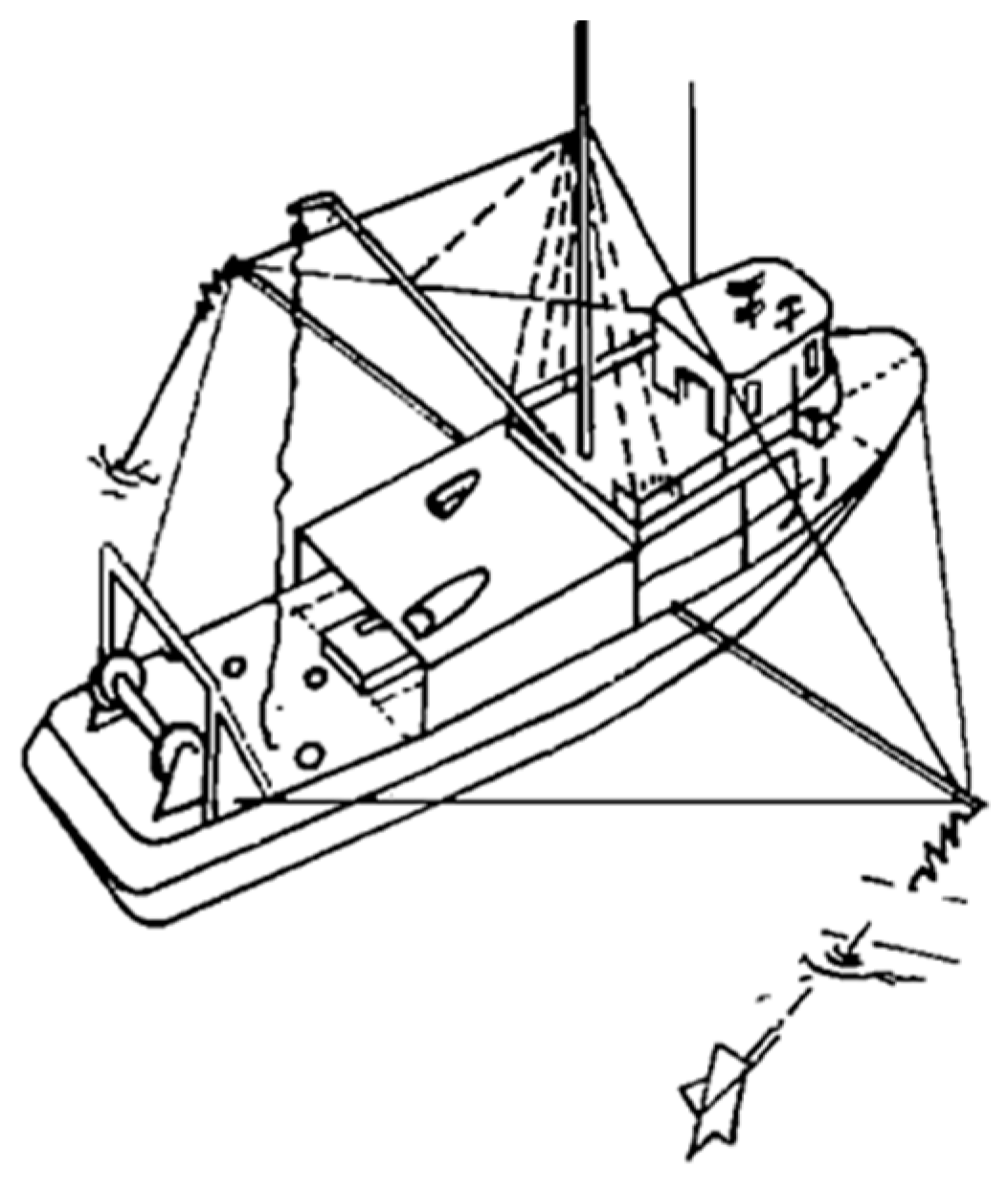

| Fishing | Paravanes | Bass, 1998 [41] |

| Fishing | Threat perception | Murray, 2000 [63] |

| Fishing | Culture | Matheson et al., 2001 [19] |

| Fishing | Narrative curricula | Howe, 2003 [64] |

| Canada | Injury experience | Acheson, 2003 [20] |

| Fishing | Ergonomics | Fulmer, 2003 [43] |

| Canada | Swimming failure | Brooks et al. 2005 [49] |

| Brazil | Culture, photoprotection | Bezerra et al., 2011 [23] |

| Aquaculture | Job hazard analysis | Myers and Durborow, 2012 [29] |

| Fishing | US observer program | Craig, 2014 [62] |

| US | Quota system | Pfeiffer and Gratz, 2016 [57] |

References

- Myers, M.; Durborow, R.; Kane, A. Gulf of Mexico seafood harvesters: Part 1. Occupational Injury and Fatigue Risk Factors. Safety 2018, 4, 31. [Google Scholar] [CrossRef]

- Myers, M.; Durborow, R.; Kane, A. Gulf of Mexico seafood harvesters: Part 2. Occupational health-related risk factors. Safety 2018, 4, 27. [Google Scholar] [CrossRef]

- Syron, L.; Case, S.; Kloczko, D.; Mason, K.; Lucas, D.; Teske, T. Commercial Fishing Fatality Summary: Gulf of Mexico Region. NIOSH, CDC, USA, Publication No. 2017-174, 2017 July. Available online: https://www.cdc.gov/niosh/docs/2017-174/pdf/2017-174.pdf (accessed on 11 October 2017).

- National Institute for Occupational Safety and Health. List of Journal Articles on Occupational Safety in the Fishing Industry 1954–2012. Centers for Disease Control, USA, Undated. Available online: https://www.cdc.gov/niosh/topics/fishing/pdfs/Fishing_Safety_Bibliography_1954-2012.pdf (accessed on 7 July 2017).

- Lincoln, J.M.; Hudson, D.S.; Conway, G.A.; Pescatore, R. (Eds.) Proceedings of the International Fishing Industry Safety and Health Conference, Woods Hole, MA, USA, 23–25 October 2000; Available online: https://www.cdc.gov/niosh/docs/2003-102/pdfs/2003-102.pdf (accessed on 12 November 2017).

- Mode, N.A.; Wopat, P.; Conway, G.A. (Eds.) Proceedings of the Second International Fishing Industry Safety and Health Conference, Sitka, AK, USA, 22–24 September 2003; DHHS publication No. (NIOSH) 2006-114, April 2006. Available online: https://stacks.cdc.gov/view/cdc/6721 (accessed on 12 November 2017).

- Carruth, A.K.; Levin, J.L.; Gilmore, K.; Bui, T.; Gallardo, G.; Evert, W.; Sealey, L. Cultural influences on safety and health education among Vietnamese fishermen. J. Agromed. 2010, 15, 375–385. [Google Scholar] [CrossRef] [PubMed]

- Levin, J.L.; Gilmore, K.; Carruth, A.; Wickman, A.; Shepherd, S.; Gallardo, G.; Nonnenmann, M. Helping Gulf shrimpers adopt safety measures: Importance of partnerships and research to practice. J. Agromed. 2012, 17, 15–21. [Google Scholar] [CrossRef] [PubMed]

- Levin, J.L.; Gilmore, K.; Shepherd, S.; Wickman, A.; Carruth, A.; Nalbone, J.T.; Gallardo, G.; Nonnenmann, M.W. Factors influencing safety among a group of commercial fishermen along the Texas Gulf Coast. J. Agromed. 2010, 15, 363–374. [Google Scholar] [CrossRef] [PubMed]

- Levin, J.L.; Gilmore, K.; Wickman, A.; Shepherd, S.; Shipp, E.; Nonnenmann, M.; Carruth, A. Workplace safety interventions for commercial fishermen of the Gulf. J. Agromed. 2016, 21, 178–189. [Google Scholar] [CrossRef] [PubMed]

- Lucas, D.; Woodward, C.; Lincoln, J. Fatal and nonfatal injuries involving fishing vessel winches—Southern shrimp fleet, United States, 2000–2001. MMWR 2013, 62, 157–160. [Google Scholar]

- Lincoln, J.M.; Lucas, D.L.; McKibbin, R.W.; Woodward, C.C.; Bevan, J.E. Reducing commercial fishing deck hazards with engineering solutions for winch design. J. Saf. Res. 2008, 39, 231–235. [Google Scholar] [CrossRef] [PubMed]

- National Institute for Occupational Safety and Health. Commercial Fishing Safety: Engineering Innovations. 8 June 2015. Available online: https://www.cdc.gov/niosh/topics/fishing/engineering.html (accessed on 9 July 2017).

- Lincoln, J.M.; Woodward, C.C.; King, G.W.; Case, S.L.; Lucas, D.L.; Teske, T.D. Preventing fatal winch entanglements in the US southern shrimp fleet: A research to practice approach. J. Saf. Res. 2017, 60, 119–123. [Google Scholar] [CrossRef] [PubMed]

- Bloswick, B.S.; Dzugan, J. Ergonomics training in the commercial fishing industry: Emerging issues and gaps in knowledge. J. Agromed. 2014, 19, 87–89. [Google Scholar] [CrossRef] [PubMed]

- Bloswick, D.S.; Dzugan, J. Development of an Ergonomics Training Program for the Commercial Fishing Industry: Charges, Challenges and Changes. J. Agromed. 2014, 19, 203. [Google Scholar] [CrossRef]

- Carruth, A.; Levin, J.; Creel, E.; Sorensen, J.; Lincoln, J. Commercial Fishing Safety in the Gulf of Mexico and the Southwest Ag Center: The Decade in Review. In Proceedings of the STTI 28th International Nursing Research Congress, Dublin, Ireland, 27–31 July 2017. [Google Scholar]

- Manuele, F.A.; Main, B.W. On acceptable risk: What level of risk if any, is acceptable in the workplace? EHS Today. 8 January 2002. Available online: http://www.ehstoday.com/news/ehs_imp_35066 (accessed on 2 September 2017).

- Matheson, C.; Morrison, S.; Murphy, E.; Lawrie, T.; Ritchie, L.; Bond, C. The health of fishermen in the catching sector of the fishing industry: A gap analysis. Occup. Med. (Lond.) 2001, 51, 305–311. [Google Scholar] [CrossRef] [PubMed]

- Acheson, V. Fishers’ attributed causes of accidents and implications for prevention education. In Proceedings of the Second International Fishing Industry Safety and Health Conference, Sitka, AK, USA, 22–24 September 2003; DHHS (NIOSH) Publication No. 2006-114, National Institute for Occupational Safety and Health, Centers for Disease Control, USA. 2003; pp. 225–236. Available online: https://www.cdc.gov/niosh/docs/2006-114/pdfs/2006-114.pdf (accessed on 28 May 2017).

- Törner, M.; Eklöf, M. Participatory Analysis of Accidents. Risk Perception among Fishermen and Control of Risks through Participatory Analysis of Accidents and Incidents. In Proceedings of the International Fishing Industry Safety and Health Conference, Woods Hole, MA, USA, 23–25 October 2000; Lincoln, J.M., Hudson, D.S., Conway, G.A., Pescatore, R., Eds.; National Institute for Occupational Safety and Health, Centers for Disease Control and Prevention, 2003; pp. 237–241. Available online: https://www.cdc.gov/niosh/docs/2003-102/pdfs/2003102.pdf (accessed on 28 May 2017).

- Marshall, S.W.; Kucera, K.; Loomis, D.; McDonald, M.A.; Lipscomb, H.J. Work related injuries in small scale commercial fishing. Inj. Prev. 2004, 10, 217–221. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bezerra, S.M.; Sotto, M.N.; Orii, N.M.; Alves, C.; Duarte, A.J. Effects of long-term chronic exposure to sun radiation in immunological system of commercial fishermen in Recife, Brazil. An. Bras. Dermatol. 2011, 86, 222–233. [Google Scholar] [CrossRef] [PubMed]

- Bye, R.; Lamvick, G.M. Professional culture and risk perception: Coping with danger on board small fishing boats and offshore service vessels. Reliab. Eng. Syst. Saf. 2007, 92, 1756–1763. [Google Scholar] [CrossRef]

- Brooks, B. Not drowning, waving! Safety management and occupational culture in an Australian commercial fishing port. Saf. Sci. 2005, 43, 795–814. [Google Scholar] [CrossRef]

- Hávold, J.I. Safety culture aboard fishing vessels. Saf. Sci. 2010, 48, 1054–1061. [Google Scholar] [CrossRef]

- Christiansen, J.M.; Hovmand, S.R. Prevention of Accidents at Work in Nordic Fisheries: What Has Worked? TemaNord: Copenhagen, Denmark, 23 April 2017; Available online: https://norden.diva-portal.org/smash/get/diva2:1078287/FULLTEXT02.pdf (accessed on 1 September 2017).

- Murray, M.; Fitzpatrick, D.; O’Connell, C. Fishermen’s blues: Factors related to accidents and safety among Newfoundland fishermen. Work Stress 1997, 11, 292–297. [Google Scholar] [CrossRef]

- Myers, M.L.; Durborow, R.M. Aquacultural Safety and Health. In Health and Environment in Aquaculture; Carvalho, E., Ed.; IntechOpen: London, UK, 2012. [Google Scholar] [Green Version]

- Bloswick, B.S.; Husberg, B.J.; Blumhagen, E. Use of Operating Hazard Analysis to Review on-Deck Procedures in Commercial Crab Fishing. In Proceedings of the Second International Fishing Industry Safety and Health Conference, Sitka, AK, USA, 22–24 September 2003; National Institute for Occupational Safety and Health, Centers for Disease Control, USA, DHHS (NIOSH) Publication No. 2006-114, 2003. pp. 45–56. Available online: https://www.cdc.gov/niosh/docs/2006-114/pdfs/2006-114.pdf (accessed on 28 May 2017).

- Jensen, O.C.; Stage, S.; Noer, P. Classification and coding of commercial fishing injuries by work processes: An experience in the Danish fresh market fishing industry. Am. J. Ind. Med. 2005, 47, 528–537. [Google Scholar] [CrossRef] [PubMed]

- Syron, L.N.; Lucas, D.L.; Bovbjerg, V.E.; Bethel, J.W.; Kincl, L.D. Utility of a work process classification system for characterizing non-fatal injuries in the Alaska commercial fishing industry. Int. J. Circumpolar Health 2016, 75, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Schulte, P.A.; Rinehart, R.; Okun, A.; Geraci, C.L.; Heidel, D.S. National Prevention through Design (PtD) Initiative. J. Saf. Res. 2008, 39, 115–121. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wogalter, M.S. Purposes and scope of warnings. In Handbook of Warnings; Wogalter, M.S., Ed.; Lawrence Erlbaum Associates: Mahwah, NJ, USA, 2006; pp. 3–10. ISBN 9780805847246. [Google Scholar]

- Haddon, W. Strategies in preventive medicine: Passive vs. active approaches to reducing human wastage. J. Trauma 1974, 14, 353–354. [Google Scholar] [CrossRef] [PubMed]

- Jensen, O.C.; Petursdottir, G.; Holmen, I.M.; Abrahamsen, A.; Lincoln, J. A review of fatal accident incidence rate trends in fishing. Int. Marit. Health 2014, 65, 47–52. [Google Scholar] [CrossRef] [PubMed]

- Meek, M.; Brown, W.R.; Fulford, K.G. A shipbuilders’ view of safety. Marit. Policy Manag. 1985, 12, 251–262. [Google Scholar] [CrossRef]

- Lucas, D.L.; Lincoln, J.M. Fatal falls overboard on commercial fishing vessels in Alaska. Am. J. Ind. Med. 2007, 50, 962–968. [Google Scholar] [CrossRef] [PubMed]

- Backus, A.S.; Brochu, P.J.; Lincoln, J.M.; Bensyl, D.M.; Ciampa, J.R.; Smith, T.J.; Conway, G.A. Work Practices, Entanglement of Lobstermen, and Entanglement Prevention Devices in the Maine Lobster Fishery: A Preliminary Survey. In Proceedings of the International Fishing Industry Safety and Health Conference, Woods Hole, MA, USA, 23–25 October 2000; Lincoln, J.M., Hudson, D.S., Conway, G.A., Pescatore, R., Eds.; Centers for Disease Control and Prevention National Institute for Occupational Safety and Health, 2003; pp. 269–282. Available online: https://www.cdc.gov/niosh/docs/2003-102/pdfs/2003102.pdf (accessed on 28 May 2017).

- Webster, B.; Birmingham, R.; Jones, E.; Roskilly, T. Developing an Artificially Intelligent Roll Stabilization System for Use on Fishing Vessels. In Proceedings of the 8th International Conference on the Stability of Ships and Ocean Vehicles, Madrid, Spain, 15–19 September 2003; Escuela Tecnica Superior de Ingenieros Navales, 2003; pp. 757–774. Available online: http://www.shipstab.org/files/Proceedings/STAB/STAB2003/Papers/Paper%2060.pdf (accessed on 18 June 2017).

- Bass, D.W. Roll Stabilization for small fishing vessels using paravanes and anti-roll tanks. Mar. Technol. 1998, 35, 74–84. [Google Scholar]

- Mirka, G.A.; Ning, X.; Jin, S.; Haddad, O.; Kucera, K.L. Ergonomic intervention for commercial crab fishermen. Int. J. Ind. Ergon. 2011, 41, 481–487. [Google Scholar] [CrossRef]

- Fulmer, S. Measuring Risk of Cumulative Musculoskeletal Trauma in Fishing Vessels. In Proceedings of the International Fishing Industry Safety and Health Conference, Woods Hole, MA, USA, 23–25 October 2000; Lincoln, J.M., Hudson, D.S., Conway, G.A., Pescatore, R., Eds.; Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, 2003; pp. 341–349. Available online: https://www.cdc.gov/niosh/docs/2003-102/pdfs/2003102.pdf (accessed on 28 May 2017).

- Remmen, L.N.; Herttua, K.; Riss-Jepsen, J.; Berg-Beckhoff, G. Fatigue and workload among Danish fishermen. Int. Marit. Health 2017, 68, 252–259. [Google Scholar] [CrossRef] [PubMed]

- Wallace, B. Slip Resistance under Varying Environmental Conditions. In Proceedings of the Second International Fishing Industry Safety and Health Conference, Sitka, AK, USA, 22–24 September 2003; National Institute for Occupational Safety and Health, Centers for Disease Control and Prevention, DHHS (NIOSH) Publication No. 2006-114. 2003; pp. 45–56, 65–75. Available online: https://www.cdc.gov/niosh/docs/2006-114/pdfs/2006-114.pdf (accessed on 28 May 2017).

- Durborow, R.M.; Myers, M.L.; Kane, A.S. Clam Mariculture Safety in South Carolina: A Case Study. In Proceedings of the Fifth International Fishing Industry Safety and Health Conference, St. John’s, NL, Canada, 10–13 June 2018. [Google Scholar]

- Turner, S.; Wylde, J.; Langham, M.; Sharpe, S.; Jackson, K. MCA Lifejacket Wear–Behavioral Change. 12 August 2009. Maritime Coastguard Agency & the Royal National Lifeboat Institution, United Kingdom. Available online: http://www.nasbla.org/HigherLogic/System/DownloadDocumentFile.ashx?DocumentFileKey=67784c66-3c9e-4003-8c31-f5258cc9e4f6&forceDialog=0 (accessed on 1 June 2017).

- Lucas, D.; Lincoln, J.; Somervell, P.; Teske, T. Worker satisfaction with personal flotation devices (PFDs) in the fishing industry: Evaluations in actual use. Appl. Ergon. 2012, 43, 747–752. [Google Scholar] [CrossRef] [PubMed]

- Brooks, C.J.; Howard, K.A.; Neifer, S.K. How much did cold shock and swimming failure contribute to drowning deaths in the fishing industry in British Columbia 1976–2002? Occup. Med (Lond). 2005, 55, 459–462. [Google Scholar] [CrossRef] [PubMed]

- Lucas, D.L.; Lincoln, J.M.; Carozza, S.E.; Bovbjerg, V.E.; Kincl, L.D.; Teske, T.D.; Somervell, P.D.; Anderson, P.J. Predictors of personal flotation device (PFD) use among workers in the Alaska commercial fishing industry. Saf. Sci. 2013, 53, 177–185. [Google Scholar] [CrossRef]

- Lucas, D.L.; Lincoln, J.M.; Teske, T. Intervention Development (Part 1): Personal Flotation Device Use among Commercial Fishermen: Evaluations of Comfort. In Proceedings of the Council of State and Territorial Epidemiologists Annual Conference, Anchorage, AK, USA, 19–23 June 2016; Available online: https://cste.confex.com/cste/2016/webprogram/Paper6644.html (accessed on 1 June 2017).

- National Institute for Occupational Safety and Health. DHHS (NIOSH) Publication Number 2013-131. Centers for Disease Control and Prevention, US Department of Human Services. Available online: https://www.cdc.gov/niosh/docs/2013-131/default.html (accessed on 19 April 2018).

- Sorensen, J. The Use of Personal Flotation Devices in the Northeast Lobster Fishing Industry: An Examination of the Decision Making Process. In Proceedings of the 19th Triennial Congress of the International Ergonomics Association, Melbourne, Australia, 9–14 August 2015. [Google Scholar]

- Weil, R. Lobstermen test new PFD designs. Natl. Fisherman 2017, 98, 6–7. [Google Scholar]

- Rosenthal, F.S.; Phoon, C.; Bakalian, A.E.; Taylor, H.R. The ocular dose of ultraviolet radiation to outdoor workers. Invest. Ophthalmol. Vis. Sci. 1988, 29, 649–656. [Google Scholar] [PubMed]

- Dzugan, J. 25 Years of Training Commercial Fishermen. In Proceedings of the National Transportation Safety Board Fishing Vessel Safety Forum, Washington, DC, USA, 13–14 October 2010; Available online: https://www.ntsb.gov/news/events/Documents/2010_Fishing_Vessel_Safety_FRM-Panel6b3-Dzugan.pdf (accessed on 4 September 2017).

- Pfeiffer, L.; Gratz, T. The effect of rights-based fisheries management on risk taking and fishing safety. Proc. Natl. Acad. Sci. USA 2016, 113, 2615–2620. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Marvasti, A.; Dakhlia, S. Occupational safety and the shift from common to individual fishing quotas in the Gulf of Mexico. South Econ. J. 2017, 83, 705–720. [Google Scholar] [CrossRef]

- Törner, M.; Cagner, M.; Nilsson, B.; Nording, P.-O. Occupational injury in Swedish fishery: 2. Promoting implementation of safety measures. Occup. Ergon. 1999/2000, 2, 91–104. [Google Scholar]

- Hall-Arber, M.; Mrakovcich, K.L. Reducing risk to life and limb: Safety training steps towards resilience in Massachusetts’ commercial fishing industry. Hum. Ecol. Rev. 2008, 15, 201–212. [Google Scholar]

- Dzugan, J. The development and efficacy of safety training for commercial fishermen. J. Agromed. 2014, 19, 351–356. [Google Scholar] [CrossRef] [PubMed]

- Craig, B. Commercial Fishing Vessel Safety and the National Marine Fisheries Service—United States Coast Guard Memorandum on Observer Safety. Report to the National Observer Program National Marine Fisheries Service Office of Science and Technology; December 2014. Available online: https://www.st.nmfs.noaa.gov/Assets/Observer-rogram/pdf/MoA_&_Safety_Decal_Report_v5_Final_rev-1.pdf (accessed on 27 May 2017).

- Murray, M. The Use of Narrative Theory in Understanding and Preventing Accidents in the Fishing Industry. In Proceedings of the International Fishing Industry Safety and Health Conference, Woods Hole, MA, USA, 23–25 October 2000; Lincoln, J.M., Hudson, D.S., Conway, G.A., Pescatore, R., Eds.; Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, 2000; pp. 243–250. Available online: https://www.cdc.gov/niosh/docs/2003-102/pdfs/2003102.pdf (accessed on 7 June 2017).

- Howe, B.L. Stability Training for Fishermen: Anchored Instruction Using Narrative Theory and Video for Learning Transfer. In Proceedings of the Second International Fishing Industry Safety and Health Conference, Sitka, AK, USA, 22–24 September 2003; National Institute for Occupational Safety and Health, Centers for Disease Control and Prevention, DHHS (NIOSH) Publication No. 2006-114, 2003. pp. 263–280. Available online: https://www.cdc.gov/niosh/docs/2006-114/pdfs/2006-114.pdf (accessed on 28 May 2017).

- Teutsch, S.M. A framework for assessing the effectiveness of disease and injury prevention. MMWR 1992, 41, 1–12. [Google Scholar] [PubMed]

- Sienkiewicz, J.M. Forecasting Extreme Ocean Waves. In Proceedings of the International Fishing Industry Safety and Health Conference, Woods Hole, MA, USA, 23–25 October 2000; Lincoln, J.M., Hudson, D.S., Conway, G.A., Pescatore, R., Eds.; Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, 2003; pp. 123–130. Available online: https://www.cdc.gov/niosh/docs/2003-102/pdfs/2003102.pdf (accessed on 28 May 2017).

- Wu, Y.; Pelot, R.P.; Hilliard, C. The effect of weather factors on the severity of fishing boat accidents in Atlantic Canada. Risk Manag. 2005, 7, 21–40. [Google Scholar] [CrossRef]

- Wu, Y.; Pelot, R.P.; Hilliard, C. The influence of weather conditions on the relative incident rate of fishing vessels. Risk Anal. 2009, 29, 985–999. [Google Scholar] [CrossRef] [PubMed]

- Woodley, C. Quota-Based Fishery Management Regimes. In Proceedings of the International Fishing Industry Safety and Health Conference, Woods Hole, MA, USA, 23–25 October 2000; Lincoln, J.M., Hudson, D.S., Conway, G.A., Pescatore, R., Eds.; Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, 2003; pp. 161–171. Available online: https://www.cdc.gov/niosh/docs/2003-102/pdfs/2003102.pdf (accessed on 28 May 2017).

- Jepsen, J.R.; Zhao, Z.; Pekan, C.; Barnett, M.; van Leeuwen, W.M.A. Risk factors for fatigue in shipping, the consequences for seafarers’ health and options for preventive action. In Maritime Psychology: Research in Organizational& Health Behavior at Sea; MacLachlan, M., Ed.; Springer: Cham, Switzerland, 2017; pp. 127–150. ISBN 978-3-319-45428-3. [Google Scholar] [CrossRef]

- Runyan, C.W. Introduction: Back to the future—Revisited Haddon’s conceptualization of injury epidemiology and prevention. Epidemiol. Rev. 2003, 25, 60–64. [Google Scholar] [CrossRef] [PubMed]

- Barnett, D.J.; Balicer, R.D.; Blodgett, D.; Fews, A.L.; Parker, C.L.; Links, J.M. The application of the Haddon matrix to public health readiness and response planning. Environ. Health Perspect. 2005, 113, 561–566. [Google Scholar] [PubMed]

- Quan, L.; Osborne, J. 2011–2016 Washington State Open Water Drowning Prevention Policy Plan for Children and Youth; Final Grant Report, Executive Summary; Seattle Children’s Hospital, University of Washington School of Medicine and Naval Base Kitsap: Seattle, WA, USA, 2016. [Google Scholar]

- Myers, M.L. Occupational Safety and Health Policy; American Public Health Association: Washington, DC, USA, 2015; pp. 24–25. ISBN 978-0-87533-271-4. [Google Scholar]

- Hornbeak, K.B.; Auerbach, P.S. Marine envenomation. Emerg. Med. Clin. N. Am. 2017, 35, 321–337. [Google Scholar] [CrossRef] [PubMed]

- Martinis, V.A. The Noise Profile and Hearing Levels of Commercial Fishermen. Master’s Thesis, University of Washington, Seattle, WA, USA, 1977. [Google Scholar]

- Thalmann, E.D. Diving hazards. In Safety and Health in Agriculture, Forestry, and Fisheries; Langley, R.L., McLymore, R.L., Meggs, W.J., Roberson, G.T., Eds.; Government Institutes: Rockville, MD, USA, 1997; pp. 617–641. ISBN 13 978-0865875524. [Google Scholar]

- Fishing Partnership Support Services Burlington, MA, USA. Available online: http://fishingpartnership.org/services/ (accessed on 10 September 2017).

| Study | Findings |

|---|---|

| Acheson interviewed 12 British Columbian fishers in Canada from a variety of vessels types who had experience with an injury or participated in an incident [20]. | Fishers downgrade risk by not reporting work injuries. Denial and trivialization of danger is part of the occupational culture. The author suggests fisher participation in which they discuss their own experience through the lens of risk assessment and their own injuries and near misses. |

| Törner and Eklöf investigated fishers’ attitudes towards risks and attempted to enhance a sense of risk control in their work. They began with a questionnaire to 92 subjects followed by two discussion groups of two and three crews that met six times over eight months [21]. | The fishers described 43 incidents and reported that technology was at fault in 34 (79%) of the incidents, deficient work organization was at fault in 5 (12%) cases and 4 (9%) were caused by an individual’s actions. Common factors included weather (n = 16; 37%), deficient routines (n = 10; 23%) and faulty equipment (n = 8; 19%). One conclusion was that slipping was a risk factor, which was underreported since it became a norm. |

| Marshall et al. focused on 215 commercial fishers in small and medium scale operations in North Carolina. Most fishers were self-employed or working in small operations [22]. | A principle concern was making a “day-to-day living” and a general theme included a reluctance to seek medical care and concerns regarding regulations. They likely lacked job-related health insurance or workers’ compensation coverage. |

| Bezerra et al. conducted a study of 19 Brazilian fishers that included an evaluation of clinical, histological and immunological effects of chronic exposure to ultraviolet radiation from the sun [23]. | Fishers stay with their occupation longer than other workers and they start as adolescents based on family tradition or contacts with other fishers. They concluded that fishers learn through experience whereas workers in other occupations require prior training and thus start work later in life. |

| Bye and Lamvick surveyed 487 employees and interviewed 45 subjects from fishing and other vessels in Norway to determine the relationship of risk perception to countermeasures [24]. | Small fishing vessels, 35 feet or less in length, were found as the most dangerous but 71% of injuries were never reported. Several subjects stated that their work was dangerous but they rarely discussed this danger among crew members. Defects on the vessel could be easily fixed but remained unrepaired. Fatalism ruled: 13% did not know how to swim, 41% said they rarely donned a PFD and 34% rarely used a safety line on board. Donning a PFD could lead to ridicule by the crew and fishers on passing vessels. |

| Brooks examined safety management and culture in 2002 in a small Australian fishing town [25]. | The simple shared mission was to catch quality fish and sell them to buyers and the skipper’s word was “law.” Family continuity over time in the business and independence was important, risk taking was enculturated and experience was more important than training. A new deckhand typically experienced 10 near misses on their first day on the job, which dropped dramatically within a week. They assumed that humanity is subservient to the powerful sea. The workers grasped the majority of physical risks well but failed to design, plan, or implement risk reduction measures. The challenge is to build a learning culture with actions based on risk perceptions. |

| Hávold investigated safety measures among 9 Norwegian fishers based on initial conditions [26]. | These conditions included the fishery type, type and size of vessel, fisher time-based experience. He identified the experience of injuries or near-misses as a learning effect. |

| Christiansen and Hovmand reported on interventions to protect workers in the Nordic nations [27]. | Nordic fishers rated written materials, guidelines and information low and preferred direct dialogue, which appear to have greater impact on safety. They stated that an effective safety culture requires the skipper to take the lead. |

| Murray et al. interviewed 55 fishers from small communities in Newfoundland, Canada about factors related to injuries and fatalism preceded by high threat perception and anxiety [28]. | Major worries were the fishery (n = 44; 80%), my family (n = 37; 67%), money (n = 34; 62%), qualifying for unemployment insurance (n = 25; 46%), damaging gear or boat (n = 23; 42%), the weather (n = 17; 31%), competition with other boats (n = 12; 22%) and argument with the boss or crew (n = 3; 4%). |

| Fall Overboard Controls | Line Entanglement Prevention |

|---|---|

| Engineering Controls (Alaska fishers) | Engineering Controls (Percentages are ratings by Massachusetts Lobstermen) |

| Raise gunnels (gunwales) | Washrail (gunwale) above the knee (95%) |

| Enclose workspaces | Rope locker/bin (a compartment built under the deck (69%) |

| Guard against gear entanglement by reducing line coils on the deck with line bins and lockers | Bucket/pipe as fairlead (rope fed from a bin through a deck aperture up and into the water; 51%) |

| Install motor kill switches reachable by the potential victim | Temporary abrasive, such as salt (39%) |

| Wear a water detection device to cut the motor off | Safety shut-off cord for engine (35%) |

| Equip the pilot house with detectors and crew members with transmitters that sound a warning from a small device activated when the fall overboard victim is in the water (personal locator beacon) | Sensor mat for shutting off engine (30%) |

| Install non-slip surfaces, including fiber mats and non-skid grates | Nonskid mats (95%) High traction deck (85%) |

| Administrative controls | Escape options (in order of importance) |

| Conducting survival drills | Have a sternman |

| Assuring the availability and use of PFDs | Wear a knife for cutting the rope |

| Zero tolerance for alcohol consumption | Have a knife mounted in the stern |

| Carry a diver’s knife when line entanglement is a potential exposure to enable the victim to cut the line | Have a line to kill the engine |

| Source: Lucas and Lincoln [38] | Source: Backus et al. [39] |

| Problem | Intervention |

|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Subjects | Use Reported by Subjects before Test | Reasons for Not Wearing PFDs | Preferred PFDs after Use | |||

|---|---|---|---|---|---|---|

| Always | Never | Sometimes | Frequently | |||

| Trawlers | 51% | 12% | 11% | 26% |

|

|

| ||||||

| ||||||

| ||||||

| Crabbers | 22% | 16% | 50% | 12% |

|

|

|

| |||||

| ||||||

| Longliners | - | 64% | 31% | 5% |

|

|

| ||||||

| Gillnetters | 5% | 55% | 30% | 10% |

|

|

|

| |||||

| ||||||

| Dungeness crabbers | 6% | 51% | 33% | 5% |

|

|

|

| |||||

| ||||||

| Positive Features Expressed by Subjects Regarding Different PFDs | ||||||

| ||||||

| Health Effects/Hazards | Potential Interventions |

|---|---|

| Fatigue | Avoid work to exhaustion, get sleep, sleep without interruption, use caffeine, control sea-sickness, noise control, automate workload processes |

| Fatalities | Wear PFDs in skiffs or on deck, use personal locator beacons and EPIRBs, fish in fair weather, conduct drills, maintain USCG sticker on vessel, learn to swim, know how to issue a Mayday call, know CPR and resuscitation, increase vessel stability |

| Non-fatal injuries | Guards on winches, use high friction footwear and decks, wear and maintain gloves, reduce clutter on deck, know first aid |

| Musculoskeletal disorders | Avoid heavy lifting (by using other lift means or with help), twisting, repetitive motions; teach captains ergonomic principles to encourage innovations, job redesign |

| Biological hazards | Recognize and avoid contact with poisonous and toxic aquatic species, treat toxic shock and stingray stings, wear protective clothing |

| Skin and eye hazards | Prevent sunburn with sun screen, wear broad rimed hat to protect eyes and lips from sunlight, avoid skin contact with fish, wear UV protected glasses |

| Breathing hazards | Work in ventilated areas when handling fish, use protective gear around chemicals and fish bioaerosols |

| Hearing hazards | Wear hearing protectors in the engine room, avoid carbon monoxide exposure |

| Dangerous work processes | Use job hazard analysis, redesign tasks to avoid hazards |

| Lack of safety culture | Teach with participatory hands-on methods, share stories, use pictures, consider family involvement, focus on captains and unacceptable risks, recognize and share innovations |

| Mariculture hazards | Wear hearing protection around noise, avoid electrical hazards (use ground fault interrupters), avoid falls and falling objects, ban open footwear, schedule work time to avoid heat stress |

| Factor | Pre-Event | Event | Post-Event |

|---|---|---|---|

| Technology | Skiff without personal activator to activate a kill switch, Stowed PFD Priority: PFD available, PLB and engine kill switch | Motor keeps skiff moving from fisher Priority: PLB and engine kill switch | Skiff motors far from victim |

| Environment | Physical: Storm, wind, deep water Priority: Fish in fair weather | Physical: High waves, wind | Physical: High waves, wind Social: No insurance Priority: Insurance availability |

| Personal | Working alone, not wearing PFD, poor swimmer Priority: Swimming skills, PFD use | Fall overboard | Victim drowned, lost at sea |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Myers, M.L.; Durborow, R.M.; Kane, A.S. Gulf of Mexico Seafood Harvesters: Part 3. Potential Occupational Risk Reduction Measures. Safety 2018, 4, 33. https://0-doi-org.brum.beds.ac.uk/10.3390/safety4030033

Myers ML, Durborow RM, Kane AS. Gulf of Mexico Seafood Harvesters: Part 3. Potential Occupational Risk Reduction Measures. Safety. 2018; 4(3):33. https://0-doi-org.brum.beds.ac.uk/10.3390/safety4030033

Chicago/Turabian StyleMyers, Melvin L., Robert M. Durborow, and Andrew S. Kane. 2018. "Gulf of Mexico Seafood Harvesters: Part 3. Potential Occupational Risk Reduction Measures" Safety 4, no. 3: 33. https://0-doi-org.brum.beds.ac.uk/10.3390/safety4030033