Safety Vision of Agricultural Tractors: An Engineering Perspective Based on Recent Studies (2009–2019)

Abstract

:1. Introduction

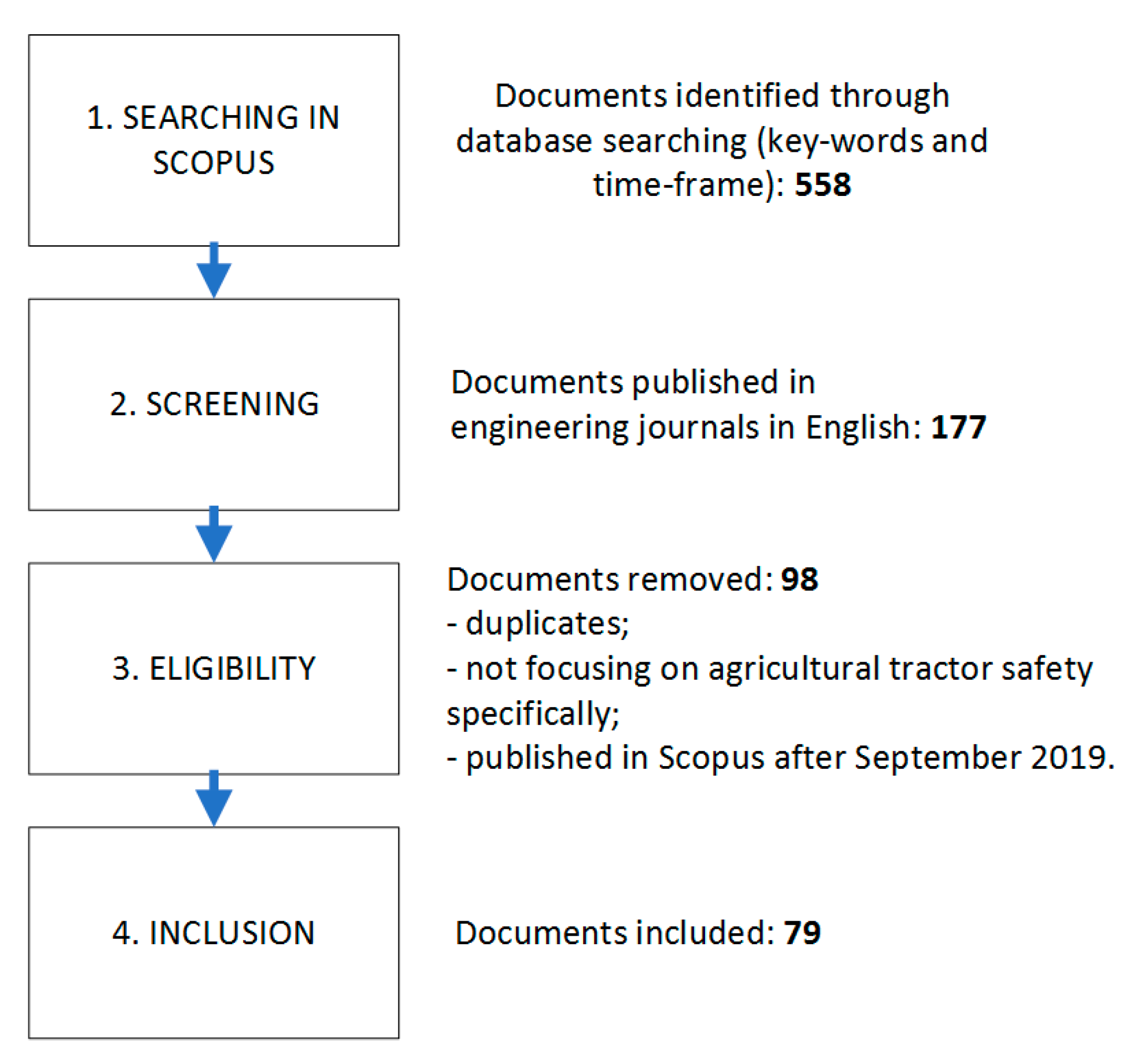

2. Materials and Methods

- Identification of material (definition of the scope, the database, and search criteria);

- Screening of pertinent articles (application of search criteria);

- Eligibility evaluation (abstract analysis for inclusion/exclusion);

- Data analysis and synthesis (full-text review).

- Type of publication: i.e., the engineering journals that published the selected documents, the affiliation country of the first author when the paper was published, the year of publication, etc.

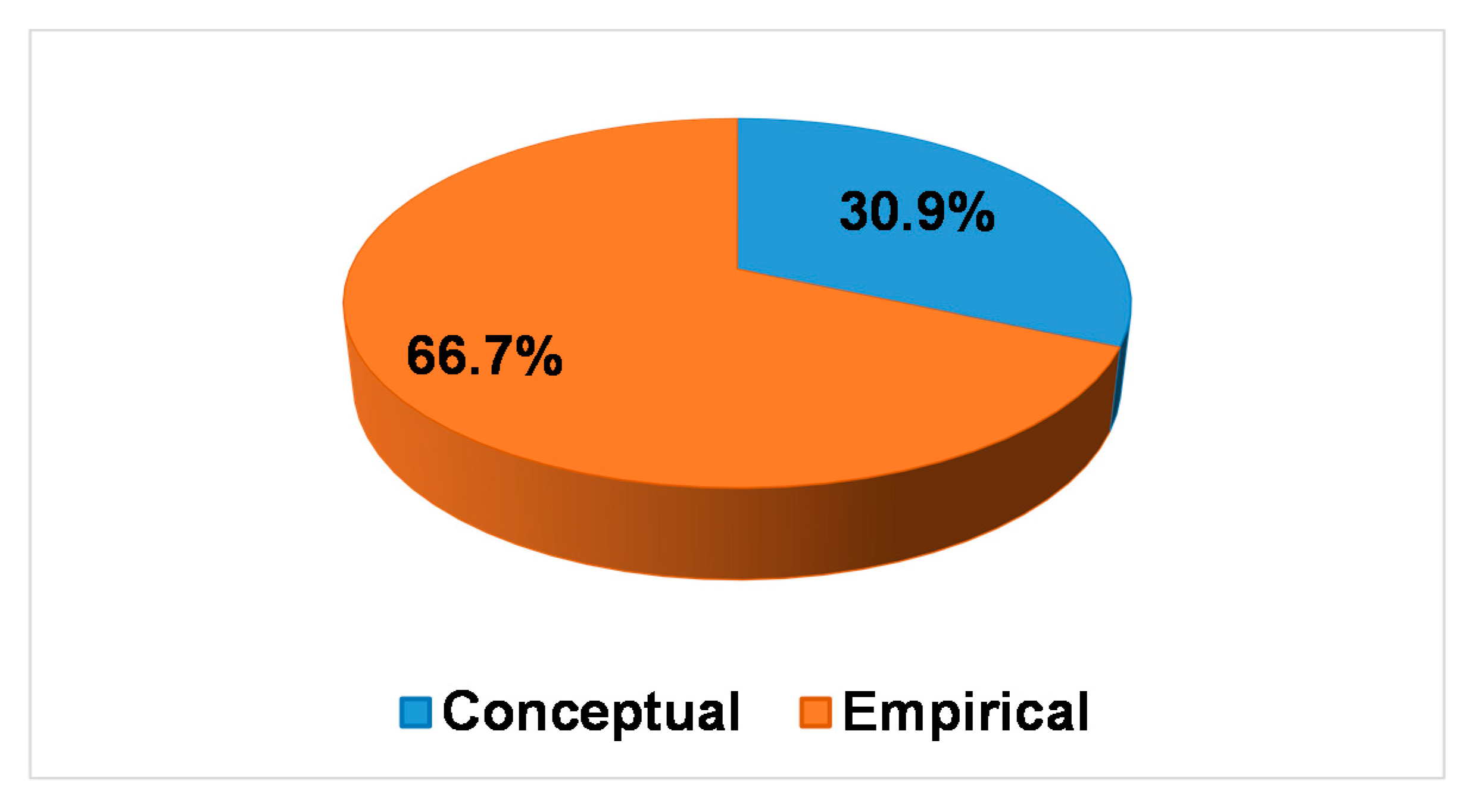

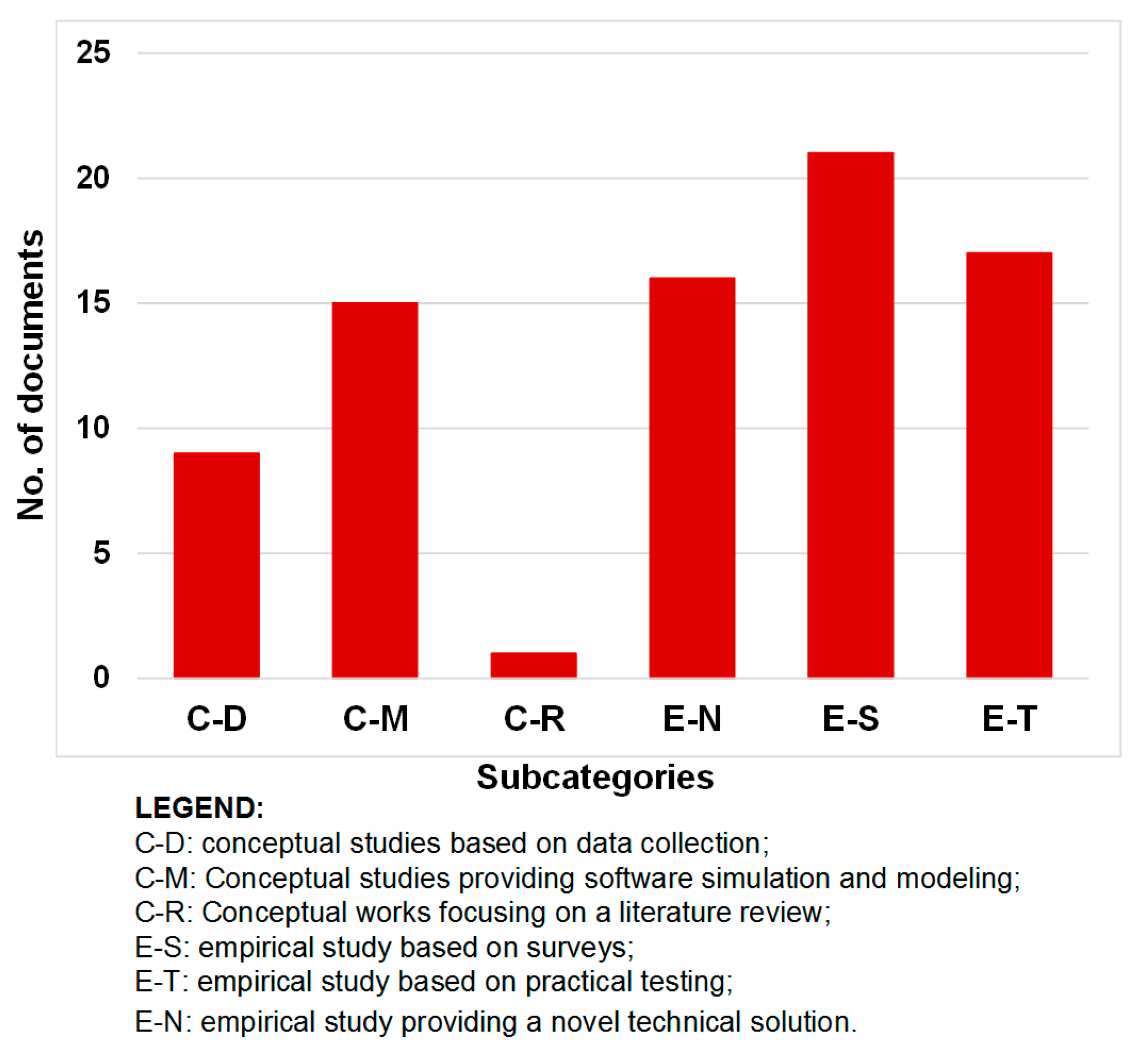

- Research category: distinguishing the selected documents into empirical and conceptual works. In detail, adapting the criteria provided by the above-mentioned studies [48,49] to the context of agricultural tractor safety, we considered:

- “empirical study”: a research work focused on the development of novel technical solutions, the practical test of the performances of the tractor and its components, as well as articles undertaking surveys and case studies;

- “conceptual study”: a research work aimed at providing theoretical concepts, review works, simulations, or theoretical modeling.

Based on this, a more detailed classification was performed, dividing empirical studies into the following subcategories:- E-S: empirical study based on surveys and interviews;

- E-T: empirical study based on practical testing of real equipment and user behavior;

- E-N: empirical study providing a novel technical solution, e.g., a prototype.

As far as conceptual works are concerned, the following subcategories were defined:- C-D: studies based on data collection and analysis (e.g., accident statistics);

- C-M: studies providing software simulation and modeling;

- C-R: works focusing on a literature review.

These sub-categories refer to the target of each study and the means used to achieve it. For instance, if an article proposed an assessment model for which validation is carried out through a practical case study, the paper was classified as C-M (and not as E-T), since it aimed to provide a conceptual output. - Research streams: i.e., the classification of documents in accordance with a reference framework representing the main issues of agricultural tractor safety. This analysis was aimed at investigating the research trends related to tractor safety in the engineering field, underlining the aspects dealt with by the selected documents [50,51]. For this purpose, as a classification benchmark, the following research streams were used:

- S.1.

- Mechanical hazards (stability, mobility, entanglement, etc.);

- S.2.

- Protective devices (ROPS, FOPS, PTO shield, etc.);

- S.3.

- Command and control (steering system, etc.);

- S.4.

- Other hazards (e.g., vibrations, noise, etc.);

- S.5.

- Ergonomics (technical features related to: user comfort, actuation forces, visibility, etc.);

- S.6.

- Information (safety signs, operational and warning signals, user training, etc.);

- S.7.

- Conformity (i.e., compliance with technical standards and mandatory requirements both from the constructive and users’ standpoints);

- S.8.

- User behavior (safety attitudes and behavior of users, human error, etc.).

3. Results

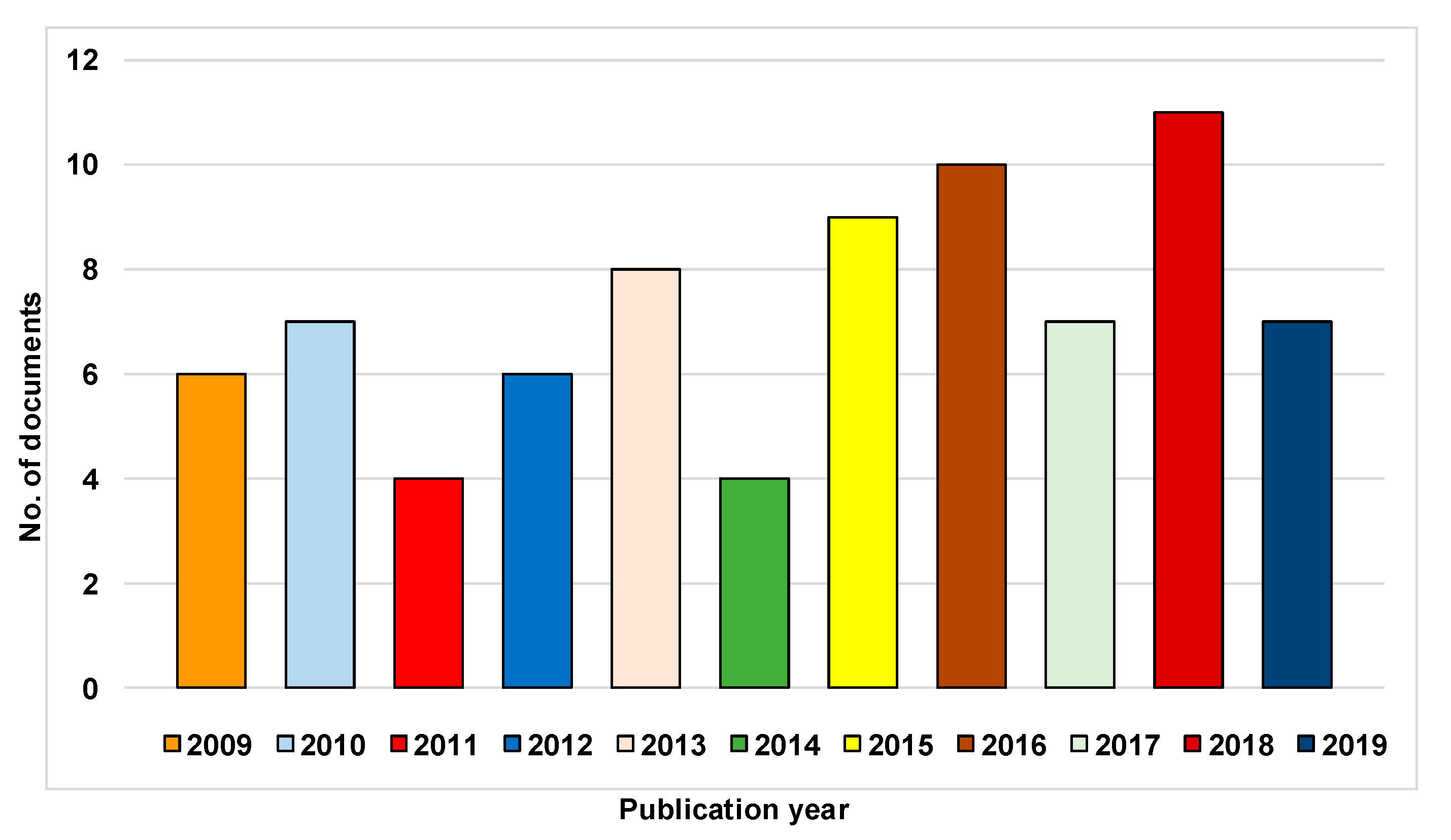

3.1. Type of Publication

3.2. Research Categories

3.3. Research Streams

3.3.1. Mechanical Hazards

3.3.2. Protective Systems

3.3.3. Command and Control

3.3.4. Other Hazards

3.3.5. Ergonomics

3.3.6. Information

3.3.7. Conformity

3.3.8. User Behavior

4. Discussion

4.1. Discussion of Research Trends

- The lack of studies promoting ROPS retrofitting and user training programs in other countries (e.g., in the European Union) could reveal the need to implement/increase these activities in such places. In fact, although the Directive 2009/104/EC indicates that self-propelled work equipment should be driven only by workers who have been appropriately trained in the safe use of such equipment [137], training and competence qualifications of tractor users have not been discussed sufficiently.

- There is a need to improve the effectiveness and usability of technical standards for ROPS testing and homologation, so as to make ROPS design and manufacturing easier and less expensive [73,76], while avoiding at the same time the failure of homologated protective structures [70]. The latter issue was stressed by different studies, shedding light on the necessity of updating technical standards such as the OECD Codes, taking into account the features of modern tractors (e.g., the tractor ballast [120]) and how they are used in practice [65,118]. Similarly, the lack of a clear reference for dynamic tests of ROPS was outlined [117,126], while the inadequacy of the standards related to FROPSs testing (e.g., concerning the grasping area [99] and the actuation torque [97]) needs to be further investigated.

4.2. Limitations

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

Appendix A

- E-S: empirical study based on surveys and interviews;

- E-T: empirical study based on practical testing of real equipment;

- E-N: empirical study providing a novel technical solution, e.g., a prototype;

- C-D: conceptual studies based on data collection and analysis (e.g., accident statistics);

- C-M: conceptual studies providing software simulation and modeling;

- C-R: conceptual works focusing on a literature review;

- S.1: Mechanical hazards;

- S.2: Protective devices;

- S.3: Command and control;

- S.4: Other hazards;

- S.5: Ergonomics;

- S.6: Information;

- S.7: Conformity;

- S.8: User behavior.

| No. | Author | Year | Category | Stream |

| [80] | Ahamed et al. | 2009 | E-N | S.3 |

| [78] | Al-Bassit et al. | 2019 | E-N | S.2 |

| [70] | Alfaro et al. | 2010 | C-M | S.2. |

| [73] | Alkhaledi et al. | 2013 | E-N | S.2. |

| [119] | Arana et al. | 2011 | C-M | S.7. |

| [76] | Ayers et al. | 2016 | C-M | S.2. |

| [108] | Bertacchini et al. | 2014 | E-N | S.6. |

| [69] | Bhondave et al. | 2017 | E-N | S.1 |

| [126] | Bietresato et al. | 2018 | E-N | S.7 |

| [79] | Bo et al. | 2018 | E-N | S.3 |

| [102] | Caffaro and Cavallo | 2015 | E-S | S.6 |

| [103] | Caffaro et al. | 2017 | E-S | S.6 |

| [104] | Caffaro et al. | 2018 | E-S | S.6 |

| [100] | Casazza et al. | 2016 | E-T | S.5 |

| [82] | Castagnetti et al. | 2015 | E-N | S.3 |

| [87] | Catania et al. | 2013 | E-T | S.4 |

| [136] | Cole et al. | 2016 | E-S | S.8 |

| [110] | Cole et al. | 2009 | C-D | S.7 |

| [89] | Cutini et al. | 2012 | E-S | S.4 |

| [90] | Cutini et al. | 2016 | E-T | S.4 |

| [91] | Cutini et al. | 2017 | E-T | S.4 |

| [88] | Cutini et al. | 2019 | E-T | S.4 |

| [133] | Di Nocera et al. | 2018 | E-S | S.8 |

| [94] | Ehlers and Field | 2017 | E-T | S.5 |

| [95] | Ehlers and Field | 2016 | E-T | S.5 |

| [86] | Ehlers et al. | 2017 | E-T | S.3 |

| [123] | Fargnoli et al. | 2018 | E-S | S.7 |

| [67] | Franceschetti et al. | 2016 | E-N | S.1 |

| [77] | Franceschetti and Rondelli | 2019 | E-T | S.2 |

| [64] | Franceschetti et al. | 2019 | E-T | S.1 |

| [96] | Gilad and Byran | 2015 | C-M | S.5 |

| [71] | Guan et al. | 2011 | E-N | S.2 |

| [118] | Guzzomi and Rondelli | 2013 | C-D | S.7 |

| [131] | Hard et al. | 2015 | E-S | S.8 |

| [132] | Hard et al. | 2016 | E-S | S.8 |

| [111] | Hard and Myers | 2011 | C-D | S.7 |

| [114] | Harris et al. | 2010 | E-T | S.7 |

| [115] | Harris et al. | 2011 | C-M | S.7 |

| [37] | Houshyar and Houshyar | 2018 | E-S | S.8 |

| [120] | Jarén et al. | 2009 | C-M | S.7 |

| [130] | Jenkins et al. | 2012 | E-S | S.8 |

| [106] | Jepsen | 2012 | E-S | S.8 |

| [34] | Jones et al. | 2013 | C-D | S.7 |

| [122] | Kabir et al. | 2017 | E-T | S.7 |

| [84] | Kaizu and Choi | 2012 | E-N | S.3 |

| [127] | Keskin et al. | 2012 | E-S | S.8 |

| [97] | Khorsandi and Ayers | 2018 | E-T | S.5 |

| [66] | Khorsandi et al. | 2018 | C-M | S.1 |

| [98] | Khorsandi | 2016 | C-M | S.5 |

| [72] | Latorre-Biel et al. | 2019 | E-N | S.2 |

| [117] | Lindhorst et al. | 2018 | C-M | S.7 |

| [109] | Liu and Koc | 2015 | E-N | S.6 |

| [134] | Lleras et al. | 2016 | E-N | S.8 |

| [135] | Lombardi and Fargnoli | 2018 | C-M | S.8 |

| [63] | Mann and Dee Jepsen | 2017 | C-R | S.6 |

| [65] | Mazzetto et al. | 2013 | C-M | S.1 |

| [74] | Monarca et al. | 2013 | E-T | S.2 |

| [75] | Monarca et al. | 2015 | C-D | S.2 |

| [20] | Myers et al. | 2009 | E-S | S.7 |

| [125] | Myers and Purschwitz | 2012 | C-D | S.7 |

| [99] | Pessina et al. | 2016 | E-T | S.5 |

| [116] | Poojary and Kalamkar | 2009 | C-M | S.7 |

| [93] | Rakhra and Mann | 2013 | E-T | S.5 |

| [21] | Rondelli et al. | 2018 | C-D | S.7 |

| [121] | Rondelli and Guzzomi | 2010 | C-D | S.7 |

| [101] | Rondelli et al. | 2013 | C-M | S.5 |

| [83] | Rovira-Más | 2010 | C-M | S.3 |

| [81] | Ruggeri et al. | 2014 | E-N | S.3 |

| [18] | Schwab et al. | 2019 | E-S | S.8 |

| [68] | Seyedabadi | 2015 | C-M | S.1 |

| [113] | Sorensen et al. | 2010 | E-S | S.7 |

| [92] | Sviridova and Sakai | 2015 | E-T | S.4 |

| [85] | Takai et al. | 2014 | E-N | S.3 |

| [105] | Tebeaux | 2010 | E-S | S.6 |

| [128] | Tillapaugh et al. | 2010 | E-S | S.8 |

| [124] | Tinc et al. | 2015 | C-D | S.7 |

| [112] | Tonelli et al. | 2009 | E-S | S.7 |

| [107] | Vincent et al. | 2019 | E-S | S.8 |

| [129] | Weil et al. | 2014 | E-S | S.8 |

References

- Cecchini, M.; Cossio, F.; Marucci, A.; Monarca, D.; Colantoni, A.; Petrelli, M.; Allegrini, E. Survey on the status of enforcement of European directives on health and safety at work in some Italian farms. J. Food Agric. Environ. 2013, 11, 595–600. [Google Scholar] [CrossRef]

- Vigoroso, L.; Caffaro, F.; Cavallo, E. Warning against Critical Slopes in Agriculture: Comprehension of Targeted Safety Signs in a Group of Machinery Operators in Italy. Int. J. Environ. Res. Public Health 2019, 16, 611. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fargnoli, M.; Lombardi, M.; Haber, N.; Puri, D. The Impact of Human Error in the Use of Agricultural Tractors: A Case Study Research in Vineyard Cultivation in Italy. Agriculture 2018, 8, 82. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.; Lee, K.; Räsänen, K. Agricultural injuries in Korea and errors in systems of safety. Ann. Agric. Environ. Med. 2016, 23, 432–436. [Google Scholar] [CrossRef]

- Ivascu, L.; Cioca, L.-I. Occupational Accidents Assessment by Field of Activity and Investigation Model for Prevention and Control. Safety 2019, 5, 12. [Google Scholar] [CrossRef] [Green Version]

- European Agency for Safety and Health at Work (EU-OSHA). Maintenance in Agriculture—A Safety and Health Guide; Publications Office of the European Union: Luxembourg, 2011. [Google Scholar] [CrossRef]

- Burgus, S.; Duysen, E. Identifying Topics and Dissemination Methods for Agricultural Safety and Health Messages. Safety 2017, 3, 3. [Google Scholar] [CrossRef] [Green Version]

- Canadian Agricultural Injury Reporting (CAIR). 2016. Available online: https://www.cair-sbac.ca/wp-content/uploads/2017/02/CASA-CAIR-Report-English-FINAL-Web.pdf (accessed on 2 September 2019).

- Safe Work Australia. Work Health and Safety in the Agricultural Industry-2016. Available online: https://www.safeworkaustralia.gov.au/system/files/documents/1702/whs-in-the-agricultural-industry.pdf (accessed on 2 September 2019).

- Chae, H.; Min, K.; Park, J.; Kim, K.; Kim, H.; Lee, K. Estimated rate of agricultural injury: The Korean farmers’ occupational disease and injury survey. Ann. Occup. Environ. Med. 2014, 26, 8. [Google Scholar] [CrossRef]

- Cividino, S.R.S.; Pergher, G.; Zucchiatti, N.; Gubiani, R. Agricultural Health and Safety Survey in Friuli Venezia Giulia. Agriculture 2018, 8, 9. [Google Scholar] [CrossRef] [Green Version]

- Fargnoli, M.; Vita, L.; Gattamelata, D.; Laurendi, V.; Tronci, M. A reverse engineering approach to enhance machinery design for safety. In DS 70, Proceedings of the DESIGN 2012, the 12th International Design Conference, Dubrovnik, Croatia, 21–24 May 2012; Marjanovic, D., Storga, M., Pavkovic, N., Bojcetic, N., Eds.; International Design Conference: Dubrovnik, Croatia, 2012; pp. 627–636. ISBN 978-953-7738-17-4. [Google Scholar]

- Yoder, A.M.; Sorensen, J.A.; Foster, F.; Myers, M.; Murphy, D.; Cook, G.; May, J.; Jenkins, P. Selecting Target Populations for ROPS Retrofit Programs in Pennsylvania and Vermont. J. Agric. Saf. Health 2013, 19, 175–190. [Google Scholar] [CrossRef]

- Jadhav, R.; Achutan, C.; Haynatzki, G.; Rajaram, S.; Rautiainen, R. Risk factors for agricultural injury: A systematic review and meta-analysis. J. Agromed. 2015, 20, 434–449. [Google Scholar] [CrossRef]

- Cavallo, E.; Ferrari, E.; Bollani, L.; Coccia, M. Attitudes and behaviour of adopters of technological innovations in agricultural tractors: A case study in Italian agricultural system. Agric. Syst. 2014, 130, 44–54. [Google Scholar] [CrossRef]

- Hallman, E.M. ROPS retrofitting: Measuring effectiveness of incentives and uncovering inherent barriers to success. J. Agric. Saf. Health 2005, 11, 75–84. [Google Scholar] [CrossRef] [PubMed]

- Cavallo, E.; Langle, T.; Bueno, D.; Tsukamoto, S.; Görücü, S.; Murphy, D. Rollover protective structure (ROPS) retrofitting on agricultural tractors: Goals and approaches in different countries. J. Agromed. 2014, 19, 208–209. [Google Scholar] [CrossRef]

- Schwab, C.V.; Arbuckle, J.G.; Hanna, H.M. Barriers and Motivators for Tractors ROPS Retrofitting in Iowa. J. Agric. Saf. Health 2019, 25, 1–9. [Google Scholar] [CrossRef]

- Ayers, P.; Khorsandi, F.; Wang, X.; Araujo, G. ROPS designs to protect operators during agricultural tractor rollovers. J. Terramech. 2018, 75, 49–55. [Google Scholar] [CrossRef]

- Myers, M.L.; Cole, H.P.; Westneat, S.C. Injury severity related to overturn characteristics of tractors. J. Saf. Res. 2009, 40, 165–170. [Google Scholar] [CrossRef]

- Rondelli, V.; Casazza, C.; Martelli, R. Tractor rollover fatalities, analyzing accident scenario. J. Saf. Res. 2018, 67, 99–106. [Google Scholar] [CrossRef]

- Sun, C.; Nakashima, H.; Shimizu, H.; Miyasaka, J.; Ohdoi, K. Physics engine application to overturning dynamics analysis on banks and uniform slopes for an agricultural tractor with a rollover protective structure. Biosyst. Eng. 2019, 185, 150–160. [Google Scholar] [CrossRef] [Green Version]

- Erkol, Z.; Buken, B.; Hekimoglu, Y.; Erkol, H.; Ince, H.; Erzengin, O.U. Analysis of tractor-related deaths. J. Agromed. 2013, 18, 87–97. [Google Scholar] [CrossRef]

- Pessina, D.; Facchinetti, D. A survey on fatal accidents for overturning of agricultural tractors in Italy. Chem. Eng. Trans. 2017, 58, 79–84. [Google Scholar] [CrossRef]

- Fargnoli, M.; Laurendi, V.; Tronci, M. Design for safety in agricultural machinery. In DS 60, Proceedings of the DESIGN 2010, the 11th International Design Conference, Dubrovnik, Croatia, 17–20 May 2010; Marjanovic, D., Storga, M., Pavkovic, N., Bojcetic, N., Eds.; International Design Conference: Dubrovnik, Croatia, 2010; pp. 701–710. ISBN 978-953-7738-03-7. [Google Scholar]

- Cecchini, M.; Colantoni, A.; Monarca, D.; Cossio, F.; Riccioni, S. Survey on the status of enforcement of European directives on health and safety at work in some farms of central Italy. Chem. Eng. Trans. 2017, 58, 103–108. [Google Scholar] [CrossRef]

- Kumar, A.; Varghese, M.; Mohan, D. Equipment-related injuries in agriculture: An international perspective. Inj. Control Saf. Promot. 2000, 7, 175–186. [Google Scholar] [CrossRef]

- Kogler, R.; Quendler, E.; Boxberger, J. Occupational accidents with agricultural machinery in Austria. J. Agromed. 2016, 21, 61–70. [Google Scholar] [CrossRef] [PubMed]

- Irwin, A.; Poots, J. Investigation of UK farmer go/no-go decisions in response to tractor-based risk scenarios. J. Agromed. 2018, 23, 154–165. [Google Scholar] [CrossRef] [PubMed]

- Myers, M.L. Folding ROPS or automatically deployable ROPS? J. Agric. Saf. Health 2015, 21, 201–204. [Google Scholar] [CrossRef]

- Vallone, M.; Bono, F.; Quendler, E.; Febo, P.; Catania, P. Risk exposure to vibration and noise in the use of agricultural track-laying tractors. Ann. Agric. Environ. Med. 2016, 23, 591–597. [Google Scholar] [CrossRef] [Green Version]

- Jamshidi, N.; Abdollahi, S.M.; Maleki, A. A survey on the actuating force on brake and clutch pedal controls in agricultural tractor in use in Iran. Pol. Ann. Med. 2016, 23, 113–117. [Google Scholar] [CrossRef]

- Antunes, S.M.; Cordeiro, C.; Teixeira, H.M. Analysis of fatal accidents with tractors in the Centre of Portugal: Ten years analysis. Forens. Sci. Int. 2018, 287, 74–80. [Google Scholar] [CrossRef]

- Jones, C.B.; Day, L.; Staines, C. Trends in tractor related fatalities among adults working on farms in Victoria, Australia, 1985–2010. Accid. Anal. Prev. 2013, 50, 110–114. [Google Scholar] [CrossRef]

- Karbeyaz, K.; Şimşek, Ü.; Yilmaz, A. Deaths Related to Tractor Accidents in Eskişehir, Turkey: A 25-Year Analysis. J. Forens. Sci. 2019, 64, 1731–1734. [Google Scholar] [CrossRef]

- Tormoehlen, S.A.; Field, W.E. Summary of Indiana Farm Fatalities Involving Individuals 55 Years and Older-1988-2017. Safety 2019, 5, 39. [Google Scholar] [CrossRef] [Green Version]

- Houshyar, E.; Houshyar, M. Tractor safety and related injuries in Iranian farms. Saf. Sci. 2018, 103, 88–93. [Google Scholar] [CrossRef]

- Caffaro, F.; Lundqvist, P.; Micheletti Cremasco, M.; Nilsson, K.; Pinzke, S.; Cavallo, E. Machinery-Related Perceived Risks and Safety Attitudes in Senior Swedish Farmers. J. Agromed. 2018, 23, 78–91. [Google Scholar] [CrossRef] [PubMed]

- Irwin, A.; Caruso, L.; Tone, I. Thinking ahead of the tractor: Driver safety and situation awareness. J. Agromed. 2019, 24, 288–297. [Google Scholar] [CrossRef] [PubMed]

- Fargnoli, M.; Lombardi, M.; Puri, D. Applying Hierarchical Task Analysis to Depict Human Safety Errors during Pesticide Use in Vineyard Cultivation. Agriculture 2019, 9, 158. [Google Scholar] [CrossRef] [Green Version]

- Colantoni, A.; Monarca, D.; Laurendi, V.; Villarini, M.; Gambella, F.; Cecchini, M. Smart Machines, Remote Sensing, Precision Farming, Processes, Mechatronic, Materials and Policies for Safety and Health Aspects. Agriculture 2018, 8, 47. [Google Scholar] [CrossRef] [Green Version]

- Molari, G.; Ayers, P.D.; Meyer, H.G.; Rondelli, V. Special Issue: Engineering advances to improve the safety of agricultural machines. Biosyst. Eng. 2019, 185, 1–3. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Preferred reporting items for systematic reviews and meta-analyses: The prisma statement. Int. J. Surg. 2010, 8, 336–341. [Google Scholar] [CrossRef] [Green Version]

- Thomé, A.M.T.; Scavarda, L.F.; Scavarda, A.J. Conducting systematic literature review in operations management. Prod. Plan. Control 2016, 27, 408–420. [Google Scholar] [CrossRef]

- Enya, A.; Pillay, M.; Dempsey, S. A Systematic Review on High Reliability Organisational Theory as a Safety Management Strategy in Construction. Safety 2018, 4, 6. [Google Scholar] [CrossRef] [Green Version]

- Mongeon, P.; Paul-Hus, A. The journal coverage of Web of Science and Scopus: A comparative analysis. Scientometrics 2016, 106, 213–228. [Google Scholar] [CrossRef]

- Massaro, M.; Dumay, J.; Guthrie, J. On the shoulders of giants: Undertaking a structured literature review in accounting. Acc. Audit. Acc. J. 2016, 29, 767–801. [Google Scholar] [CrossRef]

- Carnevalli, J.A.; Miguel, P.A.C. Review, analysis and classification of the literature on QFD-Types of research, difficulties and benefits. Int. J. Prod. Econ. 2008, 114, 737–754. [Google Scholar] [CrossRef]

- Verbano, C.; Venturini, K. Managing risks in SMEs: A literature review and research agenda. J. Technol. Manag. Innov. 2013, 8, 186–197. [Google Scholar] [CrossRef]

- Verbano, C.; Venturini, K. Development paths of risk management: Approaches, methods and fields of application. J. Risk Res. 2011, 14, 519–550. [Google Scholar] [CrossRef]

- Ho, W.; Zheng, T.; Yildiz, H.; Talluri, S. Supply chain risk management: A literature review. Int. J. Prod. Res. 2015, 53, 5031–5069. [Google Scholar] [CrossRef]

- European Union (EU). Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on Machinery, and Amending Directive 95/16/EC. Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=celex:32006L0042 (accessed on 2 September 2019).

- Llory, M. Human-and work-centred safety: Keys to a new conception of management. Ergonomics 1997, 40, 1148–1158. [Google Scholar] [CrossRef]

- Karwowski, W. Ergonomics and human factors: The paradigms for science, engineering, design, technology and management of human-compatible systems. Ergonomic 2005, 48, 436–463. [Google Scholar] [CrossRef]

- Houssin, R.; Sun, H.; Gardoni, M. A behavioural design approach to improving mechanical system design with integration of use conditions. Int. J. Des. Innov. Res. 2010, 5, 1–24. [Google Scholar]

- Sadeghi, L.; Dantan, J.Y.; Mathieu, L.; Siadat, A.; Aghelinejad, M.M. A design approach for safety based on Product-Service Systems and Function–Behavior–Structure. CIRP J. Manuf. Sci. Technol. 2017, 9, 44–56. [Google Scholar] [CrossRef] [Green Version]

- European Union (EU). Guide to application of the Machinery Directive 2006/42/EC. Edition 2.2—October 2019. Available online: https://osha.europa.eu/it/legislation/guidelines/guide-application-machinery-directive-200642ec (accessed on 25 November 2019).

- International Labour Office (ILO). Safety and Health in Agriculture; ILO Code of Practice; International Labour Office: Geneva, Switzerland, 2011; Available online: https://www.ilo.org/global/topics/safety-and-health-at-work/normative-instruments/code-of-practice/WCMS_161135/lang--en/index.htm (accessed on 2 September 2019).

- Hagel, L.; King, N.; Dosman, J.A.; Lawson, J.; Trask, C.; Pickett, W.; Saskatchewan Farm Injury Cohort Study Team. Profiling the safety environment on Saskatchewan farms. Saf. Sci. 2016, 82, 103–110. [Google Scholar] [CrossRef]

- Pinzke, S.; Svennefelt, C.A.; Lundqvist, P. Occupational injuries in Swedish agriculture–development and Preventive actions. J. Agric. Saf. Health 2018, 24, 193–211. [Google Scholar] [CrossRef]

- Vinayak, K.; Kodali, R. Benchmarking the quality function deployment models. Benchmarking Int. J. 2013, 20, 825–854. [Google Scholar] [CrossRef]

- Ayers, P.D.; Rondelli, V. Tractor ROPS and stability research: Introduction to this special issue. J. Agric. Saf. Health 2016, 22, 213–214. [Google Scholar] [CrossRef] [Green Version]

- Mann, A.; Dee Jepsen, S. Using expert panel data to guide youth agricultural safety and health training resources in the US. Safety 2017, 3, 4. [Google Scholar] [CrossRef] [Green Version]

- Franceschetti, B.; Rondelli, V.; Ciuffoli, A. Comparing the influence of roll-over protective structure type on tractor lateral stability. Saf. Sci. 2019, 115, 42–50. [Google Scholar] [CrossRef]

- Mazzetto, F.; Bietresato, M.; Gasparetto, A.; Vidoni, R. Simulated stability tests of a small articulated tractor designed for extreme-sloped vineyards. Agric. Eng. 2013, XLIV(s2), 663–668. [Google Scholar] [CrossRef]

- Khorsandi, F.; Ayers, P.D.; Freeland, R.S.; Wang, X. Modeling the effect of liquid movement on the center of gravity calculation of agricultural vehicles. J. Terramech. 2018, 75, 37–48. [Google Scholar] [CrossRef]

- Franceschetti, B.; Capacci, E.; Rondelli, V. Effects of rubber tracks on narrow-track tractors on the non-continuous rolling prediction model. J. Agric. Saf. Health 2016, 22, 262–273. [Google Scholar] [CrossRef] [Green Version]

- Seyedabadi, E. Finite element analysis of lift arm of a MF-285 tractor three-point hitch. J. Failure Anal. Prev. 2015, 15, 737–743. [Google Scholar] [CrossRef]

- Bhondave, B.; Ganesan, T.; Varma, N.; Renu, R.; Sabarinath, N. Design and development of electro hydraulics hitch control for agricultural tractor. SAE Int. J. Commer. Veh. 2017, 10, 405–410. [Google Scholar] [CrossRef]

- Alfaro, J.R.; Arana, I.; Arazuri, S.; Jarén, C. Assessing the safety provided by SAE J2194 Standard and Code 4 Standard code for testing ROPS, using finite element analysis. Biosyst. Eng. 2010, 105, 189–197. [Google Scholar] [CrossRef]

- Guan, J.; Hsiao, H.; Zwiener, J.V.; Current, R.S.; Lutz, T.J.; Cantis, D.M.; Powers, J.R., Jr.; Newbraugh, B.H.; Spahr, J.S. Evaluating the protective capacity of two-post ROPS for a seat-belted occupant during a farm tractor overturn. J. Agric. Saf. Health 2011, 17, 15–32. [Google Scholar] [CrossRef] [PubMed]

- Latorre-Biel, J.I.; Ballesteros, T.; Arana, I.; Alfaro, J.R. Development of an inexpensive rollover energy dissipation device to improve safety provided by ROPS. Biosyst. Eng. 2019, 185, 88–102. [Google Scholar] [CrossRef]

- Alkhaledi, K.; Means, K.; McKenzie, E., Jr.; Smith, J. Reducing occupational fatalities by using NIOSH 3rd generation automatically deployable rollover protective structure. Saf. Sci. 2013, 51, 427–431. [Google Scholar] [CrossRef]

- Monarca, D.; Cecchini, M.; Colantoni, A.; Di Giacinto, S.; Menghini, G.; Longo, L. Study on the possibility of application of a compact roll over protective structure for agricultural wheeled narrow track tractors. J. Agric. Eng. 2013, XLIV(s2), e136, 681–685. [Google Scholar] [CrossRef]

- Monarca, D.; Cecchini, M.; Di Giacinto, S.; Bedini, R.; Ghignoli, A.; Colopardi, F.; Rapiti, R. Comparison between Different Protective Devices for Agricultural Wheeled Narrow Track Tractors and a Risk Index in Orchard Work. Contemporary Eng. Sci. 2015, 8, 1205–1213. [Google Scholar] [CrossRef]

- Ayers, P.D.; Khorsandi, F.; John, Y.; Whitaker, G. Development and evaluation of a computer-based ROPS design program. J. Agric. Saf. Health 2016, 22, 247–260. [Google Scholar] [CrossRef]

- Franceschetti, B.; Rondelli, V. Models to predict the force to operate front foldable rollover protective structures for narrow-track tractors. Biosyst. Eng. 2019, 185, 126–134. [Google Scholar] [CrossRef]

- Al-Bassit, L.; Tricot, N.; Sayegh, S. Falling-object protective structure for tractors in service: Prototype design and validation. Biosyst. Eng. 2019, 185, 76–87. [Google Scholar] [CrossRef]

- Bo, H.; Liang, W.; Yuefeng, D.; Zhenghe, S.; Enrong, M.; Zhongxiang, Z. Design and Experiment on Integrated Proportional Control Valve of Automatic Steering System. IFAC-PapersOnLine 2018, 51, 389–396. [Google Scholar] [CrossRef]

- Ahamed, T.; Tian, L.; Takigawa, T.; Zhang, Y. Development of auto-hitching navigation system for farm implements using laser range finder. Trans. ASABE 2009, 52, 1793–1803. [Google Scholar] [CrossRef]

- Ruggeri, M.; Ferraresi, C.; Dariz, L.; Malaguti, G. A High Functional Safety Performance Level Machine Controller for a Medium Size Agricultural Tractor. SAE Int. J. Commer. Veh. 2014, 7, 613–618. [Google Scholar] [CrossRef]

- Castagnetti, D.; Bertacchini, A.; Spaggiari, A.; Lesnjanin, A.; Larcher, L.; Dragoni, E.; Arduini, M. A novel ball joint wear sensor for low-cost structural health monitoring of off-highway vehicles. Mech. Ind. 2015, 16, 507. [Google Scholar] [CrossRef]

- Rovira-Más, F. Sensor architecture and task classification for agricultural vehicles and environments. Sensors 2010, 10, 11226–11247. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kaizu, Y.; Choi, J. Development of a tractor navigation system using augmented reality. Eng. Agric. Environ. Food 2012, 5, 96–101. [Google Scholar] [CrossRef]

- Takai, R.; Yang, L.; Noguchi, N. Development of a crawler-type robot tractor using RTK-GPS and IMU. Eng. Agric. Environ. Food 2014, 7, 143–147. [Google Scholar] [CrossRef]

- Ehlers, S.G.; Field, W.E.; Ess, D.R. Methods of collecting and analyzing rearward visibility data for agricultural machinery: Hazard and/or object detectability. J. Agric. Saf. Health 2017, 23, 39–53. [Google Scholar] [CrossRef]

- Catania, P.; Vallone, M.; Alleri, M.; Morello, G.; Spartà, G.; Febo, P. Whole body vibrations during field operations in the vineyard. J. Agric. Eng. 2013, XLIV(s2), 710–714. [Google Scholar] [CrossRef]

- Cutini, M.; Brambilla, M.; Bisaglia, C. Assessment of a ride comfort number for agricultural tractors: A simplified approach. Biosyst. Eng. 2019, 185, 35–44. [Google Scholar] [CrossRef]

- Cutini, M.; Romano, E.; Bisaglia, C. Assessment of the influence of the eccentricity of tires on the whole-body vibration of tractor drivers during transport on asphalt roads. J. Terramech. 2012, 49, 197–206. [Google Scholar] [CrossRef]

- Cutini, M.; Costa, C.; Bisaglia, C. Development of a simplified method for evaluating agricultural tractor’s operator whole body vibration. J. Terramech. 2016, 63, 23–32. [Google Scholar] [CrossRef]

- Cutini, M.; Deboli, R.; Calvo, A.; Preti, C.; Brambilla, M.; Bisaglia, C. Ground soil input characteristics determining agricultural tractor dynamics. Appl. Eng. Agric. 2017, 33, 509. [Google Scholar] [CrossRef]

- Sviridova, N.; Sakai, K. Application of photoplethysmogram for detecting physiological effects of tractor noise. Eng. Agric. Environ. Food 2015, 8, 313–317. [Google Scholar] [CrossRef]

- Rakhra, A.K.; Mann, D.D. Evaluation of Implement Monitoring Systems. J. Agric. Saf. Health 2013, 19, 51–67. [Google Scholar] [CrossRef]

- Ehlers, S.G.; Field, W.E. Determining the effectiveness of mirrors and camera systems in monitoring the rearward visibility of self-propelled agricultural machinery. J. Agric. Saf. Health 2017, 23, 183–201. [Google Scholar] [CrossRef]

- Ehlers, S.G.; Field, W.E. Rearward visibility issues related to agricultural tractors and self-propelled machinery: Contributing factors, potential solutions. J. Agric. Saf. Health 2016, 22, 47–59. [Google Scholar] [CrossRef]

- Gilad, I.; Byran, E. Quantifying driver’s field-of-view in tractors: Methodology and case study. Int. J. Occup. Saf. Ergon. 2015, 21, 20–29. [Google Scholar] [CrossRef]

- Khorsandi, F.; Ayers, P.D. The effect of friction on actuation torques of foldable rollover protective structures. J. Agric. Saf. Health 2018, 24, 227–242. [Google Scholar] [CrossRef]

- Khorsandi, F.; Ayers, P.D.; Jackson, D.L.; Wilkerson, J. The effect of speed on foldable ROPS actuation forces. J. Agric. Saf. Health 2016, 22, 285–298. [Google Scholar] [CrossRef] [Green Version]

- Pessina, D.; Facchinetti, D.; Giordano, D.M. Narrow-track agricultural tractors: A survey on the load of the hand-operated foldable rollbar. J. Agric. Saf. Health 2016, 22, 275–284. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Casazza, C.; Martelli, R.; Rondelli, V. Evaluation of a commercial tractor safety monitoring system using a reverse engineering procedure. J. Agric. Saf. Health 2016, 22, 215–225. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rondelli, V.; Martelli, R.; Casazza, C.; Guarnieri, A. Methodological approach to assess tractor stability in normal operation in field using a commercial warning device. J. Agric. Eng. 2013, XLIV(s2), e132, 659–662. [Google Scholar] [CrossRef]

- Caffaro, F.; Cavallo, E. Comprehension of safety pictograms affixed to agricultural machinery: A survey of users. J. Saf. Res. 2015, 55, 151–158. [Google Scholar] [CrossRef]

- Caffaro, F.; Mirisola, A.; Cavallo, E. Safety signs on agricultural machinery: Pictorials do not always successfully convey their messages to target users. Appl. Ergon. 2017, 58, 156–166. [Google Scholar] [CrossRef]

- Caffaro, F.; Schmidt, S.; Murphy, D.J.; Cavallo, E. Comprehension rates of safety pictorials affixed to agricultural machinery among Pennsylvania rural population. Saf. Sci. 2018, 103, 162–171. [Google Scholar] [CrossRef]

- Tebeaux, E. Improving tractor safety warnings: Readability is missing. J. Agric. Saf. Health 2010, 16, 181–205. [Google Scholar] [CrossRef]

- Jepsen, S.D. The US Department of Labor’s tractor and machinery certification program: Management styles and perceptions held by community stakeholders and instructors. J. Agric. Saf. Health 2012, 18, 217–232. [Google Scholar] [CrossRef]

- Vincent, S.K.; Mazur, J.M.; Summey, T.E.; Namkoong, K.; Byrd, A.P. An Evaluation of Behavioral Intent in Appalachian Youth Participating in the CROPS Curriculum. J. Agric. Saf. Health 2019, 25, 25–36. [Google Scholar] [CrossRef]

- Bertacchini, A.; Napoletano, G.; Dondi, D.; Larcher, L.; Pavan, P. Optimized energy-aware wireless system for identification of the relative positioning of articulated systems in the free space. IEEE Sens. J. 2014, 14, 1682–1692. [Google Scholar] [CrossRef]

- Liu, B.; Koc, A.B. Field tests of a tractor rollover detection and emergency notification system. J. Agric. Saf. Health 2015, 21, 113–127. [Google Scholar] [CrossRef] [PubMed]

- Cole, H.P.; Piercy, L.R.; Heinz, K.L.; Westneat, S.C.; Arrowsmith, H.E.; Raymond, K.M. Safety status of farm tractors that operate on public highways in four rural Kentucky counties. J. Agric. Saf. Health 2009, 15, 207–223. [Google Scholar] [CrossRef] [PubMed]

- Hard, D.L.; Myers, J.R. Adoption of rollover protective structures (ROPS) on US farm tractors by state: 1993-1995, 2001, and 2004. J. Agric. Saf. Health 2011, 17, 157–172. [Google Scholar] [CrossRef] [PubMed]

- Tonelli, S.M.; Donham, K.J.; Leedom-Larson, K.; Sanderson, W.; Purschwitz, M. Retrofitting tractors with rollover protective structures: Perspective of equipment dealers. J. Agric. Saf. Health 2009, 15, 365–375. [Google Scholar] [CrossRef]

- Sorensen, J.A.; Jenkins, P.; Bayes, B.; Clark, S.; May, J.J. Cost-effectiveness of a ROPS social marketing campaign. J. Agric. Saf. Health 2010, 16, 31–40. [Google Scholar] [CrossRef]

- Harris, J.R.; McKenzie, E.A.; Etherton, J.R.; Cantis, D.M.; Ronaghi, M. ROPS performance during field upset and static testing. J. Agric. Saf. Health 2010, 16, 5–18. [Google Scholar] [CrossRef]

- Harris, J.R.; Winn, G.L.; Ayers, P.D.; McKenzie, E.A., Jr. Predicting the performance of cost-effective rollover protective structure designs. Saf. Sci. 2011, 49, 1252–1261. [Google Scholar] [CrossRef]

- Poojary, M.R.; Kalamkar, V.R. Validating the simulation results for testing of tractor roll-over protective structures (ROPS). J. Instit. Eng. (India) 2009, 90, 43–46. [Google Scholar]

- Lindhorst, C.M.; Hoy, R.M.; Pitla, S.K.; Kocher, M.F. Dynamic ROPS Test for Tractors over 6000 Kilograms. Trans. ASABE 2018, 61, 53–62. [Google Scholar] [CrossRef]

- Guzzomi, A.; Rondelli, V. Narrow-track wheeled agricultural tractor parameter variation. J. Agric. Saf. Health 2013, 19, 237–260. [Google Scholar] [CrossRef]

- Arana, J.I.; Alfaro, J.R.; Arazuri, S.; de León, J.P.; Jarén, C. A proposal to improve the sae standard and OECD code 4 standard code for testing ROPS. Trans. ASABE 2011, 54, 1189–1197. [Google Scholar] [CrossRef]

- Jarén, C.; Alfaro, J.R.; Arazuri, S.; de León, J.P.; Arana, J.I. Assessing rollover safety provided by ROPS tests following SAE standard J1194 versus OECD code 4. Trans. ASABE 2009, 52, 1453–1460. [Google Scholar] [CrossRef]

- Rondelli, V.; Guzzomi, A.L. Selecting ROPS safety margins for wheeled agricultural tractors based on tractor mass. Biosyst. Eng. 2010, 105, 402–410. [Google Scholar] [CrossRef]

- Kabir, M.S.N.; Chung, S.O.; Kim, Y.J.; Sung, N.S.; Hong, S.J. Measurement and evaluation of whole body vibration of agricultural tractor operator. Int. J. Agric. Biol. Eng. 2017, 10, 248–255. [Google Scholar]

- Fargnoli, M.; Lombardi, M.; Haber, N. A fuzzy-QFD approach for the enhancement of work equipment safety: A case study in the agriculture sector. Int. J. Reliab. Saf. 2018, 12, 306–326. [Google Scholar] [CrossRef]

- Tinc, P.J.; Gadomski, A.; Sorensen, J.A.; Weinehall, L.; Jenkins, P.; Lindvall, K. Applying the Consolidated Framework for implementation research to agricultural safety and health: Barriers, facilitators, and evaluation opportunities. Saf. Sci. 2018, 107, 99–108. [Google Scholar] [CrossRef]

- Myers, M.L.; Purschwitz, M.A. ROPS deficiency of gray-market tractors. J. Agric. Saf. Health 2012, 18, 129–140. [Google Scholar] [CrossRef]

- Bietresato, M.; Mazzetto, F. Increasing the safety of agricultural machinery operating on sloping grounds by performing static and dynamic tests of stability on a new-concept facility. Int. J. Saf. Secur. Eng. 2018, 8, 77–89. [Google Scholar] [CrossRef]

- Keskin, S.G.; Keskin, M.; Soysal, Y. Assessing farm tractor incidents and awareness levels of operators for tractor safety issues in the Hatay province of Turkey. J. Agric. Saf. Health 2012, 18, 113–128. [Google Scholar] [CrossRef]

- Tillapaugh, J.A.; Murphy, D.J.; Sommer, H.J., III; Garvey, P.M. Operator assessment of tractor roll angle with and without a tractor stability visual feedback device. J. Agric. Saf. Health 2010, 16, 249–264. [Google Scholar] [CrossRef]

- Weil, R.; Mellors, P.; Fiske, T.; Sorensen, J.A. A qualitative analysis of power take-off driveline shields: Barriers and motivators to shield use for New York State farmers. J. Agric. Saf. Health 2014, 20, 51–61. [Google Scholar] [CrossRef] [PubMed]

- Jenkins, P.L.; Sorensen, J.A.; Yoder, A.; Myers, M.; Murphy, D.; Cook, G.; Wright, F.; Bayes, B.; May, J.J. Prominent barriers and motivators to installing ROPS: An analysis of survey responses from Pennsylvania and Vermont. J. Agric. Saf. Health 2012, 18, 103–112. [Google Scholar] [CrossRef] [PubMed]

- Hard, D.L.; McKenzie, E.A.; Cantis, D.; May, J.; Sorensen, J.; Bayes, B.; Madden, E.; Wyckoff, S.; Stone, B.; Maass, J. A demonstration project in New York and Virginia: Retrofitting cost-effective roll-over protective structures (CROPS) on tractors. J. Agric. Saf. Health 2015, 21, 173–185. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hard, D.L.; McKenzie, E.A.; Cantis, D.; May, J.; Sorensen, J.; Bayes, B.; Madden, E.; Stone, B.; Maass, J. The NIOSH CROPS Demonstration Project: A study in New York and Virginia with an emphasis on youth. J. Agric. Saf. Health 2016, 22, 173–186. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Di Nocera, F.; Ricciardi, O.; Longo, E.; Mastrangelo, S.; Cutini, M.; Bisaglia, C. Attentional control in accidents involving agricultural tractor operators. Ergon. Des. 2018, 26, 17–23. [Google Scholar] [CrossRef] [Green Version]

- Lleras, N.O.; Brennan, S.; Murphy, D.; Klena, M.J.; Garvey, P.M.; Sommer, H.J., III. Development of an open-source tractor driving simulator for tractor stability tests. J. Agric. Saf. Health 2016, 22, 227–246. [Google Scholar] [CrossRef] [Green Version]

- Lombardi, M.; Fargnoli, M. Prioritization of hazards by means of a QFD-based procedure. Int. J. Saf. Secur. Eng. 2018, 8, 342–353. [Google Scholar] [CrossRef] [Green Version]

- Cole, H.; Myers, M.; Westneat, S. Chores at times of fatal or serious injuries associated with tractor overturns with and without rollover protection. Safety 2016, 2, 18. [Google Scholar] [CrossRef] [Green Version]

- European Union (EU). Directive 2009/104/EC of the European Parliament and of the Council of 16 September 2009 Concerning the Minimum Safety and Health Requirements for the Use of Work Equipment by Workers at Work. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32009L0104 (accessed on 25 November 2019).

- Zambon, I.; Cecchini, M.; Egidi, G.; Saporito, M.G.; Colantoni, A. Revolution 4.0: Industry vs. Agriculture in a Future Development for SMEs. Processes 2019, 7, 36. [Google Scholar] [CrossRef] [Green Version]

- Kitchenham, B.; Brereton, O.P.; Budgen, D.; Turner, M.; Bailey, J.; Linkman, S. Systematic literature reviews in software engineering—A systematic literature review. Inf. Softw. Technol. 2009, 51, 7–15. [Google Scholar] [CrossRef]

| Journal Names |

|---|

| Accident Analysis and Prevention |

| Applied Engineering in Agriculture |

| Applied Ergonomics |

| Biosystems Engineering |

| Contemporary Engineering Sciences |

| Engineering in Agriculture, Environment and Food |

| Ergonomics in Design |

| IEEE Sensors Journal |

| IFAC-PapersOnLine |

| International Journal of Agricultural and Biological Engineering |

| International Journal of Commercial Vehicles |

| International Journal of Occupational Safety and Ergonomics |

| International Journal of Reliability and Safety |

| International Journal of Safety and Security Engineering |

| Journal of Agricultural Engineering |

| Journal of Agricultural Safety and Health |

| Journal of Safety Research |

| Journal of Terramechanics |

| Journal of the Institution of Engineers (India) |

| Mechanics and Industry |

| SAE International Journal of Commercial Vehicles |

| Safety |

| Safety Science |

| Sensors |

| Transactions of the ASABE |

| Country | No. |

|---|---|

| USA | 32 |

| Italy | 27 |

| Spain | 5 |

| Japan | 3 |

| India, Iran | 2 |

| Australia, Canada, China, France, Israel, Kuwait, Korea, Turkey | 1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fargnoli, M.; Lombardi, M. Safety Vision of Agricultural Tractors: An Engineering Perspective Based on Recent Studies (2009–2019). Safety 2020, 6, 1. https://0-doi-org.brum.beds.ac.uk/10.3390/safety6010001

Fargnoli M, Lombardi M. Safety Vision of Agricultural Tractors: An Engineering Perspective Based on Recent Studies (2009–2019). Safety. 2020; 6(1):1. https://0-doi-org.brum.beds.ac.uk/10.3390/safety6010001

Chicago/Turabian StyleFargnoli, Mario, and Mara Lombardi. 2020. "Safety Vision of Agricultural Tractors: An Engineering Perspective Based on Recent Studies (2009–2019)" Safety 6, no. 1: 1. https://0-doi-org.brum.beds.ac.uk/10.3390/safety6010001