Fault-Event Trees Based Probabilistic Safety Analysis of a Boiling Water Nuclear Reactor’s Core Meltdown and Minor Damage Frequencies

Abstract

:1. Introduction

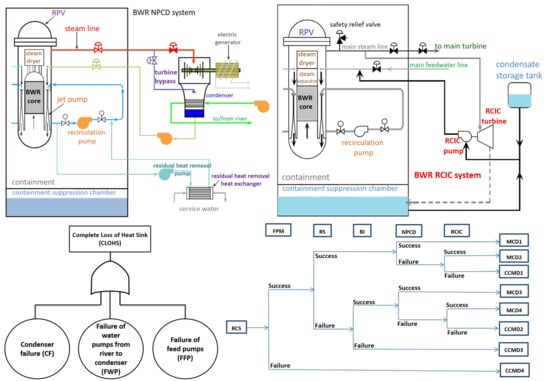

2. Materials and Methods

2.1. Survey of Safety Systems for Potential Hazards in BWR

2.2. Failure Mode Identification and BWR’s Risks Control Options

3. Fault-Event Trees Modelling and Results

3.1. Continuous Rod Withdrawal Accident (CRWA)

3.2. Main Turbine Failure (TF)

3.3. Complete Loss of Heat Sink (CLOHS)

- Condenser failure (CF) on both sides

- Failure of both water pumps (FWP) from the river to condensers

- Failure of both feed pumps (FFP)

- The fault tree is developed accordingly using a logic OR Boolean gate shown in Figure 8 below.

3.4. Large Break in RPV (LBRPV)

3.5. Rupture of Steam Line (RSL)

3.6. Leak from Instrumentation Line (LIL)

3.7. Rupture of Core Shroud (RCS)

3.8. Breakup of Drier Structure Causing Local Channel Blockage (BDS-LCB)

4. Summary of Results and Discussion

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Breyer, C. A Global Overview of Future Energy. In Future Energy; Elsevier: Amsterdam, The Netherlands, 2020; pp. 727–756. [Google Scholar]

- Eriksson, O. Nuclear Power and Resource Efficiency—A Proposal for a Revised Primary Energy Factor. Sustainability 2017, 9, 1063. [Google Scholar] [CrossRef] [Green Version]

- Merk, B.; Bankhead, M.; Litskevich, D.; Gregg, R.; Peakman, A.; Shearer, C. On a Roadmap for Future Industrial Nuclear Reactor Core Simulation in the U.K. to Support the Nuclear Renaissance. Energies 2018, 11, 3509. [Google Scholar] [CrossRef] [Green Version]

- Sekimoto, H. A Roadmap of Innovative Nuclear Energy System. J. Phys. Conf. Ser. 2017, 799, 012001. [Google Scholar] [CrossRef] [Green Version]

- Steijn, W.M.P.; Kampen, J.N.V.; Beek, D.V.; Groeneweg, J.; Gelder, P.V. An integration of human factors into quantitative risk analysis using Bayesian Belief Networks towards developing a ‘QRA+’. Saf. Sci. 2020, 122, 104514. [Google Scholar] [CrossRef]

- Cid, M.M.; Dies, J.; Tapia, C.; Diaz, P. Outage Key Safety Functions Configuration risk assessment for a three loops Westinghouse PWR. Nucl. Eng. Des. 2015, 291, 271–276. [Google Scholar] [CrossRef] [Green Version]

- Gattie, D.K. U.S. energy, climate and nuclear power policy in the 21st century: The primacy of national security. Electr. J. 2020, 33, 106690. [Google Scholar] [CrossRef]

- Goodfellow, M.J.; Dewick, P.; Wortley, J.; Azapagic, A. Public perceptions of design options for new nuclear plants in the UK. Process Saf. Environ. Prot. 2015, 94, 72–88. [Google Scholar] [CrossRef]

- Nishikawa, M.; Kato, T.; Homma, T.; Takahara, S. Changes in risk perceptions before and after nuclear accidents: Evidence from Japan. Environ. Sci. Policy 2016, 55, 11–19. [Google Scholar] [CrossRef]

- Zohuri, B.; Fathi, N. Probabilistic Risk Assessment. In Thermal-Hydraulic Analysis of Nuclear Reactors; Springer: Amsterdam, The Netherlands, 2015; pp. 479–488. [Google Scholar]

- Iman, R.L. Methods Used in Probabilistic Risk Assessment for Uncertainty and Sensitivity Analysis. In New Risks: Issues and Management. Advances in Risk Analysis; Cox, L.A., Ricci, P.F., Eds.; Springer: Boston, MA, USA, 1990; Volume 6. [Google Scholar]

- Purbaa, J.; Tjahyanib, D.; Deswandric. The implementation of fault tree analysis approaches in nuclear power plant probabilistic safety assessment. AIP Conf. Proc. 2019, 2180, 020010. [Google Scholar]

- Lee, W.; Grosh, D.; Tillman, F.; Lie, C. Fault Tree Analysis, Methods, and Applications—A Review. IEEE Trans. Reliab. 1985, 34, 194–203. [Google Scholar] [CrossRef]

- Ferdous, R.; Khan, F.; Sadiq, R.; Amyotte, P.; Veitch, B. Fault and event tree analyses for process systems risk analysis: Uncertainty handling formulations. Risk Anal. 2011, 31, 86–107. [Google Scholar] [CrossRef] [PubMed]

- Raju, S. Estimating the frequency of nuclear accidents. Sci. Glob. Secur. 2016, 24, 37–62. [Google Scholar] [CrossRef] [Green Version]

- Lavasani, S.M.; Zendegani, A.; Celik, M. An extension to Fuzzy Fault Tree Analysis (FFTA) application in petrochemical process industry. Process Saf. Environ. 2015, 93, 75–88. [Google Scholar] [CrossRef]

- Munera, H.A. A deterministic event tree approach to uncertainty, randomness and probability in individual chance processes. Theory Decis. 1992, 32, 21–55. [Google Scholar] [CrossRef]

- Jenab, K.; Dhillon, B.S. Stochastic fault tree analysis with self-loop basic events. IEEE Trans. Reliab. 2005, 54, 173–180. [Google Scholar] [CrossRef]

- Podowski, M.Z.; Luo, W.; Kirchner, R.F. Simulation of BWR core meltdown accidents using the APRIL and MAAP computer codes. In Proceedings of the Transactions of the Twenty-Second Water Reactor Safety Information Meeting, Bethesda, MD, USA, 24–26 October 1994. [Google Scholar]

- Villafuerte, J.O.; Durán, R.C.; López, H.H.; Martínez, E.A. Fundamentals of Boiling Water Reactor Safety Design and Operation. In Towards a Cleaner Planet; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- USNRC Technical Training Center. Boiling Water Reactor (BWR) Systems. In Reactor Concepts Manual; US Nuclear Regulatory Commission: Rockville, MD, USA, 2012. [Google Scholar]

- Nikitin, K.; Mueller, P.; Martin, J.; Doesburg, W.V.; Hiltbrand, D. BWR loss of coolant accident simulation by means of Relap5. Nucl. Eng. Des. 2016, 309, 113–121. [Google Scholar] [CrossRef]

- Greene, R.H. Maintenance of BWR control rod drive mechanisms. In Proceedings of the Nuclear Power Plant and Facility Maintenance Topical Meeting, Salt Lake City, UT, USA, 7–11 April 1991. [Google Scholar]

- Hurlebaus, D. An advanced scram system for BWR reactors. In Proceedings of the Reactor Congress 1977, Mannheim, Germany, 29 March–1 April 1977. (In German). [Google Scholar]

- Tinoco, H.; Buchwald, P.; Frid, W. Numerical simulation of boron injection in a BWR. Nucl. Eng. Des. 2010, 240, 221–234. [Google Scholar] [CrossRef]

- Lin, C.C.; Skarpelos, J.M. Monitoring of fission product release in a boiling water reactor. J. Radioanal. Nucl. Chem. 1997, 220, 173–181. [Google Scholar] [CrossRef]

- Lopez, H.; Erkan, N.; Okamoto, K. Reactor core isolation cooling system analysis of the Fukushima Daiichi Unit 2 accident with RELAP/ScdapSIM. J. Nucl. Sci. Technol. 2016, 53, 1899–1905. [Google Scholar] [CrossRef] [Green Version]

- Ramirez, G.C.; Chavez, M.C. Simulation of the automatic depressurization system (Ads) for a boiling water reactor (BWR) based on RELAP. In Proceedings of the 23rd SNM Annual Congress: Perspective and Development of Nuclear Energy after Fukushima, Oaxaca, Mexico, 29 July–1 August 2012; Sociedad Nuclear Mexicana: Mexico, Mexico, 2012. [Google Scholar]

- Hideo, N.; Yutaka, K.; Kanji, T. BWR Loss-ofCoolant Accident Tests at ROSA-III with High Temperature Emergency Core Coolant Injection. J. Nucl. Sci. Technol. 1988, 25, 169–179. [Google Scholar]

- Wheatley, S.; Sovacool, B.K.; Sornette, D. Reassessing the safety of nuclear power. Energy Res. Soc. Sci. 2016, 15, 96–100. [Google Scholar] [CrossRef] [Green Version]

- Minh, H.D.; Journé, V. Calculating nuclear accident probabilities from empirical frequencies. Environ. Syst. Decis. 2014, 34, 249–258. [Google Scholar]

- Ilas, G.; Liljenfeldt, H. Decay heat uncertainty for BWR used fuel due to modeling and nuclear data uncertainties. Nucl. Eng. Des. 2017, 319, 176–184. [Google Scholar] [CrossRef]

- Sembiring, T.M.; Pinem, S.; Liem, P.H. Analysis of NEA-NSC PWR Uncontrolled Control Rod Withdrawal at Zero Power Benchmark Cases with NODAL3 Code. Sci. Technol. Nucl. Install. 2017, 2017, 5151890. [Google Scholar] [CrossRef] [Green Version]

- Solis, J.; Ivanov, K.N.; Sarikaya, B.; Olson, A.M.; Hunt, K.W. Boiling Water Reactor Turbine Trip (TT) Benchmark. Volume I: Final Specifications; OECD Nuclear Energy Agency: Paris, France, 2001. [Google Scholar]

- IAEA. Assessment and Management of Ageing of Major Nuclear Power Plant Components Important to Safety: BWR Pressure Vessel Internals; Engineering Safety Section, IAEA: Vienna, Austria, 2005. [Google Scholar]

- Takahiro, S.; Makoto, N. Failure cause and failure rate evaluation on pumps of BWR plants in PSA Hypothesis testing for typical or plant specific failure rate of pumps. Denryoku Chuo Kenkyusho Hokoku 2009, 41, 1–45. [Google Scholar]

- Ivanov, K.; Olson, A.; Sartori, E. OECD/NRC BWR Turbine Trip Transient Benchmark as a Basis for Comprehensive Qualification and Studying Best-Estimate Coupled Codes. Nucl. Sci. Eng. 2004, 148, 195–207. [Google Scholar] [CrossRef]

- Godefroy, F. PSA Discussion and Conclusions. In Pre-Construction Safety Report of the UK EPR; AREVA: Paris, France, 2012; Volume 157, p. 6. [Google Scholar]

- Westinghouse. AP1000 Pre-Construction Safety Report; Westinghouse: Cranberry Township, PA, USA, 2009; p. 321. [Google Scholar]

- Kenarangui, R. Event-tree analysis by fuzzy probability. IEEE Trans. Rel. 1991, 40, 120–124. [Google Scholar] [CrossRef]

- Batzias, F.A.; Siontorou, C.C. Investigating the causes of biosensor SNR decrease by means of fault tree analysis. IEEE Trans. Instrum. Meas. 2005, 54, 1395–1406. [Google Scholar] [CrossRef]

- Mahmood, Y.A.; Ahmadi, A.; Verma, A.K.; Srividya, A.; Kumar, U. Fuzzy fault tree analysis: A review of concept and application. Int. J. Syst. Assur. Eng. Manag. 2013, 4, 19–32. [Google Scholar] [CrossRef]

- Chen, Y.; Zhen, Z.; Yu, H.; Xu, J. Application of Fault Tree Analysis and Fuzzy Neural Networks to Fault Diagnosis in the Internet of Things (IoT) for Aquaculture. Sensors 2017, 17, 153. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mohan, V.D.; Vardon, P.; Hicks, M.; Gelder, P.V. Uncertainty Tracking and Geotechnical Reliability Updating Using Bayesian Networks. In Proceedings of the 7th International Symposium on Geotechnical Safety and Risk (ISGSR), Taipei, Taiwan, 11–13 December 2019. [Google Scholar]

- Febres, J.D.; Mohamadi, F.; Mariscal, M.A.; Herrera, S.; García-Herrero, S. The Role of Journey Purpose in Road Traffic Injuries: A Bayesian Network Approach. J. Adv. Transp. 2019, 2019, 6031482. [Google Scholar] [CrossRef]

- Tolo, S.; Patelli, E.; Beer, M. Robust vulnerability analysis of nuclear facilities subject to external hazards. Stoch. Environ. Res. Risk Assess. 2017, 31, 2733–2756. [Google Scholar] [CrossRef] [Green Version]

- Lye, A.T.; Hector, E.L.; Patelli, E. Conversion of Fault Tree into Credal Network for Probabilistic Safety Assessment of a Nuclear Power Plant. In Proceedings of the 3rd International Conference on Nuclear Power Plants, London, UK, 10–11 June 2019. [Google Scholar]

- Ebisawa, K.; Teragaki, T.; Nomura, S.; Abe, H.; Shigemori, M.; Shimomoto, M. Concept and methodology for evaluating core damage frequency considering failure correlation at multi units and sites and its application. Nucl. Eng. Des. 2015, 288, 82–97. [Google Scholar] [CrossRef] [Green Version]

- Helfand, I.; Forrow, L.; Tiwari, J. Nuclear terrorism. BMJ 2002, 324, 356–359. [Google Scholar] [CrossRef] [PubMed]

- International Atomic Energy Agency. Engineering Safety Aspects of the Protection of Nuclear Power Plants against Sabotage; IAEA Nuclear Security Series No. 4; IAEA: Vienna, Italy, 2007. [Google Scholar]

- The Economist. A Cyber-Attack on an Indian Nuclear Plant Raises Worrying Questions. Available online: https://www.economist.com/asia/2019/11/01/a-cyber-attack-on-an-indian-nuclear-plant-raises-worrying-questions (accessed on 20 April 2020).

- Ferguson, T.; Lu, L. Fault tree analysis for an inspection robot in a nuclear power plant. IOP Conf. Ser. Mater. Sci. Eng. 2017, 235, 012003. [Google Scholar] [CrossRef] [Green Version]

| Plant Fault Event | Event Frequency per Year | Final Outcome Without Protections |

|---|---|---|

| Continuous rod withdrawal (CRWA) accident [33] | 5 × | Complete core meltdown (CCMD) |

| Both main turbines failure (TF) [34] | 2 × | CCMD |

| Rupture of core shroud (RCS) [35] | 1 × | Minor core damage (MCD) or MCD and CCMD |

| Condenser failure (CF) on both sides [36] | 5 × | CCMD |

| Failure of both water pumps (FWP) [36] | 2 × | CCMD |

| Failure of both feed pumps (FFP) [36] | 5 × | CCMD |

| Large break in RPV (LBRPV) [35] | 1 × | CCMD |

| Rupture of steam line (RSL) [34] | 1 × | CCMD |

| Leak from instrumentation line (LIL) in RPV [35] | 1 × | CCMD |

| Breakup of drier structure causing local channel blockage (BDS-LCB) [37] | 5 × | MCD or MCD and CCMD |

| Failure Mode of BWR Protection System | Failure Probability on Demand |

|---|---|

| Failure of reactor scram (RS) system using safety rods [23] | 1 × |

| Failure of reactor shut down using boron injection (BI) [25] | 1 × |

| Failure of normal plant cool-down (NPCD) system [21] | 3 × |

| Failure of reactor core isolation cooling (RCIC) system [27] | 6 × |

| Failure of core spray (CS) system [29] | 1.6 × |

| Failure of high-pressure coolant injection (HPCI) system [28] | 6 × |

| Failure of automatic depressurization system (ADS) [28] | 1.1 × |

| Failure of low-pressure coolant injection (LPCI) system [29] | 1.8 × |

| Failure of fission product monitor (FPM) [26] | 1 × |

| BWR Accident Type | CCMD Frequency | MCD Frequency |

|---|---|---|

| Continuous rod withdrawal accident (CRWA) | 9.00499910 × | Not applicable |

| Main turbine failure (TF) | 3.60199964 × | Not applicable |

| Complete loss of heat sink (CLOHS) | 1.80002982 × | Not applicable |

| Large break in RPV (LBRPV) | 2.97999971 × | Not applicable |

| Rupture of steam line (RSL) | 6.71726033 × | Not applicable |

| Leak from instrumentation line in RPV (LIL) | 6.71726033 × | Not applicable |

| Rupture of core shroud (RCS) | 1.179919882 × | 9.98820080 × |

| Breakup of drier structure causing local channel blockage | 5.899599410 × | 4.99410040 × |

| Total | 2.808022798 × | 5.99292048 × |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J. Fault-Event Trees Based Probabilistic Safety Analysis of a Boiling Water Nuclear Reactor’s Core Meltdown and Minor Damage Frequencies. Safety 2020, 6, 28. https://0-doi-org.brum.beds.ac.uk/10.3390/safety6020028

Li J. Fault-Event Trees Based Probabilistic Safety Analysis of a Boiling Water Nuclear Reactor’s Core Meltdown and Minor Damage Frequencies. Safety. 2020; 6(2):28. https://0-doi-org.brum.beds.ac.uk/10.3390/safety6020028

Chicago/Turabian StyleLi, Jinfeng. 2020. "Fault-Event Trees Based Probabilistic Safety Analysis of a Boiling Water Nuclear Reactor’s Core Meltdown and Minor Damage Frequencies" Safety 6, no. 2: 28. https://0-doi-org.brum.beds.ac.uk/10.3390/safety6020028