Occupational Accidents Related to Heavy Machinery: A Systematic Review

Abstract

:1. Introduction

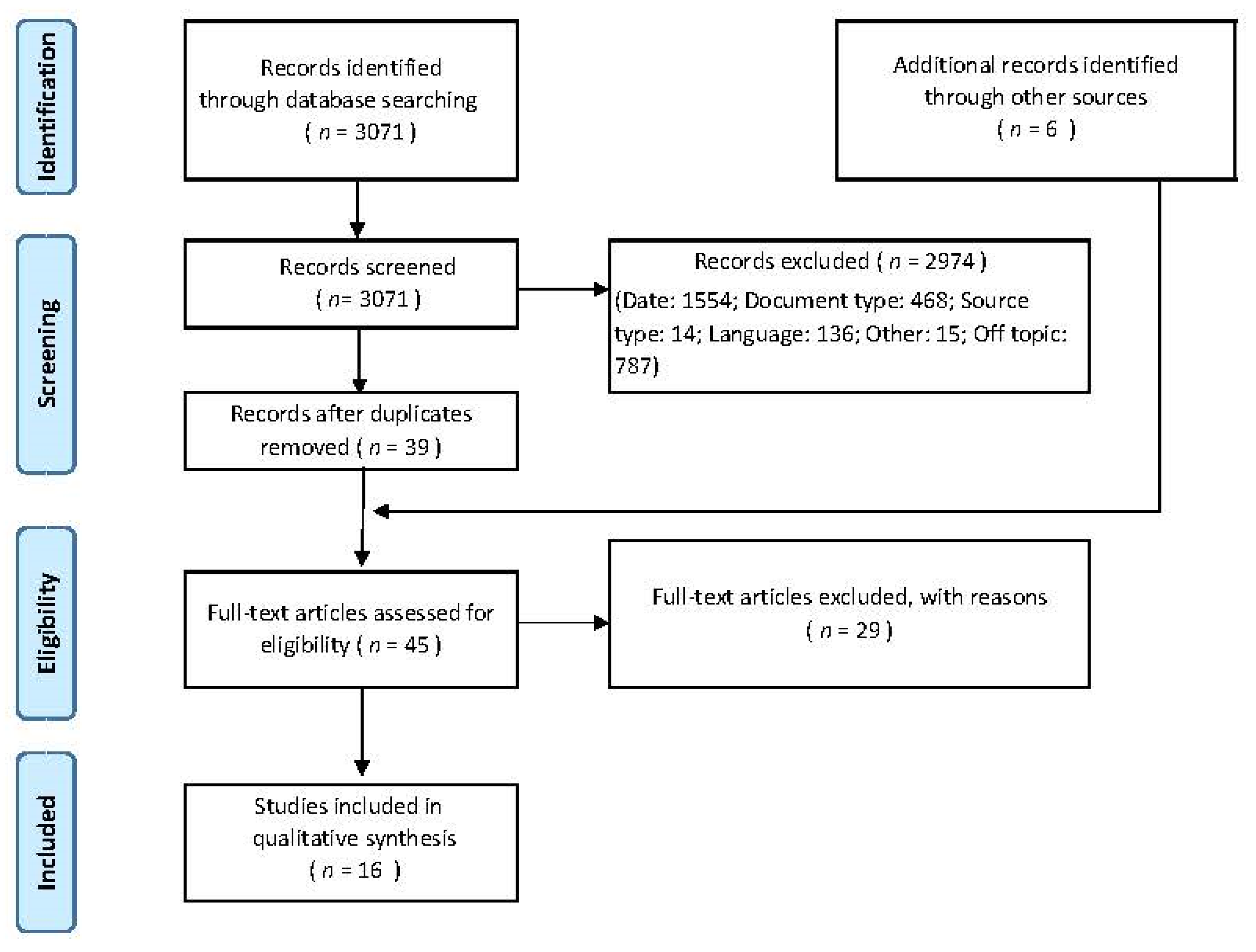

2. Methodology

- Date—only papers published between 2010 and 2018 were included in the first phase; 2010 was adopted as a result of a preliminary sensitivity analysis of the number of articles found from the selected keywords.

- Document type—only research papers were considered.

- Type of source—only peer-reviewed journals were screened.

- Language—only papers written in English were considered.

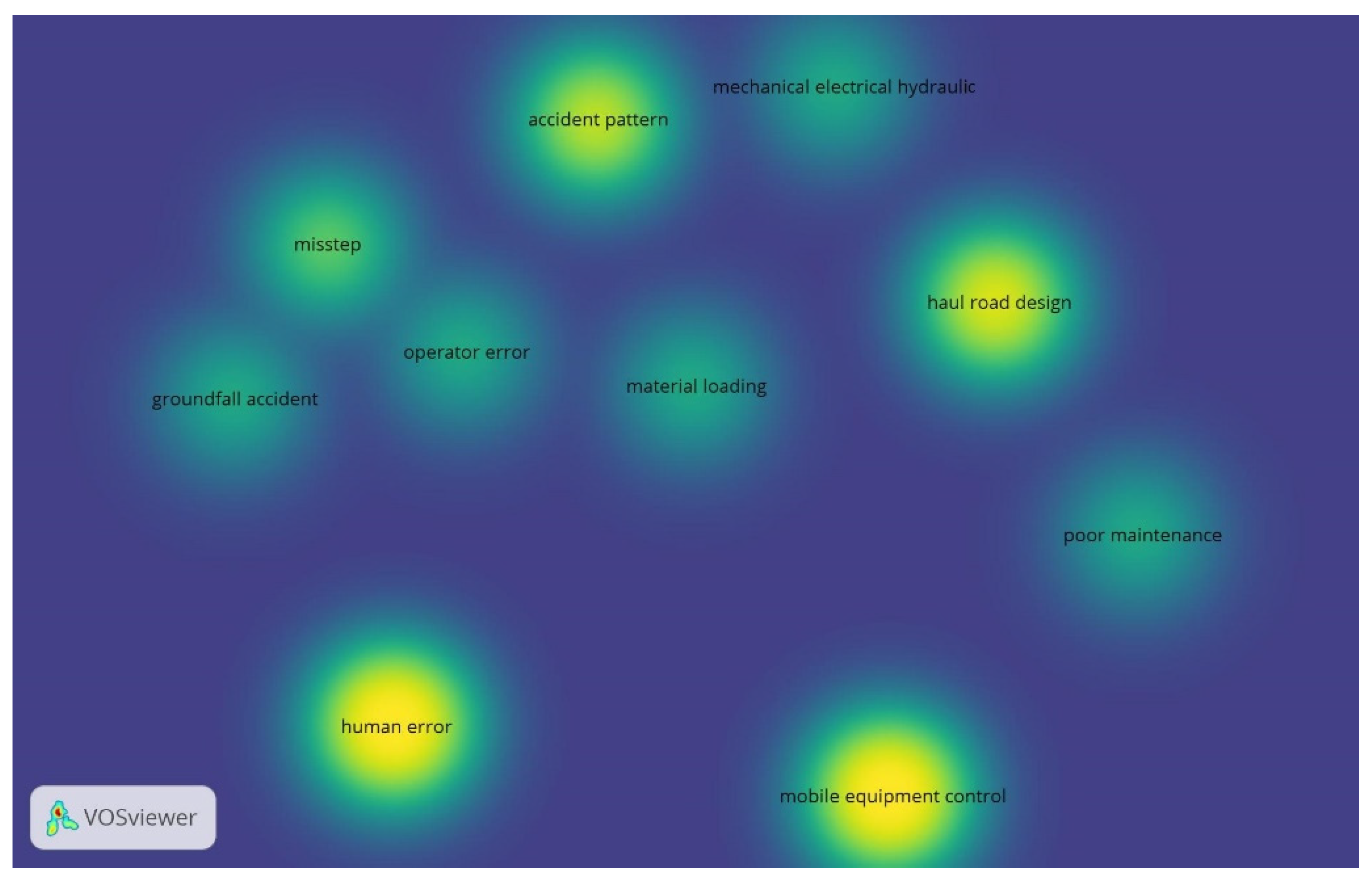

3. Results

4. Discussion

Study Limitations

5. Conclusions

5.1. General Conclusions

5.2. Practical Applications

5.3. Current Trends and Future of Operation

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Author, Year | Objective | Country | Mine/Quarry | Exploited Material | Data Source | Period Range | Risk Assessment | Standards | Population | Sample | Sample Characteristics | Questionnaire | Validation |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Kecojevic & Radomsky 2004 [42] | To analyse loader- and truck-related fatalities | USA | Not mentioned | Not mentioned | Mine Safety and Health Administration (MSHA) | 1995–2002 | Not mentioned | Not mentioned | Not applicable | Not applicable | Not applicable | Not applicable | Not applicable |

| Groves et al. 2007 [30] | To analyse the number of injuries for the period 1995–2004 | USA | Not mentioned | Not mentioned | MSHA | 1995–2004 | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not applicable | Not applicable |

| Kecojevic et al. 2007 [6] | To characterise equipment-related mining fatalities | USA | Not mentioned | Not mentioned | MSHA | 1995–2005 | Not mentioned | Not mentioned | Not applicable | Not applicable | Not applicable | Not applicable | Not applicable |

| Md-Nor et al. 2008 [43] | To develop a risk assessment for loader- and dozer-related fatalities | USA | Not mentioned | Not mentioned | MSHA | 1995–2006 | Yes | Not mentioned | Not applicable | Not applicable | Not applicable | Not applicable | Not applicable |

| Permana 2010 [8] | To develop safety management | Indonesia | Surface mine | Coal | Directorate Technique and Environment of Mineral and Coal reports | 2003–2010 | Yes | ISO 31000 | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned |

| Burgess-Limerick 2011 [50] | To identify common injury risks | Australia | Underground mine | Coal | Coal Services Pty Ltd. | June 2006–June 2008 | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned |

| Ruff et al. 2011 [44] | To study equipment accidents | USA | Both | Coal, stone, sand, and gravel, nonmetal and metal | MSHA | 2000–2007 | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not applicable | Not applicable | Not applicable |

| Onder 2013 [52] | To predict the probability of accidents | Turkey | Open-pit mine(s) | Lignite | Western Lignite Corporation (WLC) | 1996–2009 | Not mentioned | Not mentioned | Varies between 500 and 3500 over the period analysed | Not mentioned | 25–45 years old | Not mentioned | Not mentioned |

| Kumar & Ghosh 2014 [34] | To determine the accident causes | India | Open-cast mine(s) | Coal | Directorate General of Mines Safety (DGMS) | 1995–2008 | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned |

| Zhang et al. 2014 [45] | To study the root causes of accidents in West Virginia | USA | Surface mine | Coal | MSHA | 1995–2011 | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned |

| Dash et al. 2015 [7] | To identify investigating procedure gaps | India | Mine | Coal | DGMS | 1980–2000 | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned |

| Clark et al. 2016 [46] | To analyse jackleg drill accidents | USA | Mine | Metal, nonmetal, and coal | MSHA | 2003–2012 | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned |

| Dindarloo et al. 2016 [47] | To study the factors associated with severe injuries | USA | Not mentioned | Not mentioned | MSHA | 2000–2012 | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned |

| Zhang et al. 2016 [49] | To study coal mine accidents | China | Mine | Coal | Shandong Coal Mine Safety Supervision Bureau | 2005–2010 | Not mentioned | GB6441-86, GB6442-86 | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned |

| Bonsu et al. 2017 [51] | To apply a systemic approach to the analysis of accidents | South Africa | Mine | Platinum | Case study | 2010–2012 | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned |

| Nasarwanji et al. 2017 [48] | To identify the cause of injuries | USA | Mine | Not mentioned | MSHA | 1996–2015 | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned | Not mentioned |

Appendix B

| Author, Year | Accident Type | Equipment | Accident Consequences | Main Results | Accident Cause | Prevention | Limitations |

|---|---|---|---|---|---|---|---|

| Kecojevic & Radomsky 2004 [42] | Machine related | Loader, truck | Fatalities | Loader: personnel got hit, struck, or run over, representing 41% of the total fatalities. Truck: rollovers, collision with pedestrian/another vehicle, vehicle repair, or contact with utility lines. | Loader: (1) failure of mechanical components, (2) inadequate maintenance procedures, (3) failure to recognise adverse geological conditions, (4) failure to respect the loader working area, (5) failure to maintain adequate berms, (6) lack of warning signs or appropriate mine maps, (7) inadequate provisions for secure travel, (8) failure to adjust to poor weather conditions. Truck: (1) operator’s health condition, (2) failure to obey warning signs, (3) mechanical failure, (4) inadequate procedures, (5) failure to respect working area, (6) failure to recognise adverse geological conditions, (7) failure to maintain adequate berms, (8) failure to set the parking brake, (9) inadequate training | Careful job planning, proper training | Not mentioned |

| Groves et al. 2007 [30] | Machine related and others | Haulage truck, front-end loader, nonpowered hand tools, conveyor, continuous miners | Fatalities, injuries | During the period analysed, a total of 190,940 accidents, injuries, and illnesses were recorded, of which 84% were fatalities. From those, 77% were related to machinery, where most fatalities were due to haulage trucks (16%) and front-end loaders (9%), continuous miners (8%), and conveyor (6%). The remaining events included roof falls (53%), repeated trauma injuries (16%), hoisting accidents (7%), and dust disease (6%). | Poor use of equipment (awkward position, for example) | Development of new interventions and control strategies, for example, vehicles using GPS and radar-based warning systems | Not mentioned |

| Kecojevic et al. 2007 [6] | Machine related | Forklift, longwall, front-end loader, belt conveyor, dozer, LHD, haul truck, shuttle car, miner, drill | Fatalities | Haul trucks (22.3%), belt conveyors (9.3%), front-end loaders (8.5%), and miscellaneous equipment (36.6%). The proportional distribution of the remaining fatalities ranges from 6.2% for continuous miners to less than 1% for hoisting. Collision with pedestrians and rollovers are the most common accidents. | Failure of mechanical components, lack of and/or failure to obey warning signals, inadequate mechanical procedures, inadequate training, poor haulage road and dump design engineering, failure to wear a seat belt | Equipment safety training program (for both surface and underground mining operations), prevention methods | Not mentioned |

| Md-Nor et al. 2008 [43] | Machine related | Loader, dozer | Fatalities, injuries | Loader: there were a total of 43 fatalities for the period analysed. Dozer: there were a total of 30 fatalities for the period analysed. Two of the fatalities were caused by unknown hazards. Therefore, they were excluded from the analysis. | Failure to follow adequate maintenance procedure, failure of mechanical/electrical/hydraulic component, failure to identify adverse geological/site conditions, failure to respect equipment working area, failure to provide an adequate sign, failure to set the parking brake (before leaving equipment), failure to provide adequate illumination, failure to wear a seat belt, unfavourable weather conditions, failure to provide adequate berm, failure to control equipment, an inappropriate task for equipment, pushing material above hopper while loading | Risk control and implementation of control measures | Not mentioned |

| Permana 2010 [8] | Machine related, people transportation, fire, explosives | Not specified | Fatalities, injuries | The number of mine accidents increased during the period analysed. The higher-risk locations are mine pit and workshop, and “substandard tools” were considered the sources of mine accidents. | Not following the safe working procedure or standard operating procedure, workers’ lack of awareness of working safely | Mine accident risk analysis, corrective action in the safety management system | Not mentioned |

| Burgess-Limerick 2011 [50] | Machine related | Continuous miner, bolting machine, LHD, longwall, transport car, shuttle, handheld bolter | Injuries | From the reports analysed, equipment-related accidents accounted for 46% (2149) of the total accidents (4633). Continuous miner (555 accidents), bolting machine (257 accidents), LHD (351 accidents), longwall (332 accidents), transport (194 accidents), shuttle car (152 accidents), handheld bolters (115 accidents), and the remaining accidents were due to miscellaneous equipment (graders, stone dusting equipment, dolly cars, road headers, longwall move equipment, and gas drainage drilling equipment). | Roadway abnormalities, striking part of the equipment, struck by falling objects, some part of the person caught between moving parts of the equipment, handling various objects (bolting supplies, for instance), maintenance actions, access to the operating platform | Proximity detection systems, redesign of platforms, improving roadway maintenance, improving vehicle maintenance | Not mentioned |

| Ruff et al. 2011 [44] | Machine related | Conveyor, roof bolting machine, haulage truck, milling machine, LHD, front-end loader, continuous miner, crane, crusher, shuttle car, forklift, truck (not haulage), dragline, bulldozer, hand tools, locomotive | Fatalities, injuries | A total of 562 accidents were reported: coal mining (242 accidents), stone (136 accidents), sand and gravel (83 accidents), nonmetal (53 accidents), and metal mining (48 accidents). From the 562 accidents, 259 occurred during the machine’s operation, 139 occurred during maintenance or repair actions, and 34 accidents occurred while handling supplies or materials. At surface mining, the top 3 types of stationary equipment involved in accidents were conveyors, milling machines, and crushers, where the most common activities during the accident were maintenance and repair actions. As for moving equipment, trucks, loaders, scrapers, and dozers were the most mentioned equipment. | Equipment control loss, brake failure, operator error, operator visibility issues, collision with pedestrians, collision with other vehicles, maintenance and repair actions | Proximity warning systems, improved visibility, operator fatigue detector, detection of edges, improved training, emergency stop buttons | Not mentioned |

| Onder 2013 [52] | Machine related and others | Not specified | Fatalities, injuries | There was a reduction in the number of accidents over the period analysed; there was also a decrease in the number of workers. This study determined five categories of accident: mining machine (39.2%), machinery (25%), manual and mechanical handling (16.7%), hand tools (11.9%), and struck by/falling object (7.2%). | Hitting a moving object, hitting a nonmoving object, falling of an object, repair/maintenance actions, cutting with hand tool | Training, use of personal protective equipment | Not mentioned |

| Kumar & Ghosh 2014 [34] | Machine related and others | Dumper, shovel, loader, dozer | Fatalities, injuries | The distribution of accidents due to different equipment was as follows: dumper (59%), shovel/dragline (10%), tankers (10%), other heavy earthmoving machines (9%), loading machine (5%), drilling machine (2%), and other equipment (5%). | Machine reversal, haul road design, improper maintenance, human fault, operator fault, machine fault, visibility, overloading, dump design | Mine management | Not mentioned |

| Zhang et al. 2014 [45] | Machine related | Haul truck | Fatalities, injuries | Fault tree analysis was used in 12 truck reports, where the main root causes for the accident were sought. | Inadequate/improper preoperational check, poor maintenance, inadequate training, excessive speed, not following standards, brake control problems, inadequate proceeding, no seat belt provided | Training new operators, predictive maintenance | Not mentioned |

| Dash et al. 2015 [7] | Machine related | Dumper | Fatalities, injuries | Accidents related to wheeled trackless transportation system are still of concern despite all measures taken to improve the situation. | Reversal run over, front run over, lost control, collision | Not mentioned | Not mentioned |

| Clark et al. 2016 [46] | Machine related | Jackleg drill | Fatalities, injuries | Fifty-nine mines reported at least one jackleg drill incident during the analysed period: 54% were in metal mines, 31% in coal mines, and 15% in nonmetal mines. A total of 483 incidents involving this equipment were reported. | Fall of ground, failure to control equipment, falling objects, inadequate maintenance procedures, inadequate scaling, not removing the loose material, poor worksite preparation | Not mentioned | Not mentioned |

| Dindarloo et al. 2016 [47] | Machine related | Off-road truck | Fatalities, injuries | Off-road truck-related accidents reported 125 severe records, where 88 were fatalities and 52 led to permanent disabilities. | Losing control of the truck, berm/dump failure, truck/component, mechanical failure, maintenance/repair actions, failure to regard safety regulations, failure to block off/lock out the truck/bed, exiting the cab while operating the equipment | Not mentioned | Not mentioned |

| Zhang et al. 2016 [49] | Machine related and others | Not specified | Fatalities, injuries | Over the period analysed, the number of accidents decreased. Three influencing factors leading to accident were identified: lack of training and safety education, rules and regulations of safety production responsibility, and rules and regulations of supervision and inspection. | Unsafe operator behaviour, unsafe condition of equipment, unsafe condition of environment, unsafe condition of rules and regulations | Not mentioned | (1) The sample size was too small; (2) accidents were put into the same accident category, ignoring the type of accident. |

| Bonsu et al. 2017 [51] | Machine related and others | Not specified | Fatalities, injuries | The tasks more commonly associated with accident were drilling (25%), engineering tasks (24%), transportation of people (11%), and manual handling (11%). The accident causality analysis showed that “poor leadership” is the root cause of most of the violations identified. | Falls of ground, falling of material/rolling rock, slipping and falling, manual handling of material | Not mentioned | The authors could not determine the authenticity of the accident reports. |

| Nasarwanji et al. 2017 [48] | Machine related | Front-end loader | Injuries | The total number of incidents was 1457, of which, 924 occurred during front-end loader egress, 367 occurred during ingress, 70 occurred during maintenance actions, and 96 were “other tasks” or unknown tasks. | Contaminants on equipment, ground conditions | Inspecting ingress and egress systems; preventing uneven terrain, rocks, or slippery surfaces; providing adequate lighting | The numbers may not be representative, and the limited description occasionally leads to biased coding. |

References

- Kusi-Sarpong, S.; Bai, C.; Sarkis, J.; Wang, X. Green supply chain practices evaluation in the mining industry using a joint rough sets and fuzzy TOPSIS methodology. Resour. Policy 2015, 46, 86–100. [Google Scholar] [CrossRef] [Green Version]

- Parker, A.W.; Tones, M.J.; Ritchie, G.E. Development of a multilevel health and safety climate survey tool within a mining setting. J. Saf. Res. 2017, 62, 173–180. [Google Scholar] [CrossRef] [PubMed]

- Sanmiquel, L.; Rossell, J.M.; Vintró, C. Study of Spanish mining accidents using data mining techniques. Saf. Sci. 2015, 75, 49–55. [Google Scholar] [CrossRef]

- Takala, J. Burden of injury due to occupational exposures. Handb. Disabil. Work Health 2019, 1–22. [Google Scholar] [CrossRef]

- Taeger, D.; Pesch, B.; Kendzia, B.; Behrens, T.; Jöckel, K.H.; Dahmann, D.; Siemiatycki, J.; Kromhout, H.; Vermeulen, R.; Peters, S.; et al. Lung cancer among coal miners, ore miners and quarrymen: Smoking-adjusted risk estimates from the synergy pooled analysis of case—Control studies. Scand. J. Work. Environ. Health 2015, 41, 467–477. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kecojevic, V.; Komljenovic, D.; Groves, W.; Radomsky, M. An analysis of equipment-related fatal accidents in US mining operations: 1995–2005. Saf. Sci. 2007, 45, 864–874. [Google Scholar] [CrossRef]

- Dash, A.K.; Bhattcharjee, R.M.; Paul, P.S.; Tikader, M. Study and analysis of accidents due to wheeled trackless transportation machinery in Indian coal mines: Identification of gap in current investigation system. Procedia Earth Planet. Sci. 2015, 11, 539–547. [Google Scholar] [CrossRef] [Green Version]

- Permana, H. Risk assessment as a strategy to prevent mine accidents in Indonesian mining. Rev. Min. 2010, 4, 43–50. [Google Scholar]

- Holmberg, K.; Kivikytö-Reponen, P.; Härkisaari, P.; Valtonen, K.; Erdemir, A. Global energy consumption due to friction and wear in the mining industry. Tribol. Int. 2017, 115, 116–139. [Google Scholar] [CrossRef]

- Ranängen, H.; Lindman, Å. A path towards sustainability for the Nordic mining industry. J. Clean. Prod. 2017, 151, 43–52. [Google Scholar] [CrossRef]

- Comberti, L.; Demichela, M.; Baldissone, G. A combined approach for the analysis of large occupational accident databases to support accident-prevention decision making. Saf. Sci. 2018, 106, 191–202. [Google Scholar] [CrossRef]

- Kizil, M. Virtual Reality Applications in the Australian Minerals Industry; South African Institute of Mining and Metallurgy: Johannesburg, South Africa, 2003; pp. 569–574. [Google Scholar]

- Cordeiro, R.; Dias, A. Stressful life events and occupational accidents. Scand. J. Work Environ. Health 2005, 31, 139–148. [Google Scholar] [CrossRef] [Green Version]

- Sarkar, S.; Vinay, S.; Raj, R.; Maiti, J.; Mitra, P. Application of optimised machine learning techniques for prediction of occupational accidents. Comput. Oper. Res. 2019, 106, 210–224. [Google Scholar] [CrossRef]

- Yin, W.; Fu, G.; Yang, C.; Jiang, Z.; Zhu, K.; Gao, Y. Fatal gas explosion accidents in Chinese coal mines and the characteristics of unsafe behaviors: 2000–2014. Saf. Sci. 2017, 92, 173–179. [Google Scholar] [CrossRef]

- Amponsah-Tawiah, K.; Jain, A.; Leka, S.; Hollis, D.; Cox, T. Examining psychosocial and physical hazards in the Ghanaian mining industry and their implications for employees’ safety experience. J. Saf. Res. 2013, 45, 75–84. [Google Scholar] [CrossRef]

- Kia, K.; Fitch, S.M.; Newsom, S.A.; Kim, J.H. Effect of whole-body vibration exposures on physiological stresses: Mining heavy equipment applications. Appl. Ergon. 2020, 85, 103065. [Google Scholar] [CrossRef]

- Domingues, M.S.Q.; Baptista, A.L.F.; Diogo, M.T. Engineering complex systems applied to risk management in the mining industry. Int. J. Min. Sci. Technol. 2017, 27, 611–616. [Google Scholar] [CrossRef]

- Tichon, J.; Burgess-Limerick, R. A review of virtual reality as a medium for safety related training in mining. J. Health Saf. Res. Pract. 2011, 3, 33–40. [Google Scholar]

- Kazan, E.; Usmen, M.A. Worker safety and injury severity analysis of earthmoving equipment accidents. J. Saf. Res. 2018, 65, 73–81. [Google Scholar] [CrossRef] [PubMed]

- Squelch, A.P. Virtual reality for mine safety training in South Africa. J. S. Afr. Inst. Min. Metall. 2001, 101, 209–216. [Google Scholar]

- Zhang, H. Head-mounted display-based intuitive virtual reality training system for the mining industry. Int. J. Min. Sci. Technol. 2017, 27, 717–722. [Google Scholar] [CrossRef]

- Guo, H.; Yu, Y.; Skitmore, M. Visualization technology-based construction safety management: A review. Autom. Constr. 2017, 73, 135–144. [Google Scholar] [CrossRef]

- Melendez Guevara, J.A.; Torres Guerrero, F. Evaluation the role of virtual reality as a safety training tool in the context NOM-026-STPS-2008 BT. In Smart Technology. Lecture Notes of the Institute for Computer Sciences, Social Informatics and Telecommunications Engineering; Torres Guerrero, F., Lozoya-Santos, J., Gonzalez Mendivil, E., Neira-Tovar, L., Ramírez Flores, P.G., Martin-Gutierrez, J., Eds.; Springer International Publishing: Cham, Switzerland, 2018; Volume 213, pp. 3–9. [Google Scholar]

- Mallett, L.; Unger, R. Virtual reality in mine training. Mining Metall. Explor. 2007, 2, 1–4. [Google Scholar]

- Laciok, V.; Bernatik, A.; Lesnak, M. Experimental implementation of new technology into the area of teaching occupational safety for Industry 4.0. Int. J. Saf. Secur. Eng. 2020, 10, 403–407. [Google Scholar] [CrossRef]

- Dong, L.; Sun, D.; Han, G.; Li, X.; Hu, Q.; Shu, L. Velocity-free localization of autonomous driverless vehicles in underground intelligent mines. IEEE Trans. Veh. Technol. 2020, 69, 9292–9303. [Google Scholar] [CrossRef]

- Burt, C.N.; Caccetta, L. Equipment selection for surface mining: A review. Interfaces 2014, 44, 143–162. [Google Scholar] [CrossRef] [Green Version]

- Sidani, A.; Dinis, F.M.; Sanhudo, L.; Duarte, J.; Santos Baptista, J.; Poças Martins, J.; Soeiro, A. Recent tools and techniques of BIM-based virtual reality: A systematic review. Arch. Comput. Methods Eng. 2019, 28, 449–462. [Google Scholar] [CrossRef]

- Groves, W.A.; Kecojevic, V.J.; Komljenovic, D. Analysis of fatalities and injuries involving mining equipment. J. Saf. Res. 2007, 38, 461–470. [Google Scholar] [CrossRef]

- Chimamise, C.; Gombe, N.T.; Tshimanga, M.; Chadambuka, A.; Shambira, G.; Chimusoro, A. Factors associated with severe occupational injuries at mining company in Zimbabwe, 2010: A cross-sectional study. Pan Afr. Med. J. 2013, 14, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Boniface, R.; Museru, L.; Munthali, V.; Lett, R. Occupational injuries and fatalities in a tanzanite mine: Need to improve workers safety in Tanzania. Pan Afr. Med. J. 2013, 16, 120. [Google Scholar] [CrossRef] [PubMed]

- Ducarme, J.P.; Kwitowski, A.J.; Bartels, J.R. Operating speed assessments of underground mining equipment. Min. Eng. 2010, 62, 39–45. [Google Scholar]

- Kumar, R.; Ghosh, A.K. The accident analysis of mobile mine machinery in Indian opencast coal mines. Int. J. Inj. Contr. Saf. Promot. 2014, 21, 54–60. [Google Scholar] [CrossRef]

- Lundberg, J.; Rollenhagen, C.; Hollnagel, E. What-you-look-for-is-what-you-find: The consequences of underlying accident models in eight accident investigation manuals. Saf. Sci. 2009, 47, 1297–1311. [Google Scholar] [CrossRef] [Green Version]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.; Altman, D.; Antes, G.; Atkins, D.; Barbour, V.; Barrowman, N.; Berlin, J.; et al. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. PLoS Med. 2009, 6. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shamseer, L.; Moher, D.; Clarke, M.; Ghersi, D.; Liberati, A.; Petticrew, M.; Shekelle, P.; Stewart, L.A.; Altman, D.G.; Booth, A.; et al. Preferred reporting items for systematic review and meta-analysis protocols (PRISMA-P) 2015: Elaboration and explanation. BMJ 2015, 349, 1–25. [Google Scholar] [CrossRef] [Green Version]

- Duarte, J.; Baptista, J.S.; Marques, A.T. Evidence of occupational accidents with equipment in mining: A systematic review protocol. Int. J. Occup. Environ. Saf. 2018, 2, 84–88. [Google Scholar] [CrossRef]

- Wohlin, C. Guidelines for snowballing in systematic literature studies and a replication in software engineering. In Proceedings of the 18th International Conference on Evaluation and Assessment in Software Engineering—EASE’14, London, UK, 12–14 May 2014; ACM: New York, NY, USA, 2014; pp. 1–10. [Google Scholar]

- Higgins, J.; Altman, D.; Gøtzsche, P.; Jüni, P.; Moher, D.; Oxman, A.; Savović, J.; Schulz, K.; Weeks, L.; Sterne, J.A.C.C. The Cochrane Collaboration’s tool for assessing risk of bias in randomised trials. BMJ 2011, 343, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kecojevic, V.; Radomsky, M. The causes and control of loader- and truck-related fatalities in surface mining operations. Int. J. Inj. Contr. Saf. Promot. 2004, 11, 239–251. [Google Scholar] [CrossRef] [PubMed]

- Md-Nor, Z.; Kecojevic, V.; Komljenovic, D.; Groves, W. Risk assessment for loader- and dozer-related fatal incidents in US mining. Int. J. Inj. Contr. Saf. Promot. 2008, 15, 65–75. [Google Scholar] [CrossRef]

- Ruff, T.; Coleman, P.; Martini, L. Machine-related injuries in the US mining industry and priorities for safety research. Int. J. Inj. Contr. Saf. Promot. 2011, 18, 11–20. [Google Scholar] [CrossRef] [PubMed]

- Zhang, M.; Kecojevic, V.; Komljenovic, D. Investigation of haul truck-related fatal accidents in surface mining using fault tree analysis. Saf. Sci. 2014, 65, 106–117. [Google Scholar] [CrossRef]

- Clark, C.C.; Benton, D.J.; Seymour, J.B.; Martin, L.A. Jackleg drill injuries. Min. Eng. 2016, 68, 57–62. [Google Scholar] [CrossRef]

- Dindarloo, S.R.; Pollard, J.P.; Siami-Irdemoos, E. Off-road truck-related accidents in US mines. J. Saf. Res. 2016, 58, 79–87. [Google Scholar] [CrossRef] [Green Version]

- Nasarwanji, M.F.; Pollard, J.; Porter, W. An analysis of injuries to front-end loader operators during ingress and egress. Int. J. Ind. Ergon. 2017, 65, 84–92. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Shao, W.; Zhang, M.; Li, H.; Yin, S.; Xu, Y. Analysis 320 coal mine accidents using structural equation modeling with unsafe conditions of the rules and regulations as exogenous variables. Accid. Anal. Prev. 2016, 92, 189–201. [Google Scholar] [CrossRef] [PubMed]

- Burgess-Limerick, R. Injuries associated with underground coal mining equipment in Australia. Ergon. Open J. 2011, 4, 62–73. [Google Scholar] [CrossRef] [Green Version]

- Bonsu, J.; Van Dyk, W.; Franzidis, J.P.; Petersen, F.; Isafiade, A. A systemic study of mining accident causality: An analysis of 91 mining accidents from a platinum mine in South Africa. J. S. Afr. Inst. Min. Metall. 2017, 117, 59–66. [Google Scholar] [CrossRef]

- Onder, S. Evaluation of occupational injuries with lost days among opencast coal mine workers through logistic regression models. Saf. Sci. 2013, 59, 86–92. [Google Scholar] [CrossRef]

- Jehring, J.; Heinrich, H.W. Industrial accident prevention: A scientific approach. Ind. Labor Relat. Rev. 1951, 4, 609. [Google Scholar] [CrossRef]

- Turner, B.A. Man-Made Disasters; Wykeham: London, UK, 1978. [Google Scholar]

- Hollnagel, E. Investigation as an impediment to learning. In Remaining Sensitive to the Possibility of Failure; Hollnagel, E., Nemeth, C.P., Dekker, S., Eds.; Ashgate: Farnham, UK, 2008; pp. 259–268. [Google Scholar]

- Berriault, C.J.; Lightfoot, N.E.; Seilkop, S.K.; Conard, B.R. Injury mortality in a cohort of mining, smelting, and refining workers in Ontario. Arch. Environ. Occup. Health 2017, 72, 220–230. [Google Scholar] [CrossRef] [PubMed]

- Takala, J. Global estimates of traditional occupational risks. Scand. J. Work. Environ. Health Suppl. 2005, 62–67. [Google Scholar] [CrossRef]

- Onder, S.; Mutlu, M. Analyses of non-fatal accidents in an opencast mine by logistic regression model: A case study. Int. J. Inj. Contr. Saf. Promot. 2017, 24, 328–337. [Google Scholar] [CrossRef] [PubMed]

- Yu, I.T.S.; Yu, W.; Li, Z.; Qiu, H.; Wan, S.; Xie, S.; Wang, X. Effectiveness of participatory training in preventing accidental occupational injuries: A randomised-controlled trial in China. Scand. J. Work Environ. Health 2017, 43, 226–233. [Google Scholar] [CrossRef]

- Grabowski, A.; Jankowski, J. Virtual reality-based pilot training for underground coal miners. Saf. Sci. 2015, 72, 310–314. [Google Scholar] [CrossRef]

- Silva, J.F.; Jacinto, C. Finding occupational accident patterns in the extractive industry using a systematic data mining approach. Reliab. Eng. Syst. Saf. 2012, 108, 108–122. [Google Scholar] [CrossRef]

- Yilmaz, F.; Tosun, S.B. Evaluation of safety trends in construction, mining and transportation sectors in Turkey. Sigurnost 2018, 60, 13–23. [Google Scholar] [CrossRef]

- Rashid, K.M.; Louis, J. Construction equipment activity recognition from IMUs mounted on articulated implements and supervised classification. In Computing in Civil Engineering 2019: Smart Cities, Sustainability, and Resilience; American Society of Civil Engineers: Reston, VA, USA, 2019; pp. 130–138. [Google Scholar]

- Gualtieri, L.; Rauch, E.; Vidoni, R. Emerging research fields in safety and ergonomics in industrial collaborative robotics: A systematic literature review. Robot. Comput. Integr. Manuf. 2021, 67, 101998. [Google Scholar] [CrossRef]

| Type of Equipment | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Bolting Machine | Dozer | Dumper | Excavator | Forklift | Haul Truck | Jackleg Drill | LHD | Loader | |

| Type of accident | Caught between equipment [50]; slip/trip from the equipment [50]; struck by equipment [50]; | Not mentioned | Collision [7]; front run over [7]; reversal run over [7]; | Not mentioned | Not mentioned | Collision with another vehicle [42,45,47]; collision with another worker [45]; collision with pedestrian [42]; contact with public utility lines [42]; fall from vehicle [47]; rollovers [42,45] | fall of ground [46]; | Struck by equipment [50]; caught between [50]; got hit by equipment part [50]; slip/trip from the equipment [50]; | Collision with pedestrian [42]; contact with public utility lines [42]; fall from equipment [48]; replacement of the bucket [42]; rollovers [42]; slope failure [42]; |

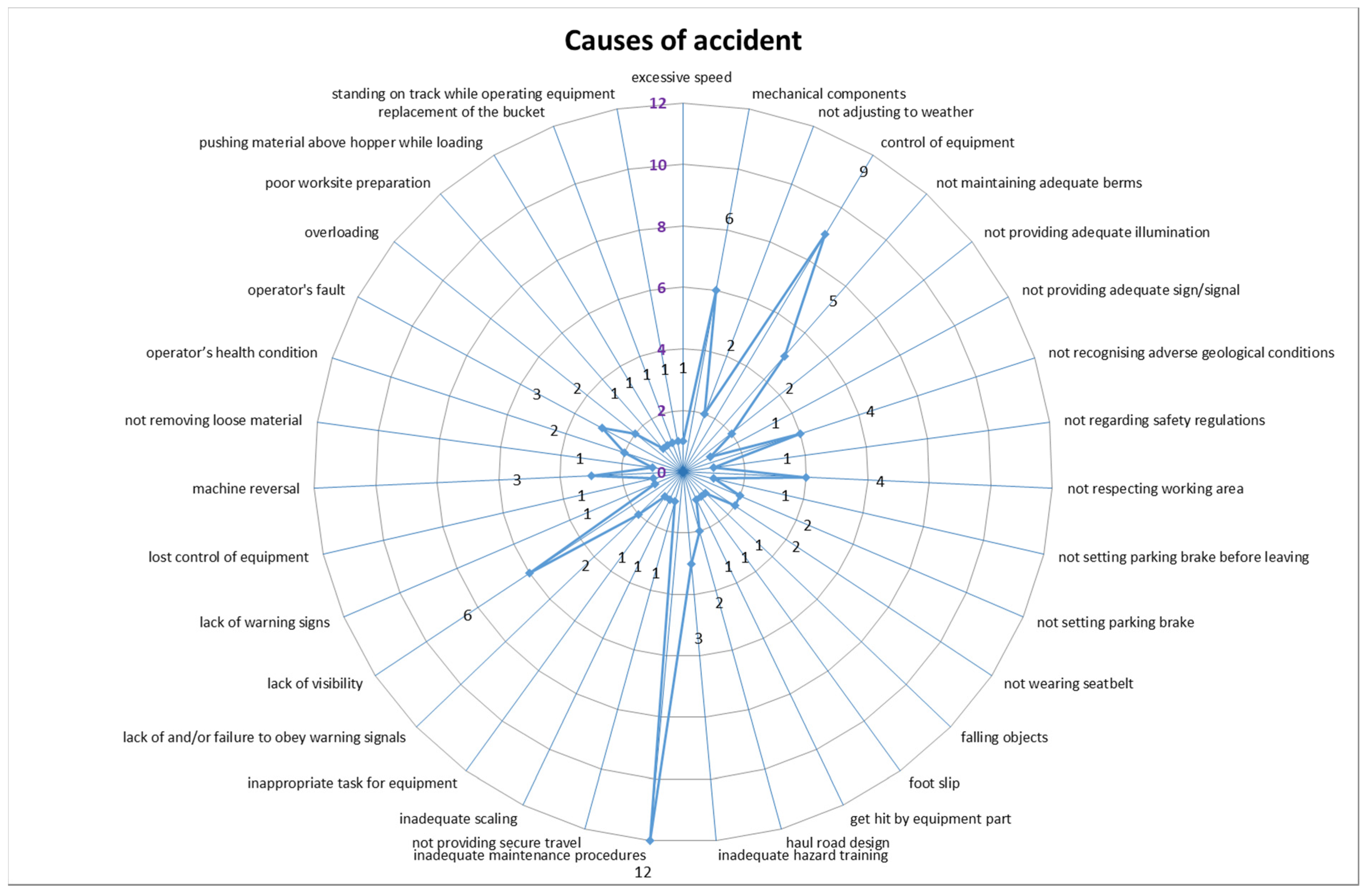

| Causes of accident | Human error -failure to control equipment [44,45]; -operator’s fault [34]; -machine reversal [34]; -overloading [34]; -standing on track while operating equipment [43]; -pushing material above hopper while loading [43]; -failure to recognise adverse geological conditions [43]; | Human error -lost control of equipment [7]; -operator’s fault [34]; -machine reversal [34]; -overloading [34]; | Human error failure to control equipment [44]; -operator’s fault [44]; machine reversal [44]; | Human error failure to control equipment [44]; | Human error failure to control equipment [44,45,47]; excessive speed [45]; failure to recognise adverse geological conditions [42]; failure to respect the truck’s working area [42,47]; failure to set the parking brake [42,45]; failure to wear seatbelt [45]; failure to regard safety regulations [47]; inadequate hazard training [42,45,47]; lack of and/or failure to obey warning signals [42,45]; operator’s health condition [42,45] | Human error failure to control equipment [46]; not removing the loose material [46]; poor worksite preparation [46] | Human error -failure to control equipment [44]; -failure to recognise adverse geological conditions [42,43]; failure to adjust to poor weather conditions [42,43]; failure to respect the loader’s working area [42,43]; failure to set parking brake before leaving [43]; failure to wear seatbelt [43]; foot slip [48]; inadequate provisions for secure travel [42]; | ||

| Maintenance inadequate maintenance procedures [50]; | Maintenance -inadequate maintenance procedures [34,43]; -failure of mechanical components [43]; | Maintenance inadequate maintenance procedures [34,45]; | Maintenance inadequate maintenance procedures [44]; | Maintenance inadequate maintenance procedures [47]; failure of mechanical components [42,45,47]; | Maintenance inadequate maintenance procedures [46]; | Maintenance inadequate maintenance procedures [50]; | Maintenance inadequate maintenance procedures [34,42,44]; failure of mechanical components [42,43]; | ||

| Design haul road design [34]; lack of visibility [34,44]; failure to provide adequate illumination [43]; failure to provide adequate sign/signal [43]; inappropriate task for equipment [43]; | Design haul road design [34]; lack of visibility [34]; | Design lack of visibility [44]; | Design lack of visibility [44]; failure to maintain adequate berms [42,45,47]; | Design falling objects [46]; inadequate scaling [46]; | Design lack of visibility [44]; failure to maintain adequate berms [42,43]; failure to provide adequate illumination [43]; lack of warning signs [42]; | ||||

| Study | Equipment | Methodology | Results | Others | |||

|---|---|---|---|---|---|---|---|

| Data Source | Standards Application | Sample Representativeness | Data Treatment | Reporting Quality | Reference Quality | ||

| [42] | Loader, truck | LR | NA | UR | UR | LR | UR |

| [30] | Haulage truck, front-end loader, nonpowered hand tools, conveyor, continuous miner | LR | NA | LR | UR | UR | UR |

| [6] | Haul truck, belt conveyor, front-end loaders, miscellaneous | LR | NA | LR | LR | UR | UR |

| [43] | Loader, dozer | LR | UR | UR | LR | LR | UR |

| [8] | Haul truck | LR | LR | LR | HR | UR | HR |

| [50] | Continuous miner, bolting machine, LHD, longwall, transport, shuttle car, handheld bolters, grader, stone dusting equipment, dolly car, road header, longwall move equipment, gas drainage drilling equipment | LR | NA | LR | UR | UR | LR |

| [44] | Conveyor, bolting machine, milling machine, LHD, front-end loader, continuous miner, crane, crusher, shuttle car, forklift, truck, shovel, hand tools | LR | NA | LR | UR | UR | LR |

| [52] | Not mentioned | LR | NA | LR | LR | LR | LR |

| [34] | Dumper, drilling machine, shovel, loader, dozer | LR | NA | LR | HR | UR | UR |

| [45] | Haul truck | LR | UR | UR | UR | LR | UR |

| [7] | Wheeled vehicles | LR | NA | LR | HR | HR | UR |

| [46] | Jackleg drill | LR | NA | HR | HR | HR | HR |

| [47] | Off-road truck | LR | NA | UR | LR | LR | LR |

| [49] | Not mentioned | LR | NA | HR | LR | LR | LR |

| [51] | Not mentioned | LR | NA | HR | HR | LR | HR |

| [48] | Front-end loader | LR | NA | UR | UR | LR | LR |

| HR—high risk; LR—low risk; NA—not applicable; UR—unclear risk. | |||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duarte, J.; Marques, A.T.; Santos Baptista, J. Occupational Accidents Related to Heavy Machinery: A Systematic Review. Safety 2021, 7, 21. https://0-doi-org.brum.beds.ac.uk/10.3390/safety7010021

Duarte J, Marques AT, Santos Baptista J. Occupational Accidents Related to Heavy Machinery: A Systematic Review. Safety. 2021; 7(1):21. https://0-doi-org.brum.beds.ac.uk/10.3390/safety7010021

Chicago/Turabian StyleDuarte, J., A. Torres Marques, and J. Santos Baptista. 2021. "Occupational Accidents Related to Heavy Machinery: A Systematic Review" Safety 7, no. 1: 21. https://0-doi-org.brum.beds.ac.uk/10.3390/safety7010021