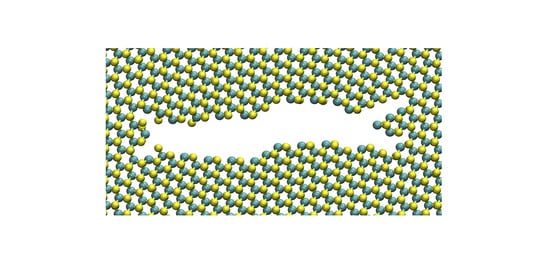

On the Elastic Properties and Fracture Patterns of MoX2 (X = S, Se, Te) Membranes: A Reactive Molecular Dynamics Study

Abstract

:1. Introduction

2. Details of Modeling

3. Results

4. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Manzeli, S.; Ovchinnikov, D.; Pasquier, D.; Yazyev, O.V.; Kis, A. 2D transition metal dichalcogenides. Nat. Rev. Mater. 2017, 2, 17033. [Google Scholar] [CrossRef]

- Chhowalla, M.; Shin, H.S.; Eda, G.; Li, L.J.; Loh, K.P.; Zhang, H. The chemistry of two-dimensional layered transition metal dichalcogenide nanosheets. Nat. Chem. 2013, 5, 263–275. [Google Scholar] [CrossRef]

- Tan, C.; Zhang, H. Two-dimensional transition metal dichalcogenide nanosheet-based composites. Chem. Soc. Rev. 2015, 44, 2713–2731. [Google Scholar] [CrossRef]

- Chhowalla, M.; Liu, Z.; Zhang, H. Two-dimensional transition metal dichalcogenide (TMD) nanosheets. Chem. Soc. Rev. 2015, 44, 2584–2586. [Google Scholar] [CrossRef]

- Xu, M.; Liang, T.; Shi, M.; Chen, H. Graphene-like two-dimensional materials. Chem. Rev. 2013, 113, 3766–3798. [Google Scholar] [CrossRef] [PubMed]

- Butler, S.Z.; Hollen, S.M.; Cao, L.; Cui, Y.; Gupta, J.A.; Gutiérrez, H.R.; Heinz, T.F.; Hong, S.S.; Huang, J.; Ismach, A.F.; et al. Progress, challenges, and opportunities in two-dimensional materials beyond graphene. ACS Nano 2013, 7, 2898–2926. [Google Scholar] [CrossRef] [PubMed]

- Qian, X.; Shen, S.; Liu, T.; Cheng, L.; Liu, Z. Two-dimensional TiS 2 nanosheets for in vivo photoacoustic imaging and photothermal cancer therapy. Nanoscale 2015, 7, 6380–6387. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Tan, C.; Zhang, H.; Wang, L. Two-dimensional graphene analogues for biomedical applications. Chem. Soc. Rev. 2015, 44, 2681–2701. [Google Scholar] [CrossRef]

- Wang, Q.H.; Kalantar-Zadeh, K.; Kis, A.; Coleman, J.N.; Strano, M.S. Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nat. Nanotechnol. 2012, 7, 699–712. [Google Scholar] [CrossRef]

- Wilson, J.A.; Yoffe, A. The transition metal dichalcogenides discussion and interpretation of the observed optical, electrical and structural properties. Adv. Phys. 1969, 18, 193–335. [Google Scholar] [CrossRef]

- Eda, G.; Yamaguchi, H.; Voiry, D.; Fujita, T.; Chen, M.; Chhowalla, M. Photoluminescence from chemically exfoliated MoS2. Nano Lett. 2011, 11, 5111–5116. [Google Scholar] [CrossRef] [PubMed]

- Yun, Q.; Lu, Q.; Zhang, X.; Tan, C.; Zhang, H. Three-dimensional architectures constructed from transition-metal dichalcogenide nanomaterials for electrochemical energy storage and conversion. Angew. Chem. Int. Ed. 2018, 57, 626–646. [Google Scholar] [CrossRef]

- Mak, K.F.; Lee, C.; Hone, J.; Shan, J.; Heinz, T.F. Atomically thin MoS2: A new direct-gap semiconductor. Phys. Rev. Lett. 2010, 105, 136805. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ruppert, C.; Aslan, O.B.; Heinz, T.F. Optical properties and band gap of single-and few-layer MoTe2 crystals. Nano Lett. 2014, 14, 6231–6236. [Google Scholar] [CrossRef] [PubMed]

- Jariwala, D.; Sangwan, V.K.; Lauhon, L.J.; Marks, T.J.; Hersam, M.C. Emerging device applications for semiconducting two-dimensional transition metal dichalcogenides. ACS Nano 2014, 8, 1102–1120. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Chang, T.R.; Zhou, B.; Cui, Y.T.; Yan, H.; Liu, Z.; Schmitt, F.; Lee, J.; Moore, R.; Chen, Y.; et al. Direct observation of the transition from indirect to direct bandgap in atomically thin epitaxial MoSe2. Nat. Nanotechnol. 2014, 9, 111. [Google Scholar] [CrossRef]

- Eftekhari, A. Molybdenum diselenide (MoSe2) for energy storage, catalysis, and optoelectronics. Appl. Mater. Today 2017, 8, 1–17. [Google Scholar] [CrossRef]

- Eda, G.; Maier, S.A. Two-dimensional crystals: Managing light for optoelectronics. ACS Nano 2013, 7, 5660–5665. [Google Scholar] [CrossRef]

- Zhang, X.; Lai, Z.; Ma, Q.; Zhang, H. Novel structured transition metal dichalcogenide nanosheets. Chem. Soc. Rev. 2018, 47, 3301–3338. [Google Scholar] [CrossRef]

- Yu, Y.; Nam, G.H.; He, Q.; Wu, X.J.; Zhang, K.; Yang, Z.; Chen, J.; Ma, Q.; Zhao, M.; Liu, Z.; et al. High phase-purity 1T’-MoS2-and 1T’-MoSe2-layered crystals. Nat. Chem. 2018, 10, 638–643. [Google Scholar] [CrossRef]

- Ostadhossein, A.; Rahnamoun, A.; Wang, Y.; Zhao, P.; Zhang, S.; Crespi, V.H.; Van Duin, A.C. ReaxFF reactive force-field study of molybdenum disulfide (MoS2). J. Phys. Chem. Lett. 2017, 8, 631–640. [Google Scholar] [CrossRef] [PubMed]

- Castellanos-Gomez, A.; Poot, M.; Steele, G.A.; Van Der Zant, H.S.; Agraït, N.; Rubio-Bollinger, G. Elastic properties of freely suspended MoS2 nanosheets. Adv. Mater. 2012, 24, 772–775. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Castellanos-Gomez, A.; van Leeuwen, R.; Buscema, M.; van der Zant, H.S.; Steele, G.A.; Venstra, W.J. Single-layer MoS2 mechanical resonators. Adv. Mater. 2013, 25, 6719–6723. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Castellanos-Gomez, A.; Roldán, R.; Cappelluti, E.; Buscema, M.; Guinea, F.; van der Zant, H.S.; Steele, G.A. Local strain engineering in atomically thin MoS2. Nano Lett. 2013, 13, 5361–5366. [Google Scholar] [CrossRef] [Green Version]

- Cooper, R.C.; Lee, C.; Marianetti, C.A.; Wei, X.; Hone, J.; Kysar, J.W. Nonlinear elastic behavior of two-dimensional molybdenum disulfide. Phys. Rev. B 2013, 87, 035423. [Google Scholar] [CrossRef] [Green Version]

- Jiang, J.W.; Park, H.S. Mechanical properties of MoS2/graphene heterostructures. Appl. Phys. Lett. 2014, 105, 033108. [Google Scholar] [CrossRef] [Green Version]

- Jiang, J.W.; Park, H.S.; Rabczuk, T. Molecular dynamics simulations of single-layer molybdenum disulphide (MoS2): Stillinger-Weber parametrization, mechanical properties, and thermal conductivity. J. Appl. Phys. 2013, 114, 064307. [Google Scholar] [CrossRef] [Green Version]

- Kang, J.; Sahin, H.; Peeters, F.M. Mechanical properties of monolayer sulphides: A comparative study between MoS2, HfS 2 and TiS 3. Phys. Chem. Chem. Phys. 2015, 17, 27742–27749. [Google Scholar] [CrossRef]

- Khan, M.B.; Jan, R.; Habib, A.; Khan, A.N. Evaluating mechanical properties of few layers MoS2 nanosheets-polymer composites. Adv. Mater. Sci. Eng. 2017, 2017, 3176808. [Google Scholar] [CrossRef] [Green Version]

- Liang, T.; Phillpot, S.R.; Sinnott, S.B. Parametrization of a reactive many-body potential for Mo–S systems. Phys. Rev. B 2009, 79, 245110. [Google Scholar] [CrossRef]

- Liu, K.; Yan, Q.; Chen, M.; Fan, W.; Sun, Y.; Suh, J.; Fu, D.; Lee, S.; Zhou, J.; Tongay, S.; et al. Elastic properties of chemical-vapor-deposited monolayer MoS2, WS2, and their bilayer heterostructures. Nano Lett. 2014, 14, 5097–5103. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Manzeli, S.; Allain, A.; Ghadimi, A.; Kis, A. Piezoresistivity and strain-induced band gap tuning in atomically thin MoS2. Nano Lett. 2015, 15, 5330–5335. [Google Scholar] [CrossRef] [Green Version]

- Yazyev, O.V.; Kis, A. MoS2 and semiconductors in the flatland. Mater. Today 2015, 18, 20–30. [Google Scholar] [CrossRef]

- Mortazavi, B.; Ostadhossein, A.; Rabczuk, T.; Van Duin, A.C. Mechanical response of all-MoS2 single-layer heterostructures: A ReaxFF investigation. Phys. Chem. Chem. Phys. 2016, 18, 23695–23701. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Miró, P.; Ghorbani-Asl, M.; Heine, T. Two dimensional materials beyond MoS2: Noble-transition-metal dichalcogenides. Angew. Chem. Int. Ed. 2014, 53, 3015–3018. [Google Scholar] [CrossRef] [PubMed]

- Frisenda, R.; Drüppel, M.; Schmidt, R.; de Vasconcellos, S.M.; de Lara, D.P.; Bratschitsch, R.; Rohlfing, M.; Castellanos-Gomez, A. Biaxial strain tuning of the optical properties of single-layer transition metal dichalcogenides. NPJ 2D Mater. Appl. 2017, 1, 1–7. [Google Scholar] [CrossRef]

- Jaques, Y.M.; Manimunda, P.; Nakanishi, Y.; Susarla, S.; Woellner, C.F.; Bhowmick, S.; Asif, S.A.S.; Galvão, D.S.; Tiwary, C.S.; Ajayan, P.M.; et al. Differences in the Mechanical Properties of Monolayer and Multilayer WSe2/MoSe2. MRS Adv. 2018, 3, 373–378. [Google Scholar] [CrossRef] [Green Version]

- Jiang, M.; Zhang, J.; Wu, M.; Jian, W.; Xue, H.; Ng, T.W.; Lee, C.S.; Xu, J. Synthesis of 1T-MoSe2 ultrathin nanosheets with an expanded interlayer spacing of 1.17 nm for efficient hydrogen evolution reaction. J. Mater. Chem. A 2016, 4, 14949–14953. [Google Scholar] [CrossRef]

- Iguiñiz, N.; Frisenda, R.; Bratschitsch, R.; Castellanos-Gomez, A. Revisiting the buckling metrology method to determine the Young’s modulus of 2D materials. Adv. Mater. 2019, 31, 1807150. [Google Scholar] [CrossRef] [Green Version]

- Johari, P.; Shenoy, V.B. Tuning the electronic properties of semiconducting transition metal dichalcogenides by applying mechanical strains. ACS Nano 2012, 6, 5449–5456. [Google Scholar] [CrossRef]

- Kumar, A.; Ahluwalia, P. Mechanical strain dependent electronic and dielectric properties of two-dimensional honeycomb structures of MoX2 (X = S, Se, Te). Phys. B Condens. Matter 2013, 419, 66–75. [Google Scholar] [CrossRef]

- Mortazavi, B.; Berdiyorov, G.R.; Makaremi, M.; Rabczuk, T. Mechanical responses of two-dimensional MoTe2; pristine 2H, 1T and 1T’ and 1T’/2H heterostructure. Extrem. Mech. Lett. 2018, 20, 65–72. [Google Scholar] [CrossRef] [Green Version]

- May, P.; Khan, U.; Coleman, J.N. Reinforcement of metal with liquid-exfoliated inorganic nano-platelets. Appl. Phys. Lett. 2013, 103, 163106. [Google Scholar] [CrossRef] [Green Version]

- Rano, B.R.; Syed, I.M.; Naqib, S. Ab initio approach to the elastic, electronic, and optical properties of MoTe2 topological Weyl semimetal. J. Alloys Compd. 2020, 829, 154522. [Google Scholar] [CrossRef] [Green Version]

- Sun, Y.; Pan, J.; Zhang, Z.; Zhang, K.; Liang, J.; Wang, W.; Yuan, Z.; Hao, Y.; Wang, B.; Wang, J.; et al. Elastic properties and fracture behaviors of biaxially deformed, polymorphic MoTe2. Nano Lett. 2019, 19, 761–769. [Google Scholar] [CrossRef] [PubMed]

- Deng, S.; Li, L.; Li, M. Stability of direct band gap under mechanical strains for monolayer MoS2, MoSe2, WS2 and WSe2. Phys. E Low Dimens. Syst. Nanostruct. 2018, 101, 44–49. [Google Scholar] [CrossRef] [Green Version]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Freitas, R.R.; de Brito Mota, F.; Rivelino, R.; De Castilho, C.; Kakanakova-Georgieva, A.; Gueorguiev, G.K. Tuning band inversion symmetry of buckled III-Bi sheets by halogenation. Nanotechnology 2016, 27, 055704. [Google Scholar] [CrossRef]

- Dos Santos, R.; Rivelino, R.; de Brito Mota, F.; Gueorguiev, G.; Kakanakova-Georgieva, A. Dopant species with Al–Si and N–Si bonding in the MOCVD of AlN implementing trimethylaluminum, ammonia and silane. J. Phys. D Appl. Phys. 2015, 48, 295104. [Google Scholar] [CrossRef]

- Pereira, M.L.; Ribeiro, L.A. Thermomechanical insight into the stability of nanoporous graphene membranes. FlatChem 2020, 24, 100196. [Google Scholar] [CrossRef]

- Humphrey, W.; Dalke, A.; Schulten, K. VMD: Visual molecular dynamics. J. Mol. Graph. 1996, 14, 33–38. [Google Scholar] [CrossRef]

- Mises, R.V. Mechanik der festen Körper in plastisch-deformablen Zustand. Math. Phys. Klasse 1913, 4, 582–592. [Google Scholar]

- Heyes, D.M. Pressure tensor of partial-charge and point-dipole lattices with bulk and surface geometries. Phys. Rev. B 1994, 49, 755. [Google Scholar] [CrossRef] [PubMed]

- Sirk, T.W.; Moore, S.; Brown, E.F. Characteristics of thermal conductivity in classical water models. J. Chem. Phys. 2013, 138, 064505. [Google Scholar] [CrossRef] [PubMed]

- Thompson, A.P.; Plimpton, S.J.; Mattson, W. General formulation of pressure and stress tensor for arbitrary many-body interaction potentials under periodic boundary conditions. J. Chem. Phys. 2009, 131, 154107. [Google Scholar] [CrossRef] [Green Version]

- Surblys, D.; Matsubara, H.; Kikugawa, G.; Ohara, T. Application of atomic stress to compute heat flux via molecular dynamics for systems with many-body interactions. Phys. Rev. E 2019, 99, 051301. [Google Scholar] [CrossRef] [Green Version]

- Ghobadi, N. A comparative study of the mechanical properties of multilayer MoS2 and graphene/MoS2 heterostructure: Effects of temperature, number of layers and stacking order. Curr. Appl. Phys. 2017, 17, 1483–1493. [Google Scholar] [CrossRef]

- Lee, J.U.; Yoon, D.; Cheong, H. Estimation of Young’s modulus of graphene by Raman spectroscopy. Nano Lett. 2012, 12, 4444–4448. [Google Scholar] [CrossRef] [Green Version]

| Temperature [K] | 2H-MoS | |||||

| Strain-h | Strain-v | |||||

| [GPa] | FS [%] | US [GPa] | [GPa] | FS [%] | US [GPa] | |

| 10 K | 145 | 19 | 19 | 139 | 22 | 17 |

| 300 K | 135 | 12 | 14 | 130 | 14 | 14 |

| Temperature [K] | 2H-MoSe | |||||

| Strain-h | Strain-v | |||||

| [GPa] | FS [%] | US [GPa] | [GPa] | FS [%] | US [GPa] | |

| 10 K | 160 | 23 | 26 | 155 | 27 | 25 |

| 300 K | 154 | 17 | 22 | 149 | 20 | 21 |

| Temperature [K] | 2H-MoTe | |||||

| Strain-h | Strain-v | |||||

| [GPa] | FS [%] | US [GPa] | [GPa] | FS [%] | US [GPa] | |

| 10 K | 125 | 25 | 23 | 122 | 30 | 21 |

| 300 K | 121 | 18 | 19 | 118 | 20 | 18 |

| Temperature [K] | 1T-MoS | |||||

| Strain-h | Strain-v | |||||

| [GPa] | FS [%] | US [GPa] | [GPa] | FS [%] | US [GPa] | |

| 10 K | 124 | 13 | 12 | 120 | 14 | 11 |

| 300 K | 133 | 5 | 7 | 110 | 8 | 8 |

| Temperature [K] | 1T-MoSe | |||||

| Strain-h | Strain-v | |||||

| [GPa] | FS [%] | US [GPa] | [GPa] | FS [%] | US [GPa] | |

| 10 K | 127 | 12 | 11 | 124 | 15 | 12 |

| 300 K | 114 | 7 | 8 | 112 | 8 | 8 |

| Temperature [K] | 1T-MoTe | |||||

| Strain-h | Strain-v | |||||

| [GPa] | FS [%] | US [GPa] | [GPa] | FS [%] | US [GPa] | |

| 10 K | 118 | 13 | 11 | 114 | 16 | 11 |

| 300 K | 107 | 8 | 8 | 103 | 9 | 8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pereira Júnior, M.L.; Viana de Araújo, C.M.; De Sousa, J.M.; de Sousa Júnior, R.T.; Roncaratti Júnior, L.F.; Ferreira Giozza, W.; Ribeiro Júnior, L.A. On the Elastic Properties and Fracture Patterns of MoX2 (X = S, Se, Te) Membranes: A Reactive Molecular Dynamics Study. Condens. Matter 2020, 5, 73. https://0-doi-org.brum.beds.ac.uk/10.3390/condmat5040073

Pereira Júnior ML, Viana de Araújo CM, De Sousa JM, de Sousa Júnior RT, Roncaratti Júnior LF, Ferreira Giozza W, Ribeiro Júnior LA. On the Elastic Properties and Fracture Patterns of MoX2 (X = S, Se, Te) Membranes: A Reactive Molecular Dynamics Study. Condensed Matter. 2020; 5(4):73. https://0-doi-org.brum.beds.ac.uk/10.3390/condmat5040073

Chicago/Turabian StylePereira Júnior, Marcelo Lopes, Cícera Maria Viana de Araújo, José Moreira De Sousa, Rafael Timóteo de Sousa Júnior, Luiz Fernando Roncaratti Júnior, William Ferreira Giozza, and Luiz Antonio Ribeiro Júnior. 2020. "On the Elastic Properties and Fracture Patterns of MoX2 (X = S, Se, Te) Membranes: A Reactive Molecular Dynamics Study" Condensed Matter 5, no. 4: 73. https://0-doi-org.brum.beds.ac.uk/10.3390/condmat5040073