Exploring an AM-Enabled Combination-of-Functions Approach for Modular Product Design

Abstract

:1. Introduction

2. Modular Design: Theory and Applications

- Decrease in production cost due to re-usability of components across different families

- Ease of product updating due to functional modules

- Increased product variety from a smaller set of components

- Decreased order lead-time due to fewer different components

- Ease of design and testing due to the decoupling of product functions

- Ease of service due to differential consumption

- Design of parts and subsystems should be done by specialized teams of experts

- After design, an integration phase will be required for the system, during which the parts and sub-assemblies are converted into a usable system or product

- Every aspect of the system should be standardized as much as possible

- Every design technique used or derived should be developed to be as widely applicable as possible

- Integrate further plans for testing, maintenance, and upgrades into the original design process

- Consider end-of-life disassembly, recycling, and retirement during the design process

- Every component and subsystem should be easily upgradable and repairable

- Systems should be easily reconfigurable for as many missions as possible

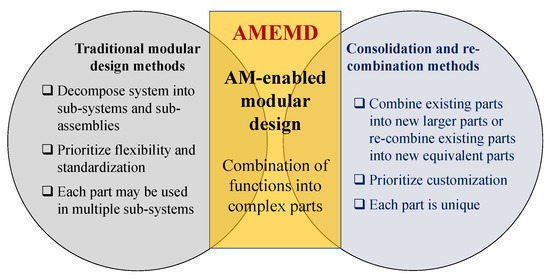

3. AM-Enabled Modular Design (AMEMD) Concept

Specific characteristics of this design methodology are:The process of decomposing a system into sets of functionalities or functions which can be performed by the design and additive manufacturing of multi-functional complex parts. These complex parts will be integrated together to produce the whole system. The functionality of the new system must be equal or superior to a system built from sub-assemblies of off-the-shelf parts, while containing fewer physical parts and interfaces.

- Complexity vs standardization: An increase in geometric complexity that results in fewer, but more function-dense parts is preferred over standardization of the parts and the use of assemblies of simple parts

- Optimization: Optimization for performance of complex parts is preferred over standardization

- Design and integration: Design teams for each of the complex parts focus on the design optimization and integration of the part into the system or product

- Design prototyping: System design prototypes can be produced quickly using AM technologies, aiding design and integration efforts

- On-demand manufacturing: For relatively simple systems, all AM parts, both original and replacement or upgrade parts, are manufactured on-demand directly from CAD data and are not kept in stock. For parts that belong to systems with certification requirements or that require constant stand-by spares, batches of parts can be made and kept as spares, with the option to make more on-demand if needed.

- Serviceability: While the parts are usually non-serviceable, they are easily replaced or upgraded, as long as the system allows access to the parts after completion (i.e., a “line-replaceable unit”)

- Part disposal: Old parts that are worn out or upgraded are easily recycled due to the low-hazard status of most AM-processes materials

- User customization: Parts of the system are almost infinitely customizable and optimizable during the design, but usually not customizable in the field after production

- Mass customization: Several parts can be made at once using the same machine and the same batch of raw materials; there may be several of the same part or several different parts in a batch

- Core mission: There is only one core mission or set of missions for each system configuration, but this is offset by the increased speed and reduced cost of production and by the optimization of the design before use

4. Domain Applicability

5. Case Study: Re-Design of AIM-120 AMRAAM Airframe

5.1. Overview and Model Details

5.2. Examination of Part Combination Opportunities

- Nose cone—upper electronics housing: The nose cone holds the guidance for the missile and may need to be replaced or upgraded, so it is best to not eliminate this interface.

- Upper and lower electronics housing: One of the details that can be derived from the promotional literature for the AIM-120 is that the upper section which holds the electronics is made in two pieces, which can be easily combined into a single piece, assuming that the internal components will allow this. It is assumed that it was originally made in two parts to allow customized connections to the internal parts; using AM to create an optimized internal structure to connect to the electronics should allow the combination of these two parts. In addition to removing an interface, 12 of the fasteners can also be eliminated. Preserving access to the electronics for assembly and maintenance would be an important design consideration during the part re-combination. This should be checked to ensure that either no conflict exists or the AM part can be modified to account for it.

- Electronics housing to payload: It is obvious that the payload section needs to be easily accessible to the user of the missile, so it would be best to retain this interface as-is.

- Payload to upper control surfaces: For this missile, the upper control surfaces are fixed to the airframe and assumed to be made from the same material as the airframe. Therefore, the upper control surfaces can and should be integrated into the payload housing. The front fins could be combined with either the payload section or the motor/fuel section, but the best choice is the payload section; this is primarily to ensure that the air flows smoothly around the fins and that interface issues will not affect the leading surface of the control fin.

- Payload to motor/fuel section: As previously stated, the payload section should be independent as much as possible, so this interface should remain. Access to the motor and fuel supply are also reasons to retain the interface between the payload and motor/fuel sections.

- Motor to nozzle section: The rear control surfaces are driven by actuators near the nozzle and the nozzle and motor interface may need to be maintained and inspected.

- Nozzle section to rear control surface hinges: Since the hinges need to be free-moving and connected to internal actuators, no combination can be accomplished.

- Hinges to rear control surfaces: Since the rear control surfaces and hinges are both made from aluminum in this model, and their combination is relatively small, AMEMD makes sense for these parts.

5.3. Part Re-Combination and New System Model

5.4. Part Re-Design and Optimization

5.4.1. Electronics Housing Optimization

5.4.2. Payload and Upper Control Surfaces

5.4.3. Rear Control Surfaces

5.5. Design Evaluation

- Manufacturing: The manufacturing process for the system should have been improved, with a particular focus on reducing production time and cost. In this case, a number of parts were re-combined which may reduce the assembly time; however, it is possible that the assembly time would increase if the condensed parts required any special tools or new processes to integrate with the other parts. For the airframe re-design, this may be an issue for the electronics housing if the internal components of the missile require easy access. The designer should consider this a trade-off when it is a problem; this may be mitigated during the design by producing a new assembly procedure which considers integration with the larger housing section.

- Functionality and Performance: In order for AMEMD to be useful, it must produce some benefit to the designer. Therefore, it must be established that the new design gives at least one measurable benefit and that the general performance is at least as good as the old design. In this case, the performance and reliability of the missile must be at least as good as a missile which follows the original design. It was clear during the consolidation and optimization of the modified parts that the weight was certainly reduced, which may have a positive impact on performance and control. An additional advantage which may be gained from using AM is the presence of a layered surface if untreated; this may reduce drag on the airframe by providing a small surface roughness to reduce the laminar fluid flow around the airframe.

- Usability: In order for the new product or system to be useful, it must be reliable and useful for its core mission. The particular considerations for this and all AM-related designs are those discussed for the domain applicability, namely repairability, maintainability, and the possibility of upgrading the system. No matter how reliable the system is, there will eventually be breakdowns and needed part upgrades and so this must be considered during design. In terms of AM, repairability is sometimes possible but it should not be assumed for most AM parts. Maintainability and component upgrades are dependent on how the system is broken down; in general, any broken or worn parts made using AM would need to simply be replaced instead of being maintained or upgrades. However, this can be mitigated by the ability of AM to build complex and custom geometry and tailored materials, as this can reduce the need for maintenance. The on-demand manufacturability of AM parts would also reduce the need for part upgrades, as new part designs can be built as needed and the old one thrown away or recycled. For the missile airframe, the basic design is fairly well established, so it should be easy to design and manufacture new parts as needed in the field. Since the usability of the design is already established any upgrades or repairs would use a similar design to the old one, with similar reliability and usability.

6. Summary and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rosen, D.W. Computer-Aided Design for Additive Manufacturing of Cellular Structures. Comput.-Aided Des. Appl. 2007, 4, 585–594. [Google Scholar] [CrossRef]

- Parthasarathy, J.; Starly, B.; Raman, S. A design for the additive manufacture of functionally graded porous structures with tailored mechanical properties for biomedical applications. J. Manuf. Process. 2011, 13, 160–170. [Google Scholar] [CrossRef]

- Doubrovski, Z.; Verlinden, J.C.; Geraedts, J.M.P. Optimal Design for Additive Manufacturing: Opportunities and Challenges. In Volume 9: 23rd International Conference on Design Theory and Methodology; 16th Design for Manufacturing and the Life Cycle Conference; ASME: New York City, NY, USA, 2011. [Google Scholar] [CrossRef]

- Yang, S.; Zhao, Y.F. Additive manufacturing-enabled design theory and methodology: A critical review. Int. J. Adv. Manuf. Technol. 2015, 80, 327–342. [Google Scholar] [CrossRef]

- Schmelzle, J.; Kline, E.V.; Dickman, C.J.; Reutzel, E.W.; Jones, G.; Simpson, T.W. (Re)Designing for Part Consolidation: Understanding the Challenges of Metal Additive Manufacturing. J. Mech. Des. 2015, 137, 111404. [Google Scholar] [CrossRef]

- Yang, S.; Santoro, F.; Sulthan, M.A.; Zhao, Y.F. A numerical-based part consolidation candidate detection approach with modularization considerations. Res. Eng. Des. 2018. [Google Scholar] [CrossRef]

- Oh, Y.; Zhou, C.; Behdad, S. Part decomposition and assembly-based (Re) design for additive manufacturing: A review. Addit. Manuf. 2018, 22, 230–242. [Google Scholar] [CrossRef]

- Yang, S.; Tang, Y.; Zhao, Y.F. A new part consolidation method to embrace the design freedom of additive manufacturing. J. Manuf. Process. 2015, 20, 444–449. [Google Scholar] [CrossRef]

- Jayal, A.; Badurdeen, F.; Dillon, O.; Jawahir, I. Sustainable manufacturing: Modeling and optimization challenges at the product, process and system levels. CIRP J. Manuf. Sci. Technol. 2010, 2, 144–152. [Google Scholar] [CrossRef]

- Susman, G. Integrating Design and Manufacturing for Competitive Advantage; Oxford University Press: Oxford, UK, 1992. [Google Scholar]

- Bralla, J.G. Design for Manufacturability Handbook; McGraw-Hill Education: New York City, NY, USA, 1998. [Google Scholar]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Chan, K.S.; Koike, M.; Mason, R.L.; Okabe, T. Fatigue Life of Titanium Alloys Fabricated by Additive Layer Manufacturing Techniques for Dental Implants. Metall. Mater. Trans. A 2012, 44, 1010–1022. [Google Scholar] [CrossRef]

- Jardini, A.L.; Larosa, M.A.; de Carvalho Zavaglia, C.A.; Bernardes, L.F.; Lambert, C.S.; Kharmandayan, P.; Calderoni, D.; Filho, R.M. Customised titanium implant fabricated in additive manufacturing for craniomaxillofacial surgery. Virtual Phys. Prototyp. 2014, 9, 115–125. [Google Scholar] [CrossRef]

- Salmi, M.; Tuomi, J.; Paloheimo, K.S.; Björkstrand, R.; Paloheimo, M.; Salo, J.; Kontio, R.; Mesimäki, K.; Mäkitie, A.A. Patient-specific reconstruction with 3D modeling and DMLS additive manufacturing. Rapid Prototyp. J. 2012, 18, 209–214. [Google Scholar] [CrossRef]

- Akmal, J.; Salmi, M.; Mäkitie, A.; Björkstrand, R.; Partanen, J. Implementation of Industrial Additive Manufacturing: Intelligent Implants and Drug Delivery Systems. J. Funct. Biomater. 2018, 9, 41. [Google Scholar] [CrossRef] [PubMed]

- Guo, N.; Leu, M.C. Additive manufacturing: Technology, applications and research needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing; Springer: Berlin, Germany, 2016. [Google Scholar]

- Lei, N.; Yao, X.; Moon, S.K.; Bi, G. An additive manufacturing process model for product family design. J. Eng. Des. 2016, 27, 751–767. [Google Scholar] [CrossRef]

- Agard, B.; Bassetto, S. Modular design of product families for quality and cost. Int. J. Prod. Res. 2013, 51, 1648–1667. [Google Scholar] [CrossRef]

- Jiao, J.R.; Simpson, T.W.; Siddique, Z. Product family design and platform-based product development: A state-of-the-art review. J. Intell. Manuf. 2007, 18, 5–29. [Google Scholar] [CrossRef]

- Nayak, R.U.; Chen, W.; Simpson, T.W. A Variation-Based Method for Product Family Design. Eng. Optim. 2002, 34, 65–81. [Google Scholar] [CrossRef] [Green Version]

- Gonzalez-Zugasti, J.P.; Otto, K.N.; Baker, J.D. Assessing value in platformed product family design. Res. Eng. Des. 2001, 13, 30–41. [Google Scholar] [CrossRef]

- Patterson, A.E.; Thomas, L.D.; Messimer, S.L. Disruptive Effects of Additive Technologies on SE Product Lifecycle. Procedings of the JANNAF Technical Interchange Conference, Huntsville, AL, USA, 23–25 August 2016. [Google Scholar] [CrossRef]

- Liu, P.; Huang, S.H.; Mokasdar, A.; Zhou, H.; Hou, L. The impact of additive manufacturing in the aircraft spare parts supply chain: Supply chain operation reference (SCOR) model based analysis. Prod. Plan. Control 2013, 25, 1169–1181. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Partanen, J.; Holmström, J. Additive manufacturing in the spare parts supply chain. Comput. Ind. 2014, 65, 50–63. [Google Scholar] [CrossRef]

- ASTM. F2792-12a: Standard Terminology for Additive Manufacturing Technologies. ASTM Stand. 2012. [Google Scholar] [CrossRef]

- Patterson, A.E.; Collopy, P.; Messimer, S.L. State-of-the-Art Survey of Additive Manufacturing Technologies, Methods, and Materials; Technical Report, Report Number UAH 2015-06; Department of Industrial & Systems Engineering and Engineering Management, University of Alabama in Huntsville: Huntsville, IL, USA, 2015. [Google Scholar] [CrossRef]

- Patterson, A.E.; Allison, J.T. Manufacturability Constraint Formulation for Design Under Hybrid Additive-Subtractive Manufacturing. In ASME 2018 IDETC/CIE: 23rd Deign for Manufacturing and the Life Cycle Conference (DFMLC); ASME: Quebec City, QC, Canada, 2018. [Google Scholar] [CrossRef]

- Murthy, D.; Østerås, T.; Rausand, M. Component reliability specification. Reliab. Eng. Syst. Saf. 2009, 94, 1609–1617. [Google Scholar] [CrossRef]

- Aal, A.; Polte, T. On component reliability and system reliability for automotive applications. In Proceedings of the IEEE International Integrated Reliability Workshop Final Report, South Lake Tahoe, CA, USA, 14–18 October 2012. [Google Scholar] [CrossRef]

- Elsayed, E.A. Reliability Engineering (Wiley Series in Systems Engineering and Management); Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Hohenbichler, M.; Rackwitz, R. First-order concepts in system reliability. Struct. Saf. 1982, 1, 177–188. [Google Scholar] [CrossRef]

- Chern, M.S. On the computational complexity of reliability redundancy allocation in a series system. Oper. Res. Lett. 1992, 11, 309–315. [Google Scholar] [CrossRef]

- Frey, D.; Palladino, J.; Sullivan, J.; Atherton, M. Part count and design of robust systems. Syst. Eng. 2007, 10, 203–221. [Google Scholar] [CrossRef]

- ElMaraghy, W.; ElMaraghy, H.; Tomiyama, T.; Monostori, L. Complexity in engineering design and manufacturing. CIRP Ann. 2012, 61, 793–814. [Google Scholar] [CrossRef]

- Xu, Z.; Kuo, W.; Lin, H.H. Optimization limits in improving system reliability. IEEE Trans. Reliab. 1990, 39, 51–60. [Google Scholar] [CrossRef]

- Billinton, R.; Allan, R.N. Reliability Evaluation of Engineering Systems; Springer: Berlin, Germany, 1983. [Google Scholar]

- Anderson, K.B.; Lockwood, S.Y.; Martin, R.S.; Spence, D.M. A 3D Printed Fluidic Device that Enables Integrated Features. Anal. Chem. 2013, 85, 5622–5626. [Google Scholar] [CrossRef] [PubMed]

- Dind, A.; Lufkin, S.; Rey, E. A Modular Timber Construction System for the Sustainable Vertical Extension of Office Buildings. Designs 2018, 2, 30. [Google Scholar] [CrossRef]

- Sharafi, P.; Nemati, S.; Samali, B.; Ghodrat, M. Development of an Innovative Modular Foam-Filled Panelized System for Rapidly Assembled Postdisaster Housing. Buildings 2018, 8, 97. [Google Scholar] [CrossRef]

- Zhang, X.; Huang, Y.; Li, L.; Yeh, W.C. Power and Capacity Consensus Tracking of Distributed Battery Storage Systems in Modular Microgrids. Energies 2018, 11, 1439. [Google Scholar] [CrossRef]

- Mishra, A.; Mondini, A.; Dottore, E.D.; Sadeghi, A.; Tramacere, F.; Mazzolai, B. Modular Continuum Manipulator: Analysis and Characterization of Its Basic Module. Biomimetics 2018, 3, 3. [Google Scholar] [CrossRef]

- Demir, İ.; Aliaga, D.G.; Benes, B. Near-convex decomposition and layering for efficient 3D printing. Addit. Manuf. 2018, 21, 383–394. [Google Scholar] [CrossRef]

- Liu, J. Guidelines for AM part consolidation. Virtual Phys. Prototyp. 2016, 11, 133–141. [Google Scholar] [CrossRef]

- Yang, S.; Zhao, Y.F. Additive Manufacturing-Enabled Part Count Reduction: A Lifecycle Perspective. J. Mech. Des. 2018, 140, 031702. [Google Scholar] [CrossRef]

- Yang, S.; Zhao, Y. Conceptual design for assembly in the context of additive manufacturing. In Proceedings of the 26th Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 10–12 August 2016. [Google Scholar]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. 2016, 65, 737–760. [Google Scholar] [CrossRef] [Green Version]

- Mhapsekar, K.; McConaha, M.; Anand, S. Additive Manufacturing Constraints in Topology Optimization for Improved Manufacturability. J. Manuf. Sci. Eng. 2018, 140, 051017. [Google Scholar] [CrossRef]

- Meisel, N.; Williams, C. An Investigation of Key Design for Additive Manufacturing Constraints in Multimaterial Three-Dimensional Printing. J. Mech. Des. 2015, 137, 111406. [Google Scholar] [CrossRef]

- Kok, Y.; Tan, X.; Wang, P.; Nai, M.; Loh, N.; Liu, E.; Tor, S. Anisotropy and heterogeneity of microstructure and mechanical properties in metal additive manufacturing: A critical review. Mater. Des. 2018, 139, 565–586. [Google Scholar] [CrossRef]

- Popovich, A.A.; Sufiiarov, V.S.; Borisov, E.V.; Polozov, I.A.; Masaylo, D.V.; Grigoriev, A.V. Anisotropy of mechanical properties of products manufactured using selective laser melting of powdered materials. Russ. J. Non-Ferr. Met. 2017, 58, 389–395. [Google Scholar] [CrossRef]

- Ahn, S.H.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic material properties of fused deposition modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257. [Google Scholar] [CrossRef] [Green Version]

- Kaji, F.; Barari, A. Evaluation of the Surface Roughness of Additive Manufacturing Parts Based on the Modelling of Cusp Geometry. IFAC-PapersOnLine 2015, 48, 658–663. [Google Scholar] [CrossRef]

- Townsend, A.; Senin, N.; Blunt, L.; Leach, R.; Taylor, J. Surface texture metrology for metal additive manufacturing: A review. Precis. Eng. 2016, 46, 34–47. [Google Scholar] [CrossRef]

- Alfieri, V.; Argenio, P.; Caiazzo, F.; Sergi, V. Reduction of Surface Roughness by Means of Laser Processing over Additive Manufacturing Metal Parts. Materials 2016, 10, 30. [Google Scholar] [CrossRef] [PubMed]

- Patterson, A.E.; Messimer, S.L.; Farrington, P.A. Overhanging Features and the SLM/DMLS Residual Stresses Problem: Review and Future Research Need. Technologies 2017, 5, 15. [Google Scholar] [CrossRef]

- Mukherjee, T.; Zhang, W.; DebRoy, T. An improved prediction of residual stresses and distortion in additive manufacturing. Comput.l Mater. Sci. 2017, 126, 360–372. [Google Scholar] [CrossRef]

- Li, C.; Liu, Z.; Fang, X.; Guo, Y. Residual Stress in Metal Additive Manufacturing. Procedia CIRP 2018, 71, 348–353. [Google Scholar] [CrossRef]

- Hernandez, R.; Singh, H.; Messimer, S.; Patterson, A. Design and Performance of Modular 3-D Printed Solid-Propellant Rocket Airframes. Aerospace 2017, 4, 17. [Google Scholar] [CrossRef]

- Chung, W.H.; Kremer, G.E.O.; Wysk, R.A. Life cycle implications of product modular architectures in closed-loop supply chains. Int. J. Adv. Manuf. Technol. 2013, 70, 2013–2028. [Google Scholar] [CrossRef]

- Gershenson, J.K.; Prasad, G.J.; Zhang, Y. Product modularity: Definitions and benefits. J. Eng. Des. 2003, 14, 295–313. [Google Scholar] [CrossRef]

- Baldwin, C.; Clark, K. Managing in the Age of Modularity. Harvard Bus. Rev. 1997, 75, 84–93. [Google Scholar]

- Bonvoisin, J.; Halstenberg, F.; Buchert, T.; Stark, R. A systematic literature review on modular product design. J. Eng. Des. 2016, 27, 488–514. [Google Scholar] [CrossRef]

- Todorova, G.; Burisin, B. Do firms innovate through integrated modular designs? Disentangling the effects of types of modularity on types of innovation. In KITeS Knowledge, Internationalization, and Technology Studies; Technical Report; Bocconi University: Milan, Italy, 2009. [Google Scholar]

- Ulrich, K. Fundamentals of Product Modularity. In Management of Design; Springer: Berlin, Germany, 1994; pp. 219–231. [Google Scholar] [CrossRef]

- Ozman, M. Modularity, Industry Life Cycle and Open Innovation. J. Technol. Manag. Innovat. 2011, 6, 26–34. [Google Scholar] [CrossRef]

- Ettlie, J.E.; Kubarek, M. Design Reuse in Manufacturing and Services. J. Prod. Innovat. Manag. 2008, 25, 457–472. [Google Scholar] [CrossRef]

- Kassi, T.; Leisti, S.; Puheloinen, T. Impact of product modular design on agile manufacturing. Mechanika 2008, 74, 56–62. [Google Scholar]

- Ericsson, A.; Erixon, G. Controlling Design Variants: Modular Product Platforms; Society of Manufacturing Engineers: Dearborn, MI, USA, 1999. [Google Scholar]

- Kreng, V.B.; Lee, T.P. QFD-based modular product design with linear integer programming—A case study. J. Eng. Des. 2004, 15, 261–284. [Google Scholar] [CrossRef]

- Kremer, G.E.O.; Gupta, S. Analysis of modularity implementation methods from an assembly and variety viewpoints. Int. J. Adv. Manuf. Technol. 2012, 66, 1959–1976. [Google Scholar] [CrossRef]

- Okudan, G.E.; Chiu, M.C.; Kim, T.H. Perceived feature utility-based product family design: A mobile phone case study. J. Intell. Manuf. 2012, 24, 935–949. [Google Scholar] [CrossRef]

- Agard, B.; Kusiak, A. Data-mining-based methodology for the design of product families. Int. J. Prod. Res. 2004, 42, 2955–2969. [Google Scholar] [CrossRef]

- Otto, K.N.; Wood, K.L. Product Evolution: A Reverse Engineering and Redesign Methodology. Res. Eng. Des. 1998, 10, 226–243. [Google Scholar] [CrossRef]

- Stone, R.B.; McAdams, D.A.; Kayyalethekkel, V.J. A product architecture-based conceptual DFA technique. Des. Stud. 2004, 25, 301–325. [Google Scholar] [CrossRef]

- Asan, U.; Polat, S.; Serdar, S. An integrated method for designing modular products. J. Manuf. Technol. Manag. 2004, 15, 29–49. [Google Scholar] [CrossRef]

- Wasley, N.S.; Lewis, P.K.; Mattson, C.A.; Ottosson, H.J. Experimenting with concepts from modular product design and multi-objective optimization to benefit people living in poverty. Dev. Eng. 2017, 2, 29–37. [Google Scholar] [CrossRef]

- Yigit, A.S.; Ulsoy, A.G.; Allahverdi, A. Optimizing modular product design for reconfigurable manufacturing. J. Intell. Manuf. 2002, 13, 309–316. [Google Scholar] [CrossRef]

- Levin, M.S. Combinatorial optimization in system configuration design. Autom. Remote Control 2009, 70, 519–561. [Google Scholar] [CrossRef]

- Kuo, T.C.; Huang, S.H.; Zhang, H.C. Design for manufacture and design for ‘X’: Concepts, applications, and perspectives. Comput. Ind. Eng. 2001, 41, 241–260. [Google Scholar] [CrossRef]

- Gatenby, D.A.; Foo, G. Design for X (DFX): Key to Competitive, Profitable Products. AT&T Tech. J. 1990, 69, 2–13. [Google Scholar] [CrossRef]

- Chiu, M.C.; Okudan, G. An Integrative Methodology for Product and Supply Chain Design Decisions at the Product Design Stage. J. Mech. Des. 2011, 133, 021008. [Google Scholar] [CrossRef]

- Gu, P.; Hashemian, M.; Sosale, S.; Rivin, E. An Integrated Modular Design Methodology for Life-Cycle Engineering. CIRP Ann. 1997, 46, 71–74. [Google Scholar] [CrossRef]

- Ma, J.; Kremer, G.E.O. A sustainable modular product design approach with key components and uncertain end-of-life strategy consideration. Int. J. Adv. Manuf. Technol. 2015, 85, 741–763. [Google Scholar] [CrossRef]

- Mutingi, M.; Dube, P.; Mbohwa, C. A Modular Product Design Approach for Sustainable Manufacturing in A Fuzzy Environment. Procedia Manuf. 2017, 8, 471–478. [Google Scholar] [CrossRef]

- Kristianto, Y.; Helo, P. Product architecture modularity implications for operations economy of green supply chains. Transp. Res. Part E Logist. Transp. Rev. 2014, 70, 128–145. [Google Scholar] [CrossRef]

- Yang, Q.; Yu, S.; Sekhari, A. A modular eco-design method for life cycle engineering based on redesign risk control. Int. J. Adv. Manuf. Technol. 2011, 56, 1215–1233. [Google Scholar] [CrossRef]

- Wang, Q.; Tang, D.; Yin, L.; Yang, J. A Method for Green Modular Design Considering Product Platform Planning Strategy. Procedia CIRP 2016, 56, 40–45. [Google Scholar] [CrossRef]

- Booker, J.; Swift, K.; Brown, N. Designing for assembly quality: Strategies, guidelines and techniques. J. Eng. Des. 2005, 16, 279–295. [Google Scholar] [CrossRef]

- Gu, P.; Sosale, S. Product modularization for life cycle engineering. Robot. Comput.-Integr. Manuf. 1999, 15, 387–401. [Google Scholar] [CrossRef]

- Sosa, M.E.; Eppinger, S.D.; Rowles, C.M. Identifying Modular and Integrative Systems and Their Impact on Design Team Interactions. J. Mech. Des. 2003, 125, 240. [Google Scholar] [CrossRef]

- Li, Z.S.; Mobin, M.S. System reliability assessment incorporating interface and function failure. In Proceedings of the Annual Reliability and Maintainability Symposium (RAMS), Palm Harbor, FL, USA, 26–29 January 2015. [Google Scholar] [CrossRef]

- Ebeling, C.E. An Introduction to Reliability and Maintainability Engineering; Waveland Press: Long Grove, IL, USA, 2009. [Google Scholar]

- Blanchard, B.S.; Fabrycky, W.J. Systems Engineering and Analysis, 4th ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2005. [Google Scholar]

- NASA. NASA Systems Engineering Handbook: NASA/Sp-2016-6105 Rev2 - Full Color Version; 12th Media Services: Suwanee, GA, USA, 2017. [Google Scholar]

- Sommerer, S.; Guevara, M.D.; Landis, M.A.; Rizzuto, J.M.; Sheppard, J.M.; Grant, C.J. System-of-Systems Engineering in Air and Missile Defense. Johns Hopkins APL Tech. Dig. 2012, 31, 5–20. [Google Scholar]

- Becker, R.; Grzesiak, A.; Henning, A. Rethink assembly design. Assem. Autom. 2005, 25, 262–266. [Google Scholar] [CrossRef]

- Salemi, B.; Moll, M.; Shen, W.-M. SUPERBOT: A Deployable, Multi-Functional, and Modular Self-Reconfigurable Robotic System. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems, Beijing, China, 9–15 October 2006. [Google Scholar] [CrossRef]

- Kelmar, L.; Khosla, P. Automatic generation of kinematics for a reconfigurable modular manipulator system. In Proceedings of the IEEE International Conference on Robotics and Automation, Philadelphia, PA, USA, 24–29 April 1988. [Google Scholar] [CrossRef]

- Berman, B. 3-D printing: The new industrial revolution. Bus. Horiz. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Petrick, I.J.; Simpson, T.W. 3D Printing Disrupts Manufacturing: How Economies of One Create New Rules of Competition. Res.-Technol. Manag. 2013, 56, 12–16. [Google Scholar] [CrossRef]

- Thomas, D. Costs, benefits, and adoption of additive manufacturing: A supply chain perspective. Int. J. Adv. Manuf. Technol. 2015, 85, 1857–1876. [Google Scholar] [CrossRef] [PubMed]

- Charter, M. Sustainable Product Design. In The Durable Use of Consumer Products; Springer: Berlin, Germany, 1998; pp. 57–68. [Google Scholar] [CrossRef]

- Allison, N.; Richards, J. Current status and future trends for disposable technology in the biopharmaceutical industry. J. Chem. Technol. Biotechnol. 2013, 89, 1283–1287. [Google Scholar] [CrossRef]

- Maidin, S.B.; Campbell, I.; Pei, E. Development of a design feature database to support design for additive manufacturing. Assem. Autom. 2012, 32, 235–244. [Google Scholar] [CrossRef] [Green Version]

- Boothroyd, G.; Knight, W. Design for assembly. IEEE Spectrum. 1993, 30, 53–55. [Google Scholar] [CrossRef]

- Mok, H.S.; Kim, C.H.; Kim, C.B. Automation of mold designs with the reuse of standard parts. Expert Syst. Appl. 2011, 38, 12537–12547. [Google Scholar] [CrossRef]

- Culley, S.J. Classification approaches for standard parts to aid design reuse. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 1999, 213, 203–207. [Google Scholar] [CrossRef]

- Novak, S.; Eppinger, S.D. Sourcing By Design: Product Complexity and the Supply Chain. Manag. Sci. 2001, 47, 189–204. [Google Scholar] [CrossRef] [Green Version]

- Laverne, F.; Segonds, F.; Anwer, N.; Coq, M.L. Assembly Based Methods to Support Product Innovation in Design for Additive Manufacturing: An Exploratory Case Study. J. Mech. Des. 2015, 137, 121701. [Google Scholar] [CrossRef] [Green Version]

- Tang, Y.; Yang, S.; Zhao, Y.F. Sustainable Design for Additive Manufacturing Through Functionality Integration and Part Consolidation. In Handbook of Sustainability in Additive Manufacturing; Springer: Singapore, 2016; pp. 101–144. [Google Scholar] [CrossRef]

- Niazi, K. AIM-120 AMRAAM. GrabCAD Model. Available online: https://grabcad.com/library/aim-120-amraam-1 (accessed on 30 May 2018).

- Gonzalez-Sanchez, M.; Amezquita-Brooks, L.; Liceaga-Castro, E.; del C Zambrano-Robledo, P. Simplifying quadrotor controllers by using simplified design models. In Proceedings of the 52nd IEEE Conference on Decision and Control, Florence, Italy, 10–13 December 2013. [Google Scholar] [CrossRef]

- Kim, C.; Mijar, A.; Arora, J. Development of simplified models for design and optimization of automotive structures for crashworthiness. Struct. Multidiscip. Optim. 2001, 22, 307–321. [Google Scholar] [CrossRef]

- Lu, X.; Xie, L.; Yu, C.; Lu, X. Development and application of a simplified model for the design of a super-tall mega-braced frame-core tube building. Eng. Struct. 2016, 110, 116–126. [Google Scholar] [CrossRef] [Green Version]

- AMRAAM Missile: Modern, Versatile, and Proven. Available online: https://www.raytheon.com/capabilities/products/amraam (accessed on 15 June 2018).

- Snelling, D.; Williams, C.; Druschitz, A. A comparison of binder burnout and mechanical characteristics of printed and chemically bonded sand molds. In Proceedings of the 2014 Solid Freeform Fabrication Symposium, Austin, TX, USA, 13–15 August 2014. [Google Scholar]

- Kumar, S.; Kruth, J.P. Composites by rapid prototyping technology. Mater. Des. 2010, 31, 850–856. [Google Scholar] [CrossRef]

- Louvis, E.; Fox, P.; Sutcliffe, C.J. Selective laser melting of aluminium components. J. Mater. Process. Technol. 2011, 211, 275–284. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Everitt, N.M.; Maskery, I.; Ashcroft, I.; Tuck, C. Selective laser melting of aluminum alloys. MRS Bull. 2017, 42, 311–319. [Google Scholar] [CrossRef] [Green Version]

- Vyatskikh, A.; Delalande, S.; Kudo, A.; Zhang, X.; Portela, C.M.; Greer, J.R. Additive manufacturing of 3D nano-architected metals. Nat. Commun. 2018, 9. [Google Scholar] [CrossRef] [PubMed]

- Chang, J.; He, J.; Mao, M.; Zhou, W.; Lei, Q.; Li, X.; Li, D.; Chua, C.K.; Zhao, X. Advanced Material Strategies for Next-Generation Additive Manufacturing. Materials 2018, 11, 166. [Google Scholar] [CrossRef] [PubMed]

- Slotwinski, J.A.; Garboczi, E.J.; Hebenstreit, K.M. Porosity Measurements and Analysis for Metal Additive Manufacturing Process Control. J. Res. Nat. Inst. Stand. Technol. 2014, 119, 494. [Google Scholar] [CrossRef] [PubMed]

| Design with Modules | Involves designing a new product out of existing pools of pre-defined modules or parts; conceptually, this is similar to assembling a set of Lego-blocks |

| Identifying Modules | Requires a deep understanding of the product or system and includes studying the current product, evaluating the component grouping, clustering the components accordingly, then redesigning and integrating the defined modules and their interfaces |

| Design of Modules | Necessitates the design of new modules to meet new requirements or to replace obsolete or poorly-designed modules |

| Standardization | AM allows the standardization of components, but it is usually more efficient and effective to prioritize optimization of the parts over standardization. |

| Serviceability | Most AM parts do not allow service on the parts after they are built and must simply be replaced when they wear out. The AM materials are typically highly recyclable and may even be recycled and made into new raw material by the part manufacturer, drastically reducing costs and simplifying the supply chain. The great reduction in cost, both from the elimination of tooling and from recycled materials, could offset the disadvantages of using non-serviceable parts. |

| User customization | AM-based design could potentially reduce the number of parts in the system, reducing the ability of the customer to modify the system. However, this can be offset by the ability to more completely customize the system during the design stage, reducing the need for the user to modify or optimize it in service. The need for a do-it-all system is greatly reduced when the system can be optimized for its mission at a low cost, as is the case with AM-enabled design. |

| Item | Component | Number in Model |

|---|---|---|

| 1 | Nose cone | 1 |

| 2 | Front electronics and control section | 1 |

| 3 | Rear electronics and control section | 1 |

| 4 | Payload housing section | 1 |

| 5 | Front control surfaces (fixed) | 4 |

| 6 | Fuel and motor housing section | 1 |

| 7 | Nozzle and rear control housing section | 1 |

| 8 | Rear control surfaces (adjustable) | 4 |

| 9 | Rear control surface actuator hinges | 4 |

| 10 | Fasteners | 60 |

| Sub-Assembly | Parts |

|---|---|

| Nose cone | Nose cone |

| Electronics housing | Front electronics and control section |

| Rear electronics and control section | |

| Payload section | Payload housing |

| Front control surfaces | |

| Fuel and motor housing | Fuel and motor housing section |

| Rear housing | Nozzle and rear control housing section |

| Rear control surfaces | |

| Rear control surface actuator hinges |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chadha, C.; Crowe, K.A.; Carmen, C.L.; Patterson, A.E. Exploring an AM-Enabled Combination-of-Functions Approach for Modular Product Design. Designs 2018, 2, 37. https://0-doi-org.brum.beds.ac.uk/10.3390/designs2040037

Chadha C, Crowe KA, Carmen CL, Patterson AE. Exploring an AM-Enabled Combination-of-Functions Approach for Modular Product Design. Designs. 2018; 2(4):37. https://0-doi-org.brum.beds.ac.uk/10.3390/designs2040037

Chicago/Turabian StyleChadha, Charul, Kathryn A. Crowe, Christina L. Carmen, and Albert E. Patterson. 2018. "Exploring an AM-Enabled Combination-of-Functions Approach for Modular Product Design" Designs 2, no. 4: 37. https://0-doi-org.brum.beds.ac.uk/10.3390/designs2040037