A Strategic Roadmap for the Manufacturing Industry to Implement Industry 4.0

Abstract

:1. Introduction

2. Applications of Industry 4.0 Enabling Technologies

2.1. Additive Manufacturing

2.2. Augmented Reality

2.3. Simulation

2.4. Autonomous Robots

2.5. Industrial Internet of Things

2.6. Big Data Analytics

2.7. Cloud Computing

2.8. Cyber Security

2.9. Horizontal and Vertical Integration

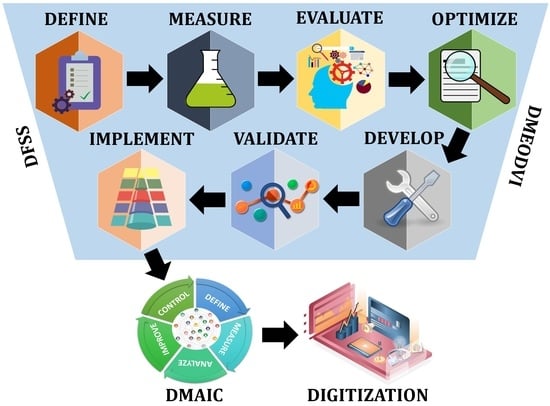

3. Industry 4.0 Roadmap Conceptualization

4. Phases of the Strategic Industry 4.0 Roadmap

3.1. First Phase: DEFINE

3.2. Second Phase: MEASURE

3.3. Third Phase: EVALUATE

3.4. Fourth Phase: OPTIMIZE

3.5. Fifth Phase: DEVELOP

3.6. Sixth Phase: VALIDATE

3.7. Seventh Phase: IMPLEMENT

5. Conclusions

Funding

Conflicts of Interest

References

- Popkova, E.G.; Ragulina, Y.V.; Bogoviz, A.V. Fundamental differences of transition to industry 4.0 from previous industrial revolutions. In Industry 4.0: Industrial Revolution of the 21st Century; Springer: Cham, Swizerland, 2019; pp. 21–29. [Google Scholar]

- Kagermann, H.; Helbig, J.; Hellinger, A.; Wahlster, W. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0: Securing the Future of German Manufacturing Industry; Final Report of the Industrie 4.0 Working Group; Forschungsunion: Germany, 2013. [Google Scholar]

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inform. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Lu, Y. Industry 4.0: A survey on technologies, applications and open research issues. J. Ind. Inform. Integr. 2017, 6, 1–10. [Google Scholar] [CrossRef]

- Lee, J.; Kao, H.A.; Yang, S. Service innovation and smart analytics for industry 4.0 and big data environment. Procedia Cirp 2014, 16, 3–8. [Google Scholar] [CrossRef] [Green Version]

- Gorecky, D.; Schmitt, M.; Loskyll, M.; Zühlke, D. Human-machine-interaction in the industry 4.0 era. In Proceedings of the 2014 12th IEEE international conference on industrial informatics (INDIN), Porto Alegre, RS, Brazil, 27–30 July 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 289–294. [Google Scholar]

- Kiel, D.; Müller, J.M.; Arnold, C.; Voigt, K.I. Sustainable industrial value creation: Benefits and challenges of industry 4.0. Int. J. Innov. Manag. 2017, 21, 1740015. [Google Scholar] [CrossRef]

- Available online: https://slcontrols.com/benefits-of-industry-4–0/ (accessed on 10 April 2020).

- Industry 4.0. Available online: https://ec.europa.eu/growth/tools-databases/dem/monitor/tags/industry-40 (accessed on 10 April 2020).

- What does the Fourth Industrial Revolution (4IR) Mean for UK Business? Available online: https://innovateuk.blog.gov.uk/2017/03/28/what-does-the-fourth-industrial-revolution-4ir-mean-for-uk-business/ (accessed on 10 April 2020).

- Urciuoli, L.; Hintsa, J.; Ahokas, J. Drivers and barriers affecting usage of e-Customs—A global survey with customs administrations using multivariate analysis techniques. Gov. Inform. Quart. 2013, 30, 473–485. [Google Scholar] [CrossRef]

- Müller, J.M.; Däschle, S. Business model innovation of industry 4.0 solution providers towards customer process innovation. Processes 2018, 6, 260. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Q.; Geng, Y. Drivers and barriers of extended supply chain practices for energy saving and emission reduction among Chinese manufacturers. J. Clean. Prod. 2013, 40, 6–12. [Google Scholar] [CrossRef]

- About the GrowIn 4.0 Project. Available online: https://northsearegion.eu/growin4/about-the-growin-40-project/ (accessed on 10 April 2020).

- Industry 4.0. Available online: https://www.industry.gov.au/funding-and-incentives/industry-40 (accessed on 10 April 2020).

- Hermann, M.; Pentek, T.; Otto, B. January. Design principles for industrie 4.0 scenarios. In Proceedings of the 2016 49th Hawaii international conference on system sciences (HICSS), Koloa, HI, USA, 5–8 January 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 3928–3937. [Google Scholar]

- Industry 4.0 Design Principles. Available online: https://www.rmit.edu.au/industry/develop-your-workforce/tailored-workforce-solutions/c4de/articles/industry-40-design-principles (accessed on 10 April 2020).

- Luthra, S.; Mangla, S.K. Evaluating challenges to Industry 4.0 initiatives for supply chain sustainability in emerging economies. Process. Saf. Environ. Prot. 2018, 117, 168–179. [Google Scholar] [CrossRef]

- Available online: https://www.infopulse.com/blog/the-main-benefits-and-challenges-of-industry-4–0-adoption-in-manufacturing/ (accessed on 10 April 2020).

- Sarvari, P.A.; Ustundag, A.; Cevikcan, E.; Kaya, I.; Cebi, S. Technology roadmap for Industry 4.0. In Industry 4.0: Managing the Digital Transformation; Springer: Cham, Swizerland, 2018; pp. 95–103. [Google Scholar]

- Ghobakhloo, M. The future of manufacturing industry: A strategic roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef] [Green Version]

- Pessl, E.; Sorko, S.R.; Mayer, B. Roadmap Industry 4.0–implementation guideline for enterprises. Int. J. Sci. Technol. Soc. 2017, 5, 193–202. [Google Scholar] [CrossRef]

- Colli, M.; Madsen, O.; Berger, U.; Møller, C.; Wæhrens, B.V.; Bockholt, M. Contextualizing the outcome of a maturity assessment for Industry 4.0. Ifac-papersonline 2018, 51, 1347–1352. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A.; Sokolov, B.; Werner, F.; Ivanova, M. A dynamic model and an algorithm for short-term supply chain scheduling in the smart factory industry 4.0. Int. J. Prod. Res. 2016, 54, 386–402. [Google Scholar] [CrossRef] [Green Version]

- Butt, J. A Novel Additive Manufacturing Process for the Production of Metal Parts. Ph.D. Thesis, Anglia Ruskin University, Cambridge, UK, 2016. [Google Scholar]

- Butt, J.; Shirvani, H. Additive, subtractive, and hybrid manufacturing processes. In Advances in Manufacturing and Processing of Materials and Structures; CRC Press: Boca Raton, FL, USA, 2018; pp. 187–218. [Google Scholar]

- ISO. ISO ASTM52900–15, Standard Terminology for Additive Manufacturing—General Principles—Terminology; ASTM International: West Conshohocken, PA, USA, 2015; Available online: www.astm.org (accessed on 10 April 2020).

- Ko, H.; Moon, S.K.; Hwang, J. Design for additive manufacturing in customized products. Int. J. Precis. Eng. Manuf. 2015, 16, 2369–2375. [Google Scholar] [CrossRef]

- Butt, J.; Mebrahtu, H.; Shirvani, H. Strength analysis of aluminium foil parts made by composite metal foil manufacturing. Prog. Addit. Manuf. 2016, 1, 93–103. [Google Scholar] [CrossRef] [Green Version]

- Butt, J.; Onimowo, D.A.; Gohrabian, M.; Sharma, T.; Shirvani, H. A desktop 3D printer with dual extruders to produce customised electronic circuitry. Front. Mech. Eng. 2018, 13, 528–534. [Google Scholar] [CrossRef]

- Gao, J. August. Production of Multiple Material Parts Using a Desktop 3D Printer. In Advances in Manufacturing Techno, XXXI: Proceedings of the 15th International Conference on Manufacturing Research, Incorporating the 32nd National Conference on Manufacturing Research, University of Greenwich, London, UK, 5–7 September 2017; IOS Press: Amsterdam, The Netherlands, 2017; Volume 6, p. 148. [Google Scholar]

- Butt, J.; Hewavidana, Y.; Mohaghegh, V.; Sadeghi-Esfahlani, S.; Shirvani, H. Hybrid Manufacturing and Experimental Testing of Glass Fiber Enhanced Thermoplastic Composites. J. Manuf. Mater. Process. 2019, 3, 96. [Google Scholar] [CrossRef] [Green Version]

- Seifi, M.; Gorelik, M.; Waller, J.; Hrabe, N.; Shamsaei, N.; Daniewicz, S.; Lewandowski, J.J. Progress towards metal additive manufacturing standardization to support qualification and certification. Jom 2017, 69, 439–455. [Google Scholar] [CrossRef]

- Butt, J.; Mebrahtu, H.; Shirvani, H. Microstructure and mechanical properties of dissimilar pure copper foil/1050 aluminium composites made with composite metal foil manufacturing. J. Mater. Process. Technol. 2016, 238, 96–107. [Google Scholar] [CrossRef]

- Butt, J.; Ghorabian, M.; Mohaghegh, V.; Shirvani, H. Finite Element Modeling and Mechanical Testing of Metal Composites Made by Composite Metal Foil Manufacturing. J. Manuf. Mater. Process. 2019, 3, 81. [Google Scholar] [CrossRef] [Green Version]

- Butt, J.; Shirvani, H. Experimental analysis of metal/plastic composites made by a new hybrid method. Addit. Manuf. 2018, 22, 216–222. [Google Scholar] [CrossRef]

- Yakout, M.; Cadamuro, A.; Elbestawi, M.A.; Veldhuis, S.C. The selection of process parameters in additive manufacturing for aerospace alloys. Int. J. Adv. Manuf. Technol. 2017, 92, 2081–2098. [Google Scholar] [CrossRef]

- Böckin, D.; Tillman, A.M. Environmental assessment of additive manufacturing in the automotive industry. J. Clean. Prod. 2019, 226, 977–987. [Google Scholar] [CrossRef]

- Khoshnevis, B.; Hwang, D.; Yao, K.T.; Yeh, Z. Mega-scale fabrication by contour crafting. Int. J. Ind. Syst. Eng. 2006, 1, 301–320. [Google Scholar] [CrossRef] [Green Version]

- Available online: https://www.branch.technology/ (accessed on 2 April 2020).

- Available online: https://d-shape.com/ (accessed on 2 April 2020).

- Bos, F.; Wolfs, R.; Ahmed, Z.; Salet, T. Additive manufacturing of concrete in construction: Potentials and challenges of 3D concrete printing. Virtual Phys. Prototyp. 2016, 11, 209–225. [Google Scholar] [CrossRef] [Green Version]

- Keating, S.J.; Leland, J.C.; Cai, L.; Oxman, N. Toward site-specific and self-sufficient robotic fabrication on architectural scales. Sci. Robot. 2017, 2, eaam8986. [Google Scholar] [CrossRef]

- World’s 1st 3D Printed Neighborhood Being Built in Mexico. Available online: https://www.wbur.org/hereandnow/2020/02/06/worlds-first-3d-printed-neighborhood-mexico (accessed on 2 April 2020).

- WinSun deploys 3D Printed Isolation Wards for Coronavirus Medical Staff. Available online: https://www.3dprintingmedia.network/winsun-3d-printed-isolation-wards-coronavirus-medical-workers/ (accessed on 2 April 2020).

- Popovich, A.; Sufiiarov, V.; Polozov, I.; Borisov, E.; Masaylo, D. Producing hip implants of titanium alloys by additive manufacturing. Int. J. Biopr. 2016, 2, 78–84. [Google Scholar] [CrossRef] [Green Version]

- 3D Printing Community Responds to COVID-19 and Coronavirus Resources. Available online: https://3dprintingindustry.com/news/3d-printing-community-responds-to-covid-19-and-coronavirus-resources-169143/ (accessed on 3 April 2020).

- Gattullo, M.; Uva, A.E.; Fiorentino, M.; Gabbard, J.L. Legibility in industrial AR: Text style, color coding, and illuminance. IEEE Comput. Graph. Appl. 2015, 35, 52–61. [Google Scholar] [CrossRef]

- Ceruti, A.; Marzocca, P.; Liverani, A.; Bil, C. Maintenance in aeronautics in an Industry 4.0 context: The role of Augmented Reality and Additive Manufacturing. J. Comput. Des. Eng. 2019, 6, 516–526. [Google Scholar] [CrossRef]

- Mujber, T.S.; Szecsi, T.; Hashmi, M.S. Virtual reality applications in manufacturing process simulation. J. Mater. Process. Technol. 2004, 155, 1834–1838. [Google Scholar] [CrossRef]

- Gracia, L.; Perez-Vidal, C.; Mronga, D.; de Paco, J.M.; Azorin, J.M.; de Gea, J. Robotic manipulation for the shoe-packaging process. Int. J. Adv. Manuf. Technol. 2017, 92, 1053–1067. [Google Scholar] [CrossRef]

- Gervautz, M.; Schmalstieg, D. Anywhere interfaces using handheld augmented reality. Computer 2012, 45, 26–31. [Google Scholar] [CrossRef]

- Chi, H.L.; Kang, S.C.; Wang, X. Research trends and opportunities of augmented reality applications in architecture, engineering, and construction. Autom. Constr. 2013, 33, 116–122. [Google Scholar] [CrossRef]

- Zhou, F.; Duh, H.B.L.; Billinghurst, M. Trends in augmented reality tracking, interaction and display: A review of ten years of ISMAR. In Proceedings of the 2008 7th IEEE/ACM International Symposium on Mixed and Augmented Reality, Cambridge, UK, 15–18 September 2008; IEEE: Piscataway, NJ, USA, 2008; pp. 193–202. [Google Scholar]

- Piumsomboon, T.; Altimira, D.; Kim, H.; Clark, A.; Lee, G.; Billinghurst, M. Grasp-Shell vs gesture-speech: A comparison of direct and indirect natural interaction techniques in augmented reality. In Proceedings of the 2014 IEEE International Symposium on Mixed and Augmented Reality (ISMAR), Munich, Germany, 10–12 September 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 73–82. [Google Scholar]

- Nee, A.Y.; Ong, S.K.; Chryssolouris, G.; Mourtzis, D. Augmented reality applications in design and manufacturing. CIRP Ann. 2012, 61, 657–679. [Google Scholar] [CrossRef]

- Akçayır, M.; Akçayır, G. Advantages and challenges associated with augmented reality for education: A systematic review of the literature. Educational Research Review 2017, 20, 1–11. [Google Scholar] [CrossRef]

- Posada, J.; Zorrilla, M.; Dominguez, A.; Simoes, B.; Eisert, P.; Stricker, D.; Rambach, J.; Döllner, J.; Guevara, M. Graphics and media technologies for operators in industry 4.0. IEEE Comput. Graph. Appl. 2018, 38, 119–132. [Google Scholar] [CrossRef] [PubMed]

- Segura, Á.; Diez, H.V.; Barandiaran, I.; Arbelaiz, A.; Álvarez, H.; Simões, B.; Posada, J.; García-Alonso, A.; Ugarte, R. Visual computing technologies to support the Operator 4.0. Comput. Ind. Eng. 2018, 105550. [Google Scholar] [CrossRef]

- Makris, S.; Pintzos, G.; Rentzos, L.; Chryssolouris, G. Assembly support using AR technology based on automatic sequence generation. CIRP Ann. 2013, 62, 9–12. [Google Scholar] [CrossRef]

- Uva, A.E.; Gattullo, M.; Manghisi, V.M.; Spagnulo, D.; Cascella, G.L.; Fiorentino, M. Evaluating the effectiveness of spatial augmented reality in smart manufacturing: A solution for manual working stations. Int. J. Adv. Manuf. Technol. 2018, 94, 509–521. [Google Scholar] [CrossRef]

- Molineros, J.; Sharma, R. Computer vision for guiding manual assembly. In Proceedings of the 2001 IEEE International Symposium on Assembly and Task Planning (ISATP2001). Assembly and Disassembly in the Twenty-First Century, Fukuoka, Japan, 28–30 May 2001; (Cat. No. 01TH8560). IEEE: Piscataway, NJ, USA, 2001; pp. 362–368. [Google Scholar]

- Doshi, A.; Smith, R.T.; Thomas, B.H.; Bouras, C. Use of projector based augmented reality to improve manual spot-welding precision and accuracy for automotive manufacturing. Int. J. Adv. Manuf. Technol. 2017, 89, 1279–1293. [Google Scholar] [CrossRef] [Green Version]

- Zhou, J.; Lee, I.; Thomas, B.; Menassa, R.; Farrant, A.; Sansome, A. In-situ support for automotive manufacturing using spatial augmented reality. Int. J. Virtual Real. 2012, 11, 33–41. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Z.; Liu, C.; Xu, X. Visualisation of the Digital Twin data in manufacturing by using Augmented Reality. Procedia CIRP 2019, 81, 898–903. [Google Scholar] [CrossRef]

- Lee, H. Real-time manufacturing modeling and simulation framework using augmented reality and stochastic network analysis. Virtual Real. 2019, 23, 85–99. [Google Scholar] [CrossRef]

- Blaga, A.; Tamas, L. Augmented Reality for Digital Manufacturing. In Proceedings of the 2018 26th Mediterranean Conference on Control and Automation (MED), Zadar, Croatia, 19–22 June 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 173–178. [Google Scholar]

- Guala, F. Models, simulations, and experiments. In Model-Based Reasoning; Springer: Boston, MA, USA, 2002; pp. 59–74. [Google Scholar]

- Ngaile, G.; Altan, T. Simulations of manufacturing processes: Past, present, and future. Adv. Technol. Plast. 2002, 1, 271–282. [Google Scholar]

- Wörner, M.; Ertl, T.; Miksch, S.; Santucci, G. Visual analysis of advanced manufacturing simulations. In Proceedings of the EuroVa 2011: International Workshop on Visual Analytics, Bergen, Norway, 31 May 2011; pp. 29–32. [Google Scholar]

- Acheson, C.; Mackle, D.; Murphy, A.; Butterfield, J.; Higgins, P.; Collins, R.; Tame, R. Using design of experiments to define factory simulations for manufacturing investment decisions. In Proceedings of the 34th International Manufacturing Conference, Sligo, Ireland, 30–31 August 2017. [Google Scholar]

- Ruediger, P.; Hagen, H. Dealing with uncertainties in manufacturing process simulations. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2017; Volume 869, pp. 226–233. [Google Scholar]

- Al-Tamimi, A.A.; Quental, C.; Folgado, J.; Peach, C.; Bartolo, P. Stress analysis in a bone fracture fixed with topology-optimised plates. Biomech. Model. Mechanobiol. 2019, 19, 693–699. [Google Scholar] [CrossRef] [Green Version]

- Grivc, U.; Deržič, D.; Muhič, S. Numerical optimisation and experimental validation of divided rail freight brake disc crown. J. Mod. Transp. 2019, 27, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Migliaccio, M.; Montanaro, A.; Beatrice, C.; Napolitano, P.; Allocca, L.; Fraioli, V. Experimental and numerical analysis of a high-pressure outwardly opening hollow cone spray injector for automotive engines. Fuel 2017, 196, 508–519. [Google Scholar] [CrossRef]

- Khan, M.A.A.; Butt, J.; Mebrahtu, H.; Shirvani, H.; Alam, M.N. Data-Driven Process Reengineering and Optimization Using a Simulation and Verification Technique. Designs 2018, 2, 42. [Google Scholar] [CrossRef] [Green Version]

- Khan, M.A.A.; Butt, J.; Mebrahtu, H.; Shirvani, H.; Sanaei, A.; Alam, M.N. Integration of Data-Driven Process Re-Engineering and Process Interdependence for Manufacturing Optimization Supported by Smart Structured Data. Designs 2019, 3, 44. [Google Scholar] [CrossRef] [Green Version]

- Stadnicka, D.; Antonelli, D. Application of value stream mapping and possibilities of manufacturing processes simulations in automotive. FME Trans. 2015, 43, 279–286. [Google Scholar] [CrossRef]

- Avventuroso, G.; Silvestri, M.; Frazzon, E.M. Additive manufacturing plant for large scale production of medical devices: A simulation study. IFAC-PapersOnLine 2018, 51, 1442–1447. [Google Scholar] [CrossRef]

- Bekey, G.A. Autonomous Robots: From Biological Inspiration to Implementation and Control; MIT Press: Cambridge, MA, USA, 2005. [Google Scholar]

- Engelberger, J.F. Robot in Practice: Manag. and Applications of Industrial Robots; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Djuric, A.M.; Urbanic, R.J.; Rickli, J.L. A framework for collaborative robot (CoBot) integration in advanced manufacturing systems. SAE Int. J. Mater. Manuf. 2016, 9, 457–464. [Google Scholar] [CrossRef]

- A Positioning Paper by the International Federation of Robotics. Available online: https://ifr.org/downloads/papers/IFR_Demystifying_Collaborative_Robots.pdf (accessed on 3 April 2020).

- International Organization for Standardization. ISO/TS 15066: 2016 Robots and Robotic Devices-Collaborative Robots; International Organization for Standardization: Geneva, Switzerland, 2016. [Google Scholar]

- ISO. ISO 10218–1:2011 Robots and Robotic Devices—Safety Requirements for Industrial Robots—Part 1: Robots; International Organization for Standardization: Geneva, Switzerland, 2011. [Google Scholar]

- ISO. ISO 10218–2: 2011: Robots and Robotic Devices–Safety Requirements for Industrial Robots–Part 2: Robot Systems and Integration; International Organization for Standardization: Geneva, Switzerland, 2011. [Google Scholar]

- Fast-Berglund, Å.; Palmkvist, F.; Nyqvist, P.; Ekered, S.; Åkerman, M. Evaluating cobots for final assembly. Procedia CIRP 2016, 44, 175–180. [Google Scholar] [CrossRef] [Green Version]

- Cherubini, A.; Passama, R.; Crosnier, A.; Lasnier, A.; Fraisse, P. Collaborative manufacturing with physical human–robot interaction. Robot. Comput.-Integr. Manuf. 2016, 40, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Sadik, A.R.; Urban, B. An ontology-based approach to enable knowledge representation and reasoning in worker–cobot agile manufacturing. Future Internet 2017, 9, 90. [Google Scholar] [CrossRef] [Green Version]

- Meziane, R.; Otis, M.J.D.; Ezzaidi, H. Human-robot collaboration while sharing production activities in dynamic environment: SPADER system. Robot. Comput.-Integr. Manuf. 2017, 48, 243–253. [Google Scholar] [CrossRef] [Green Version]

- Kildal, J.; Tellaeche, A.; Fernández, I.; Maurtua, I. Potential users’ key concerns and expectations for the adoption of cobots. Procedia CIRP 2018, 72, 21–26. [Google Scholar] [CrossRef]

- Mariscal, M.A.; González-Pérez, J.; Khalid, A.; Gutierrez-Llorente, J.M.; García-Herrero, S. Risks management and cobots. Identifying critical variables. Safety 2011, 10218, 2. [Google Scholar]

- Xiong, H.; Mei, Q.; Zhao, Y. Efficient and provably secure certificateless parallel key-insulated signature without pairing for IIoT environments. IEEE Syst. J. 2019. [Google Scholar] [CrossRef]

- The Internet of Things in Manufacturing: Benefits, Use Cases and Trends. Available online: https://www.i-scoop.eu/internet-of-things-guide/internet-of-things-in-manufacturing/ (accessed on 4 April 2020).

- Seven Things You Need To Know About IIoT in Manufacturing. Available online: https://www.forbes.com/sites/louiscolumbus/2019/06/02/seven-things-you-need-to-know-about-iiot-in-manufacturing_updated/#180b80db5f56 (accessed on 4 April 2020).

- Schneider, S. The industrial internet of things (iiot) applications and taxonomy. Internet Things Data Anal. Handb. 2017, 41–81. [Google Scholar] [CrossRef]

- Rose, K.; Eldridge, S.; Chapin, L. The Internet of Things: An Overview; The Internet Society (ISOC): Reston, VA, USA, 2015; Volume 80. [Google Scholar]

- Boyes, H.; Hallaq, B.; Cunningham, J.; Watson, T. The industrial internet of things (IIoT): An analysis framework. Comput. Ind. 2018, 101, 1–12. [Google Scholar] [CrossRef]

- IoT in Manufacturing: The Ultimate Guide. Available online: https://www.scnsoft.com/blog/iot-in-manufacturing#Adoption_drivers (accessed on 4 April 2020).

- Lee, J.; Bagheri, B.; Kao, H.A. A cyber-physical systems architecture for industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Monostori, L.; Kádár, B.; Bauernhansl, T.; Kondoh, S.; Kumara, S.; Reinhart, G.; Sauer, O.; Schuh, G.; Sihn, W.; Ueda, K. Cyber-physical systems in manufacturing. Cirp Ann. 2016, 65, 621–641. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Grieves, M.; Vickers, J. Digital twin: Mitigating unpredictable, undesirable emergent behavior in complex systems. In Transdisciplinary Perspectives on Complex Systems; Springer: Cham, Swizerland, 2017; pp. 85–113. [Google Scholar]

- Sisinni, E.; Saifullah, A.; Han, S.; Jennehag, U.; Gidlund, M. Industrial internet of things: Challenges, opportunities, and directions. IEEE Trans. Ind. Inform. 2018, 14, 4724–4734. [Google Scholar] [CrossRef]

- Kiel, D.; Arnold, C.; and Voigt, K.I. The influence of the Industrial Internet of Things on business models of established manufacturing companies–A business level perspective. Technovation 2017, 68, 4–19. [Google Scholar] [CrossRef]

- Gierej, S. The framework of business model in the context of Industrial Internet of Things. Procedia Eng. 2017, 182, 206–212. [Google Scholar] [CrossRef]

- Yerra, V.A.; Pilla, S. IIoT-Enabled Production System for Composite Intensive Vehicle Manufacturing. SAE Int. J. Eng. 2017, 10, 209–214. [Google Scholar] [CrossRef]

- Vita, R.; Caldas, N.; Basto, J.; Alcalá, S.; Diniz, F. An IIoT-based architecture for decision support in the aeronautic industry. In MATEC Web of Conferences; EDP Sciences: Les Ulis, French, 2019; Volume 304, p. 04004. [Google Scholar]

- Arnold, C.; and Voigt, K.I. Ecosystem Effects of the Industrial Internet of Things on Manufacturing Companies. Acta Infol. 2017, 1, 99–108. [Google Scholar]

- Seetharaman, A.; Patwa, N.; Saravanan, A.S.; Sharma, A. Customer expectation from industrial internet of things (IIOT). J. Manuf. Technol. Manag. 2019, 30, 1161–1178. [Google Scholar] [CrossRef]

- Balaji, V.; Venkumar, P.; Sabitha, M.S.; Amuthaguka, D. DVSMS: Dynamic value stream mapping solution by applying IIoT. Sādhanā 2020, 45, 38. [Google Scholar] [CrossRef]

- Available online: https://www.iiconsortium.org/ (accessed on 4 April 2020).

- Zhang, Y.; Ren, S.; Liu, Y.; Si, S. A big data analytics architecture for cleaner manufacturing and maintenance processes of complex products. J. Clean. Prod. 2017, 142, 626–641. [Google Scholar] [CrossRef] [Green Version]

- Beyer, M.A.; Laney, D. The importance of ‘big data’: A definition. Stamford CT Gart. 2012, 21, 2014–2018. [Google Scholar]

- Tewari, S.; Dwivedi, U.D. Ensemble-based big data analytics of lithofacies for automatic development of petroleum reservoirs. Comput. Ind. Eng. 2019, 128, 937–947. [Google Scholar] [CrossRef]

- The 42 V’s of Big Data and Data Science. Available online: https://www.elderresearch.com/blog/42-v-of-big-data (accessed on 4 April 2020).

- Gandomi, A.; Haider, M. Beyond the hype: Big data concepts, methods, and analytics. Int. J. Inform. Manag. 2015, 35, 137–144. [Google Scholar] [CrossRef] [Green Version]

- Toro, C.; Barandiaran, I.; Posada, J. A perspective on Knowledge Based and Intelligent systems implementation in Industrie 4.0. Procedia Comput. Sci. 2015, 60, 362–370. [Google Scholar] [CrossRef] [Green Version]

- Toro, C.; Vaquero, J.; Graña, M.; Sanín, C.; Szczerbicki, E.; Posada, J. Building domain ontologies from engineering standards. Cybern. Syst. 2012, 43, 114–126. [Google Scholar] [CrossRef]

- Belhadi, A.; Zkik, K.; Cherrafi, A.; Yusof, M. Understanding the capabilities of Big Data Analytics for manufacturing process: Insights from literature review and multiple case study. Comput. Ind. Eng. 2019, 106099. [Google Scholar] [CrossRef]

- Joseph, R.C.; Johnson, N.A. Big data and transformational government. It Prof. 2013, 15, 43–48. [Google Scholar] [CrossRef]

- Banerjee, A.; Bandyopadhyay, T.; Acharya, P. Data analytics: Hyped up aspirations or true potential? Vikalpa 2013, 38, 1–12. [Google Scholar] [CrossRef]

- Cheng, Y.; Chen, K.; Sun, H.; Zhang, Y.; Tao, F. Data and knowledge mining with big data towards smart production. J. Ind. Inform. Integr. 2018, 9, 1–13. [Google Scholar] [CrossRef]

- Raghupathi, W.; Raghupathi, V. Big data analytics in healthcare: Promise and potential. Health Inform. Sci. Syst. 2014, 2, 3. [Google Scholar] [CrossRef] [PubMed]

- Nedelcu, B. About big data and its challenges and benefits in manufacturing. Database Syst. J. 2013, 4, 10–19. [Google Scholar]

- Big Data Analytics in Manufacturing Industry Set to Exceed $4.5 Billion by 2025—Condition Monitoring to Register Significant Growth. Available online: https://www.prnewswire.com/news-releases/big-data-analytics-in-manufacturing-industry-set-to-exceed-4-5-billion-by-2025---condition-monitoring-to-register-significant-growth-301033518.html (accessed on 4 April 2020).

- Zhong, R.Y.; Xu, C.; Chen, C.; and Huang, G.Q. Big data analytics for physical internet-based intelligent manufacturing shop floors. Int. J. Prod. Res. 2017, 55, 2610–2621. [Google Scholar] [CrossRef]

- Moyne, J.; Iskandar, J. Big data analytics for smart manufacturing: Case studies in semiconductor manufacturing. Processes 2017, 5, 39. [Google Scholar] [CrossRef] [Green Version]

- O’Donovan, P.; Leahy, K.; Bruton, K.; O’Sullivan, D.T. An industrial big data pipeline for data-driven analytics maintenance applications in large-scale smart manufacturing facilities. J. Big Data 2015, 2, 25. [Google Scholar] [CrossRef] [Green Version]

- Mani, V.; Delgado, C.; Hazen, B.T.; Patel, P. Mitigating supply chain risk via sustainability using big data analytics: Evidence from the manufacturing supply chain. Sustainability 2017, 9, 608. [Google Scholar] [CrossRef] [Green Version]

- Kibria, M.G.; Nguyen, K.; Villardi, G.P.; Zhao, O.; Ishizu, K.; Kojima, F. Big data analytics, machine learning, and artificial intelligence in next-generation wireless networks. IEEE Access 2018, 6, 32328–32338. [Google Scholar] [CrossRef]

- Mell, P.; Grance, T. The NIST definition of cloud computing. Nat. Inst. Sci. Technol. 2011, 800, 145. [Google Scholar]

- Why Move To The Cloud? 10 Benefits of Cloud Computing. Available online: https://www.salesforce.com/uk/blog/2015/11/why-move-to-the-cloud-10-benefits-of-cloud-computing.html (accessed on 5 April 2020).

- Aljabre, A. Cloud computing for increased business value. Int. J. Bus. Soc. Sci. 2012, 3, 234–239. [Google Scholar]

- Manvi, S.S.; Shyam, G.K. Resource management for Infrastructure as a Service (IaaS) in cloud computing: A survey. J. Netw. Comput. Appl. 2014, 41, 424–440. [Google Scholar] [CrossRef]

- Paraiso, F.; Haderer, N.; Merle, P.; Rouvoy, R.; Seinturier, L. A federated multi-cloud PaaS infrastructure. In Proceedings of the 2012 IEEE Fifth International Conference on Cloud Computing, Honolulu, HI, USA, 24–29 June 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 392–399. [Google Scholar]

- Wu, L.; Garg, S.K.; Buyya, R. SLA-based resource allocation for software as a service provider (SaaS) in cloud computing environments. In Proceedings of the 2011 11th IEEE/ACM International Symposium on Cluster, Cloud and Grid Computing, Newport Beach, CA, USA, 23–26 May 2011; IEEE: Piscataway, NJ, USA, 2011; pp. 195–204. [Google Scholar]

- Mahali, M.I. Smart door locks based on internet of things concept with mobile backend as a service. Elinvo (Electron. Inform. Vocat. Educ.) 2016, 1, 171–181. [Google Scholar] [CrossRef]

- Lynn, T.; Rosati, P.; Lejeune, A.; Emeakaroha, V. A preliminary review of enterprise serverless cloud computing (function-as-a-service) platforms. In Proceedings of the 2017 IEEE International Conference on Cloud Computing Technol. and Sci. (CloudCom), Hong Kong, China, 11–14 December 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 162–169. [Google Scholar]

- Baldini, I.; Castro, P.; Chang, K.; Cheng, P.; Fink, S.; Ishakian, V.; Mitchell, N.; Muthusamy, V.; Rabbah, R.; Slominski, A.; et al. Serverless computing: Current trends and open problems. In Research Advances in Cloud Computing; Springer: Singapore, Singapore, 2017; pp. 1–20. [Google Scholar]

- Xu, X. From cloud computing to cloud manufacturing. Robot. Comput.-Integr. Manuf. 2012, 28, 75–86. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, X.; Zhang, L.; Wang, L.; Zhong, R.Y. Workload-based multi-task scheduling in cloud manufacturing. Robot. Comput.-Integr. Manuf. 2017, 45, 3–20. [Google Scholar] [CrossRef]

- Jian, C.F.; Wang, Y. Batch task scheduling-oriented optimization modelling and simulation in cloud manufacturing. Int. J. Simul. Model. 2014, 13, 93–101. [Google Scholar] [CrossRef]

- Lartigau, J.; Nie, L.; Xu, X.; Zhan, D.; Mou, T. Scheduling methodology for production services in cloud manufacturing. In Proceedings of the 2012 International Joint Conference on Service Sciences, Shanghai, China, 24–26 May 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 34–39. [Google Scholar]

- Tao, F.; Cheng, Y.; Da Xu, L.; Zhang, L.; Li, B.H. CCIoT-CMfg: Cloud computing and internet of things-based cloud manufacturing service system. IEEE Trans. Ind. Inform. 2014, 10, 1435–1442. [Google Scholar]

- Jin, H.; Yao, X.; Chen, Y. Correlation-aware QoS modeling and manufacturing cloud service composition. J. Intell. Manuf. 2017, 28, 1947–1960. [Google Scholar] [CrossRef]

- Tao, F.; LaiLi, Y.; Xu, L.; Zhang, L. FC-PACO-RM: A parallel method for service composition optimal-selection in cloud manufacturing system. IEEE Trans. Ind. Inform. 2012, 9, 2023–2033. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, L.; Venkatesh, V.C.; Luo, Y.; Cheng, Y. Cloud manufacturing: A computing and service-oriented manufacturing model. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2011, 225, 1969–1976. [Google Scholar] [CrossRef]

- Oliveira, T.; Thomas, M.; Espadanal, M. Assessing the determinants of cloud computing adoption: An analysis of the manufacturing and services sectors. Inform. Manag. 2014, 51, 497–510. [Google Scholar] [CrossRef]

- He, W.; Xu, L. A state-of-the-art survey of cloud manufacturing. Int. J. Comput. Integr. Manuf. 2015, 28, 239–250. [Google Scholar] [CrossRef]

- Singhal, A. Data Warehousing and Data Mining Techniques for Cyber Security; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2007; Volume 31. [Google Scholar]

- What is Cyber Security? Available online: https://www.ncsc.gov.uk/section/about-ncsc/what-is-cyber-security (accessed on 5 April 2020).

- Global Cybersecurity Risks in the Manufacturing Industry. Available online: https://www.willistowerswatson.com/en-US/Insights/2019/07/decode-cyber-brief-global-cybersecurity-risks-in-the-manufacturing-industry (accessed on 5 April 2020).

- Ani, U.P.D.; He, H.; Tiwari, A. Review of cybersecurity issues in industrial critical infrastructure: Manufacturing in perspective. J. Cyber Secur. Technol. 2017, 1, 32–74. [Google Scholar] [CrossRef] [Green Version]

- ISO/IEC 27001 Information Security Management. Available online: https://www.iso.org/isoiec-27001-information-security.html (accessed on 5 April 2020).

- Wells, L.J.; Camelio, J.A.; Williams, C.B.; White, J. Cyber-physical security challenges in manufacturing systems. Manuf. Lett. 2014, 2, 74–77. [Google Scholar] [CrossRef]

- Sturm, L.D.; Williams, C.B.; Camelio, J.A.; White, J.; Parker, R. Cyber-physical vulnerabilities in additive manufacturing systems: A case study attack on the. STL file with human subjects. J. Manuf. Syst. 2017, 44, 154–164. [Google Scholar] [CrossRef]

- Vincent, H.; Wells, L.; Tarazaga, P.; Camelio, J. Trojan detection and side-channel analyses for cyber-security in cyber-physical manufacturing systems. Procedia Manuf. 2015, 1, 77–85. [Google Scholar] [CrossRef] [Green Version]

- DeSmit, Z.; Elhabashy, A.E.; Wells, L.J.; Camelio, J.A. 2016, Cyber-physical vulnerability assessment in manufacturing systems. Procedia Manuf. 2015, 5, 1060–1074. [Google Scholar] [CrossRef] [Green Version]

- Hutchins, M.J.; Bhinge, R.; Micali, M.K.; Robinson, S.L.; Sutherland, J.W.; Dornfeld, D. Framework for identifying cybersecurity risks in manufacturing. Procedia Manuf. 2015, 1, 47–63. [Google Scholar] [CrossRef] [Green Version]

- Tuptuk, N.; Hailes, S. Security of smart manufacturing systems. J. Manuf. Syst. 2018, 47, 93–106. [Google Scholar] [CrossRef]

- Wu, D.; Ren, A.; Zhang, W.; Fan, F.; Liu, P.; Fu, X.; Terpenny, J. Cybersecurity for digital manufacturing. J. Manuf. Syst. 2018, 48, 3–12. [Google Scholar] [CrossRef]

- Ren, A.; Wu, D.; Zhang, W.; Terpenny, J.; Liu, P. Cyber security in smart manufacturing: Survey and challenges. In IISE Annual Conference Proceedings; Institute of Industrial and Systems Engineers (IISE): Peachtree Corners, GA, USA, 2017; pp. 716–721. [Google Scholar]

- Stock, T.; Seliger, G. Opportunities of sustainable manufacturing in industry 4.0. Procedia Cirp 2016, 40, 536–541. [Google Scholar] [CrossRef] [Green Version]

- Shafiq, S.I.; Sanin, C.; Szczerbicki, E.; Toro, C. Virtual engineering object/virtual engineering process: A specialized form of cyber physical system for Industrie 4.0. Procedia Comput. Sci. 2015, 60, 1146–1155. [Google Scholar] [CrossRef] [Green Version]

- Qin, J.; Liu, Y.; Grosvenor, R. A categorical framework of manufacturing for industry 4.0 and beyond. Procedia Cirp 2016, 52, 173–178. [Google Scholar] [CrossRef] [Green Version]

- Zhong, R.Y.; Xu, X.; Klotz, E.; Newman, S.T. Intelligent manufacturing in the context of industry 4.0: A review. Engineering 2017, 3, 616–630. [Google Scholar] [CrossRef]

- Kim, D.G.; Park, M.G. Horizontal integration between cyber physical system based on industry 4.0 and manufacture execution systems through middleware building. J. Korea Multimed. Soc. 2014, 17, 1484–1493. [Google Scholar] [CrossRef] [Green Version]

- Gerber, T.; Bosch, H.C.; Johnsson, C. Vertical Integration of decision relevant production information into IT-Systems of manufacturing companies. IFAC Proc. Vol. 2012, 45, 811–816. [Google Scholar] [CrossRef]

- Bicaku, A.; Maksuti, S.; Palkovits-Rauter, S.; Tauber, M.; Matischek, R.; Schmittner, C.; Mantas, G.; Thron, M.; Delsing, J. Towards trustworthy end-to-end communication in industry 4.0. In Proceedings of the 2017 IEEE 15th International Conference on Industrial Informatics (INDIN), Emden, Germany, 24–26 July 2017; IEEE: Piscataway, NJ, USA, July, 2017; pp. 889–896. [Google Scholar]

- Liu, Q.; Chen, J.; Liao, Y.; Mueller, E.; Jentsch, D.; Boerner, F.; She, M. An application of horizontal and vertical integration in cyber-physical production systems. In Proceedings of the 2015 International Conference on Cyber-Enabled Distributed Computing and Knowledge Discovery, Xi’an, China, 17–19 September 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 110–113. [Google Scholar]

- Mazak, A.; Huemer, C. HoVer: A modeling framework for horizontal and vertical integration. In Proceedings of the 2015 IEEE 13th International Conference on Industrial Informatics (INDIN), Cambridge, UK, 22–24 July 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 1642–1647. [Google Scholar]

- Laurier, W.; Poels, G. Track and trace future, present, and past product and money flows with a resource-event-agent model. Inform. Syst. Manag. 2012, 29, 123–136. [Google Scholar] [CrossRef]

- Unver, H.O. An ISA-95-based manufacturing intelligence system in support of lean initiatives. Int. J. Adv. Manuf. Technol. 2013, 65, 853–866. [Google Scholar] [CrossRef]

- Zhuo, Y.; Alvarez, C.; Feldmann, K. Horizontal and vertical integration of product data for the design of moulded interconnect devices. Int. J. Comput. Integr. Manuf. 2009, 22, 1024–1036. [Google Scholar] [CrossRef]

- Foidl, H.; Felderer, M. Research challenges of industry 4.0 for quality management. In Proceedings of the International Conference on Enterprise Resource Planning Systems, Poznán, Poland, 24–26 June 2015; Springer: Cham, Swizerland; pp. 121–137. [Google Scholar]

- ISO. ISO 9000: Quality Management Systems-Fundamentals and Vocabulary (ISO 9000: 2005); International Organization for Standardization: Geneva, Switzerland, 2005; Volume 1. [Google Scholar]

- Zhou, K.; Liu, T.; Zhou, L. Industry 4.0: Towards future industrial opportunities and challenges. In Proceedings of the 2015 12th International conference on fuzzy systems and knowledge discovery (FSKD), Chongqing, China, 29–31 May 2012; IEEE: Piscataway, NJ, USA, 2015; pp. 2147–2152. [Google Scholar]

- Dalenogare, L.S.; Benitez, G.B.; Ayala, N.F.; Frank, A.G. The expected contribution of Industry 4.0 technologies for industrial performance. Int. J. Prod. Econ. 2018, 204, 383–394. [Google Scholar] [CrossRef]

- Rüßmann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Justus, J.; Engel, P.; Harnisch, M. Industry 4.0: The future of productivity and growth in manufacturing industries. Boston Consult. Group 2015, 9, 54–89. [Google Scholar]

- Ramayah, T.; Roy, M.H.; Arokiasamy, S.; Zbib, I.; Ahmed, Z.U. Critical success factors for successful implementation of enterprise resource planning systems in manufacturing organisations. Int. J. Bus. Inform. Syst. 2007, 2, 276–297. [Google Scholar] [CrossRef]

- Drohomeretski, E.; Gouvea da Costa, S.E.; Pinheiro de Lima, E.; Garbuio, P.A.D.R. Lean, Six Sigma and Lean Six Sigma: An analysis based on operations strategy. Int. J. Prod. Res. 2014, 52, 804–824. [Google Scholar] [CrossRef]

- Liverani, A.; Caligiana, G.; Frizziero, L.; Francia, D.; Donnici, G.; Dhaimini, K. Design for Six Sigma (DFSS) for additive manufacturing applied to an innovative multifunctional fan. Int. J. Interact. Des. Manuf. (IJIDeM) 2019, 13, 309–330. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Nenonen, S.; Brodie, R.J.; Storbacka, K.; Peters, L.D. Theorizing with managers: How to achieve both academic rigor and practical relevance? Eur. J. Mark. 2017, 51, 1130–1152. [Google Scholar] [CrossRef]

- Feldman, M.S.; Orlikowski, W.J. Theorizing practice and practicing theory. Organ. Sci. 2011, 22, 1240–1253. [Google Scholar] [CrossRef] [Green Version]

- Brodie, R.J.; Nenonen, S.; Peters, L.D.; Storbacka, K. Theorizing with managers to bridge the theory-praxis gap. European J. Mark. 2017, 51, 1173–1177. [Google Scholar] [CrossRef]

- Weick, K.E. What theory is not, theorizing is. Adm. Sci. Q. 1995, 40, 385–390. [Google Scholar] [CrossRef] [Green Version]

- Cornelius, I. Theorizing information for information science. Ann. Rev. Inform. Sci. Technol. 2002, 36, 392–425. [Google Scholar] [CrossRef]

- Browaeys, M.J.; Baets, W. Cultural complexity: A new epistemological perspective. Learn. Organ. 2003, 10, 332–339. [Google Scholar] [CrossRef]

- Putnik, G.D.; Browaeys, M.J.; Fisser, S. Lean and agile: An epistemological reflection. Learn. Organ. 2012, 19, 207–218. [Google Scholar]

- 11 Known Design for Six Sigma (DFSS) Methodologies. Available online: https://www.scmdojo.com/design-six-sigma-methodologies/ (accessed on 5 April 2020).

- Jayaram, A. Lean six sigma approach for global supply chain management using industry 4.0 and IIoT. In Proceedings of the 2016 2nd International Conference on Contemporary Computing and Informatics (IC3I), Greater Noida, India, 14–17 December 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 89–94. [Google Scholar]

- Arcidiacono, G.; Pieroni, A. The Revolution Lean Six Sigma 4.0. Int. J. Adv. Sci. Eng. Inform. Technol. 2018, 8, 141–149. [Google Scholar] [CrossRef] [Green Version]

- Zwikael, O.; Chih, Y.Y.; Meredith, J.R. Project benefit management: Setting effective target benefits. Int. J. Proj. Manag. 2018, 36, 650–658. [Google Scholar] [CrossRef]

- Ungerman, O.; Dedkova, J.; Gurinova, K. The impact of marketing innovation on the competitiveness of enterprises in the context of industry 4.0. J. Compet. 2018, 10, 132. [Google Scholar] [CrossRef]

- Fernández-Caramés, T.M.; Blanco-Novoa, O.; Froiz-Míguez, I.; Fraga-Lamas, P. Towards an Autonomous Industry 4.0 Warehouse: A UAV and Blockchain-Based System for Inventory and Traceability Applications in Big Data-Driven Supply Chain Management. Sensors 2019, 19, 2394. [Google Scholar] [CrossRef] [Green Version]

- Altamony, H.; Al-Salti, Z.; Gharaibeh, A.; Elyas, T. The relationship between change management strategy and successful enterprise resource planning (ERP) implementations: A theoretical perspective. Int. J. Bus. Manag. Econ. Res. 2016, 7, 690–703. [Google Scholar]

- Leyh, C.; Schäffer, T.; Bley, K.; Forstenhäusler, S. Assessing the IT and software landscapes of Industry 4.0-Enterprises: The maturity model SIMMI 4.0. In Information Technology for Management: New Ideas and Real Solutions; Springer: Cham, Swizerland, 2016; pp. 103–119. [Google Scholar]

- Zarei, M.; Mohammadian, A.; Ghasemi, R. Internet of things in industries: A survey for sustainable development. Int. J. Innov. Sustain. Dev. 2016, 10, 419–442. [Google Scholar] [CrossRef]

- Vanpoucke, E.; Vereecke, A.; Muylle, S. Leveraging the impact of supply chain integration through information technology. Int. J. Oper. Prod. Manag. 2017, 37, 510–530. [Google Scholar] [CrossRef]

- Cong, L.W.; He, Z. Blockchain disruption and smart contracts. Rev. Financ. Stud. 2019, 32, 1754–1797. [Google Scholar] [CrossRef]

- Tupa, J.; Simota, J.; Steiner, F. Aspects of risk management implementation for Industry 4.0. Procedia Manuf. 2017, 11, 1223–1230. [Google Scholar] [CrossRef]

- Kelley, S.W.; Turley, L.W. Consumer perceptions of service quality attributes at sporting events. J. Bus. Res. 2001, 54, 161–166. [Google Scholar] [CrossRef]

- Bolar, A.A.; Tesfamariam, S.; Sadiq, R. Framework for prioritizing infrastructure user expectations using Quality Function Deployment (QFD). Int. J. Sustain. Built Environ. 2017, 6, 16–29. [Google Scholar] [CrossRef]

- Martí Bigorra, A.; Isaksson, O. Combining customer needs and the customer’s way of using the product to set customer-focused targets in the House of Quality. Int. J. Prod. Res. 2017, 55, 2320–2335. [Google Scholar] [CrossRef]

- Goedhart, R.; Schoonhoven, M.; Does, R.J. Guaranteed in-control performance for the Shewhart X and X control charts. J. Qual. Technol. 2017, 49, 155–171. [Google Scholar] [CrossRef]

- Tran, K.P.; Castagliola, P.; Celano, G. Monitoring the ratio of population means of a bivariate normal distribution using CUSUM type control charts. Stat. Pap. 2018, 59, 387–413. [Google Scholar] [CrossRef]

- Meudt, T.; Metternich, J.; Abele, E. Value stream mapping 4.0: Holistic examination of value stream and information logistics in production. CIRP Ann. 2017, 66, 413–416. [Google Scholar] [CrossRef]

- An Industry 4 Readiness Assessment Tool. Available online: https://warwick.ac.uk/fac/sci/wmg/research/scip/reports/final_version_of_i4_report_for_use_on_websites.pdf (accessed on 10 April 2020).

- Industry 4.0 Readiness Online Self-Check for Businesses. Available online: https://www.industrie40-readiness.de/?lang=en (accessed on 10 April 2020).

- Available online: https://i4–0-self-assessment.pwc.nl/i40/landing/ (accessed on 10 April 2020).

- Industry4WRD. Available online: https://www.miti.gov.my/miti/resources/National%20Policy%20on%20Industry%204.0/Industry4WRD_Booklet.pdf (accessed on 10 April 2020).

- Akay, D.; Demıray, A.; Kurt, M. Collaborative tool for solving human factors problems in the manufacturing environment: The Theory of Inventive Problem Solving Technique (TRIZ) method. Int. J. Prod. Res. 2008, 46, 2913–2925. [Google Scholar] [CrossRef]

- Aithal, P.S.; Kumar, P.M. Using six thinking hats as a tool for lateral thinking in organizational problem solving. Int. J. Eng. Res. Mod. Educ. (IJERME) 2016, 1, 225–234. [Google Scholar]

- Butt, J.; Jedi, S. Redesign of an In-Market Conveyor System for Manufacturing Cost Reduction and Design Efficiency Using DFMA Methodology. Designs 2020, 4, 6. [Google Scholar] [CrossRef] [Green Version]

- Begam, M.S.; Swamynathan, R.; Sekkizhar, J. Current trends on lean management–A review. Int. J. Lean Think. 2013, 4, 15–21. [Google Scholar]

- Gen, M.; Lin, L. Multiobjective evolutionary algorithm for manufacturing scheduling problems: State-of-the-art survey. J. Intell. Manuf. 2014, 25, 849–866. [Google Scholar] [CrossRef]

- Sukthomya, W.; Tannock, J. The optimisation of neural network parameters using Taguchi’s design of experiments approach: An application in manufacturing process modelling. Neural Comput. Appl. 2005, 14, 337–344. [Google Scholar] [CrossRef]

- Braimah, M.N.; Anozie, A.N.; Odejobi, O.J. Utilization of Response sUrface Methodology (RSM) in the Optimization of Crude Oil Refinery Process, New Port-Harcourt Refinery, Nigeria. J. Eng. Sci. Technol. 2016, 3, 4361–4369. [Google Scholar]

- Available online: https://sixsigmastudyguide.com/pilot-plan/ (accessed on 10 April 2020).

- Antony, J.; Kumar, M.; Labib, A. Gearing Six Sigma into UK manufacturing SMEs: Results from a pilot study. J. Oper. Res. Soc. 2008, 59, 482–493. [Google Scholar] [CrossRef]

- Georgoulias, K.; Papakostas, N.; Chryssolouris, G.; Stanev, S.; Krappe, H.; Ovtcharova, J. Evaluation of flexibility for the effective change management of manufacturing organizations. Robot. Comput.-Integr. Manuf. 2009, 25, 888–893. [Google Scholar] [CrossRef]

- Leach, L. Schedule and cost buffer sizing: How to account for the bias between project performance and your model. Proj. Manag. J. 2003, 34, 34–47. [Google Scholar] [CrossRef] [Green Version]

- Carroll, B. Leadership in lean, empowering manufacturing organizations. J. Organ. Excell. 2001, 20, 81–90. [Google Scholar] [CrossRef]

- May, G.; Stahl, B. The significance of organizational change management for sustainable competitiveness in manufacturing: Exploring the firm archetypes. Int. J. Prod. Res. 2017, 55, 4450–4465. [Google Scholar] [CrossRef]

- Six Sigma Study Guide. Available online: https://sixsigmastudyguide.com/implementation-plan/ (accessed on 10 April 2020).

- The Power of Kaizen Teams. Available online: https://www.kaizen-news.com/the-power-of-kaizen-teams/ (accessed on 10 April 2020).

- García, J.L.; Rivera, D.G.; Iniesta, A.A. Critical success factors for Kaizen implementation in manufacturing industries in Mexico. Int. J. Adv. Manuf. Technol. 2013, 68, 537–545. [Google Scholar] [CrossRef]

- Glover, W.J.; Farris, J.A.; Van Aken, E.M.; Doolen, T.L. Critical success factors for the sustainability of Kaizen event human resource outcomes: An empirical study. Int. J. Prod. Econ. 2011, 132, 197–213. [Google Scholar] [CrossRef]

| Industry 4.0 Enabling Technologies | Opportunities | Development of Strategies | |

|---|---|---|---|

| 1 | Additive Manufacturing | Design flexibility, reduced set-up and tooling time, lightweight and customized products, less waste, effective for mass production of both large-scale and small-scale structures |

|

| 2 | Augmented Reality | Faster and smarter product development and assembly, enhanced operator performance, expert support provision, effective machine maintenance and quality assurance | |

| 3 | Simulation | Optimize product/process parameters, reduced investment risk, waste minimization, allows faster prototyping, virtual analysis of complex scenarios | |

| 4 | Autonomous Robots | Increase efficiency and productivity, reduce error and re-work, operator safety, exponential learning by collecting and analyzing machine data | |

| 5 | Industrial Internet of Things | Interconnected systems, production visibility, better inventory management, safe working environment, reduce machine downtime, increase quality | |

| 6 | Big Data Analytics | Asset/supply chain optimization, product design/quality, better future forecasting and identification of trends, higher customer satisfaction | |

| 7 | Cloud Computing | Low capital costs, flexibility of operations, disaster recovery, automatic software updates, increased collaboration, freedom of operation, data security, opportunities for upskilling workforce | |

| 8 | Cyber Security | Protect data and reduce risk of hacking, inspires customer confidence, increase productivity, protect against spyware, worms, and viruses | |

| 9 | Horizontal and Vertical Integration | Optimize supply chain, increase differentiation from competition, high productivity, superior product quality, less waste, reduce set-up costs, errors, and machine downtime | |

© 2020 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Butt, J. A Strategic Roadmap for the Manufacturing Industry to Implement Industry 4.0. Designs 2020, 4, 11. https://0-doi-org.brum.beds.ac.uk/10.3390/designs4020011

Butt J. A Strategic Roadmap for the Manufacturing Industry to Implement Industry 4.0. Designs. 2020; 4(2):11. https://0-doi-org.brum.beds.ac.uk/10.3390/designs4020011

Chicago/Turabian StyleButt, Javaid. 2020. "A Strategic Roadmap for the Manufacturing Industry to Implement Industry 4.0" Designs 4, no. 2: 11. https://0-doi-org.brum.beds.ac.uk/10.3390/designs4020011