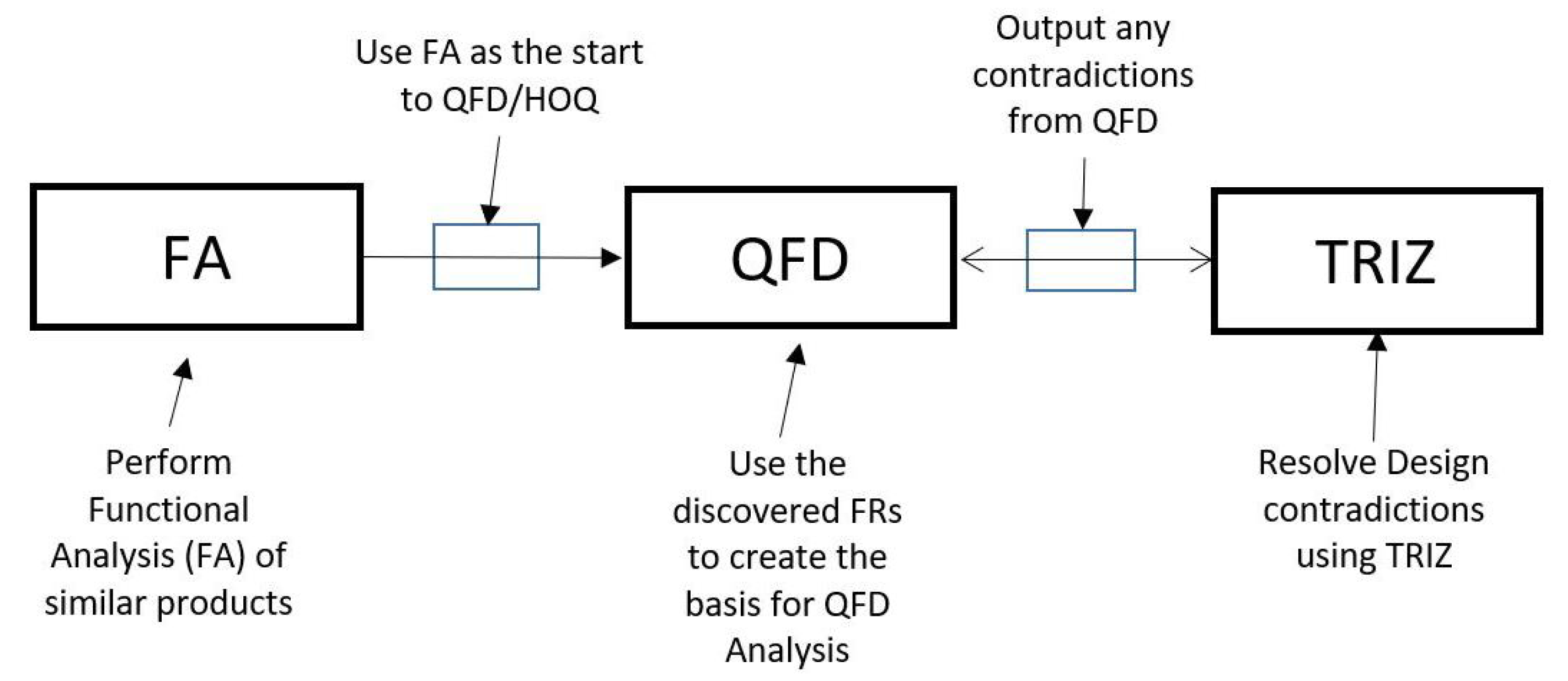

1. Introduction

Complex problems are defined and quantified in various ways such as “size, entropy, information content, thermodynamic and information required to construct, computational capacity, statistical complexity, as well as others” [

1]. Their characteristics include a dynamic character and impact on society, and they cannot be easily solved [

2]. Complex problems can also be defined by the numeric size of basic elements in a system, the variety of elements, the relationship between elements, the observer dependency, or task dependencies, as with schedules [

3].

There exist several approaches to addressing large-scale or complex problems [

4]. These various engineering approaches are specifically designed to enhance the value of, and reduce the time synthesizing, the potential solution set for resolving complex and large-scale problems. The engineering approaches that see the most widespread use in this space today include the following:

Multidisciplinary engineering: researchers from a variety of disciplines work independently;

Interdisciplinary engineering: researchers from a variety of disciplines work jointly on common problems by sharing methods or tools;

Transdisciplinary engineering: researchers from a variety of disciplines, along with domain experts and subject matter experts, use a shared conceptual framework, common terms and methods to address complex problems [

5,

6].

One proven approach to solving complex problems is using the concepts found within the transdisciplinary (TD) engineering approach. “The transdisciplinary research process is the collaboration among scholars from diverse disciplines to develop and use integrated conceptual frameworks, tools, techniques, and methodologies to solve common unstructured research problems. Transdisciplinary research creates new paradigms and provides pathways to new frontiers” [

7]. The practical focus of transdisciplinarity is a collaborative process to improve our understanding of complex issues by using collective intelligence through collective experts and multiple resources for designing and implementing solutions to challenging problems by considering the public good. The transdisciplinary engineering approach is distinctive and presents a method to integrate both classically trained education-based subject matter experts along with externally knowledgeable experts. Given that the number of disciplines has grown from seven (in the 13th century) to nearly 8000 (in 2012), there is a need to leverage TD engineering techniques for developing complete solutions to complex problems in the modern world [

8]. Numerous examples of TD engineering can be found in the literature [

9,

10,

11,

12,

13,

14].

1.1. TD Tool

TD engineering implements various tools such as Kano Analysis, KJ Diagrams, Critical to Quality (CTQ), House of Quality (HOQ)/Quality Function Design (QFD), Theory of Inventive Problem Solving (TRIZ), Axiomatic Design (AD), Interpretive Structural Modeling (ISM), and Design Structure Matrix (DSM). First, the Kano Analysis is a trusted method for evaluating customer needs (which this study refers to as customer requirements or features) and categorizing them in terms of key groups: must-have (mandatory) features, optional (performance) features, indifferent, and attractive features. KJ Diagram is used to group and prioritize the customer needs. CTQ is employed to explore the specifications of a product. It converts the customer needs into quantifiable specifications. HOQ/QFD is a mapping technique that relates the customer requirements to engineering characteristics [

15,

16]. TRIZ is a Russian-originated toolset for creative problem solving that provides a systematic mechanism for solving technical conflicts (i.e., eliminating contradictions) and driving innovation. Engineers leverage TRIZ tools when either a technical or physical contradiction is recognized in the design process. AD is a system engineering tool that converts customer requirements into functional requirements and design parameters [

17]. AD uses the independence axiom and the information axiom. ISM is a systematic method for dealing with complex issues which was proposed by Warfield in 1973 [

18]. ISM identifies relationships among certain factors, which are related to the problem or issue. DSM, a tool for managing complexity, was initiated by Don Steward in 1981 [

19]. The DSM is a method for visualizing relations and dependencies within a certain activity [

20]. It is a matrix-based tool that epitomizes information flows and allows the representation of complex tasks (or teams) [

21].

1.2. TD Tool Integration

TD engineering design has leveraged several well-known TD tools as part of the overall toolkit for design activities over the years, a variety of TD design processes have incorporated one or more of these tools together—in an integrated fashion—to enhance the design activities. Several previous methods of integration are discussed below as a background to the proposed unique integrated approach used in this research paper.

1.2.1. Integration of QFD and TRIZ

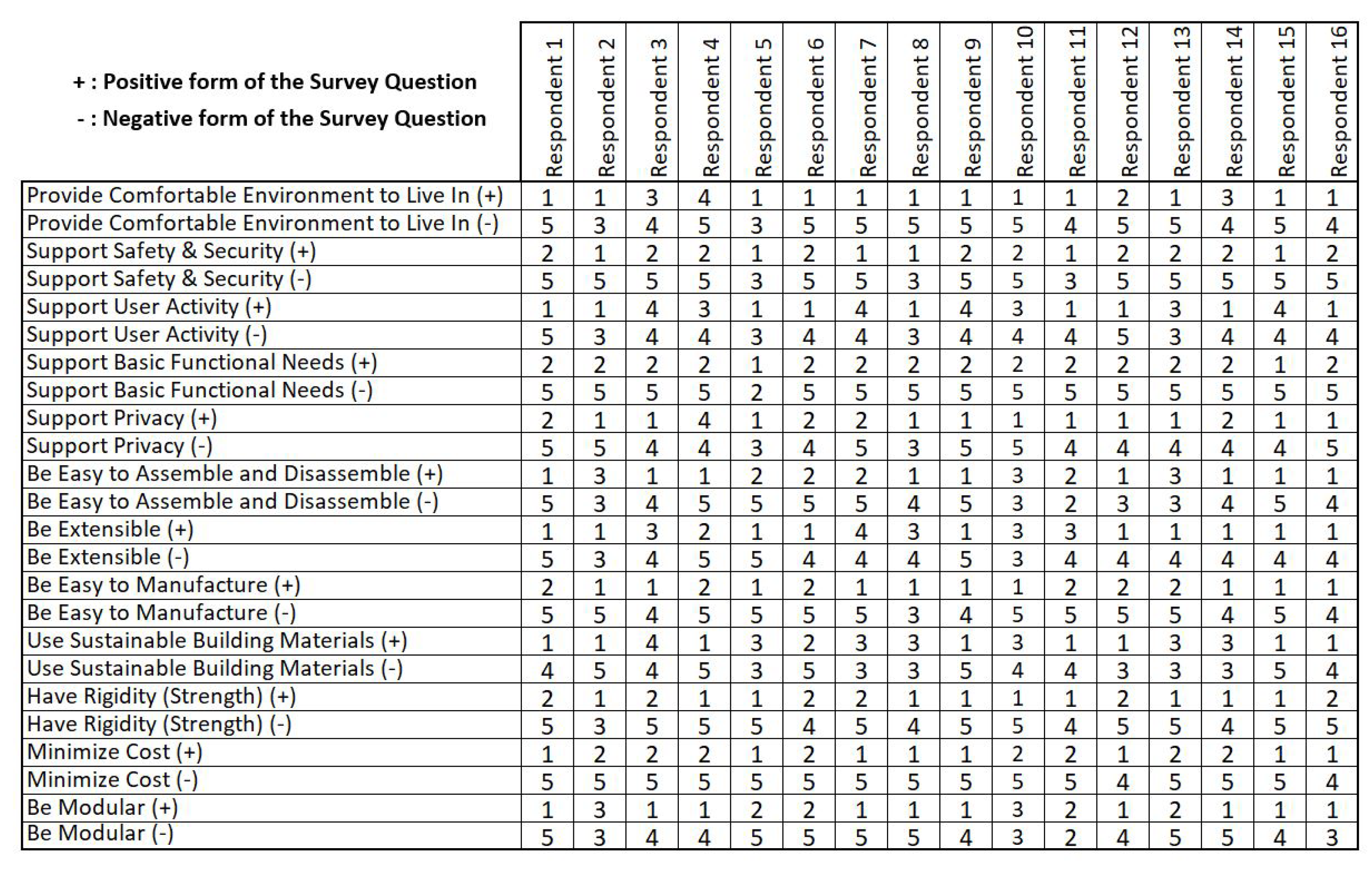

There is a natural integration point between QFD and TRIZ, whereby the technical contradictions found in the rooftop of the House of Quality (HOQ) can be addressed through the use of TRIZ’s contradiction matrix. Several research papers have been produced to show this integration, including the expanded integration of these design tools into larger elements of an integrated process for design. Mayda and Borklu [

22] incorporate the coupling of QFD/HOQ and TRIZ as the first two steps in an overall process for conceptual design based on the engineering process outlined by Pahl et al. [

23]; see

Figure 1.

1.2.2. Integration of QFD, TRIZ, and DEA

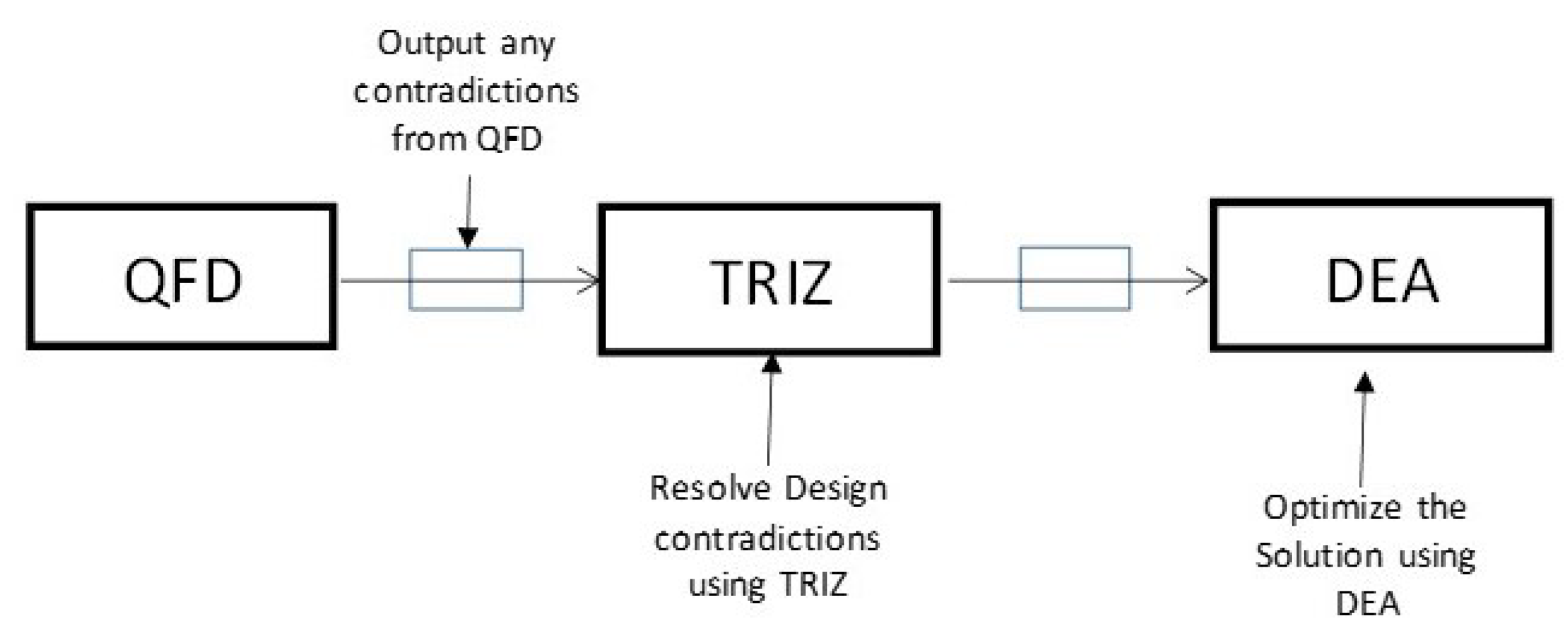

Zheng et al. [

24] took a similar approach for the integration of these same tools as Mayda and Borklu [

22], using QFD and TRIZ for a similar result. However, as shown in

Figure 2, Zheng et al. used the resulting output from the step with TRIZ as input for use in Data Envelopment Analysis (DEA). Zheng et al. actually use the Fuzzy DEA approach to “find the system optimal solution” [

24]. Later in this paper, this same concept is applied, except it substitutes Axiomatic Design (AD) instead of DEA in this third step of the process.

1.2.3. Integration of QFD and AD

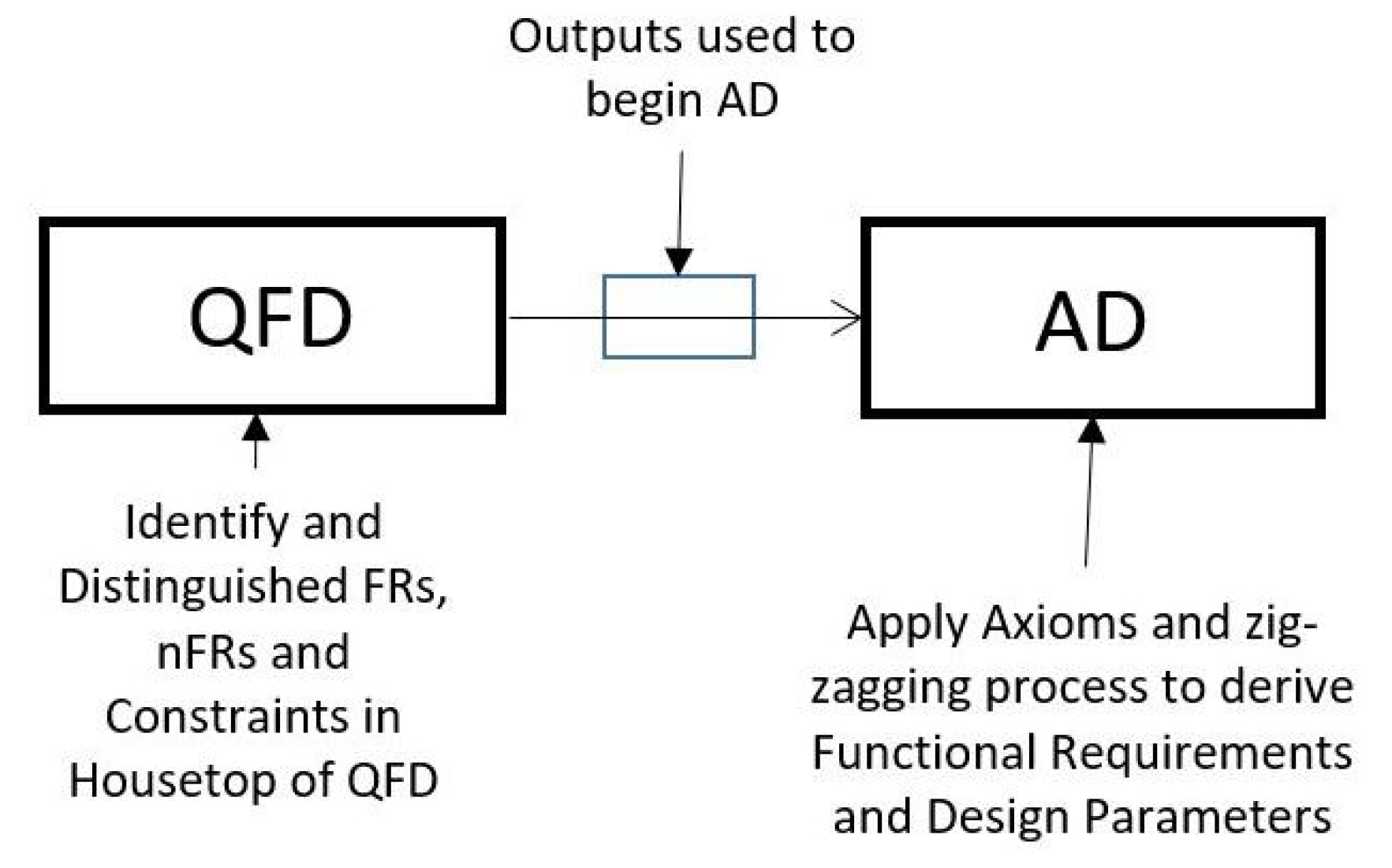

Gilbert et al. [

25] presented a study that sought to address the issue of improving designs of temporary housing for refugees in rural areas through the integration of QFD and AD. Their proposed method integrated these two transdisciplinary engineering design tools, a concept that was introduced before them [

26,

27,

28] but was extended in their evaluation of housing options through a unique application of Non-Functional Requirements (nFRs), Constraints (C), and Functional Requirements (FRs) as the top of the HOQ. Their use of AD sought to introduce, among other things, an element of creativity and an approach to quickly achieve the best solution by minimizing the iterative process of design; see

Figure 3.

1.2.4. Integration of QFD, AD, and TRIZ

Numerous research papers have been written to show the simple case of integrating the transdisciplinary tools AD and TRIZ. Tian et al. developed “an integrated model of these two methods to increase the efficiency and quality of the problem-solving process for conceptual design” [

29]. Tian et al. argued that TRIZ tools can be used to overcome the deficiencies in AD efforts. Their efforts to integrate AD and TRIZ together, however, leveraged HOQ/QFD as the starting point to derive the Product Design Specifications (PDS) as shown in

Figure 4; therefore, their approach is really an integration of QFD, AD, and TRIZ. This approach is the inverse to that proposed by Runliang and Hui [

30] below, which proposes the order of integration to be AD, QFD, and TRIZ. The assumption by Tian et al. [

29] that the PDS level requirements can be derived at the earliest stages of conceptual is drawn from Pahl et al. [

23]; however, it is in contradiction to the approach by Mayda and Borklu [

22] that used the TD toolset to help drive functional requirement development. More simplistic approaches for integration of QFD and AD are addressed by others [

31].

1.2.5. Integration of AD, QFD, and TRIZ

Runliang and Hui illustrated a model in which TRIZ, AD, and QFD tools can be integrated together to Design For Energy Savings (DFES) [

30]. In their case, the quality attribute of energy saving was important to their customers and was considered throughout the design phases. Their model of tool integration can be summarized as shown in

Figure 5. It should be noted that the model includes bi-directionality so that results from subsequent steps result in an iterative approach to design with the toolkit.

1.2.6. Integration of QFD and TRIZ

Leon [

32] presented two cases to demonstrate how the rooftop of a HOQ can be used as an input into TRIZ so that Technical Contradictions that are identified in the HOQ analysis can be addressed using the Contradiction Matrix in TRIZ (

Figure 6). A key conclusion of Leon was that “the QFD process and the construction of the HOQ should begin before a new product design is started” [

32]. This is in contrast to Runliang and Hui [

30], who suggested starting with AD and then iterating to the final design using the integration of the various tools.

1.2.7. Integration of TRIZ, DSM, and ISM

Wang et al. [

33] integrated these two tools with DSM first and then ISM as part of a two step-process. The study then employed TRIZ innovation algorithm and modular design. The TRIZ innovation algorithm helps a designer find out appropriate solutions of a concept design in a product development process. Furthermore, it studied how to construct a modular DSM and simplified assembly works. It also showed the relations between components by ISM and converted the whole design mission into an explicit plan [

33]; see

Figure 7.

This research paper will extend previous integration approaches discussed above to address the design question on temporary refugee housing. The continued displacement of refugees from their homes and homelands (now greater than 50 million people worldwide [

34]) places increased focus and attention on evolving the designs of the temporary housing that can be provided to this refugees population, especially in rural areas where housing does not already exist and must be constructed in very little time. The design of temporary refugee housing is, by the definition above, a complex engineering problem, involving societal issues in addition to engineering needs. This case study, therefore, benefits from the use of TD tools to effectively and efficiently address the design questions related to them. This research finds innovative design solutions to the temporary refugee housing complex problem by using a unique approach of integrating a set of TD Tools: Kano Analysis, KJ Diagram, Critical to Quality (CTQ), House of Quality (HOQ)/Quality Function Design (QFD), Theory of Inventive Problem Solving (TRIZ), Axiomatic Design (AD), Interpretive Structure Modeling (ISM), and Design Structure Matrix (DSM). The research concludes that the use of this unique approach for tool integration results in an innovative, decoupled design.

2. Methods

Although the integration of two or more TD tools is not new to resolve complex problems, the specific set of TD tools and their integration applied in this research paper and shown in

Figure 8 is unique. Designers can leverage this approach to elicit innovative, decoupled designs from the design team, thus meeting customer requirements. Each tool provides a piece of the overall design puzzle and works together. The output from one tool is used as input to the next tool. For brevity in this paper, the steps related to KJ are omitted as the paper is focused on the key elements of integration of the other TD tools (Kano, HOQ/QFD, TRIZ, AD, ISM, and DSM).

2.1. Design Considerations

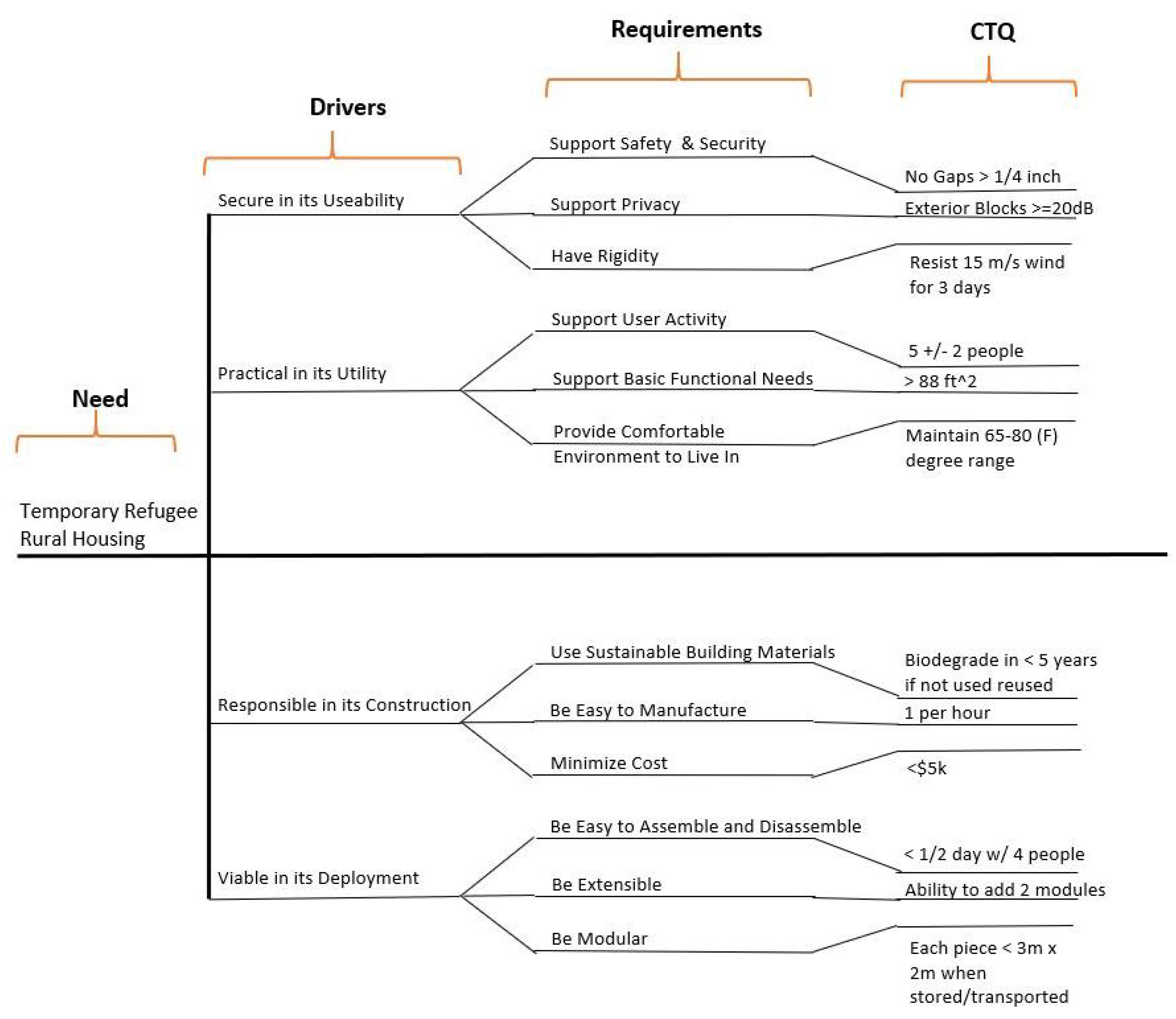

This case study maintains that the “customer” (when considering the voice of the customer) is the organization that will “purchase and provides the temporary structure” (e.g., UNHCR, Red Cross, Red Crescent). As a result of applying the nominal grouping technique (NGT) and additional research on the topic, customer needs were modified and extended to result in the list of factors (See

Figure 9). The NGT is a technique that focuses on collecting and assessing inputs from a group in a structured and outlined process, leading to similar groupings as found in the affinity diagrams. The five basic steps of the NGT process are given as follows:

Clarification of a trigger question,

Silent generation of ideas in writing by each group member,

Round-robin recording of the ideas,

An ongoing discussion of each idea for clarification and editing, and

Voting to obtain a preliminary ranking of the ideas in terms of significance [

35].

The following key modifications were made for our iteration of the design:

Eliminating “aesthetically pleasing” as aesthetics was not a priority for temporary housing, nor was it a key factor in any of the designs previously discussed;

Expanding the list of jointly regarded factors for the End User/Provider to include “Support Privacy” and “Be Extensible” in addition to modifications to original factors;

Replacing “Be Easy to Transport and Store” with “Be Modular” as the latter is more general in nature and if successful would result in ease of transportation.

The resulting list of design considerations was determined, and the considerations were consistent with the studies in the literature [

36].

Provide Comfortable Environment to Live In: Including climate control, space, ability to accommodate “furniture” or personal belongings.

Support Safety and Security: Including safety from other individuals (theft, retribution), local animals/insects (e.g., mosquitos) as well as antiseptic properties of the unit itself.

Support User Activity: Including activities such as entertaining guests, adolescent studying and young children playing. Basic functional needs are covered under the next item.

Support Basic Functional Needs: Including seeping, cooking/eating, bathing, and general hygiene.

Support Privacy: Including privacy for times without clothes, private conversations, dealing with personal matters (e.g., discipline), and personal affairs.

Be Easy to Assemble and Disassemble: The assembly and the disassembly are assumed to be performed by the provider (not the refugee).

Be Extensible:cIncluding the ability to “add-on” an extra room or to join units together to form larger units. A base unit assembly can accommodate 5 +/− 2 adults without extending the unit.

Be Easy to Manufacture: Including both the amount of lead time for manufacturing, availability of building materials, and the stability/reliability of the contracts for manufacturers and supply chain.

Use Sustainable Building Materials: Pertains to the type of material of the unit itself, including the weight. It includes consideration of the positive ECO impact for it to be recycled/reused once no longer in use as well as the avoidance of negative ECO impact to the environment around it while in use.

Have Rigidity (Strength): Including the ability to withstand various weather conditions and extremes.

Minimize Cost: Including all costs, including development, installation, and maintenance costs. It is related to the durability of the product (to reduce the replacement costs of units once they have reached end of life (EOL)).

Be Modular: Including the ability to easily replace parts/pieces of the unit as this relates to each of the previous factors above. Being modular odular also refers to the ability to transport the modular components independently, making them more easily transported.

2.2. Kano Survey

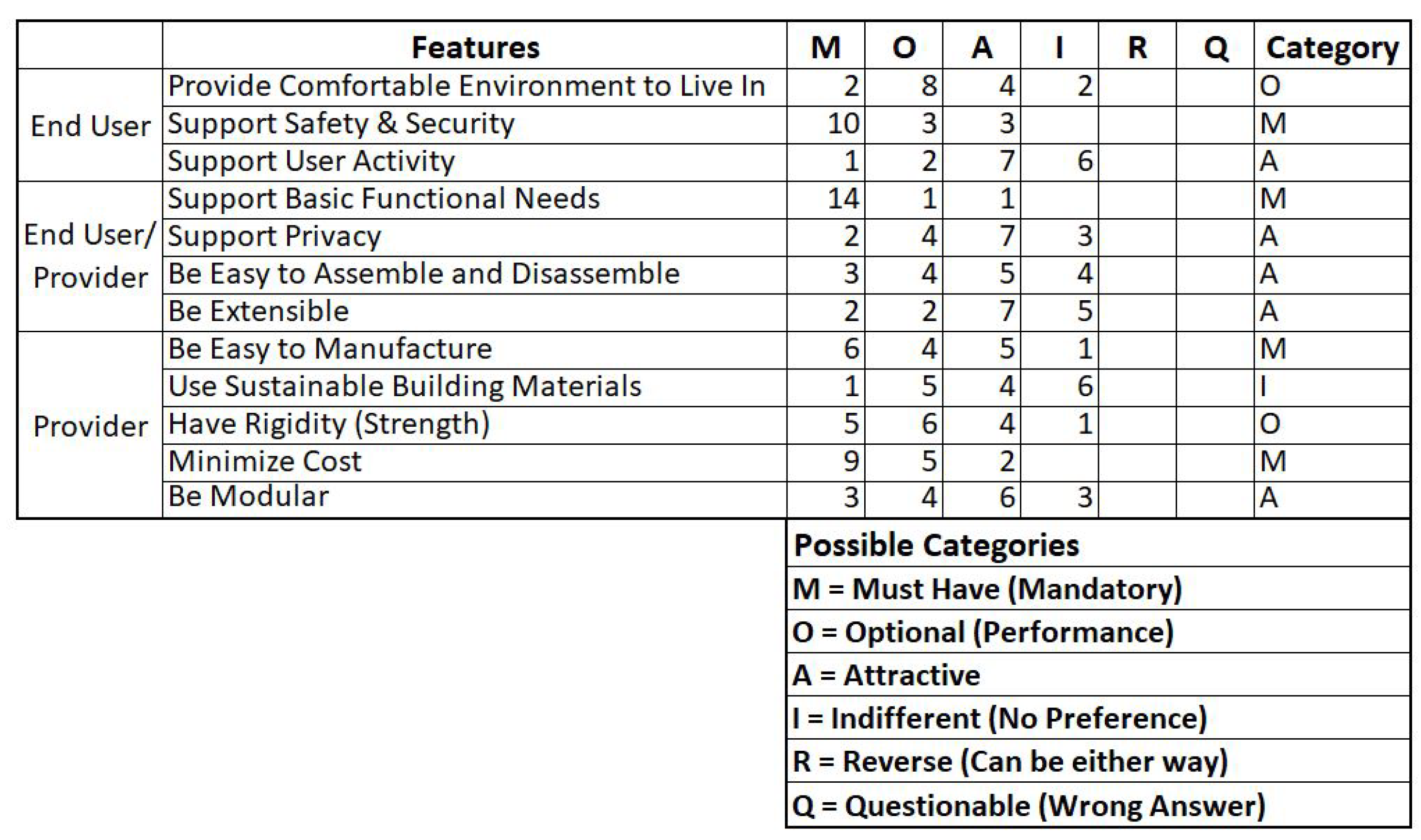

For this survey, a cross-disciplinary group of 20 individuals was selected to participate in the survey from a variety of backgrounds that included previous refugees, refugee relief volunteers, mechanical and systems engineers, system integrators, non-profit organizational leads, construction material sales professional, current humanitarian workers, international business executives, world travelers, and ex-military personnel with extensive work oversees. Participants in the applicable research survey and transdisciplinary activities were from a variety of educational and industry-leading international engineering companies; planning and development companies; secondary and higher educational institutes; charitable organizations with international work. Numerous individuals participating in the survey have decades of overseas experience, construction, and engineering backgrounds in addition to individuals from the Middle East and North Africa region, bringing diverse and important influence into the final research results. The results for the Kano survey are summarized in

Figure 10, while the detailed responses are found in

Appendix A Figure A1.

The selected category for each feature in the list was determined by the maximum survey tally as found in the results. In the case where survey tallies were close, such as with “Use Sustainable Building Materials” that scored Optional (5), Attractive (4), and Indifferent (6), the TD team deferred to the subject matter experts on the team for any special considerations that might justify a particular selection. The TD team highlighted this feature’s benefit and incorporated it in subsequent design steps.

2.3. Initial House of Quality (HOQ)/Quality Functional Deployment (QFD)

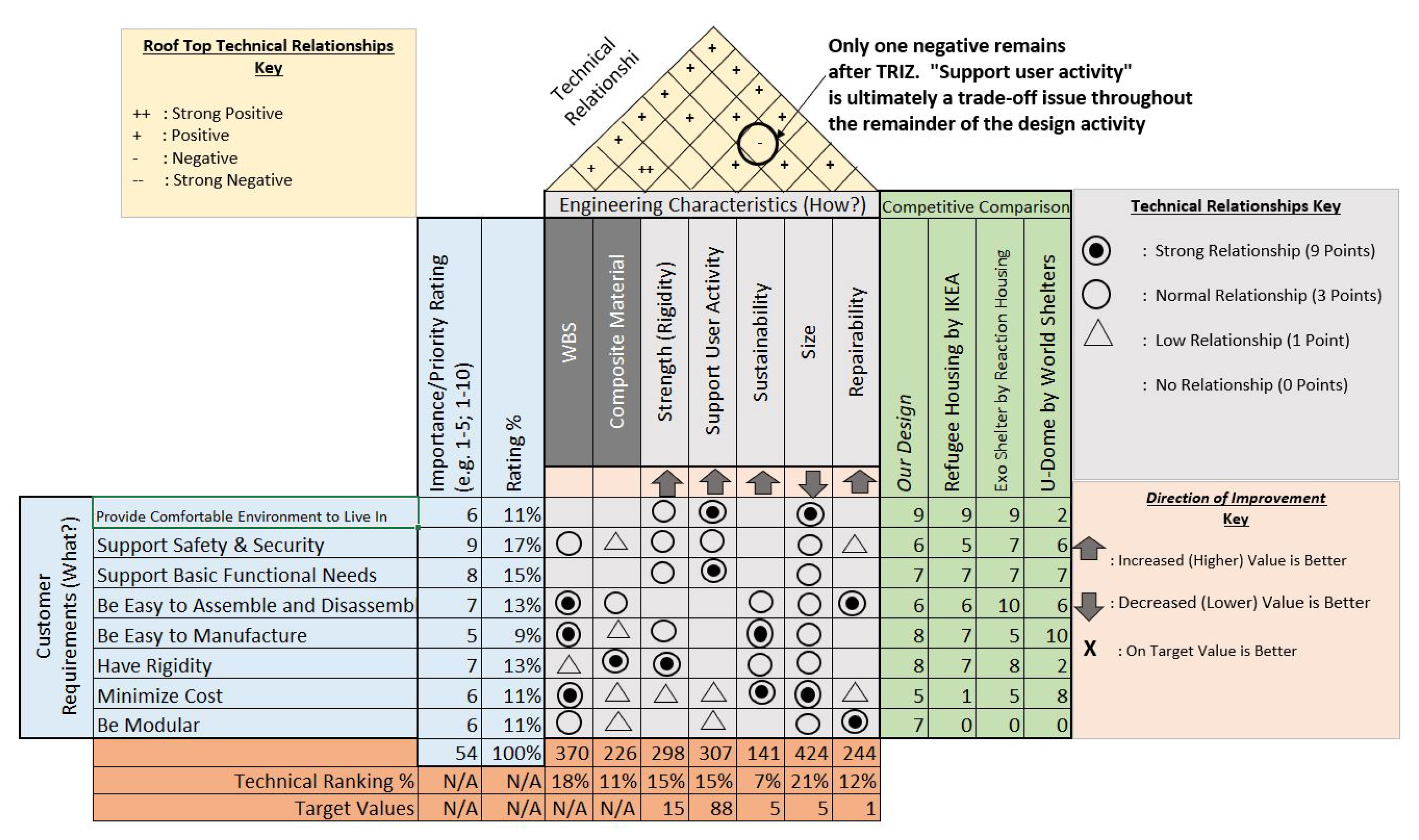

From the Kano results found in

Figure 10, we selected all of the “Must-Have/Mandatory” features, all of the “Optional/Performance” features and an agreed subset of the “Attractive” features for our design as the input for the HOQ Customer Requirements, addressing the question of “What” would be built. This is one of the first places that tool integration has been achieved. We adjusted the HOQ matrix roof top (“How” it would be built) to include engineering characteristics in order to seamlessly integrate with the next TD tool in the process. However, instead of using AD as the next tool as prior researchers had done, we followed up the use of HOQ with TRIZ and therefore consider engineering characteristics in such a way that they more easily translate into the language of TRIZ and expose any contradictions in design, earlier in the process—this approach and integrated tool ordering also serves as a forcing function to insert creativity into the design as early as possible, driving innovation up front. We leverage the Kano Analysis output, KJ Diagram and associated CTQ analysis as input into the first of two QFD/HOQ analysis steps and incorporated their influence throughout the design process (

Figure 11).

Note that there are two double negatives (“- -”) technical relationships identified between the weight and strength (rigidity) and between “Support User Activity” and “Cost of Production”. These double negatives are noted as “Conflict 1” and “Conflict 2”, respectively, in

Figure 11. These technical contradictions, now identified, will be addressed in the next step using TRIZ before the creation of the final QFD/HOQ matrix. The negative relationships were assessed by considering the “Direction of Improvement” in the House of Quality rooftop for strength and weight. For “Conflict 1”, the double negative, attempting to increase strength as much as possible, likely results in the weight increasing and therefore moving in a direction counter to the “Direction of Improvement”. For “Conflict 2”, the same negative relationship is true with respect to the “Cost of Production” and “Support User Activity” as the team determined that increasing complexity associated with supporting additional user activity in a refugee home will drive up production costs (i.e., a basic home, like a tent, is easier to manufacture since it supports sleeping, whereas a refugee home that supports complicated user activity, such as electric cooking, will drive up complexity and increase production costs).

Identifying these contradictions early is an important step in the process that increases the likelihood of innovative design (as that is the main point of TRIZ as it addresses contradictions) so that creativity is introduced early in the design process. TRIZ is leveraged to resolve the double-negative first and associated negatives with the “Strength (Rigidity)” engineering characteristic and then a reassessment will be conducted to determine if further conflicts need to be resolved before moving forward with the design.

2.4. Theory of Inventive Problem Solving (TRIZ)

Technical contradiction is often referred to as a “trade-off” such that when one feature is designed to get better, it results in negative impacts on another design feature or design parameter. A physical contradiction occurs when the two requirements are fundamentally in opposition to each other (i.e., opposite requirements). An example of a physical contradiction is wanting to develop complex software while making it easy to use. To avoid (or minimize) the negative effects on the product, creative and innovative solutions are sought out by the engineering team.

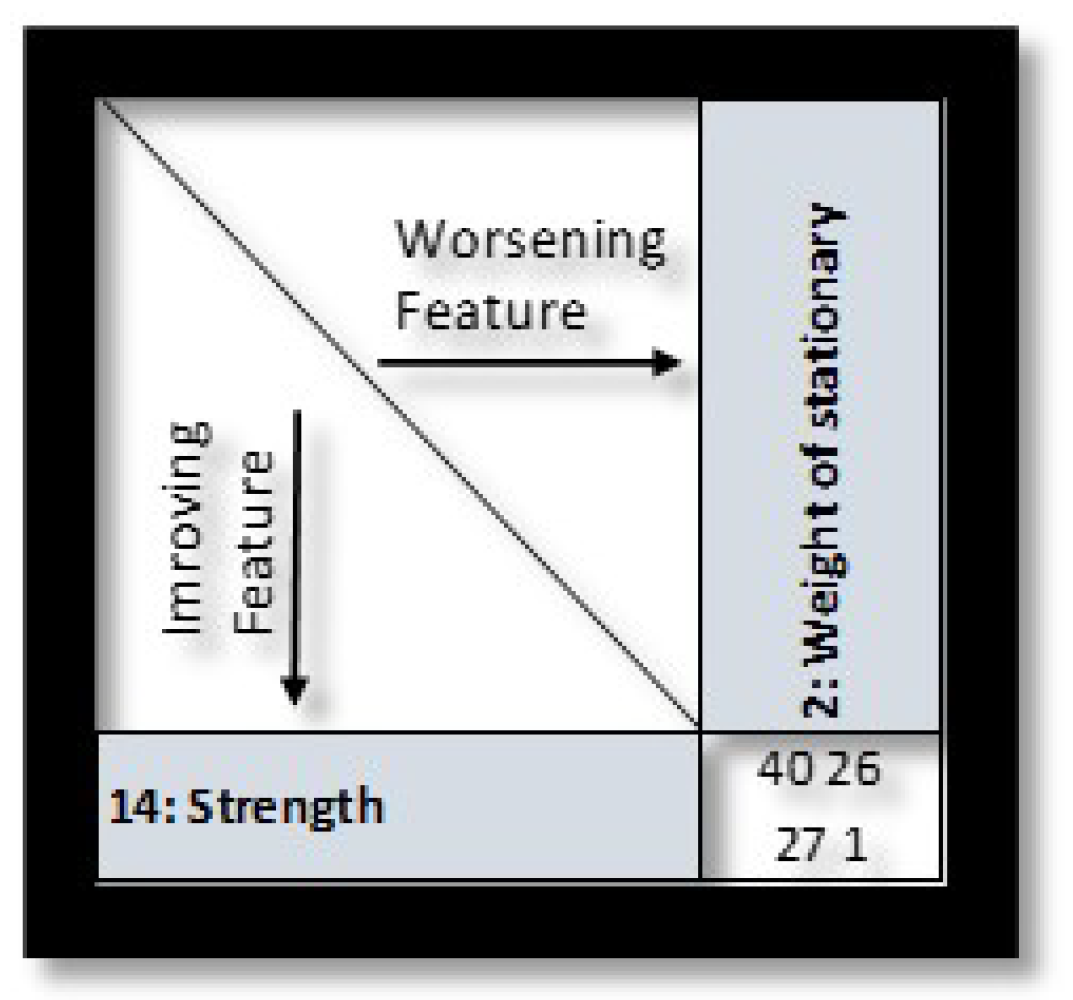

2.4.1. Resolving Conflict 1

To address “Conflict 1”, the double negative technical relationship between the engineering characteristics of weight and strength (as identified in the House of Quality HOQ1), the design turns to TRIZ. The use of TRIZ early in the design process introduces creativity in the design upfront, resolves contradictions early in the process, and leads to a more efficacious AD later in the design process. The first step was to align the engineering characteristics, weight, and strength from the HOQ rooftop with the most applicable TRIZ features. Out of possible 39 TRIZ features, the following two were identified for weight and strength:

These features are defined in the TRIZTable [

37] as provided in

Table 1.

Referring to the TRIZ contradiction table, we see that improving Item #14 (Strength) has a negative impact on Item #2 (Weight of a Stationary Object). There are four options from the inventive principles identified to creatively address this conflict: 1, 26, 27, and 40 as seen in

Figure 12.

Now that the potentials solutions have been identified for this technical requirement conflict, we refer to the potential solution details as provided below

Figure 13.

From these options, we made the following determinations for each option.

Inventive Principle #1: There is a potential solution to divide the object into independent parts as this would help with modularity; however, the aggregate weight is not reduced, the weight of the housing unit is simply broken down into various parts and therefore is not the best option. This approach was not selected.

Inventive Principle #26: This is not the best option as we cannot replace the material with an optical copy. We could consider a simplified product, but this would likely reduce the functionality or create a new negative technical contradiction with the mean time to restore. This approach was not selected.

Inventive Principle #27: This is not a good option as cheap material will not last and will increase costs in the long run. This approach was not selected.

Inventive Principle #40: This is the best option: we can select the material in such a way as to replace homogeneous materials with composite ones. Using this approach, the weight decreases as the strength increases. This selection will be carried to the second QFD/HOQ.

This choice of using composite materials will inform our selection of functional requirements in the next step as the second QFD/HOQ (HOQ2) is built.

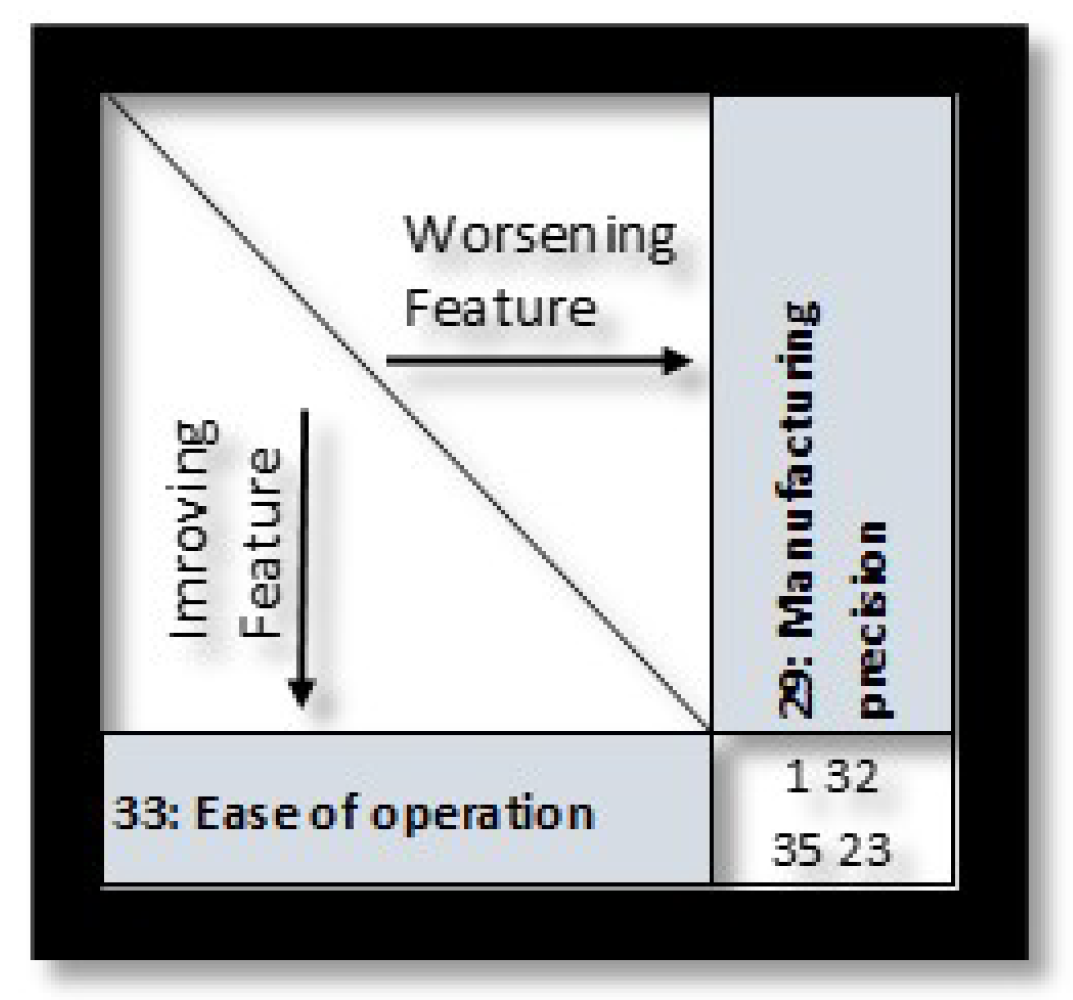

2.4.2. Resolving Conflict 2

The traditional TRIZ features are not sufficient to address Conflict 2, the negative technical relationship between the engineering characteristics of cost of production and strength (rigidity) (as identified in the House of Quality HOQ1); since they do not explicitly deal with cost, a business focused contradiction matrix was applied [

38,

39,

40,

41]. A total of 31 features are used in the business-focused TRIZ Matrix and implemented to assess what drives cost of production; the design contradiction of “Cost of Production” and “Support User Activity” is transformed to the contradiction of “Ease of Operation” (i.e., “Support User Activity” and “Manufacturing Precision” (i.e., “Cost of Production”). When we improve “Ease of Operation”, then “Manufacturing Precision” (as it relates to Cost of Production) worsens (i.e., it costs more to produce temporary refugee housing which has an increased set of easy to use user activity items; see

Figure 14).

Referring to the details of the associated TRIZ 40 Inventive Principles #1, #23, #32, and #35, we considered details associated with each option for resolving the conflict; see

Figure 15.

“Segmentation” was selected as the solution. Furthermore, the application of “Segmentation” by way of dividing an object into independent parts was executed via the use of a Work Breakdown Structure (WBS) as indicated in 1.d. as shown in

Figure 15: “Use a work breakdown structure for a large project”. The result of the TRIZ analysis for “Conflict 2”, then, is to create a Work Breakdown Structure (WBS) as an Engineering Characteristic (as opposed to using the “Cost of Production”). In this way, “Conflict 2” is resolved using TRIZ inventive principles.

2.5. Updated QFD/HOQ (HOQ2)

Now that both Conflict 1 and Conflict 2 from HOQ1 are resolved, the design considers the positive impacts this has on the updated HOQ. From

Figure 16, we can see that the first two engineering characteristics have been replaced with the resultant items from the TRIZ analysis, such that the two conflicts related to the strength (rigidity) noted previously have been resolved with the use of the WBS item and the composite material item in the rooftop of the HOQ. Additionally, after evaluating the complete rooftop, we found that all the conflicts had been resolved except one.

The selection of composite material is a key engineering characteristic for resolving the completed design and was not explored in previous research. The key selection of composite material that meets the respective strength (rigidity), weight, and sustainability needs is the cornerstone to the final design. A couple of examples of sustainable material can be listed as rammed earth, straw bale, bamboo, wool, Tesla solar tiles, structural insulation panels, biocomposites, and acetylated wood products [

42]. There is an assumption in the design that the minimum amount of rigidity is met with any product selected, and therefore there is no negative association in the rooftop of the HOQ between Sustainability and Strength. The use of sustainable material also has a positive impact as it relates to Production Cost (see

Figure 11). This positive impact was assessed by considering the number of tax breaks and government subsidies that are available to the development of products that use sustainable materials. These subsidies along with the cycle of reuse for sustainable materials introduce an arguable level of Return on Investment (ROI) according to the U.S. Environmental Protection Agency’s report on Sustainable Materials Management [

43].

With the replacement of product-based Work Breakdown Structure (WBS) instead of Cost of Production (based on the previous TRIZ conflict resolution analysis), the rooftop intersection now has a set of intersecting + (positive) relationships shown in the contradiction matrix. This positive relationship is a result of assessing the positive impact that the organization of effort has on the outcome of a product, increasing the focus of tasks and production of each level of the final product to ensure quality and complete coverage of design and development. The design target values are driven out of the Critical to Quality (CTQ) Analysis previously completed (e.g., Strength Rigidity target value of 15 relates to the CTQ 15 m/sec over three-day CTQ value for Rigidity) as seen in

Figure 17. Following on from this analysis, we set design target values of 88 ft2 for minimum space need to Support User Activity, 5 years or less for reuse or recycle of any material used as part of Sustainability, a size that accommodates 5 or more people, and repairability that can be completed in 1 day or less for each unit.

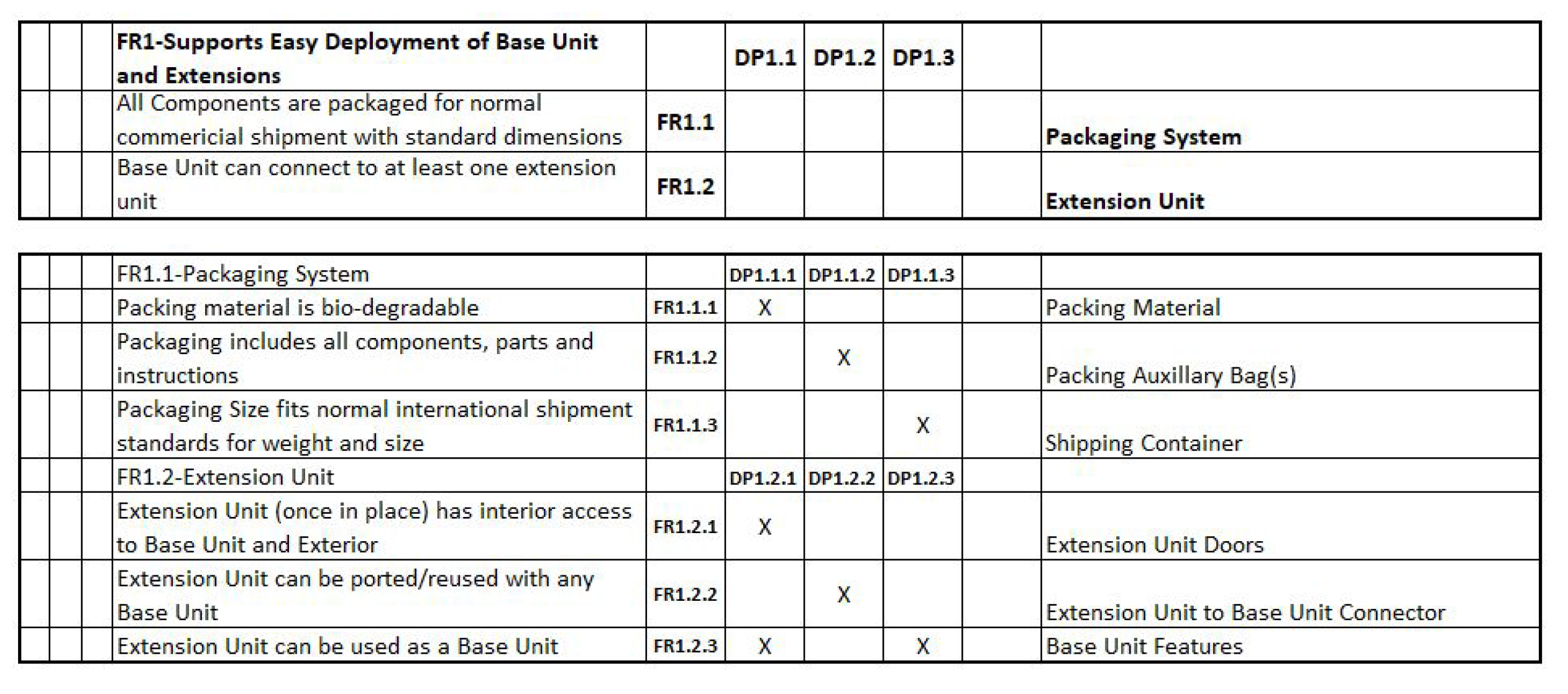

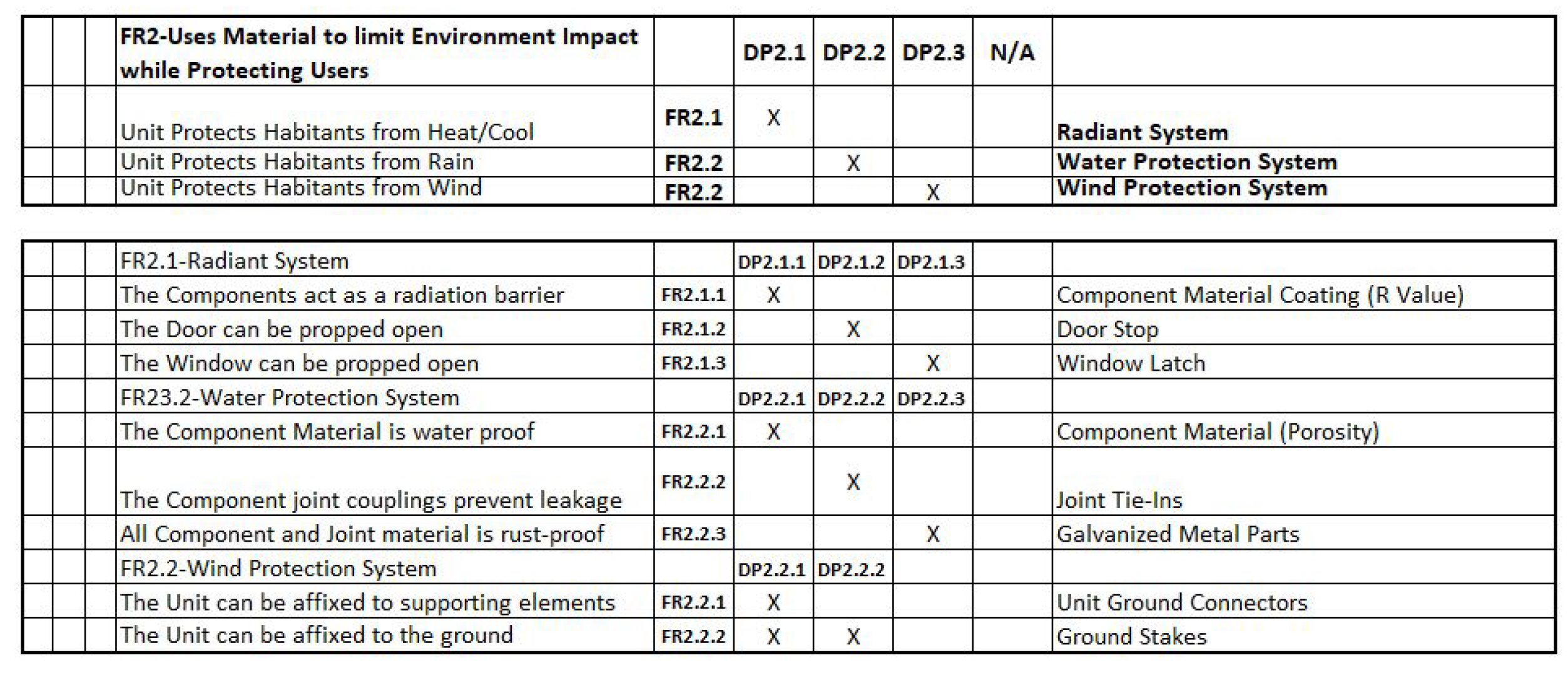

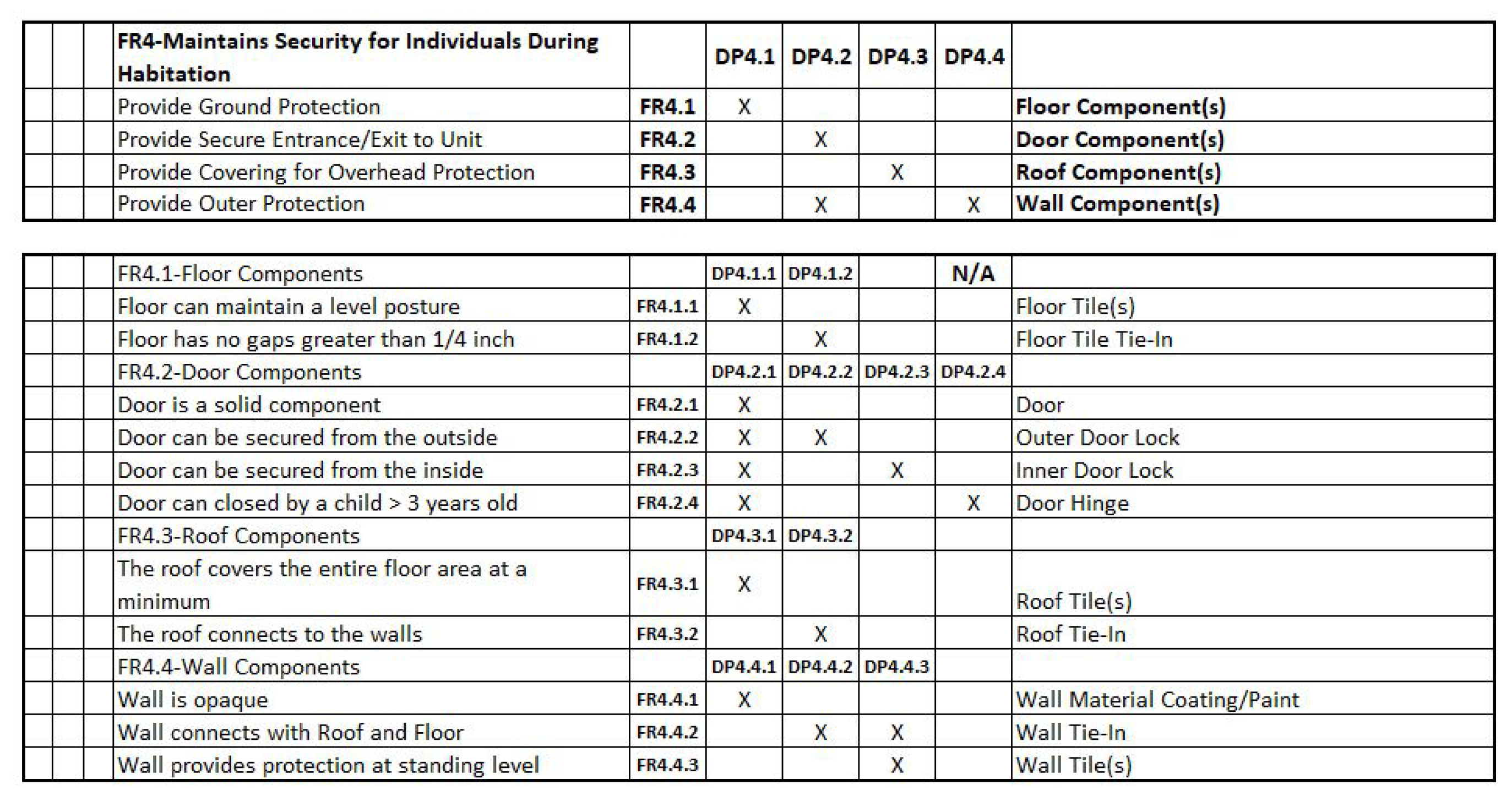

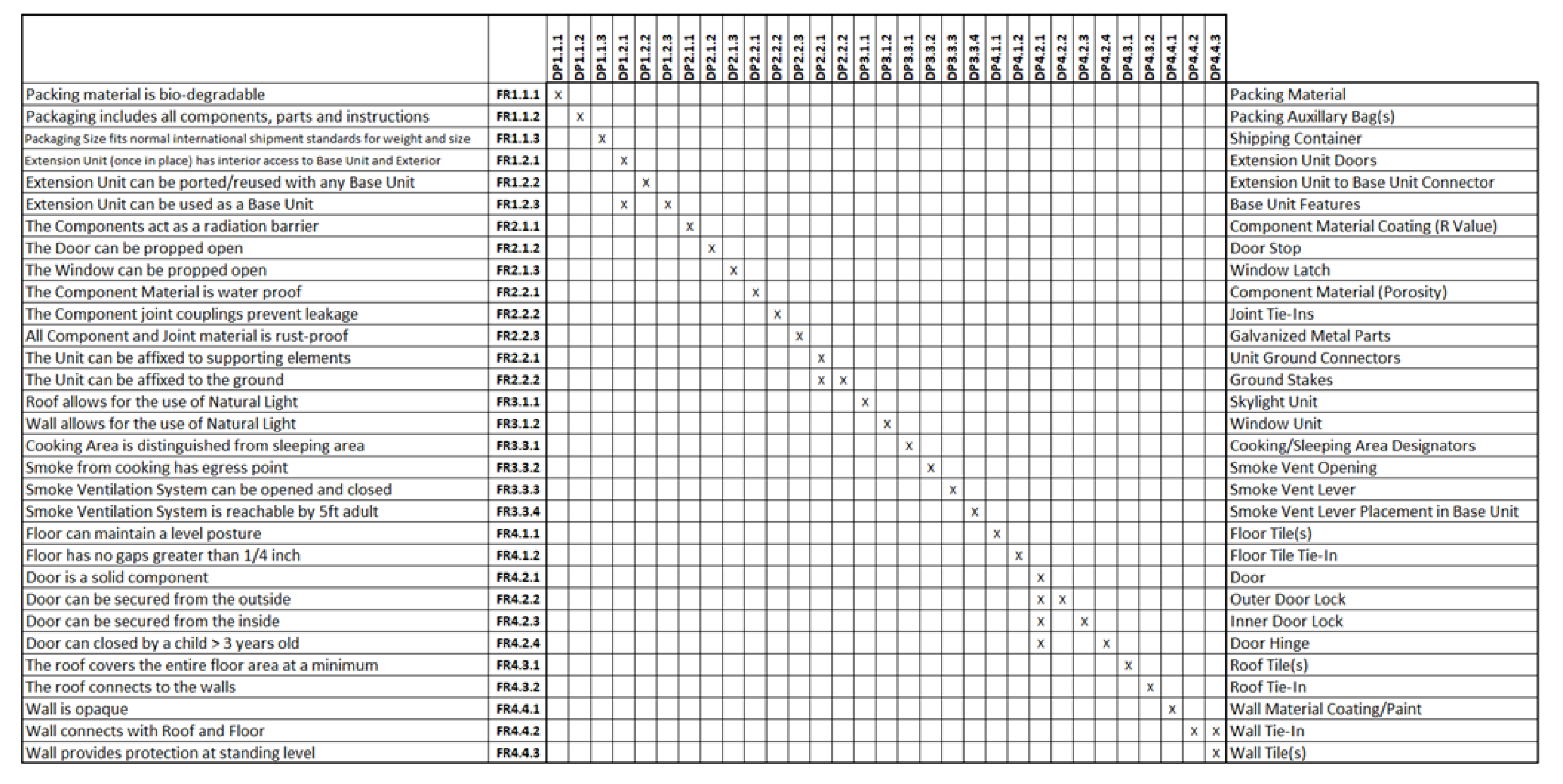

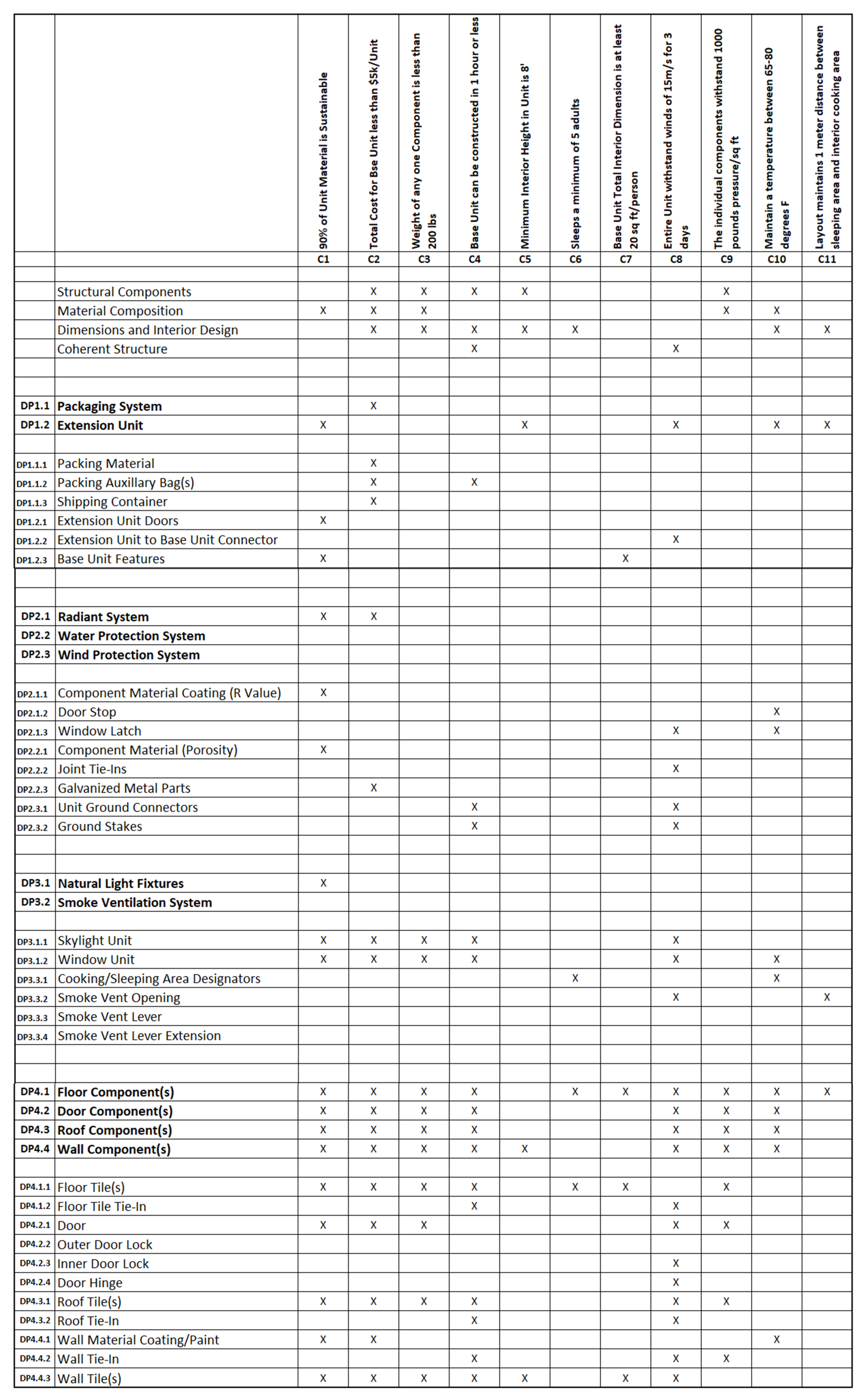

2.6. Integration of Reconstructed QFD and AD

Leveraging the output of the previous steps—HOQ/QFD and CTQ analysis—the iterative development of three levels of FRs, DPs, and associated constraints is developed. Four high-level FRs were derived, as seen in

Figure 18, accompanied by 4 DPs. The 4 DPs at the top level are:

DP1: Structural Component: Includes climate control, space, and ability to accommodate “furniture” or personal belongings.

DP2: Material Composition: Includes safety from other individuals (theft, retribution), local animals/insects (e.g., mosquitos), and antiseptic properties of the unit itself.

DP3: Dimensions and Interior Design: Includes activities such as entertaining guests, adolescent studying, and young children playing. Basic functional needs are covered under the next parameter.

DP4: Coherent Structure.

N × N matrices are leveraged at each level of the design to avoid coupled or redundant designs (an implication of Axiomatic Design with non-N × N matrices).

Equation (

1) summarizes the top-level mapping of FRs to DPs, revealing a de-coupled design as illustrated with the lower triangular matrix and ensures that the independence axiom is not violated at this stage in the design. At this point in the design, zigzagging is employed to break down the high-level functional requirements into lower-level functional requirements with associated DPs. This research included three levels of decomposition for the design of the temporary refugee housing unit. The breakdown of the various levels of FRs and DPs is presented in

Figure 19,

Figure 20,

Figure 21,

Figure 22 and

Figure 23. Multiple passes were made to ensure an uncoupled or decoupled design at each level.

From each individual pair of FR1. . . 4 × DP 1. . . 4 mappings, the complete Design Matrix (Level 3) was constructed (

Figure 23).

Following on with the AD process, 11 constraints were identified and mapped to each of the DPs at all three levels to inform the designer regarding constraints for the selection of the final design as shown in

Figure 24.

It should be noted that throughout the Axiomatic Design Process, the type of material to be used for the components of the unit to satisfy the constraints and requirements highlights the need to identify the correct material for strength without impacting the overall weight—supporting the original finding in the TRIZ activity and resulting in a search for the appropriate material from which to construct the unit’s main components, such as doors, wall, roof, and floor.

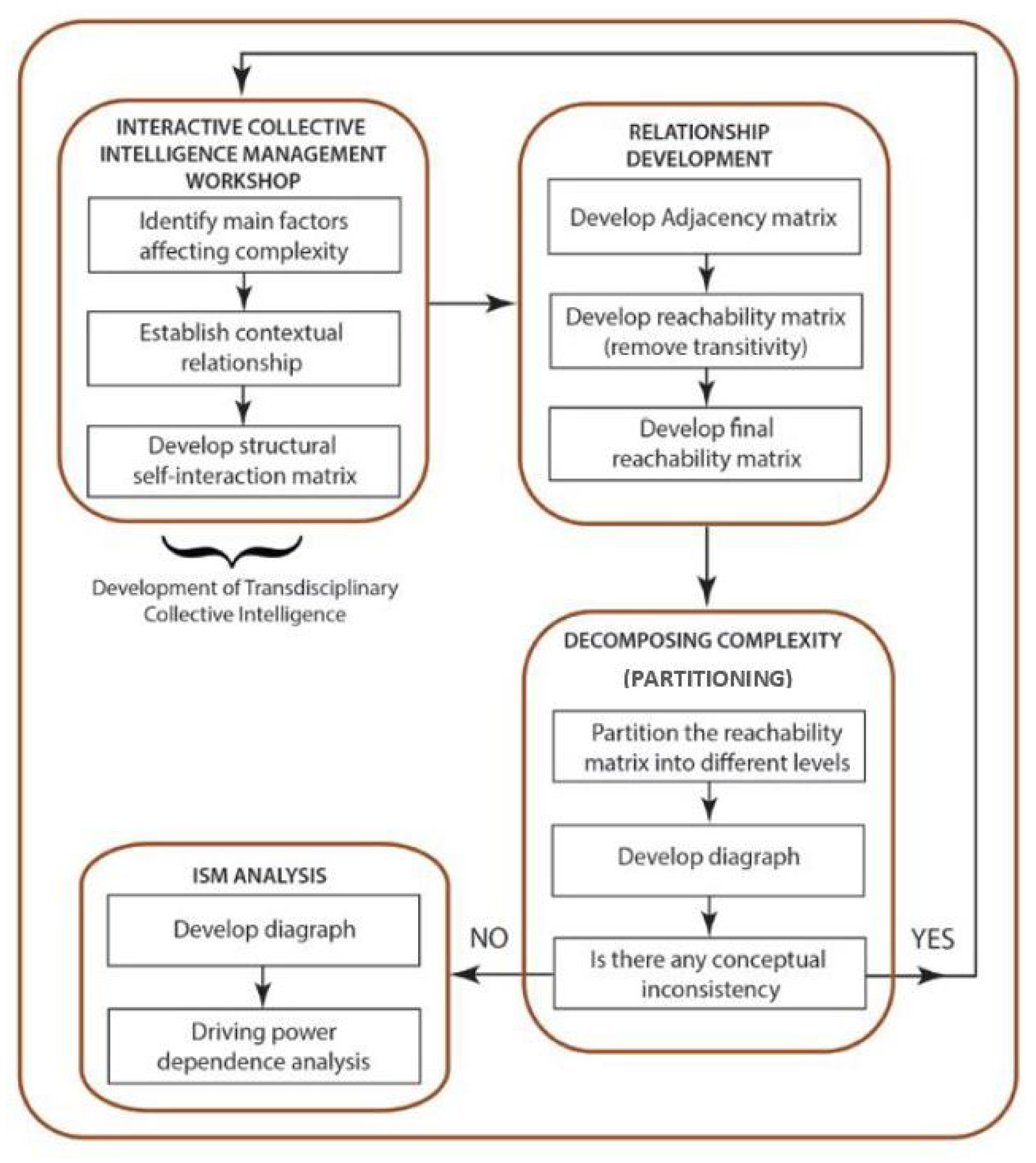

2.7. Integration of QFD and ISM

ISM now helps researchers to structure a set of different and directly related factors (elements) affecting the system into a hierarchical model so that unclear and poorly expressed conceptual system models will be well-defined [

18].

Figure 25 outlines the ISM process [

14].

Use of QFD for the development of ISM starts with the rooftop contradiction matrix information. The design transforms each of the +, ++, − relationship indicators into directional relationship indicators using input from the design team and in accordance with the ISM techniques. The relationship of each of the engineering technical requirements is then input into the Structural Self-Interaction Matrix (SSIM); see

Figure 26. The contextual relationship for each factor, the subsistence of a relation between any two factors (i and j), and the associated direction of the relation are questioned. There are four symbols used to denote the direction of relationship between the factors (i and j):

V: Variable i affects variable j

A: Variable j affects variable i

X: Both variables, i and j, affect each other

O: No relationship between variables i and j

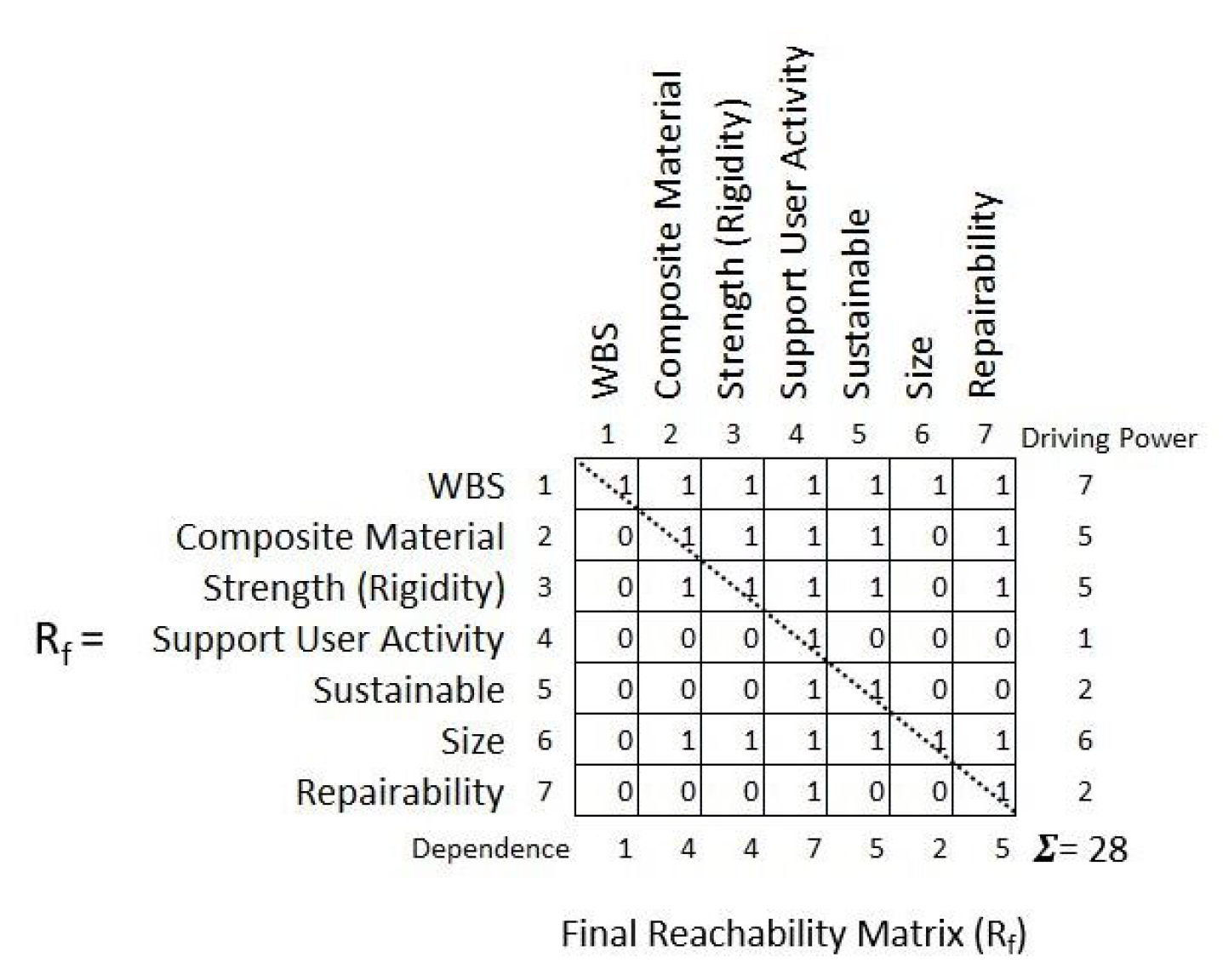

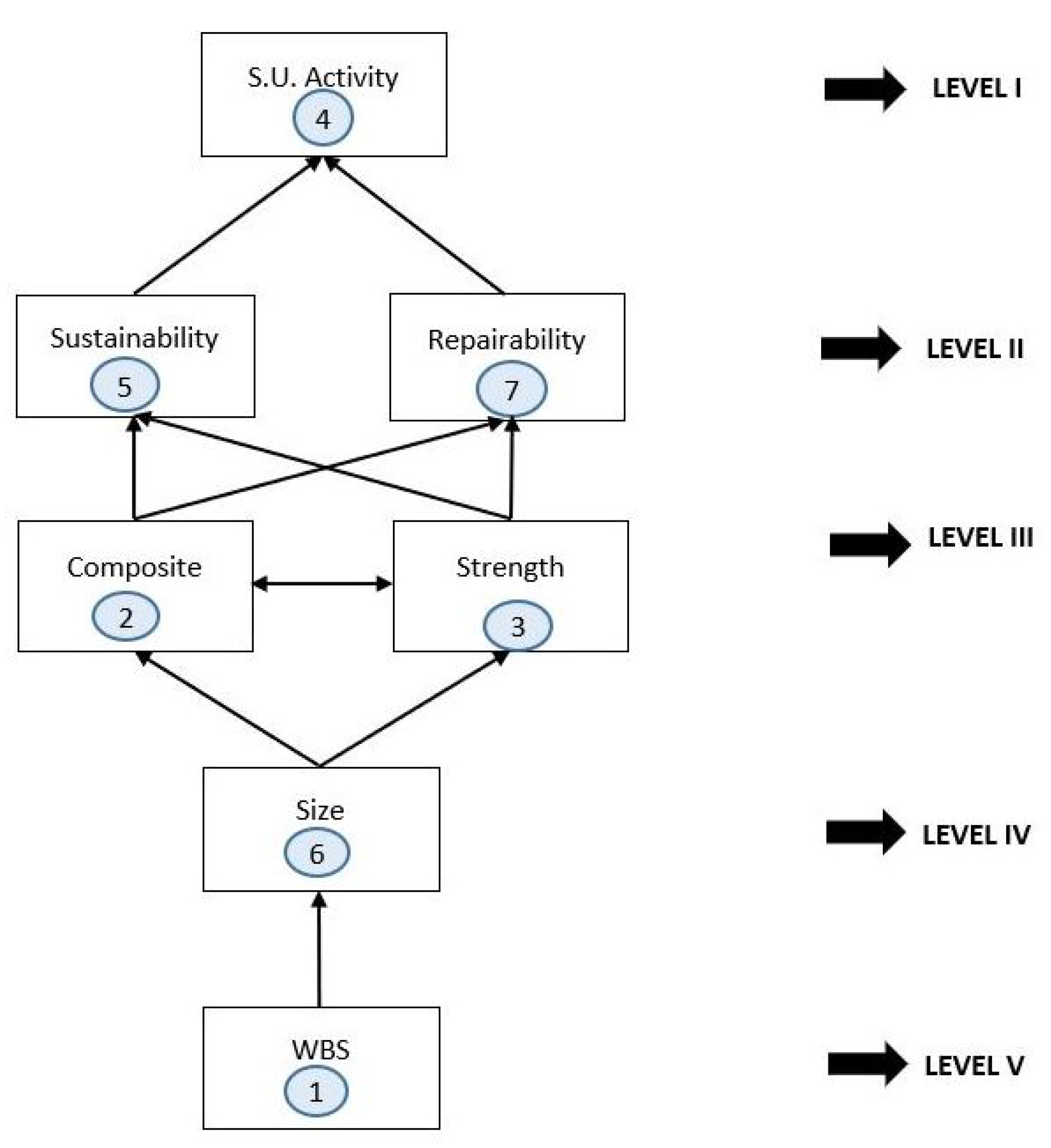

From the information and data derived in the adjacency matrix and final reachability matrix, level partitioning were performed to derive the resultant digraph (

Figure 29) and MICMAC analysis (

Figure 30). With level partitioning, the reachability and antecedent set for each variable were obtained from final reachability matrix (

Figure 29 and

Figure 30). riving force and dependence from

Figure 25 obtained earlier helped to classify the factors into groups. Positions of these groups were determined by the separation of antecedent and reachability sets. From these two sets, an intersection set was established. Next, the factors that were common in the reachability set and antecedent set were included in the intersection set. These three sets helped to identify the level of the factors. When all the factors of the intersection and reachability sets of any certain factor were the same, then that factor was identified as the top level of the ISM hierarchy. When the top-level factors were known, they were discarded from the list of remaining factors to identify the next level. This iteration process was repeated until all the levels were identified.

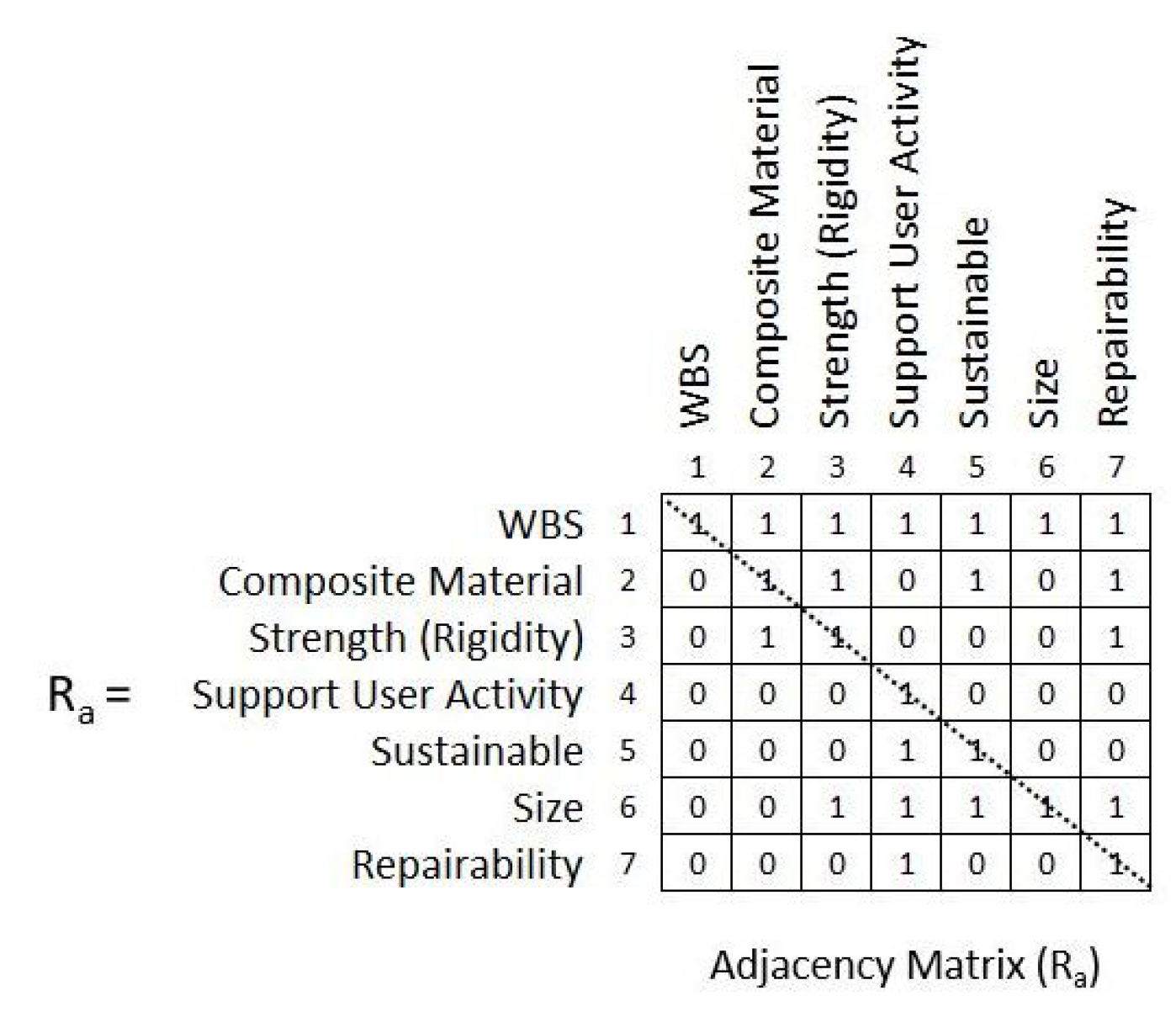

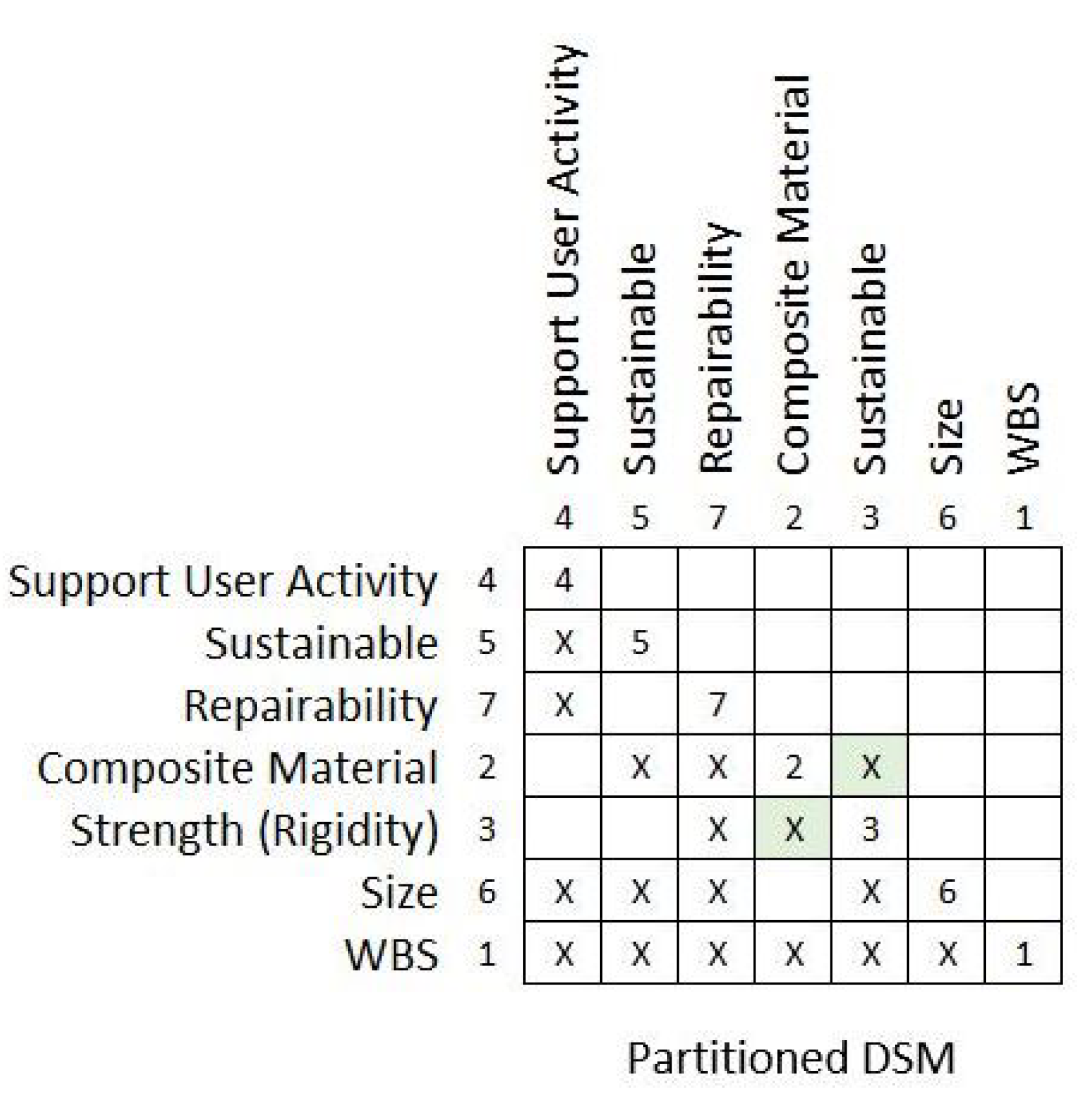

2.8. ISM and DSM Integration

The DSM can be seen as a successor to the ISM method. which has been used by the Systems Engineering community since before the introduction of the DSM.

From the ISM adjacency matrix, the design is able to translate the cell data into the DSM Matrix as seen in

Figure 31.

Figure 31b shows the unpartitioned DSM in its initial form.

Figure 32 shows the partitioned matrix after manipulation in order to move the “Xs” to lower triangle or move as close as possible to the diagonal of the matrix. Above the diagonal of DSM (upper triangular matrix), marks of feedback or cycles are not desirable—it requires time-consuming iterations.

3. Discussion

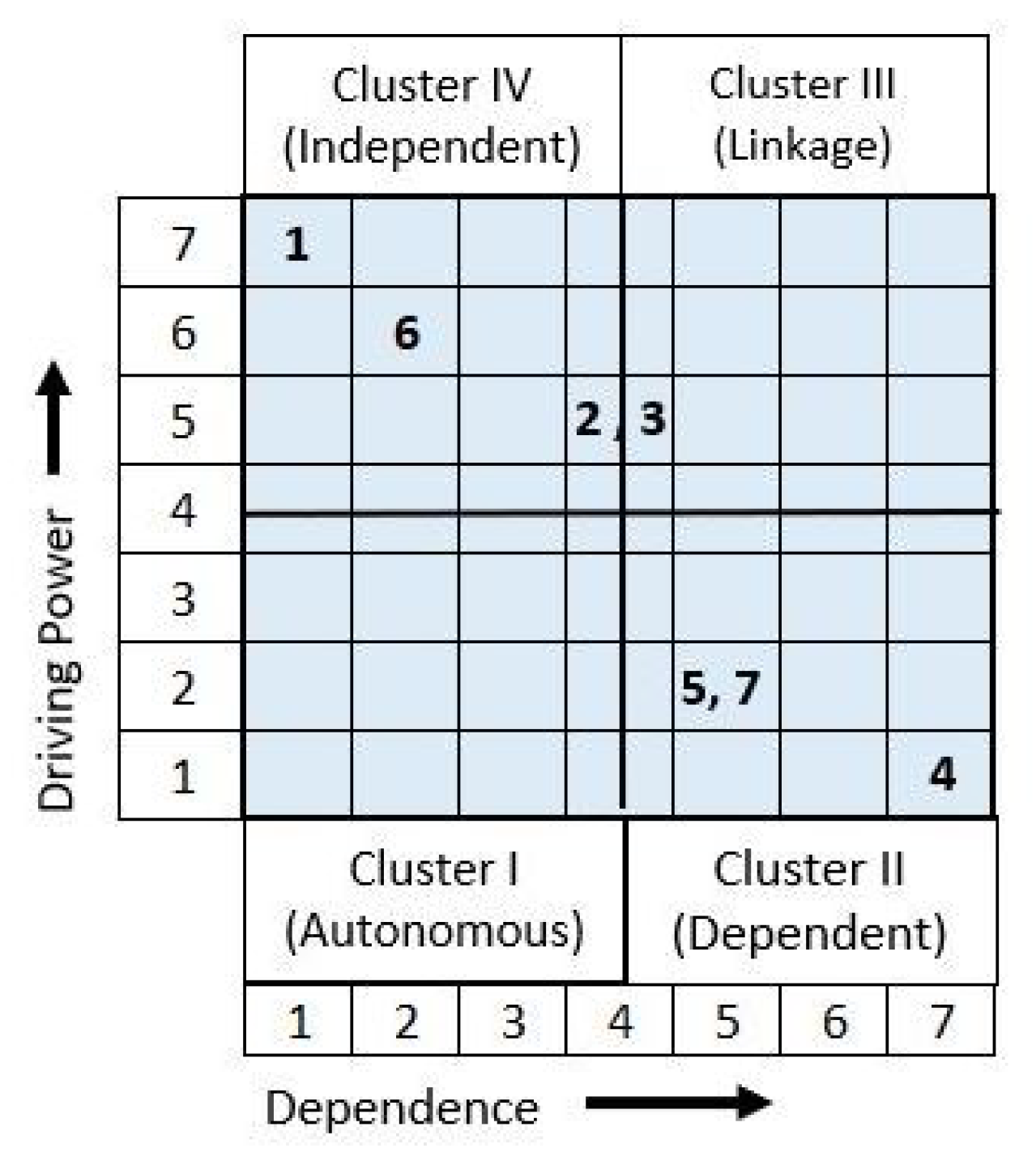

As shown in

Figure 30, seven performance measures of factors affecting the design of temporary refugee housing have been classified into four categories. Cluster I includes autonomous factors. As seen from the figure, they have low driving power and low dependence; hence, they can be eliminated from the design consideration. For this case, no factor has been identified in the autonomous quadrant. This indicates that there is no disconnected factor from the design process. Cluster II includes dependent factors that have low driving power and high dependence. As seen from

Figure 30, there are three factors (4, 5, and 7) that have a smaller guidance power, but they are dependent on other remaining factors in designing temporary refugee housing. The factors in the linkage cluster III are important due to their high driving power and high dependence—these key factors affect and depend on other factors. Although factors 2 and 3 are at the boundary of the two quadrants, they can be positioned in Cluster III—they are dependent on size factor 6 and directly affect factors 5 and 7 (

Figure 29). Cluster IV includes the independent factors of WBS (1) and have strong driving power but very week dependence, size (6), and composite (2) with moderate driving power. Since a large number of edges enter and leave in levels 2 and 3, four main important factors, Sustainability (5), Repairability (7), Composite Material (2), and Strength (3), shown in

Figure 29, are the most critical factors which need to be considered first to design successful temporary refugee housing.

As seen from

Figure 32, after partitioning attempts, the number of feedback marks above the main diagonal is reduced to one (composite material (2)), which is coupled with the strength of the structure (3). The selection of the kind of composite material to be used for the building structure must occur after the strength analysis is completed. Since there are no other feedback decision-making tasks above the diagonal, the remaining decision-making tasks on the forward mark below the diagonal (size, repairability, etc.) can proceed without any iteration.

The combination and integration of TD tools as presented in

Figure 8, including the method and order of integration, presents an avenue by which innovative design can be accomplished to meet customer needs and provide attractive features. This approach drives innovation earlier in the design process and results in minimal conflicts within the engineering characteristics as well as an uncoupled design. By utilizing a transdisciplinary approach, “provides a way to contemplate the wholeness of complex problems facing us today” [

44]. The approach focuses the design team on driving factors and identifies key interactions within the design parameters. The new and integrated TD engineering design process is applied to the problem of temporary refugee housing, resulting in the identification of composite material as a key engineering characteristic for the design team to resolve ahead of implementation, extending work previously done. Further, the use of a work breakdown structure (WBS), organized work around the production, is found to be independent, central in driving out the solutions for all the other design parameters in the solution space, followed by the size of the unit itself.

The digraph (see

Figure 29) shows the factors affecting the successful design of Temporary Refugee Housing. Especially at levels two and three, it shows complex interactions among the factors. This complexity can be described using cyclomatic complexity through digraph as [

45]:

where

E = the number of edges of the graph

N = the number of nodes of the graph

P = the number of connected components.

The number of edges (depicted as arrows) is 10, the number of nodes (depicted as rectangles) is 7, and the number of connected components, P, is equal to 1. Therefore, the cyclomatic complexity M of the digraph given in

Figure 29 is 5 (10 − 7 + 2(1)). The tolerable upper limit that has been used for cyclomatic complexity is 10 [

45]. Since the successful design of Temporary Refugee Housing through digraph shown in

Figure 29 gives a complexity of 5, we can conclude that it is not that difficult to handle the design process of this problem.

4. Conclusions

In this paper, we covered the integration of well-known TD tools that have been applied in many fields including product development, project management, many engineering disciplines, design of the organization, sustainable development, social issues, environmental issues, and others across many industries including automotive, aerospace, telecom, semiconductor, defense, transportation, energy, healthcare, agriculture, and more. This Transdisciplinary Engineering-Based Integrated Approach for the Design of Temporary Refugee Housing using Kano, HOQ/QFD, TRIZ, AD, ISM and DSM Tools, as shown in

Figure 8, was useful in identifying an appropriate set of requirements for the temporary refugee housing unit through the use of the Kano Survey; identified and addressed conflicts via HOQ/QFD; enabled innovative design through the use of HOQ/QFD and TRIZ; facilitated the a decoupled design through AD; informed the focus areas of design and implementation through the use of ISM and DSM. In particular, this methodology proved useful in highlighting the need for solutions for the material aspects of the temporary housing unit. This same process can be applied to other engineering design problems to result in an innovative, de-coupled design that meets customer needs.