Condition Assessment of Reinforced Concrete Bridges: Current Practice and Research Challenges

Abstract

:1. Introduction

2. Review Objectives

- Delineate recent research efforts on the available techniques and investigate the versatility of their applications;

- Define the strengths, limitations, and challenges associated with the application of each technique;

- Identify knowledge gaps for further research; and

- Formulate recommendations towards the selection of appropriate assessment techniques so as to identify specific deterioration types.

3. Review Methodology

- Developing a structured framework for conducting a comprehensive literature review on RC BCA based on a vast amount of papers published;

- Using this framework to gain an understanding of the current state of the RC BCA research field; and

- Developing a conceptual framework identifying areas of concern with regard to RC BCA techniques.

4. Bridge Performance Indicators

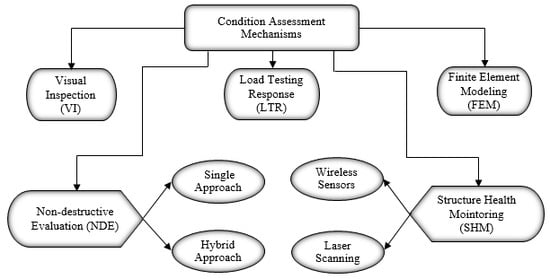

5. Bridge Condition Assessment Approaches

5.1. Visual Inspection

5.2. Load Testing

5.3. Structural Health Monitoring

5.3.1. Data Acquisition Using Sensors and Laser Scanning

5.3.2. Common Applications of SHM Systems

5.4. Non-Destructive Evaluation

5.4.1. NDE Techniques for Concrete Bridge Decks

5.4.2. NDE Using Remote Sensing Technologies

5.4.3. NDE Application Approaches

5.5. Finite Element Modelling (FEM)

6. Bridge Condition Rating Systems

7. Discussion

- It does not interrupt traffic;

- Captures in situ dynamic behaviour of the bridge undergoing in its normal service;

- Can be performed continuously, scheduled periodically, or triggered automatically; and

- Requires no special experimental arrangements. It should be noted that data collected using either NDE methods or SHM systems is the most reliable strategy to improve and update concrete bridge FEM assessment.

7.1. Challenges Requiring Further Research and Development

- The commonly used condition rating systems are qualitative in their definition, subjective in their evaluation, and are generally inadequate as a measure of bridge performance since they still largely depend on visual inspection [80];

- The BHI and Ontario BCI are easy to implement. Yet, their computations make them deterministic condition indices that do not take into account the inherent uncertainty associated with inspection results [101];

- The existing measurement methods for bridge displacement failed to realize long-term and real-time dynamic monitoring of bridge structures, essentially because of their low degree of automation and insufficient precision [52];

- There are discrepancies among the different load rating methods where the reasons for these differences should be addressed [36];

- Although NDE and SHM systems have become the most effective and significant aids for managing bridge infrastructure, there are a limited number of studies that address uncertainty in their measurements based on quantifiable data [102];

- Further work should be undertaken to demonstrate the accuracy of maturing and emerging sensors for use on SHM of bridge structures [103];

- At present, NDE methods, such as impact echo, radar, ultrasonic, resistivity and infrared are being commonly used for quantitative evaluation of bridge condition to augment visual inspection data [58]; and

- Most current research efforts aimed at verifying the capability of integrating NDE techniques to have objective condition assessment systems and determine bridge elements or components condition based on their resilience [81].

- A pre-fire risk assessment strategy should be developed to evaluate the susceptibility of a bridge to fire hazards [29].

- Defining solid criteria for the assessment of general bridge condition based on visual inspection;

- Advancing the use of NDE and SHM in mainstream bridge engineering;

- Developing various fully automated data collection systems based on integrated NDE techniques;

- Developing advanced and simplified data analysis and interpretation;

- Integrating of diverse monitoring systems;

- Developing innovative software for integrating SHM/NDE data and aiding in its interpretation;

- Developing correlations between the bridge damage and internal deterioration processes;

- Documenting the cost-benefit of the latest applied techniques and augmenting their future

- Considering the structural robustness and redundancy concepts in the bridge assessment process; and

- Focusing future research studies on most relevant problems. Indeed, fully automated data collection and interpretation analysis are the primary requirements to improve current BMSs.

7.2. Selection of Appropriate Condition Assessment Technique

- The mechanism of deterioration in the bridge being investigated;

- Expected output from the evaluation method;

- How the assessment data will be used;

- Level of complexity and available time to conduct the evaluation, and

- The geographic location as well as the traffic density and environmental conditions.

8. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hajializadeh, D.; Obrien, E.; O’Connor, A. Virtual structural health monitoring and remaining life prediction of steel bridges. Can. J. Civ. Eng. 2017, 44, 264–273. [Google Scholar] [CrossRef] [Green Version]

- Jannaty, M.; Eghbalzadeh, A.; Hosseini, S. Using field data to evaluate the complex bridge piers scour methods. Can. J. Civ. Eng. 2016, 43, 218–225. [Google Scholar] [CrossRef]

- Amini, A.; Melville, B.; Ali, T. Local scour at piled bridge piers including an examination of the superposition method. Can. J. Civ. Eng. 2014, 41, 461–471. [Google Scholar] [CrossRef]

- Prendergast, L.; Gavin, K. A review of bridge scour monitoring techniques. J. Rock Mech. Geotech. Eng. 2014, 6, 138–149. [Google Scholar] [CrossRef]

- Saviotti, A. Bridge Assessment, Management & Life Cycle Analysis. J. Mod. Appl. Sci. 2014, 8, 167–183. [Google Scholar]

- Newhook, P.; Edalatmanesh, R. Integrating reliability and structural health monitoring in the fatigue assessment of concrete bridge decks. J. Struct. Infrastruct. Eng. 2013, 9, 619–633. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, H.; OBrien, E.; Shao, X.; Tan, C. The influence of vehicle–tire contact force area on vehicle–bridge dynamic interaction. Can. J. Civ. Eng. 2016, 43, 769–772. [Google Scholar] [CrossRef]

- Elsaid, A.; Seracino, R. Rapid assessment of foundation scour using the dynamic features of bridge superstructure. J. Constr. Build. Mater. 2014, 50, 42–49. [Google Scholar] [CrossRef]

- Fisher, M.; Chowdhury, N.; Khan, A.; Atamturktur, S. An evaluation of scour measurement devices. J. Flow Meas. Instrum. 2013, 33, 55–67. [Google Scholar] [CrossRef]

- Zarafshan, A.; Iranmanesh, A.; Ansari, F. Vibration-based method and sensor for monitoring of bridge scour. J. Bridge Eng. 2012, 17, 829–838. [Google Scholar] [CrossRef]

- Coe, T.; Brandenberg, J. P-wave Reflection Imaging of a Cast-In-Steel-Shell Bridge Foundation. In Proceedings of the Geo-Frontiers Conference, Dallas, TX, USA, 13–16 March 2011. [Google Scholar]

- Briaud, L.; Hurlebaus, S.; Chang, K.; Yao, C.; Sharma, H.; Yu, O. Real-Time Monitoring of Bridge Scour Using Remote Monitoring Technology; Project; Texas Department of Transportation: Austin, TX, USA, 2011.

- Anderson, N.; Ismael, A.; Thitimakorn, T. Ground-penetrating radar: A tool for monitoring bridge scour. Environ. Eng. Geosci. 2007, 13, 1–10. [Google Scholar] [CrossRef]

- Zanjani, Z.; Patnaik, A. Finite element modeling of the dynamic response of a composite reinforced concrete bridge for structural health monitoring. Intern. J. Adv. Struct. Eng. 2014, 6, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Cai, S.; Pan, F.; Zhang, Y. Fatigue life estimation of existing bridges under vehicle and non-stationary hurricane wind. J. Wind Eng. Ind. Aerodyn. 2014, 133, 135–145. [Google Scholar] [CrossRef]

- Zhang, W.; Yuan, H. Corrosion fatigue effects on life estimation of deteriorated bridges under vehicle impacts. J. Eng. Struct. 2014, 71, 128–136. [Google Scholar] [CrossRef]

- Maekawa, K.; Fujiyama, C. Crack Water Interaction and Fatigue Life Assessment of RC Bridge Decks. In Proceedings of the 5th Biot Conference on Poromechanics, Vienna, Austria, 10–12 July 2013; pp. 2280–2289. [Google Scholar]

- Newhook, J.; Gaudet, J.; Edalatmanesh, R. Investigation of an externally restrained concrete bridge deck slab on a multi-girder bridge model. Can. J. Civ. Eng. 2011, 38, 233–241. [Google Scholar] [CrossRef]

- Edalatmanesh, R. Structural Health Monitoring Model for Fatigue Assessment in Concrete Bridge Decks. Ph.D. Thesis, Dalhousie University, Halifax, NS, Canada, 2010; 288p. [Google Scholar]

- Butt, S.; Limaye, V.; Newhook, J. Acoustic survey method to map damage in concrete bridge deck slabs. J. Acoust. Emiss. 2007, 25, 373–378. [Google Scholar]

- Muntasir, A.; Billah, L.; Alam, M. Seismic fragility assessment of highway bridges: A state-of-the-art review. J. Struct. Infrastruct. Eng. 2015, 11, 804–832. [Google Scholar] [CrossRef]

- Attary, N.; Symans, M.; Nagarajaiah, S. Performance Assessment of a Highway Bridge Structure Employing Adaptive Negative Stiffness for Seismic Protection. In Structures Congress 2013: Bridging Your Passion with Your Profession; American Society of Civil Engineers: Reston, VA, USA, 2013; pp. 1736–1746. [Google Scholar]

- Biondini, F.; Frangopol, D. Time effects on robustness and redundancy of deteriorating concrete structures. In Proceedings of the 11th International Conference on Structural Safety and Reliability, New York, NY, USA, 16–20 June 2013; pp. 1–13. [Google Scholar]

- Nogami, Y.; Akiyama, M.; Frangopol, D. Seismic design of RC bridge piers to ensure the post-disaster functionality of road network. In Proceedings of the 11th International Conference on Structural Safety and Reliability, New York, NY, USA, 16–20 June 2013; pp. 3581–3586. [Google Scholar]

- Lau, T.; Waller, L.; Vishnukanthan, K.; Sivathayalan, S. Fragility relationships for probabilistic performance-based seismic risk assessment of bridge inventories. In Proceedings of the Annual Conference-Canadian Society for Civil Engineering, Edmonton, AB, Canada, 6–9 June 2012; Volume 4, pp. 2765–2774. [Google Scholar]

- Taner, Y.; Caner, A. Target damage level assessment for seismic performance evaluation of two-column reinforced concrete bridge bents. J. Bridge Struct. 2012, 8, 135–146. [Google Scholar]

- Ozbulut, E.; Hurlebaus, S. Seismic assessment of bridge structures isolated by a shape memory alloy/rubber-based isolation system. J. Smart Mater. Struct. 2011, 20, 1–12. [Google Scholar] [CrossRef]

- Do Hyung, L.; Joonam, P.; Kihak, L.; Byeong, K. Nonlinear seismic assessment for the post-repair response of RC bridge piers. J. Compos. Part B 2011, 42, 1318–1329. [Google Scholar]

- Naser, M.; Kodur, V. A probabilistic assessment for classification of bridges against fire hazard. J. Fire Saf. 2015, 76, 65–73. [Google Scholar] [CrossRef] [Green Version]

- Garlock, M.; Paya-Zaforteza, I.; Kodur, V.; Gu, L. Fire hazard in bridges: Review, assessment and repair strategies. J. Eng. Struct. 2012, 35, 89–98. [Google Scholar] [CrossRef]

- Akula, M.; Zhang, Y.; Kamat, V.; Lynch, J. Leveraging Structural Health Monitoring for Bridge Condition Assessment. In Proceedings of the Construction Research Congress, Atlanta, GA, USA, 19–21 May 2014; pp. 1159–1168. [Google Scholar]

- Moore, M.; Phares, B.; Graybeal, B.; Rolander, D.; Washer, G. Reliability of Visual Inspection for Highway Bridges; Final Report No. FHWA-RD-01-020; Federal Highway Administration (FHWA): Washington, DC, USA, 2001; Volume 1.

- Agdas, D.; Rice, J.; Martinez, J.; Lasa, I. Comparison of Visual Inspection and SHM as Bridge Condition Assessment Methods. J. Perform. Constr. Facil. 2015, 30, 04015049. [Google Scholar] [CrossRef]

- AASHTO. Manual for Bridge Evaluation, 2nd ed.; AASHTO: Washington, DC, USA, 2011. [Google Scholar]

- Zhang, Q.; Alam, M.; Khan, S.; Jiang, J. performance-based design as per Canadian Highway Bridge Design Code (CHBDC) 2014. Can. J. Civ. Eng. 2016, 43, 741–748. [Google Scholar] [CrossRef]

- Wang, N.; Ellingwood, R.; Zureick, H. Bridge rating using system reliability assessment. II: Improvements to bridge rating practices. J. Bridge Eng. 2011, 16, 863–871. [Google Scholar] [CrossRef]

- Mosavi, A.; Sedarat, H.; O’Connor, M.; Emami, A.; Lynch, J. Calibrating a high-fidelity finite element model of a highway bridge using a multi-variable sensitivity-based optimization approach. J. Struct. Infrastruct. Eng. 2014, 10, 627–642. [Google Scholar] [CrossRef]

- Cruz, J.; Roca, J.; Escusa, G.; Carvalho, J. An alternative system for measuring displacements in bridges by using displacement transducers. In Proceedings of the 3rd conference on Smart Monitoring Assessment and Rehabilitation of Civil Structures, Antalya, Turkey, 7–9 September 2015; pp. 1–13. [Google Scholar]

- Chen, Y.; Feng, M.; Tan, C. Bridge Structural Condition Assessment Based on Vibration and Traffic Monitoring. J. Eng. Mech. 2009, 135, 747–758. [Google Scholar] [CrossRef]

- Alampalli, S. Special Issue on Non-destructive Evaluation and Testing for Bridge Inspection and Evaluation. J. Bridge Eng. 2012, 17, 827–828. [Google Scholar] [CrossRef]

- Wong, K. Design of a structural health monitoring system for long-span bridges. J. Struct. Infrastruct. Eng. 2007, 3, 169–185. [Google Scholar] [CrossRef]

- Feng, D.; Feng, M. Computer vision for SHM of civil infrastructure: From dynamic response measurement to damage detection—A review. J. Eng. Struct. 2018, 156, 105–117. [Google Scholar] [CrossRef]

- Park, K.; Kim, S.; Park, H.; Lee, K. The determination of bridge displacement using measured acceleration. J. Eng. Struct. 2005, 27, 371–378. [Google Scholar] [CrossRef]

- Glisic, B.; Inaudi, D.; Nan, C. Pile monitoring with fiber optic sensors during axial compression, pullout, and flexure tests. J. Transp. Res. Board 2002, 1808, 11–20. [Google Scholar] [CrossRef]

- Palazzo, D.; Friedmann, R.; Nadal, C.; Santos, F.M.; Veiga, L. Dynamic monitoring of structures using a robotic total station. In Proceedings of the Shaping the Change XXIII FIG Congress, Munich, Germany, 8–13 October 2006; pp. 1–10. [Google Scholar]

- Cosser, E.; Roberts, G.; Meng, X.; Dodson, A. The comparison of single frequency and dual frequency GPS for bridge deflection and vibration monitoring. In Proceedings of the 11th International Symposium on Deformation Measurements, Santorini, Greece, 25–28 May 2014; pp. 1–8. [Google Scholar]

- Chan, T.; Ashebo, D.; Tam, H.; Yu, Y.; Chan, T.; Lee, P. Vertical displacement measurements for bridges using optical fiber sensors and CCD cameras: A preliminary study. J. Struct. Health Monit. 2009, 8, 243–249. [Google Scholar] [CrossRef]

- Bell, E.; Peddle, J.; Goudreau, A. Bridge Condition Assessment using Digital Image Correlation and Structural Modeling. In Proceedings of the 6th International IABMAS Conference, Stresa, Lake Maggiore, Italy, 8–12 July 2012; pp. 330–338. [Google Scholar]

- Guan, S.; Rice, J.; Li, C.; Wang, G. Bridge deflection monitoring using small, low-cost radar sensors. In Proceedings of the Structures Congress, ASCE, Boston, MA, USA, 3–5 April 2014; pp. 2853–2862. [Google Scholar]

- Raghavan, A.; Cesnik, C.E. Review of guided-wave structural health monitoring. Shock Vib. Digest J. 2007, 39, 91–116. [Google Scholar] [CrossRef]

- Gordon, S.J.; Lichti, D.D. Modeling Terrestrial Laser Scanner Data for Precise Structural Deformation Measurement. J. Surv. Eng. 2007, 133, 72–80. [Google Scholar] [CrossRef]

- Zhao, X.; Liu, H.; Yu, Y.; Xu, X.; Hu, W.; Li, M.; Ou, J. Bridge Displacement Monitoring Method Based on Laser Projection-Sensing Technology. J. Sens. 2015, 15, 8444–8463. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bao, Y.; Li, H.; Sun, X.; Yu, Y.; Ou, J. Compressive sampling–based data loss recovery for wireless sensor networks used in civil SHM. J. Struct. Health Monit. 2013, 12, 78–95. [Google Scholar] [CrossRef]

- Higuera, M.; Rodriguez, L.; Quintela, A.; Cobo, A. Fiber optic sensors in structural health monitoring. J. Light Wave Technol. 2011, 29, 587–608. [Google Scholar] [CrossRef]

- O’Connor, S.; Lynch, J.; Gilbert, A. Compressed sensing embedded in an operational wireless sensor network to achieve energy efficiency in monitoring applications. J. Smart Mater. Struct. 2012, 23, 1–17. [Google Scholar] [CrossRef]

- Olsen, J.; Chen, Z.; Hutchinson, T.; Kuester, F. Optical Techniques for Multiscale Damage Assessment. J. Geomat. Nat. Hazards Risk 2013, 4, 49–70. [Google Scholar] [CrossRef]

- Guldur, B.; Yan, Y.; Hajjar, J. Condition Assessment of Bridges Using Terrestrial Laser Scanners. In Proceedings of the Structures Congress, Portland, OR, USA, 23–25 April 2015; pp. 355–367. [Google Scholar]

- Laory, I.; Hadj, N.; Trinh, T.; Smith, I. Measurement System Configuration for Damage Identification of Continuously Monitored Structures. J. Bridge Eng. 2012, 17, 857–866. [Google Scholar] [CrossRef] [Green Version]

- Huntley, S.A.; Valsangkar, A.J. Behaviour of H-piles supporting an integral abutment bridge. Can. Geotech. J. 2014, 51, 713–734. [Google Scholar] [CrossRef]

- Hu, X.; Wang, B. A Wireless Sensor Network-Based Structural Health Monitoring System for Highway Bridges. J. Comput. Aided Civ. Infrastruct. Eng. 2013, 28, 193–209. [Google Scholar] [CrossRef]

- Gucunski, N.; Imani, A.; Romero, F.; Nazarian, S.; Yuan, D.; Wiggenhauser, H. Non-destructive testing to identify concrete bridge deck deterioration. In Proceedings of the 92nd Meet, TRB, Washington, DC, USA, 13–17 January 2013. SHRP 2 Report. [Google Scholar]

- Yehia, S.; Abudayyeh, O.; Nabulsi, S.; Abdel-Qader, I. Detection of Common Defects in Concrete Bridge Decks Using NDE Techniques. J. Bridge Eng. 2007, 12, 215–225. [Google Scholar] [CrossRef]

- Pradhan, B.; Bhattacharjee, B. Half-Cell Potential as an Indicator of Chloride-Induced Rebar Corrosion Initiation in RC. J. Mater. Civ. Eng. 2009, 21, 543–552. [Google Scholar] [CrossRef]

- Brown, D. Mechanisms of corrosion of steel in concrete in relation to design, inspection, and repair of offshore and coastal structures. ACI Spec. Publ. 1980, 65, 169–204. [Google Scholar]

- Varnavina, A.; Khamzin, A.; Torgashov, E.; Sneed, L.; Goodwin, B.; Anderson, N. Data acquisition and processing parameters for concrete bridge deck condition assessment using ground-coupled ground penetrating radar. J. Appl. Geophys. 2015, 114, 123–133. [Google Scholar] [CrossRef]

- Cady, P.D.; Gannon, E.J. Condition Evaluation of Concrete Bridges Relative to Reinforcement Corrosion. Volume 8: Procedure Manual; SHRP-S/FR-92-110; NRC: Washington, DC, USA, 1992; 124p. [Google Scholar]

- Nazarian, S.; Baker, R.; Crain, K. Development and Testing of a Seismic Pavement Analyzer; Report SHRP-H-375, Strategic Highway Research Program; NRC: Washington, DC, USA, 1993; 169p. [Google Scholar]

- Kee, S.; Oh, T.; Popovics, J.; Arndt, R.; Zhu, J. Nondestructive Bridge Deck Testing with Air-Coupled Impact-Echo and Infrared Thermography. J. Bridge Eng. 2012, 17, 928–939. [Google Scholar] [CrossRef]

- Parisa, S.; Julia, W.; Herbert, W. Detection of Delamination in Concrete Bridge Decks by Joint Amplitude and Phase Analysis of USA Measurements. J. Bridge Eng. 2013, 19, 1–11. [Google Scholar]

- Krause, M.; Mayer, K.; Friese, M.; Milmann, B.; Mielentz, F.; Ballier, G. Progress in ultrasonic tendon ducts imaging. In Proceedings of the 7th International Symposium NDT in Civil Engineering (NDTCE 09), Nantes, France, 30 June–3 July 2009; pp. 147–154. [Google Scholar]

- Washer, G.; Fenwick, R.; Bolleni, N.; Harper, J. Effects of environmental variable on infrared imaging subsurface features of concrete bridges. J. Transp. Res. Record 2009, 2108, 107–114. [Google Scholar] [CrossRef]

- Seong, K.; Taekeum, O.; Popovics, S.; Arndt, W.; Zhu, J. Non-destructive Bridge Deck Testing with Air-Coupled IE and IR Thermography. J. Bridge Eng. 2012, 17, 928–939. [Google Scholar]

- Adhikari, S.; Moselhi, O.; Bagchi, A. Automated Prediction of Condition State Rating in Bridge Inspection. J. Gerontechnol. 2012, 11, 81–88. [Google Scholar]

- Vaghefi, K.; Oats, R.; Harris, D.; Ahlborn, T.; Brooks, C. Evaluation of Commercially Available Remote Sensors for Highway Bridge Condition Assessment. J. Bridge Eng. 2012, 17, 886–895. [Google Scholar] [CrossRef] [Green Version]

- Abudayyeh, O.; Al-Bataineh, M.; Abdel-Qader, I. An Imaging Data Model for Concrete Bridge Inspection. J. Adv. Eng. Softw. 2004, 35, 473–480. [Google Scholar] [CrossRef]

- Ahlborn, M.; Vaghefi, K.; Harris, D.; Brooks, C. Measurement and communication of bridge performance with remote sensing technologies. J. Transp. Res. Rec. 2012, 2292, 141–149. [Google Scholar] [CrossRef]

- Sanayei, M.; Phelps, J.; Sipple, J.; Bell, E.; Brenner, B. Instrumentation NDT & FEM Updating for Bridge Evaluation Using Strain measurements. J. Bridge Eng. 2012, 17, 130–138. [Google Scholar]

- Hinzen, G. Support of Macroseismic Documentation by Data from Google Street View. J. Seismol. Res. Lett. 2013, 84, 982–990. [Google Scholar] [CrossRef]

- Huston, D.; Cui, J.; Burns, D.; Hurley, D. Concrete bridge deck condition assessment with automated multi-sensor techniques. J. Struct. Infrastruct. Eng. 2011, 7, 1–11. [Google Scholar]

- Gucunski, N.; Kee, S.; La, H.; Basily, B.; Maher, A.; Ghasemi, H. Implementation of a Fully Autonomous Platform for Assessment of Concrete Bridge Decks RABIT. In Proceedings of the Structures Congress, Portland, OR, USA, 23–25 April 2015; pp. 367–378. [Google Scholar]

- Pailes, B. Damage Identification, Progression, and Condition Rating of Bridge Decks Using Multi-Modal Non-Destructive Testing. Ph.D. Thesis, Rutgers, The State University of New Jersey, New Brunswick, NJ, USA, 2014; 184p. [Google Scholar]

- Alt, D.; Meggers, D. Determination of Bridge Deck Subsurface Anomalies Using Infrared Thermography and Ground Penetrating Radar; Report FHWA-KS-96-2; Kansas Department of Transportation: Topeka, KS, USA, 1996; 18p.

- Barnes, C.; Trottier, J. Ground-penetrating radar for network-level concrete deck repair management. J. Transp. Eng. 2000, 126, 257–262. [Google Scholar] [CrossRef]

- Scott, M.; Rezaizadeh, A.; Delahaza, A.; Santos, G.; Moore, M. A comparison of NDE methods for bridge deck assessment. J. NDT E Int. 2003, 36, 245–255. [Google Scholar] [CrossRef]

- Clark, M.R.; McCann, D.M.; Forde, M.C. Application of infrared thermography to the non-destructive testing concrete and masonry bridges. J. NDT E Int. 2003, 36, 265–275. [Google Scholar] [CrossRef]

- Zheng, Y.H.; Ng, K.E. Evaluation of concrete structures by advances non-destructive test methods-impact echo, impulse response test and radar survey. In Proceedings of the NDT-CE Conference, Berlin, Germany, 16–19 September 2003. [Google Scholar]

- Wood, J.C.; Rens, K.L. Non-destructive testing of the Lawrence Street Bridge. In Proceedings of the Structures Congress: Structural Engineering and Public Safety, St. Louis, MI, USA, 18–21 May 2006; Cross, B., Finke, J., Eds.; ASCE: Reston, VA, USA, 2006; pp. 1–15. [Google Scholar]

- Algernon, D.; Hiltunen, R.; Ferraro, C.; Ishee, C. Rebar detection with cover meter and ultrasonic pulse echo combined with automated scanning system. J. Transp. Res. Rec. 2011, 2251, 123–131. [Google Scholar] [CrossRef]

- Arndt, R.; Jalinoos, F.; Cui, J.; Huston, D. Periodic NDE for bridge maintenance. In Proceedings of the Structural Faults and Repair Conference, Edinburgh, UK, 15–17 June 2010. [Google Scholar]

- Oh, T.; Kee, S.; Arndt, R.; Popovics, J.S.; Zhu, J. Comparison of NDT methods for assessment of a concrete bridge deck. J. Eng. Mech. 2013, 139, 305–314. [Google Scholar] [CrossRef]

- Sousa, H.; Bento, J.; Figueiras, J. Assessment and Management of Concrete Bridges Supported by Monitoring Data-Based Finite-Element Modeling. J. Bridge Eng. 2014, 19, 1–12. [Google Scholar] [CrossRef]

- Xia, P.; Brownjohn, J. Bridge Structural Condition Assessment Using Systematically Validated Finite-Element Model. J. Bridge Eng. 2005, 9, 418–423. [Google Scholar] [CrossRef]

- Alani, A.; Aboutalebi, M.; Kilic, G. Integrated health assessment strategy using NDT for reinforced concrete bridges. J. NDT E Int. 2013, 61, 80–94. [Google Scholar] [CrossRef]

- Ghodoosi, F.; Bagchi, A.; Zayed, T. System-Level Deterioration Model for Reinforced Concrete Bridge Decks. J. Bridge Eng. 2015, 20, 1–10. [Google Scholar] [CrossRef]

- Ghodoosi, F.; Bagchi, A.; Zayed, T. Reliability-Based Condition Assessment of an Externally Restrained Bridge Deck Considering Uncertainties in Key Design Parameters. J. Perform. Constr. Facil. 2014, 30, 04014189. [Google Scholar] [CrossRef]

- Nasrollahi, M.; Washer, G. Estimating Inspection Intervals for Bridges Based on Statistical Analysis of National Bridge Inventory Data. J. Bridge Eng. 2014, 11, 1–11. [Google Scholar] [CrossRef]

- FHWA. Recording and Coding Guide for the Structure Inventory and Appraisal of the Nation’s Bridges; FHWA-PD-96-001; Federal Highway Administration, U.S. Department of Transportation: Washington, DC, USA, 1995.

- Bektas, B.; Carriquiry, A.; Smadi, O. Using Classification Trees for Predicting National Bridge Inventory Condition Ratings. J. Infrastruct. Syst. 2013, 19, 425–433. [Google Scholar] [CrossRef]

- Reardon, M.F.; Chase, S. Migration of Element-Level Inspection Data for Bridge Management System. In Proceedings of the TRB, 95th Annual Meeting, Washington, DC, USA, 10–14 January 2016; pp. 1–15. [Google Scholar]

- Ontario Structure Inspection Manual-OSIM; Ontario Ministry of Transportation: St. Catharines, ON, Canada, 2008; 394p.

- Dinh, K.; Zayed, T.; Romero, F.; Tarussov, A. Method for Analyzing Time-Series GPR Data of Concrete Bridge Decks. J. Bridge Eng. 2015, 20, 1–8. [Google Scholar] [CrossRef]

- Hesse, A.; Atadero, R.; Ozbek, M. Uncertainty in Common NDE Techniques for Use in Risk-Based Bridge Inspection Planning: Existing Data. J. Bridge Eng. 2015, 20, 1–8. [Google Scholar] [CrossRef]

- Webb, G.; Vardanega, P.; Middleton, C. Categories of SHM deployments: Technologies and capabilities. J. Bridge Eng. 2015, 20, 04014118. [Google Scholar] [CrossRef]

| Performance Indicator | Evaluation Technique | Reference | Year |

|---|---|---|---|

| Scour Assessment | Bridge Dynamic Response (BDR) | [8] | 2014 |

| Sound Wave Devices (SWD) | [9] | 2013 | |

| Driven Rod Device and Strain-Sensor (DRD) | [10] | 2012 | |

| Fibre-Optic Bragg Grating Sensors (FBG) | [10] | 2012 | |

| Ultrasonic P-Wave Reflection Imaging (URI) | [11] | 2011 | |

| Single-Use Devices (SUD) | [12] | 2011 | |

| Ground Penetrating Radar (GPR) | [13] | 2007 | |

| Electrical Conductivity Devices (ECD) | [13] | 2007 | |

| Fatigue and Fracture Assessment | Bridge Dynamic Response Using FEM (BDR) | [14] | 2014 |

| Vehicle-Bridge-Wind Dynamic System (VWDS) | [15] | 2014 | |

| Corrosion-Fatigue Strength Reduction (CFSR) | [16] | 2014 | |

| Integrating Reliability and SHM (IR-SHM) | [6] | 2013 | |

| Crack Water Interaction (CWI) | [17] | 2013 | |

| Static Ultimate Testing (SUT) | [18] | 2011 | |

| Fatigue Damage Accumulation (FDA) | [19] | 2010 | |

| Acoustic Survey-Crack Monitoring (AS-CM) | [20] | 2007 | |

| Seismic Assessment | Seismic Fragility Analysis (SFA) | [21] | 2015 |

| Negative Stiffness Devices (NSD) | [22] | 2013 | |

| Probabilistic Static Analyses (PSA) | [23] | 2013 | |

| Seismic Design of RC Bridges | [24] | 2013 | |

| Probabilistic Performance Analysis (PPA) | [25] | 2012 | |

| Target Damage Level (TDL) | [26] | 2011 | |

| Rubber-Based Isolation System (RIS) | [27] | 2011 | |

| Post Repair Response (PRR) | [28] | 2010 |

| Monitoring System | Advantages and Limitations |

|---|---|

| Displacement Sensors [43] |

|

| Acceleration Sensors [43] |

|

| Strain Sensors [44] |

|

| Robotic Total Station [45] |

|

| GPS Satellite-Surveying [46] |

|

| Motion Detection Cameras [47] |

|

| Digital Image Cross-Correlation [48] |

|

| Radar Sensors [49] |

|

| Laser Doppler Vibrometer [50] |

|

| Terrestrial Laser Scan [51] |

|

| Laser Projection Sensing [52] |

|

| Technique | Physical Phenomena | Applications | Advantages and Limitations |

|---|---|---|---|

| Impact Echo (IE) |

|

|

|

| Ultrasonic Pulse Echo (UPE) |

|

|

|

| Half-Cell Potential (HCP) |

|

|

|

| Ground Penetrating Radar (GPR) |

|

|

|

| Infrared Thermography (IRT) |

|

|

|

| Techniques Utilized | Objective of the Study | Reference | Year |

|---|---|---|---|

| Infrared, Radar | Delamination Detection | [82] | 1996 |

| Radar, Chain Drag, Half-Cell Potential | Damage Detection | [83] | 2000 |

| Impact Echo, Radar, Chain Drag | Comparative Study | [84] | 2003 |

| Infrared, Chain Drag | Delamination Detection | [85] | 2003 |

| Radar, Impact Echo, Dynamic Response | Damage Detection | [86] | 2003 |

| Radar, Ultrasonic Echo, Hammer Sounding | Comparative Study | [87] | 2006 |

| Impact Echo, Radar, Infrared | Comparative Study | [62] | 2007 |

| Impact Echo, Ultrasonic Echo | Measuring Thickness | [88] | 2011 |

| Ultrasonic Echo, Radar, Infrared, Half-Cell Potential | Comparative Study | [89] | 2010 |

| Impact Echo, Radar, Half-Cell, Ultrasonic Surface Waves, Electrical Resistivity, Infrared, Pulse Echo, Impulse Response | Comparative Study | [61] | 2013 |

| Impact Echo, Infrared, Chain Drag | Damage Detection | [90] | 2013 |

| Technique | Description, Advantages and Limitations |

|---|---|

| Visual Inspection (VI) | Description: trained engineers recognize, register, and evaluate the physical condition of different bridge elements using inspection manuals and defined codes. The primary and most common interval for inspections is 24 months. Advantages: the most significant aid for bridge condition evaluation. BMSs rely primarily on VI to record bridge component condition ratings, which are quantified and standardized through a priority-ranking procedure. Limitations: subjective evaluation; results greatly depend on the qualifications of those conducting inspections; the findings may not be identical. Consider only the observed physical health of the bridge and cannot detect hidden defects. |

| Load Testing Response (LTR) | Description: determine the live-load carrying capacity of an existing bridge by measuring the actual load the bridge can carry without distress. Condition ratings can be determined by allowable stress, load factor, or load and resistance factor methods. Advantages: safe conservative analysis methods. The governing rating is the lesser of the shear capacity of the critical bridge component. Development and updating the load rating software is undertaken by AASHTO. Limitations: costly and time consuming. The three rating methods may lead to differently rated capacities and posting limits for the same bridge. No guidance as to which method should be used for specific circumstances. |

| Structure Health Monitoring (SHM) | Description: encompasses a range of methods and practices designed to capture structural response, detect anomalous behaviour, and to assess the bridge condition based on a combination of measurement, modelling and analysis. Advantages: reliable and potentially real-time bridge assessment. More meaningful than using load response data. Can be deployed for short-term and long-term assessment. Appropriate for movable bridges than any other method. Limitations: wireless sensors rely on battery power. The size and complexity of the bridge being monitored could result in complex systems. SHM systems often create liability issues. Require routine, on-site maintenance to sustain long-term operation. |

| Non-Destructive Evaluation (NDE) | Description: a number of techniques introduced exploit various physical phenomena (acoustic, seismic, electric, electromagnetic, and thermal, etc.) to detect and characterize deterioration processes without damaging the elements. Advantages: provide effective, and accurate condition assessment. Objectify the inspection process and make it faster and more reliable. Integration of different techniques is the best approach to identify several different damage states. Limitations: applying only one technology provides limited information about the bridge condition. No single technology is capable of identifying all of the various deterioration phenomena. Require trained personnel for data collection and analysis. |

| Finite Element Modelling (FEM) | Description: numerical analysis to investigate the behaviour and response of a bridge structural system. Usually calibrated using results of field inspection supported by NDE technologies or by static or dynamic tests on the structure. Advantages: allows detailed visualization, can be created using data from visual inspection and then parameterised and calibrated using information from NDE and SHM results. A FEM is able to satisfactorily capture short-term performance (e.g., load tests). Limitations: FE models typically require calibration. Long-term assessment is a challenge due to advances in structural materials and construction methods. |

| Concerned Assessment | Investigation Method |

|---|---|

| Map patterns of distress such as surface cracks, spalling, scaling, and erosion | Integrated visual inspection and remote sensing technologies. |

| Scour damage | Vibration based techniques, scour sensors. |

| Fatigue damage | Acoustic emission techniques (stress waves). |

| Potential of corrosion | Half-Cell Potential, electrical resistivity |

| Delamination and cracks detection | Air-coupled impact-echo and infrared thermography. |

| Corrosion detection in prestressing strands (in adjacent concrete box-beam bridges) | Magnetic techniques (using magnetic reluctance meters). |

| Damages in long-span suspension bridges | Health monitoring techniques (using strain sensors) and FEM. |

| Initial yield in posttensioned concrete beams | Acoustic emission techniques (stress waves). |

| Subsurface defects in superstructure components | Remote sensing and health monitoring technologies. |

| Unknown foundation depth, integrity and type. | Parallel seismic and ultra-seismic techniques. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Omar, T.; Nehdi, M.L. Condition Assessment of Reinforced Concrete Bridges: Current Practice and Research Challenges. Infrastructures 2018, 3, 36. https://0-doi-org.brum.beds.ac.uk/10.3390/infrastructures3030036

Omar T, Nehdi ML. Condition Assessment of Reinforced Concrete Bridges: Current Practice and Research Challenges. Infrastructures. 2018; 3(3):36. https://0-doi-org.brum.beds.ac.uk/10.3390/infrastructures3030036

Chicago/Turabian StyleOmar, Tarek, and Moncef L. Nehdi. 2018. "Condition Assessment of Reinforced Concrete Bridges: Current Practice and Research Challenges" Infrastructures 3, no. 3: 36. https://0-doi-org.brum.beds.ac.uk/10.3390/infrastructures3030036