Blast Loading Response of Reinforced Concrete Panels Externally Reinforced with Steel Strips

Abstract

:1. Introduction

Research Significance

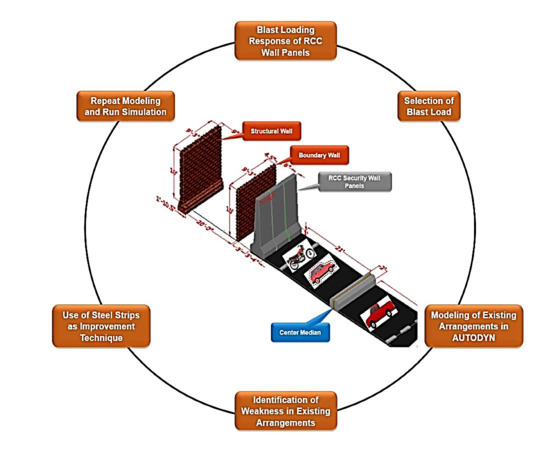

2. Methodology

2.1. Description of Blast Protection Wall Panels

2.2. Material Properties

2.3. Location of Gauges

2.4. Techniques Being Used for Strengthening/Retrofitting of Structures against Blast Loading

- Aramid fiber reinforced plastics (AFRP) [5]

- Fiber reinforced polymers (FRP) [6]

- Ultra-high performance fiber reinforced concrete [7]

- Glass fiber reinforced polymers [8]

- Carbon fiber reinforced polymers [9]

- Polyurethane elastomers [10]

- Steel jacketing [11]

- Strain hardening cementations composites [12]

- Steel plates [13]

- Glass curtain walls [14]

- FRP composites [19]

- Use of GFRP [21]

2.5. Weaknesses Observed in Existing Arrangements

- The base of the RCC wall panel is not fixed

- Intermediate space between RCC wall panels

- RCC wall panels not designed for blast loading

2.6. The Technique Used for Improvement of the Existing Structure against Blast Loading

- Drill hole with drill bit

- Install anchor

- Hammer in anchor

3. Results and Discussions

3.1. Displacement Time Relationship

3.1.1. Case I: Explosion at Face of RCC Wall Panels

- For 50 kg TNT explosion, displacement of RCC wall panel reduces from 78 mm to 0.42 mm

- For 100 kg TNT explosion, displacement of RCC wall panel reduces from 175 mm to 0.62 mm

- For 50 kg TNT explosion, displacement of structural wall reduces from 20 mm to 0.11 mm

- For 100 kg TNT explosion, displacement of structural wall reduces from 41 mm to 0.14 mm

3.1.2. Case II: Explosion at Distance of 10 ft from RCC Wall Panels

- For 50 kg TNT explosion, displacement of RCC wall panels reduces from 48 mm to 0.18 mm

- For 100 kg TNT explosion, displacement of RCC wall panels reduces from 76 mm to 0.42 mm

- For 50 kg TNT explosion, displacement of structural wall reduces from 15 mm to 0.07 mm

- For 100 kg TNT explosion, displacement of structural wall reduces from 17 mm to 0.12 mm

3.2. Pressure Time History

3.2.1. Case I: Explosion at Face of RCC Wall Panels

3.2.2. Case II: Explosion at Distance of 10 ft from RCC Wall Panels

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ding, C.; Ngo, T.; Mendis, P.; Lumantarna, R.; Zobec, M. Dynamic response of double skin façades under blast loads. Eng. Struct. 2016, 123, 155–165. [Google Scholar] [CrossRef]

- Yao, S.; Zhang, D.; Chen, X.; Lu, F.; Wang, E. Experimental and numerical study on the dynamic response of RC slabs under blast loading. Eng. Fail. Anal. 2016, 66, 120–129. [Google Scholar] [CrossRef]

- Li, J.; Wu, C.; Hao, H.; Wang, Z.; Su, Y. Experimental investigation of ultra-high performance concrete slabs under contact explosions. Int. J. Impact Eng. 2016, 93, 62–75. [Google Scholar] [CrossRef] [Green Version]

- Codina, R.; Ambrosini, D.; de Borbon, F. Experimental and numerical study of a RC member under a close-in blast loading. Eng. Struct. 2016, 127, 145–158. [Google Scholar] [CrossRef]

- Kong, X.; Qo, X.; Gu, Y.; Lawam, I.A.; Qu, Y. Numerical evaluation of blast resistance of RC slab strengthened with AFRP. Constr. Build. Mater. 2018, 178, 244–253. [Google Scholar] [CrossRef]

- Chundawat, T.S.; Vaya, D.; Sini, N.K.; Varma, I.K. Blast mitigation using FRP retrofitting and coating techniques. Polym. Compos. 2018, 39, 1389–1402. [Google Scholar] [CrossRef]

- Aoude, H.; Frederic, P.D.; Burell, R.P.; Saatcioglu, M. Behavior of ultra-high performance fiber reinforced concrete columns under blast loading. Int. J. Impact Eng. 2015, 80, 185–202. [Google Scholar] [CrossRef]

- Jacques, E.; Lloyd, A.; Asce, A.M.; Imbeau, P.; Palermo, D.; Asce, A.M. GFRP-Retrofitted Reinforced Concrete Columns Subjected to Simulated Blast Loading. J. Struct. Eng. 2015, 141, 04015028. [Google Scholar] [CrossRef]

- Chen, L.; Fang, Q.; Fan, J.; Zhang, Y.; Hao, H.; Liu, H. Responses of masonry infill walls retrofitted with CFRP, steel wire mesh and laminated bars to blast loadings. Adv.Struct. Eng. 2014, 17, 817–836. [Google Scholar] [CrossRef]

- Somarathna, H.; Raman, S.N.; Badri, K.H.; Mutalib, A.A. Mechanical characterization of polyurethane elastomers: For retrofitting application against blast effects. In Proceedings of the 3rd Conference on Smart Monitoring, Assessment and Rehabilitation of Structures (SMAR2015), Antalya, Turkey, 7 September 2015. [Google Scholar]

- Codina, R.; Ambrosini, D.; de Borbón, F. Alternatives to prevent the failure of RC members under close-in blast loadings. Eng. Fail. Anal. 2016, 60, 96–106. [Google Scholar] [CrossRef]

- Adhikary, S.D.; Chandra, L.R.; Christian, A.; Ong, K.C.G. SHCC-strengthened RC panels under near-field explosions. Constr. Build. Mater. 2018, 183, 675–692. [Google Scholar] [CrossRef]

- Chen, J.; Teng, J. Anchorage strength models for FRP and steel plates bonded to concrete. J. Struct. Eng. 2001, 127, 784–791. [Google Scholar] [CrossRef]

- Jie, G.; Guoqiang, L. Dynamic analysis of glass curtain walls with protective films subjected to blast loading. Int. J. Struct. Eng. 2012, 3, 160–169. [Google Scholar] [CrossRef]

- Lin, X.; Zhang, Y.; Hazell, P.J. Modelling the response of reinforced concrete panels under blast loading. Mater. Des. (1980–2015) 2014, 56, 620–628. [Google Scholar] [CrossRef]

- Yusof, M.A.; Rosdi, R.N.; Ismail, A.; Yahya, M.A.; Peng, N.C. Simulation of reinforced concrete blast wall subjected to air blast loading. J. Asian Sci. Res. 2014, 4, 522–533. [Google Scholar]

- Smith, P. Blast walls for structural protection against high explosive threats: A review. Int. J. Prot. Struct. 2010, 1, 67–84. [Google Scholar] [CrossRef]

- Luccioni, B.; Ambrosini, R.; Danesi, R. Analysis of building collapse under blast loads. Eng. Struct. 2004, 26, 63–71. [Google Scholar] [CrossRef]

- Buchan, P.; Chen, J. Blast resistance of FRP composites and polymer strengthened concrete and masonry structures—A state of the art review. Compos. Part B Eng. 2007, 38, 509–522. [Google Scholar] [CrossRef]

- Rasheed, A.; Farooq, S.H.; Usman, M.; Hanif, A.; Khan, N.A.; Khushnood, R.A. Structural reliability analysis of superstructure of highway bridges on China-Pakistan Economic Corridor (CPEC): A case study. J. Struct. Integr. Maint. 2018, 3, 197–207. [Google Scholar] [CrossRef]

- Razaqpur, A.G.; Tolba, A.; Contestabile, E. Blast loading response of reinforced concrete panels reinforced with externally bonded GFRP laminates. Compos. Part B Eng. 2007, 38, 535–546. [Google Scholar] [CrossRef]

- Farooq, H.; Usman, M.; Mehmood, K.; Malik, M.S.; Hanif, A. Effect of Steel Confinement on Axially Loaded Short Concrete Columns. IOP Conf. Ser. Mater.Sci.Eng. 2018, 414, 012026. [Google Scholar] [CrossRef]

- Farooq, S.H.; Ilyas, M.; Ghaffar, A. Technique for strengthening of masonry wall panels using steel strips. Asian J. Civil Eng. (Build. Hous.) 2006, 7, 621–638. [Google Scholar]

- Terrorist Activities in Last Decade and Accessed. Available online: http://www.pakistanbodycount.com (accessed on 10 August 2018).

- Khan, B.L.; Farooq, H.; Usman, M.; Butt, F.; Khan, A.Q.; Hanif, A. Effect of soil–structure interaction on a masonry structure under train-induced vibrations. Proc. Inst. Civil Eng. Struct. Build. 2018. [Google Scholar] [CrossRef]

- ANSYS AUTODYN. Available online: https://www.ansys.com (accessed on 26 August 2018).

| Properties of air | |

| State equation | Ideal gas |

| γ | 1.41 |

| Reference density | 1.225E-03 g/cm3 |

| Reference temperature | 2.882E + 02 oK |

| Specific heat (C.V.) | 7.173 + 02 J/kg K |

| Properties of reinforced concrete | |

| State equation | Linear |

| Reference density | 2.750 g/cm3 |

| Bulk modulus | 3.527E+07kPa |

| Strength model | Von Mises |

| Shear modulus | 1.220E+07 kPa |

| Elastic limit | 1.000E+04kPa |

| Failure criteria | Principal stresses |

| Failure stress | 1.000+04kPa |

| Properties of masonry | |

| State equation | Linear |

| Reference density | 2.400E+00 g/cm3 |

| Bulk modulus | 7.800E+06 kPa |

| Strength model | Mohr Coulomb |

| Shear modulus | 2.6E+06 kPa |

| Failure criteria | Principal stresses |

| Failure tension | 1.000+03 kPa |

| Ser | Location | TNT (Kilograms) |

|---|---|---|

| 1 | U.S. Consulate Karachi | 70 |

| 2 | U.S. Consulate Karachi | 100 |

| 3 | Parachinar, Pakistan | 50 |

| 4 | Charbagh, Swat Valley, KPK | 60 |

| 5 | Police Checkpoint Peshawar | 80 |

| 6 | Orakzai Agency, FATA | 95 |

| 7 | Khyber Bazaar, Peshawar | 30 |

| 8 | Timergara, Lower Dir | 75 |

| 9 | Lakki Marwat District, KPK | 79 |

| 10 | Khyber Agency, FATA | 56 |

| 11 | Ghalanai, Mohmand Agency, FATA | 50 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, R.; Farooq, S.H.; Usman, M. Blast Loading Response of Reinforced Concrete Panels Externally Reinforced with Steel Strips. Infrastructures 2019, 4, 54. https://0-doi-org.brum.beds.ac.uk/10.3390/infrastructures4030054

Khan R, Farooq SH, Usman M. Blast Loading Response of Reinforced Concrete Panels Externally Reinforced with Steel Strips. Infrastructures. 2019; 4(3):54. https://0-doi-org.brum.beds.ac.uk/10.3390/infrastructures4030054

Chicago/Turabian StyleKhan, Rizwan, Syed Hassan Farooq, and Muhammad Usman. 2019. "Blast Loading Response of Reinforced Concrete Panels Externally Reinforced with Steel Strips" Infrastructures 4, no. 3: 54. https://0-doi-org.brum.beds.ac.uk/10.3390/infrastructures4030054