3.1. Residual Stress Induced by Lathe Machining

The residual stress is determined by the X-ray diffraction sin

2ψ method. In many of the ground or lathe machined metallic surfaces, the sin

2ψ diagram is not straight and so-called ψ-split takes place [

17,

18]. However, in these experiments, the ψ-split was not observed and sin

2ψ diagram is almost straight. Thus, the residual stresses were determined by the conventional sin

2ψ method.

The effect of cutting depth on the residual stress is shown in

Figure 2. The cutting depth was changed from 0.1 mm to 1.0 mm. Axial residual stress ranges from about 0 MPa to −150 MPa but remains at around −100 MPa. Circumferential residual stress is tensile. It takes the maximum value for the cutting depth of 0.1 mm and then it gradually decreases with the cutting depth.

The effect of cutting speed on the residual stress is shown in

Figure 3. The cutting speed was changed from 2 m/min to 95 m/min. The axial residual stress is kept almost compressive. The absolute value is small and −140 MPa at the maximum. The circumferential residual stress is tensile, it increases with the cutting speed, and takes the maximum value of 570 MPa for the cutting speed of 95 m/min.

The effect of feed on the residual stress is shown in

Figure 4. Feed for every revolution of specimen was changed from 0.045 m/rev to 0.157 mm/rev. The axial residual stress is −130 MPa for the feed of 0.045 mm/rev. It slightly decreases with the feed but gradually increases with the feed. It turns tensile at the feed of 0.135 mm/rev and takes the maximum value of 80 MPa for the feed of 0.157 mm/rev. The circumferential residual stress is tensile, and it takes 340 MPa for the feed of 0.045 mm/rev. It gradually increases with the feed and takes the maximum value of 520 MPa for the feed of 0.157 mm/rev.

The residual stresses due to the lathe machining can be caused by two mechanisms. One is the burnishing effect [

19]. The machined surface is cut by the tool materials and simultaneously compressed. This causes the compressive residual stress. On the other hand, the surface layer is cut away and plastically deformed. Thus, the surface layer is heated up, so that the surface layer is thermo-plastically deformed, especially in the austenitic stainless steel. This causes the tensile residual stress. In the axial direction, the burnishing effect exceeds and the compressive residual stress seems to be caused. In the circumferential direction, the thermo-plastically deformation exceeds and the tensile residual stress seems to be caused. In particular, not using cutting oil encourages this tendency.

The residual stresses introduced by the turning depend on various cutting condition. Thus, no generalized or unified interpretation has been made. Even though, the residual stresses in mild steel turned without cutting oil were measured by Yokoyama et al. [

3]. The axial residual stress was compressive and −700 MPa. The circumferential residual stress was compressive and −500 MPa. The results of the effect of cutting speed show that the axial residual stress ranges from −400 MPa and −600 MPa, taking the compressive maximum value for the cutting speed of 100 mm/min. The circumferential residual stress ranges from −500 MPa and −200 MPa, and the compressive residual stress decreases with the increasing of cutting speed.

Results of the effect of feed show that the axial residual stress is −600 MPa for the feed of 0.03 mm/rev, but the compressive residual stress decreases with the increasing of feed; finally, it becomes −220 MPa for the feed of 0.45 mm/rev. The circumferential residual stress is −200 MPa for the feed of 0.03 mm/rev, but it increases with increasing of the feed; finally, it approaches −700 MPa for the feed of 0.45 mm/rev.

Results of the effect of cutting depth show that the axial residual stress gradually increases from −400 MPa and saturates at −600 MPa. The circumferential residual stress takes −150 MPa for small cutting depth, suddenly increases to −550 MPa, and finally gradually increases and saturates at −600 MPa.

In the carbon steel, the residual stresses induced by the turning are compressive both in the axial and circumferential direction [

3,

4,

11]. On the other hand, in this experiment using austenitic stainless steel, the residual stresses are compressive in the axial direction but tensile in the circumferential direction. In the stainless steel, the work hardening rate is very much higher and the heat conductive coefficient is very much lower compared with the carbon steel. These two physical properties induce the thermo-plastic deformation at the tip of tool material and finally cause very much high tensile residual stresses in the circumferential direction.

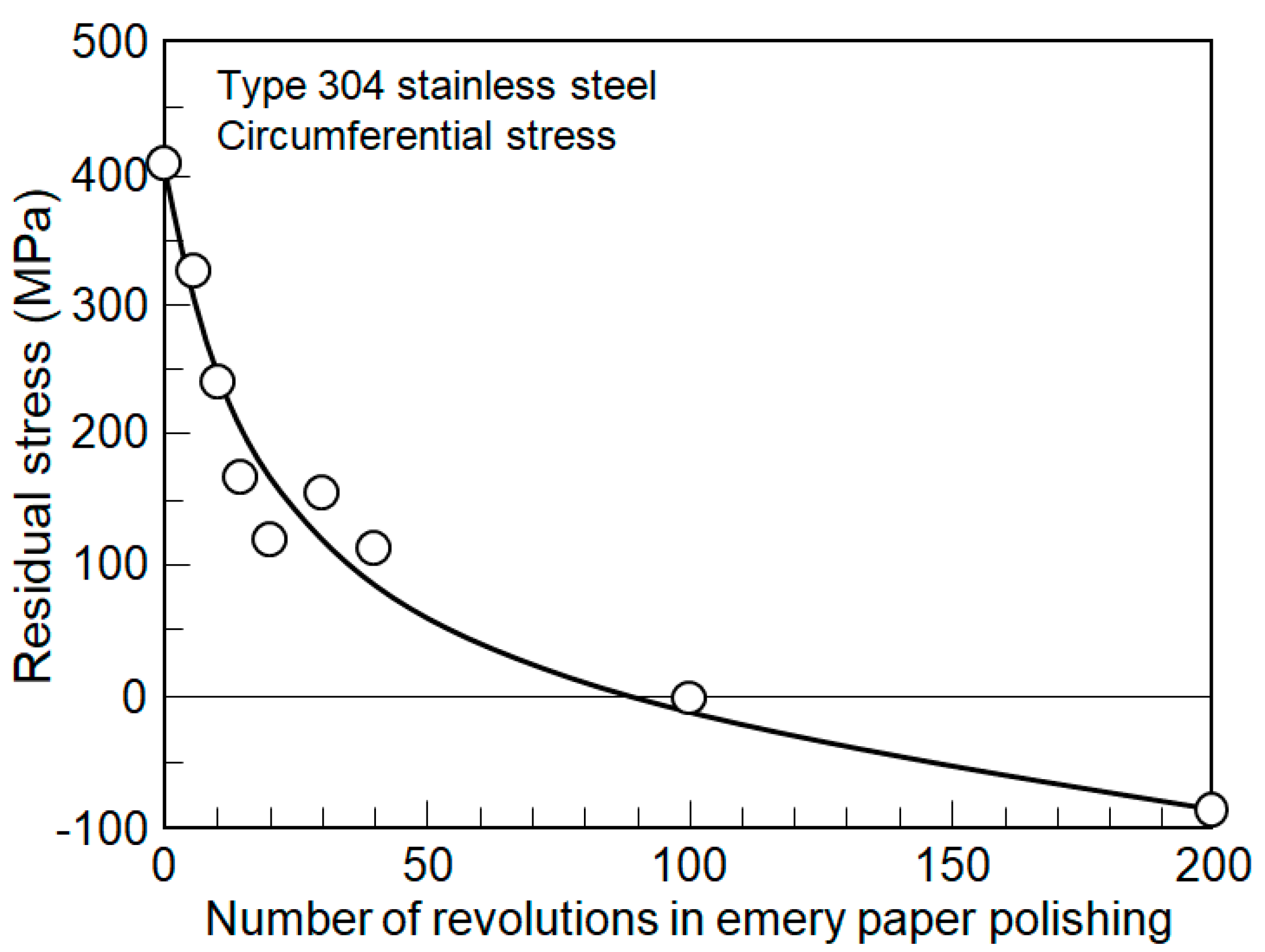

The tensile residual stress adversely affects the fatigue strength or the stress corrosion cracking. Thus, emery paper polishing is subjected to the worked surface with tensile residual stress. Improvement of tensile residual stress by the emery paper polishing is shown in

Figure 5. For the as-lathe machined condition, the residual stress is about 410 MPa. By the emery paper polishing, the tensile residual stress rapidly decreases and it turns compressive by about 100 polishings. The specimen is held in the chuck of lathe machine and the strip shaped emery paper is gripped at the turret. Thus, the polishing process is very easy. At the manufacturing site of actual equipment, the use of the flapper wheel seems to be much more cost and time effective.

The residual stress distribution in the sub-surface of lathe machined XM19 (equivalent to ASTM A240) ring is shown in

Figure 6. Outside diameter of XM19 ring is 70 mm and thickness is 6 mm. The residual stresses were measured four times. The average residual stress on the surface is 920 MPa. This is due to very high yield stress (0.2% flow stress) and work hardening characteristics of XM19. The residual stress rapidly decreases with the depth and turns out to be compressive at about 20 μm. It takes the minimum value of about −250 MPa at the depth of 40 µm and gradually approaches zero.

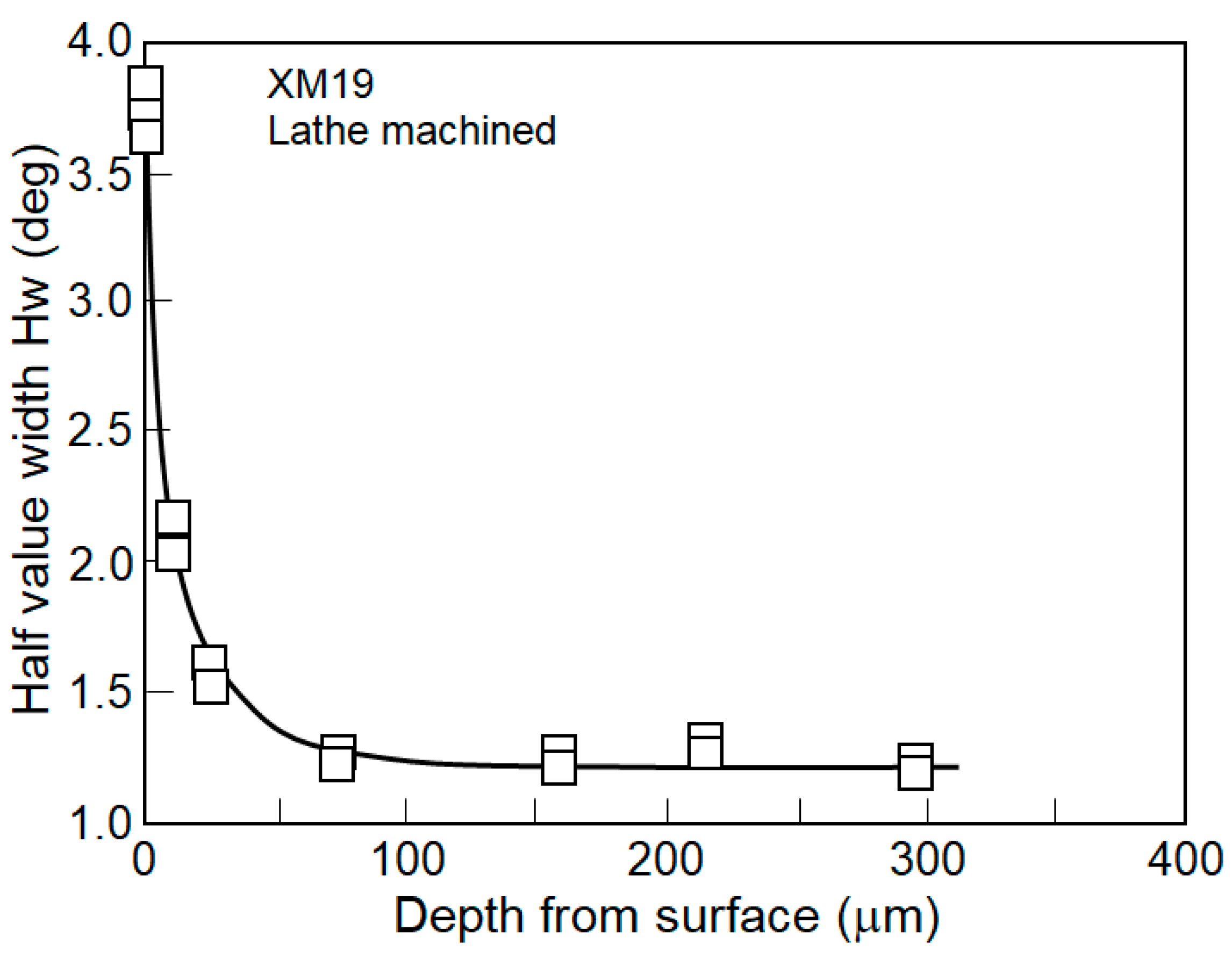

Distribution of half value width Hw is shown in

Figure 7. The half value width for the solid solution heat treatment condition is about 1.1 degrees, as can be seen at deeper than 100 µm in the figure. The half value width at the surface is about 3.75 degrees. This means that the half value width at the surface is very much larger than that of the solid solution heat treatment condition and indicates that the surface layer is remarkably plastically deformed. This large plastic deformation seems to cause very high tensile residual stress. The half value width rapidly decreases with the depth. The distribution of half value width indicates that the surface layer shallower than 50 μm is plastically deformed.

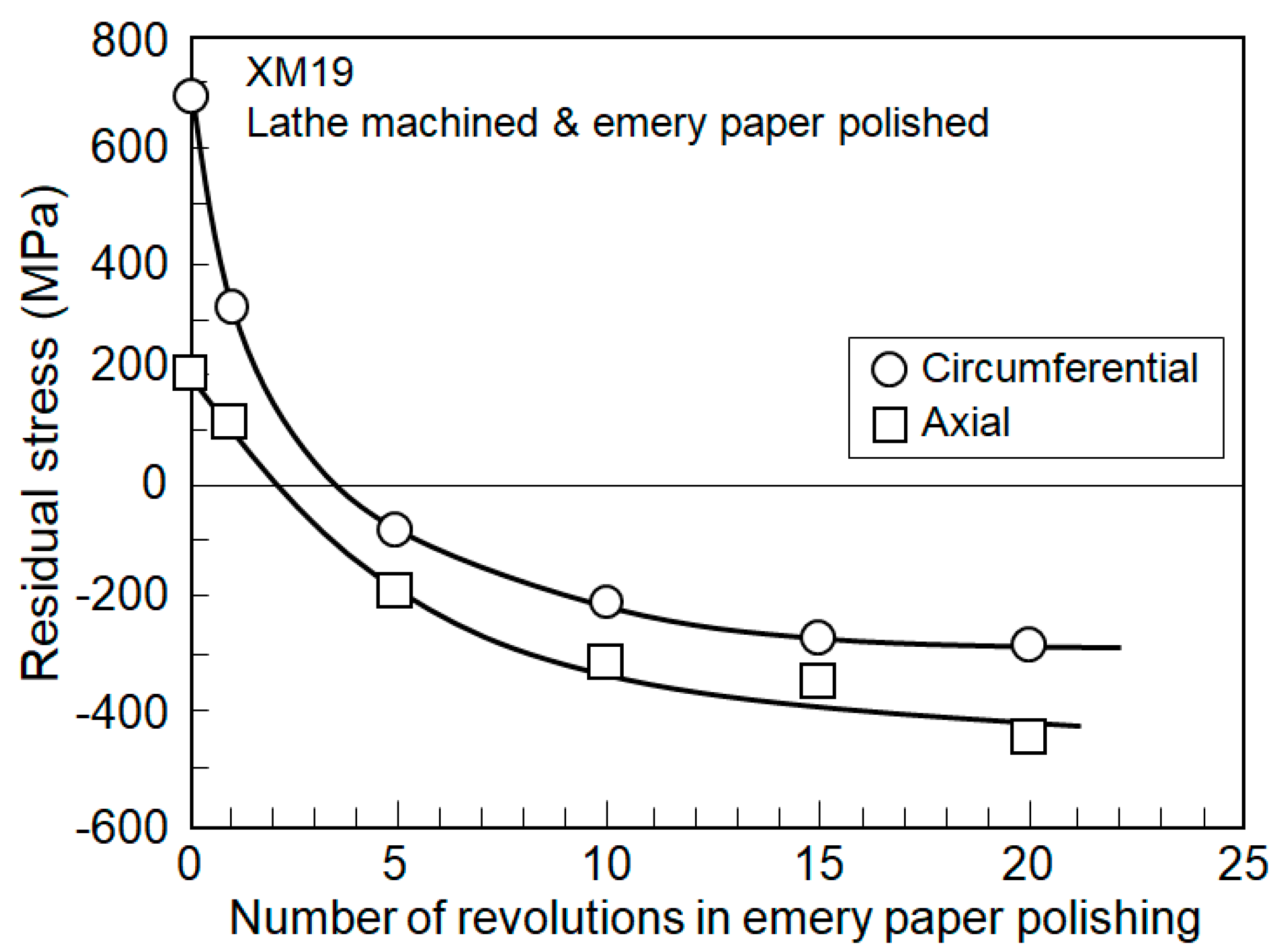

Improvement of tensile residual stress in the lathe machined XM19 ring by the emery paper polishing is shown in

Figure 8. For the as-lathe machined condition, the circumferential residual stress is 690 MPa on the surface. By the emery paper polishing, the tensile residual stress rapidly decreases. The residual stress turns to compressive by four polishings and gradually saturates to about −300 MPa. The axial residual stress is 200 MPa on the surface. By the emery paper polishing, the tensile residual stress rapidly decreases. The residual stress turns out to be compressive by the third polishing and gradually saturates at about −450 MPa. Anyway, the emery paper polishing can easily change the tensile residual stress to the compressive residual stress.

The residual stress distribution after emery paper polishing is shown in

Figure 9. The residual stress on the surface is about −200 MPa. This coincides with that of just emery paper polished surface of solution heat treated material. It turns out to be tensile deeper than 10 µm and takes the compressive at deeper than 50 µm.

The high tensile residual stress surface layer induced by the lathe machining is removed by the emery paper polishing. After the emery paper polishing, the residual stress distribution near the surface becomes that of an emery paper polished solution heat treated material. Thus, the residual stress distribution after emery paper polishing seems to be the combination of the residual stress distribution induced by the lathe machining except the high tensile residual stress surface layer and the residual stress distribution of emery paper polished solution heat treated material.

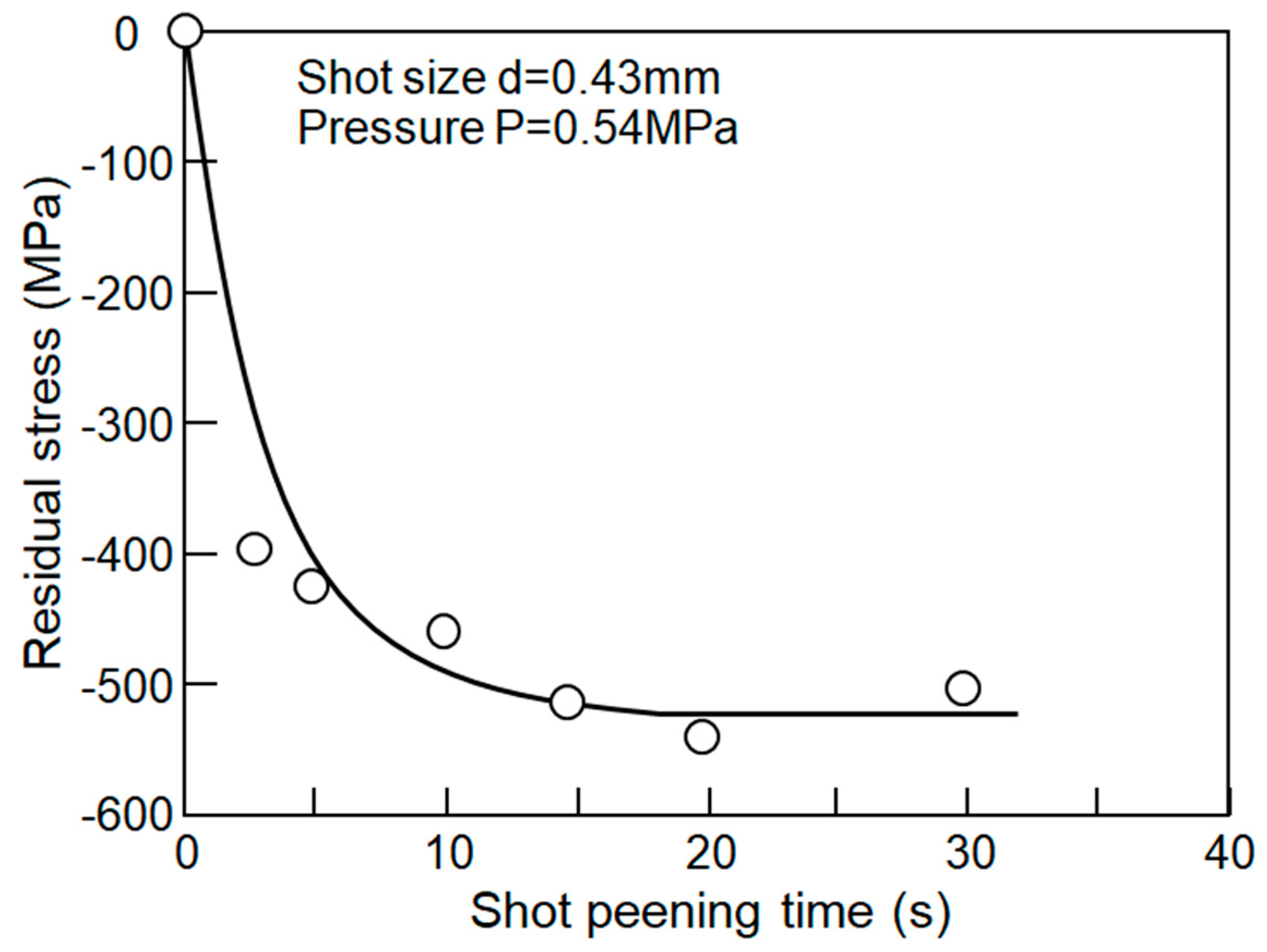

The effect of shot peening time on the residual stress in type 304 stainless steel plate is shown in

Figure 10. In the shot peening shot size is 0.63 mm in diameter, pressure is 0.54 MPa, and the distance between peening gun nozzle and the plate is about 200 mm. By applying 2.5 s, the residual stress becomes −400 MPa. It gradually decreases with the peening time and saturates after 15 s to about −520 MPa.

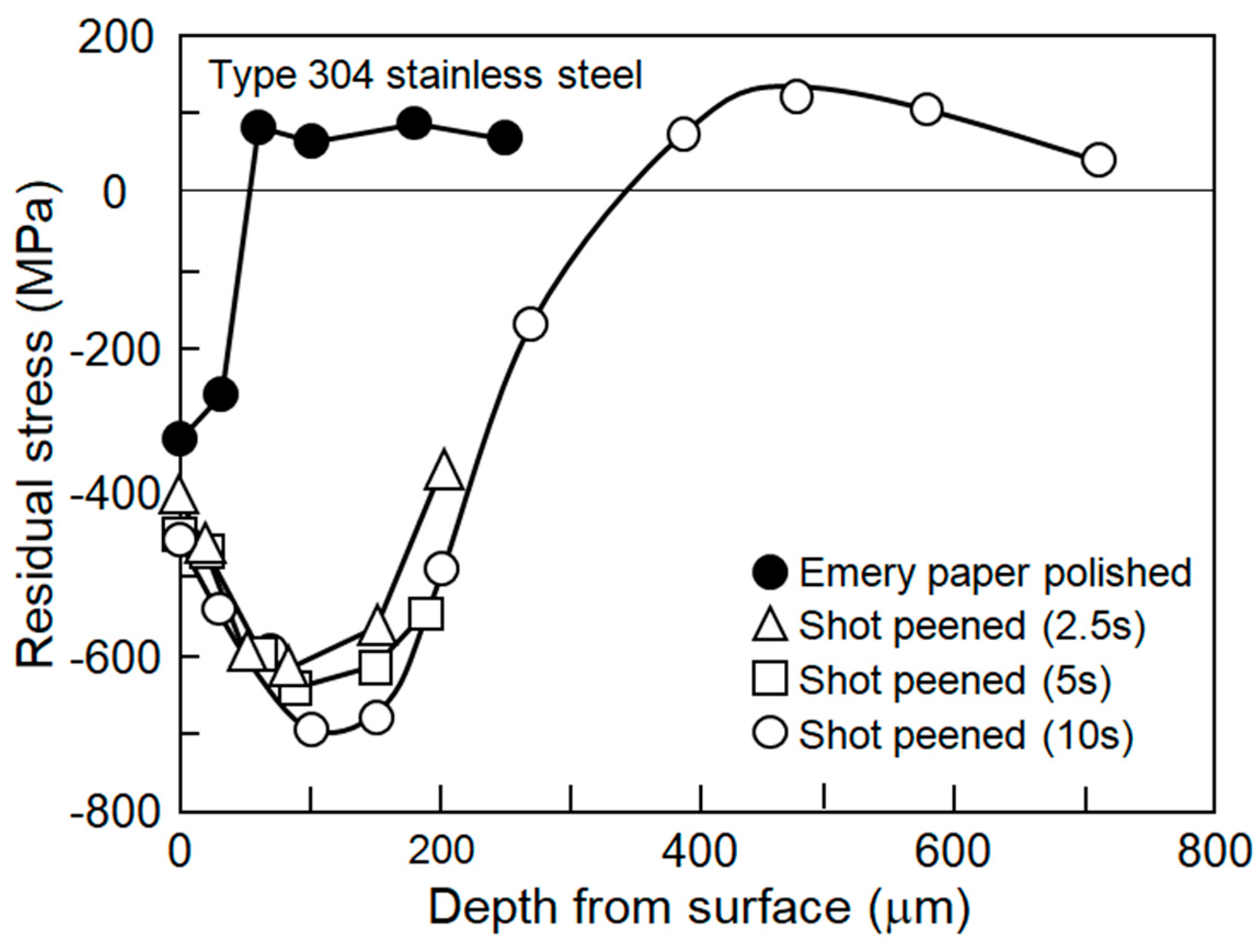

Residual stress distribution in the shot peened type 304 stainless steel plate is shown in

Figure 11. Shot peened time is 2.5, 5, and 10 s. For reference, the residual stress distribution in emery paper polished steel is shown in the

Figure 9. The residual stresses induced by the shot peening range −400 MPa and −460 MPa. They decrease with the depth, take the maximum values at about 100 µm, and gradually increase. For balancing with the compressive residual stress, the tensile residual stress is induced for deeper positions.

The residual stress distribution induced by the single shot peening in depth direction has been analyzed using FEM analysis [

20]. The results show that the residual stress on the surface is sometimes tensile and gradually decreased with the depth, and took the compressive maximum value at the depth of 250 µm. The residual stresses in surroundings of shot are remarkably small compared with those at the right below the shot. However, the residual stresses in the surroundings of multi-shot peening have not been clarified.

The residual stress distribution in the subsurface due to the shot peening is schematically shown in

Figure 12. Immediately below the surface where the shot hits, the surface layer deforms in the direction perpendicular to the surface. At this moment, the surface layer cannot be deformed in the direction parallel to the surface due to the surrounding constraints. So, the compressive residual stress is generated in the direction parallel to the surface. On the other hand, in the peripheral area hit by the shot, the surface layer deforms following the shape of the shot. This makes the surface morphology like pear surface. The part protruding from the surface is bent by the shots on both sides and then the compressive residual stress seems to be not so high. Extremely, the residual stress may become tensile. Thus, it is possible to greatly improve the residual stress formed by shot peening by removing the protruding parts with low compressive residual stress with emery paper.

Figure 13 shows the change in the residual stress formed by shot peening depending on the number of times of polishing with #240 emery paper. In the case of shot peening time of 10 s, the surface residual stress was improved from −400 MPa to −700 MPa only by polishing 20 times. In the case of shot peening time of 20 s, the surface residual stress was improved from −560 MPa to −750 MPa only by polishing 20 times. According to the analytical results of the stress field in the shot peening, it is thought that a higher compressive stress is formed due to high shear stress a little far away from the surface.

Surface morphology of shot peened and followed by emery paper polishing in type 304 stainless steel is shown in

Figure 14. Since both sides are as shot peened, the surface is a pear-like and has a large roughness, and the photograph looks black. This pear-like surface was removed and polished using #240 emery paper. As a result, the 20 times polished surface gives a metallic luster, and the roughness is much smaller. On the 10 times polished surface, many dents can be observed. These dents are formed by the impacts of the shots.

3.2. Fatigue Tests of Various Preliminary Worked-Steel

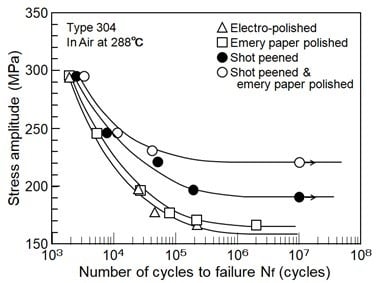

S–N curves for electro-polished, emery paper polished, shot peened, and shot peened plus emery paper polished steels in air at 288 °C are shown in

Figure 15. For the stress amplitude higher than 250 MPa, the effects of compressive residual stress and work hardening due to the plastic deformation are attenuated by repeated stress. Thus, the effect of surface working decreases, and the fatigue lives are almost the same in spite of the preliminary surface working. However, the effect of preliminary surface working is remarkable for the stress amplitude lower than 250 MPa. While the 10

6 cycle fatigue strength of the electro-polished material is 162 MPa, that of emery paper polished material is 167 MPa. As shown in

Figure 11, the compressive residual stress on the surface due to the emery paper polishing is high at −300 MPa, but the plastically deformed layer with compressive residual stress is as shallow as about 20–30 µm. This is the reason why the fatigue strength was improved by only about 10 MPa.

In the shot peened material, the fatigue strength is 191 MPa. This increase is caused by the large compressive residual stress on the surface, the remarkable plastic-hardening on the surface layer, and the deep plastically deformed region.

Fatigue strength of specimens polished with emery paper after shot peening, which is denoted as SE specimen, is 221 MPa. In SE specimens, the compressive residual stress is about 300 MPa larger than that of a shot peened specimen, while the work-hardening is almost the same. In spite of this, the fatigue strength is improved about 30 MPa. This seems to be due to the improvements of surface roughness and the local residual stress. In SE specimens, the pear-like surface formed by the shot peening is removed by the emery paper polishing and the final surface becomes smooth. However, the fatigue strength improvement of 15% could not be expected by the surface smoothing. It is suggested that the local residual stress affected the fatigue strength. As shown in

Figure 14, the residual stress at the part protruding from the surface is not highly compressive. This is obvious from the fact that the surface residual stress is improved about 300 MPa by the emery paper polishing. Conversely, this means that the residual stress at the part protruding from the surface would be −100 MPa. It is considered that the removal of this protruding portion with a relatively low compressive residual stress is effective in significantly improving fatigue strength.