Self-Organized Nanostructures Generated on Metal Surfaces under Electron Irradiation

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Gold

3.1.1. Self-Organization of Nanostructure

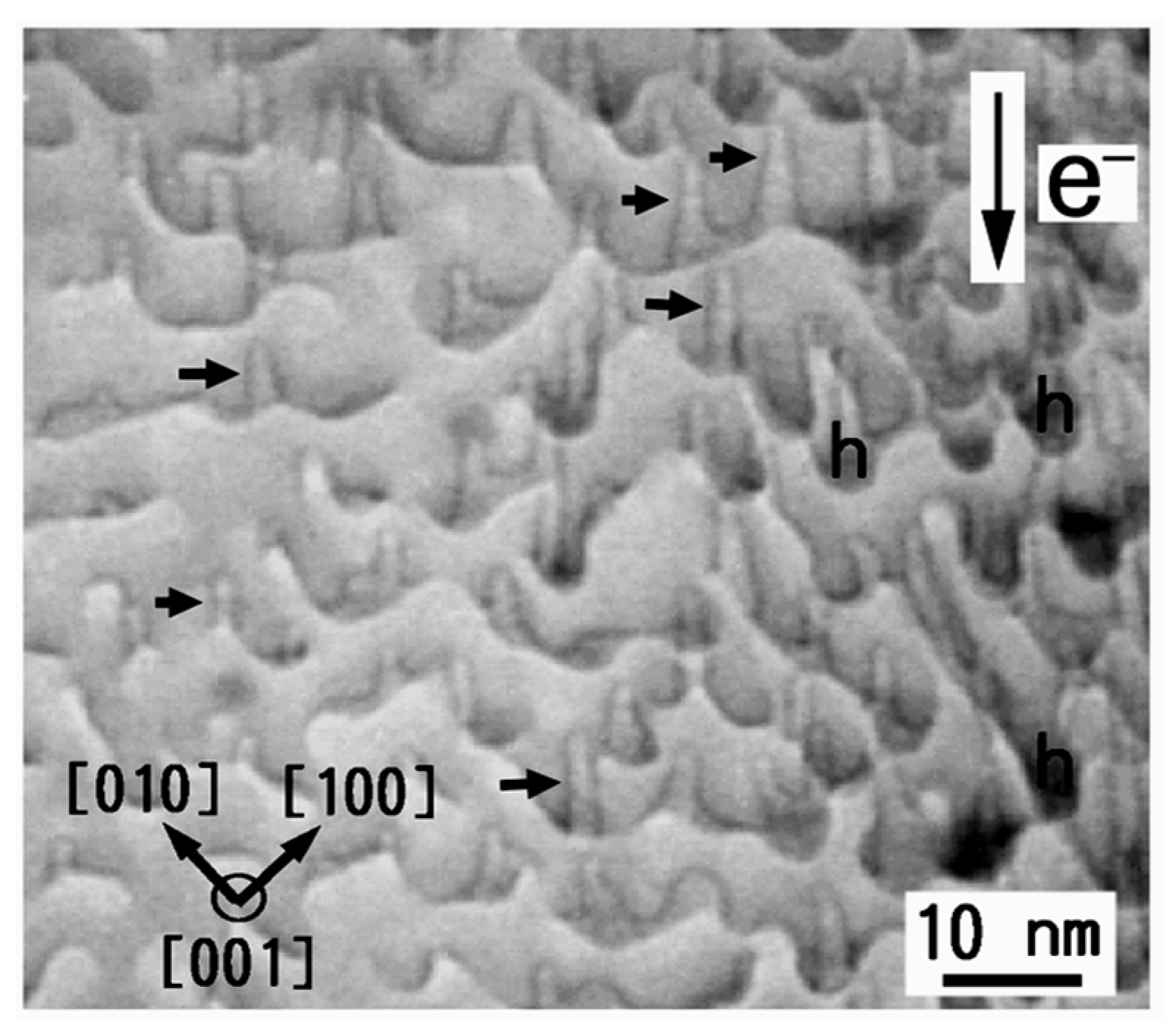

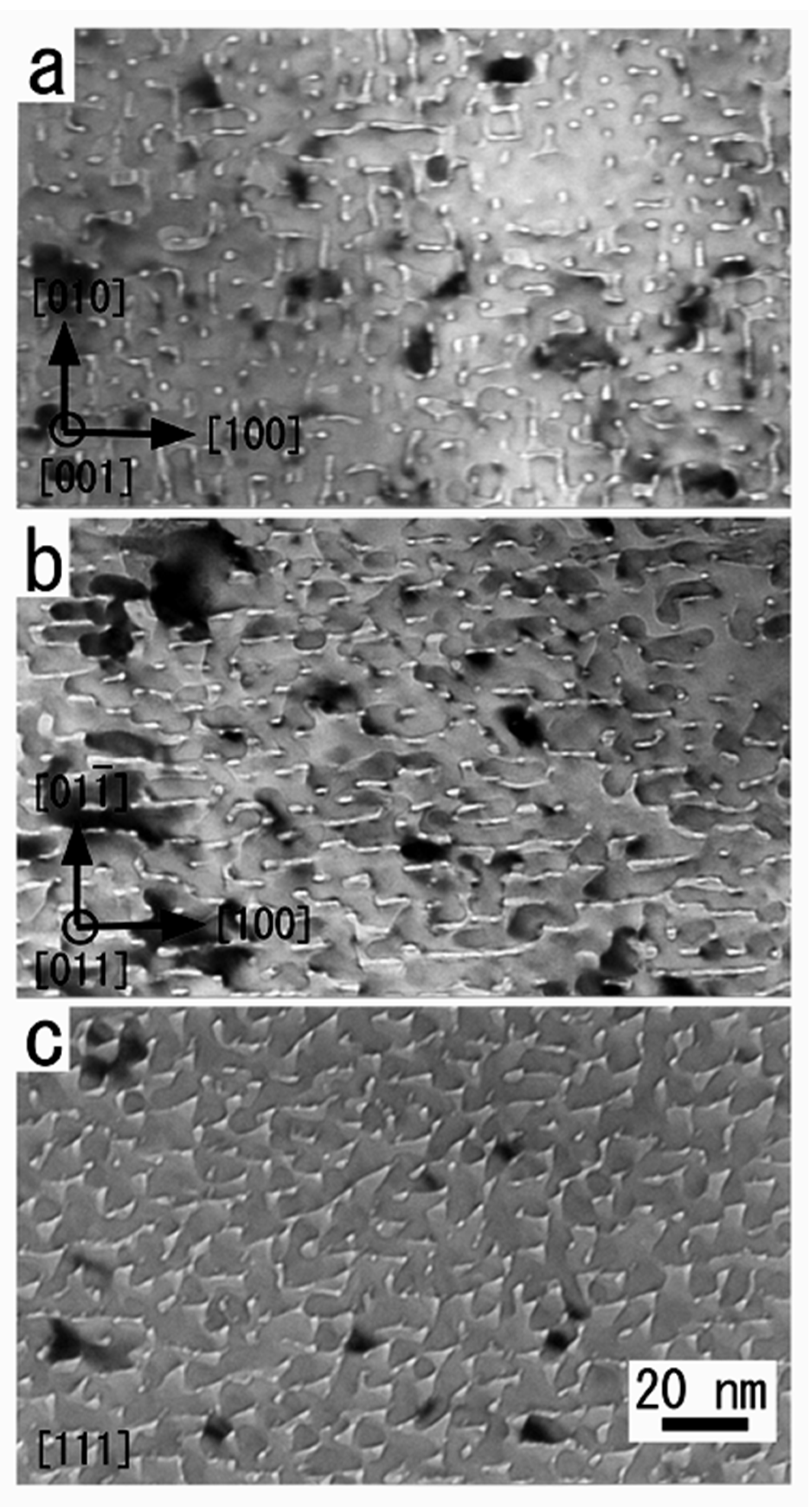

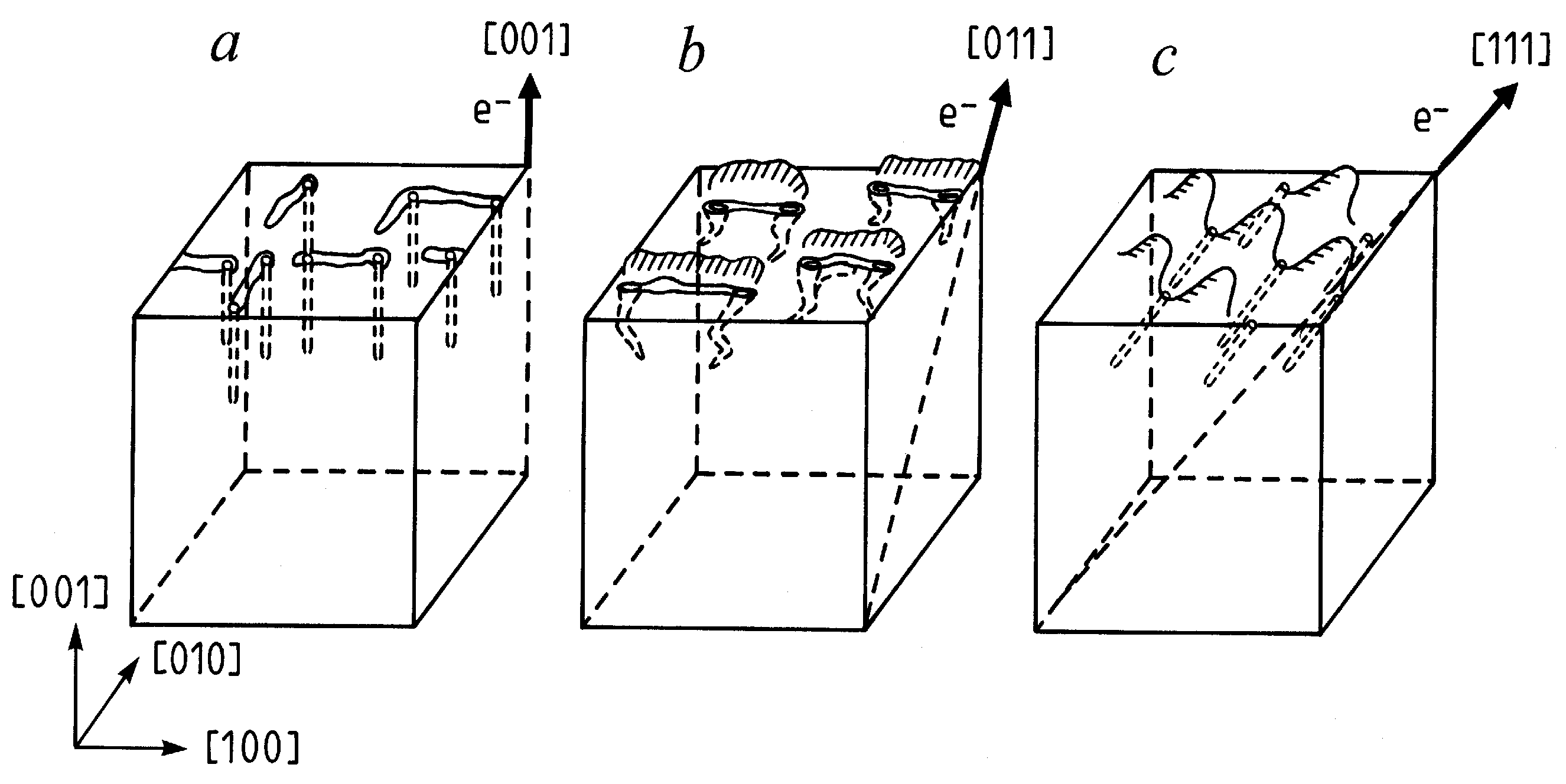

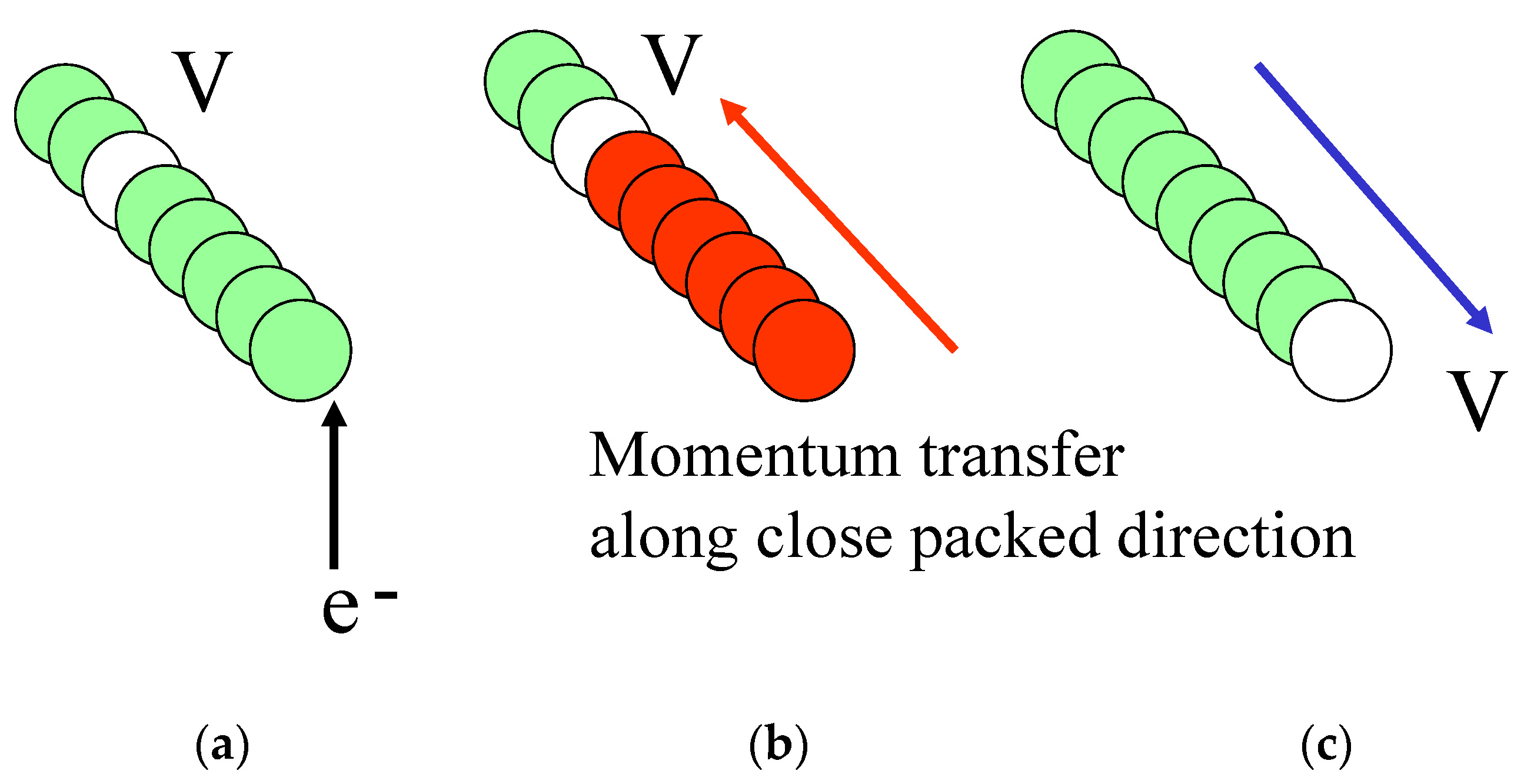

3.1.2. Irradiation Directional Dependence on the Structure

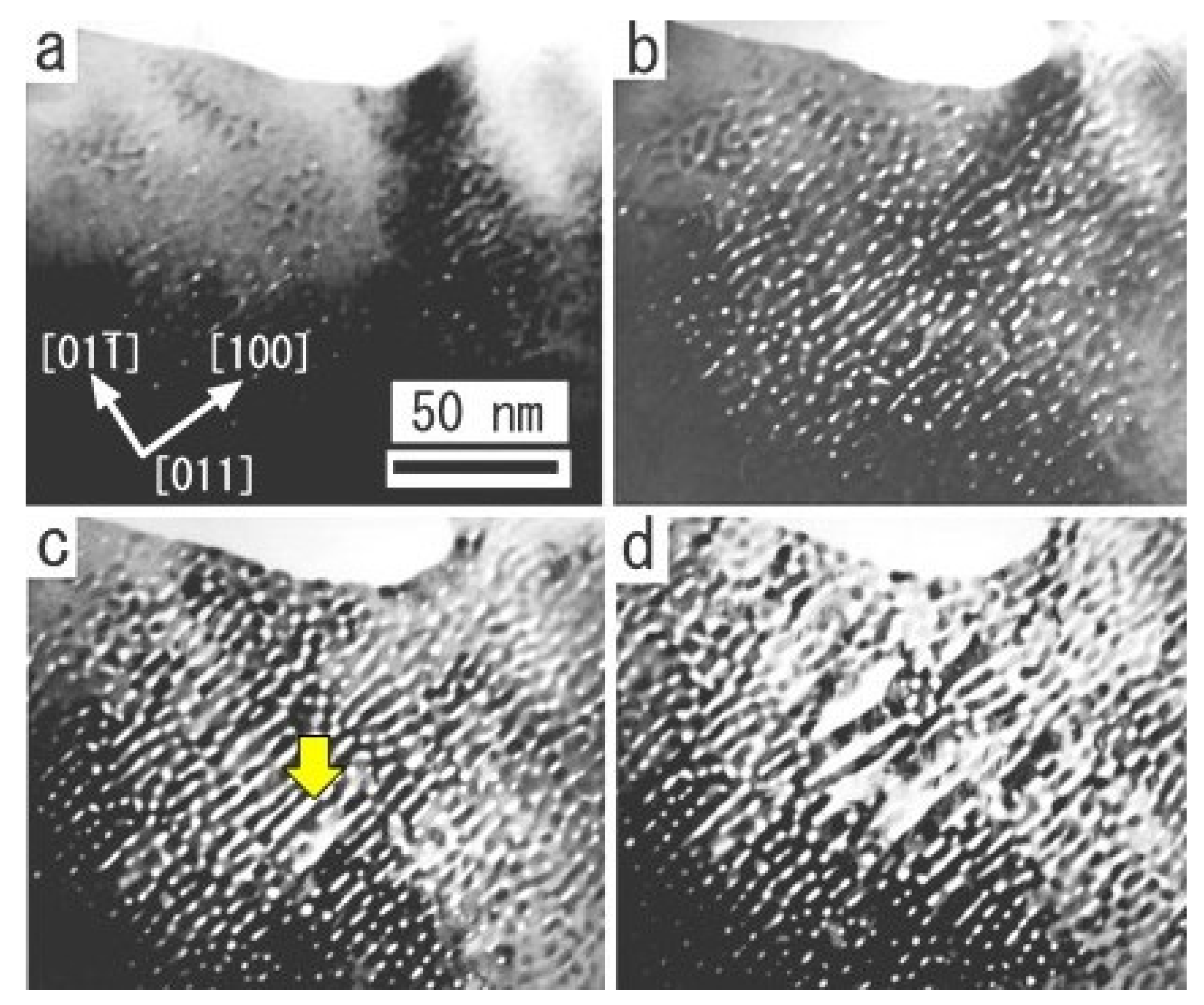

3.1.3. Generation of Nanoslits and Nanoparticles

3.1.4. Annealing of the Nanostructure at Room Temperature

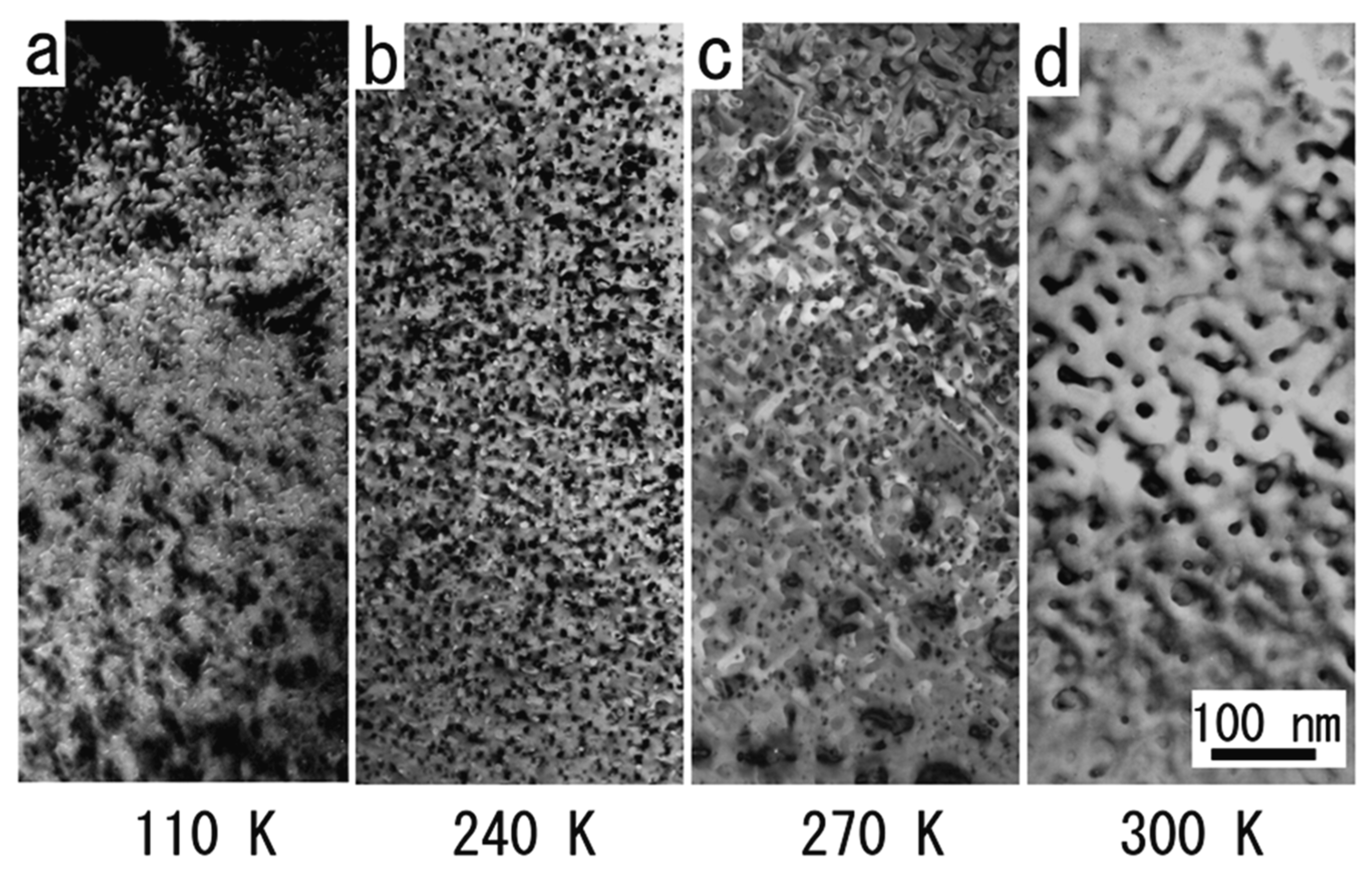

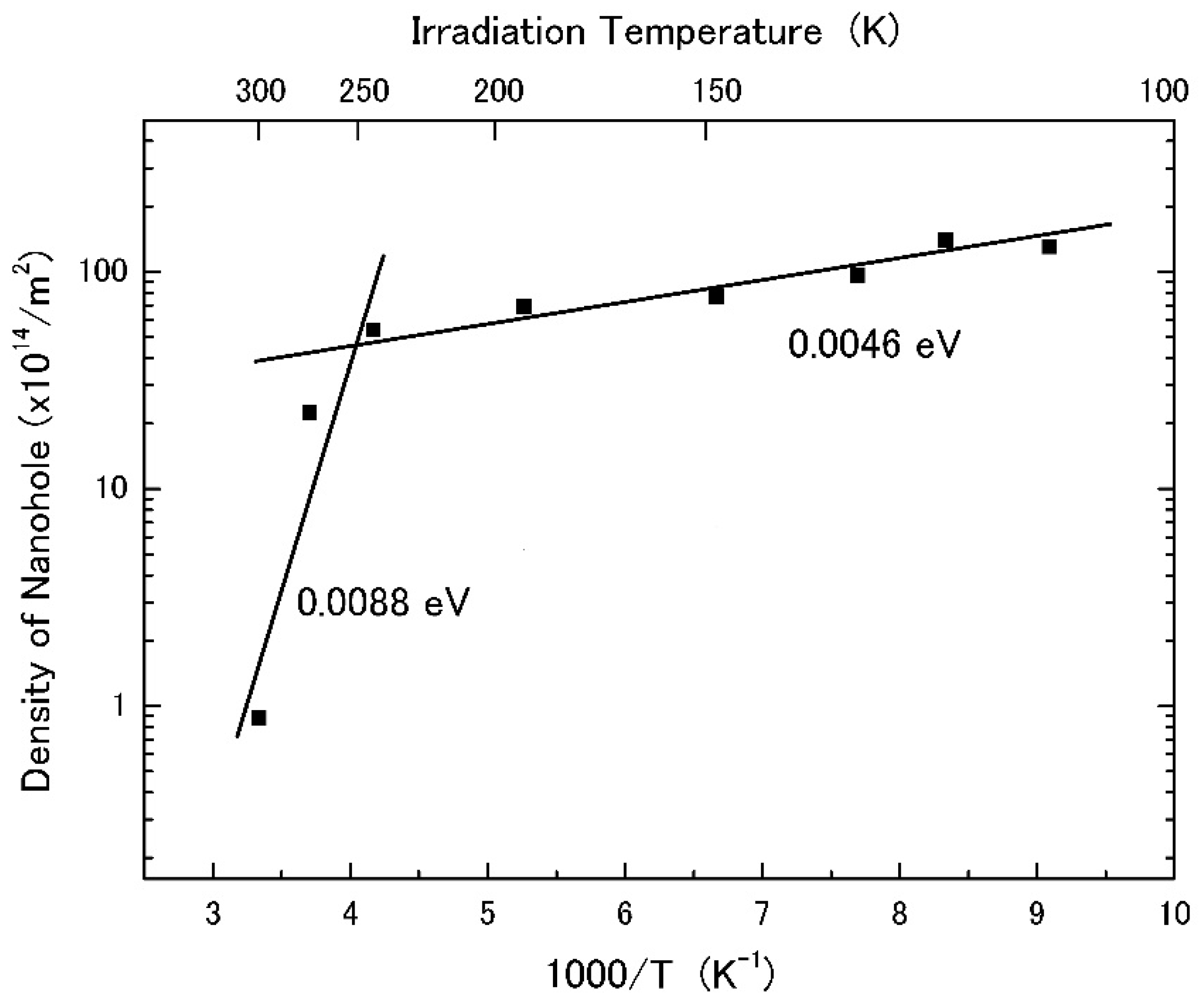

3.1.5. Irradiation Temperature Dependence on the Structure

3.2. Comparison among Gold, Silver, and Copper

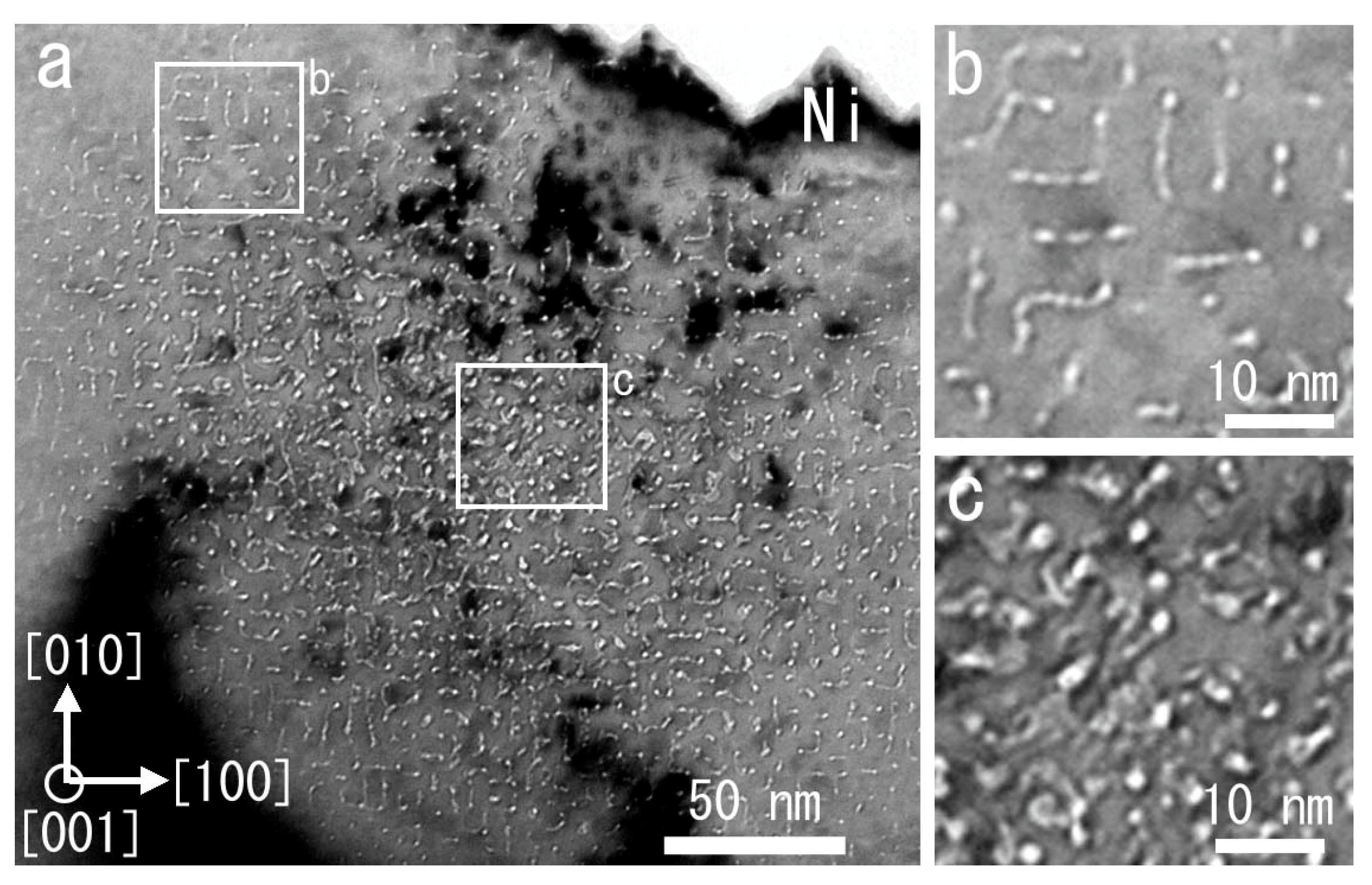

3.3. Ni

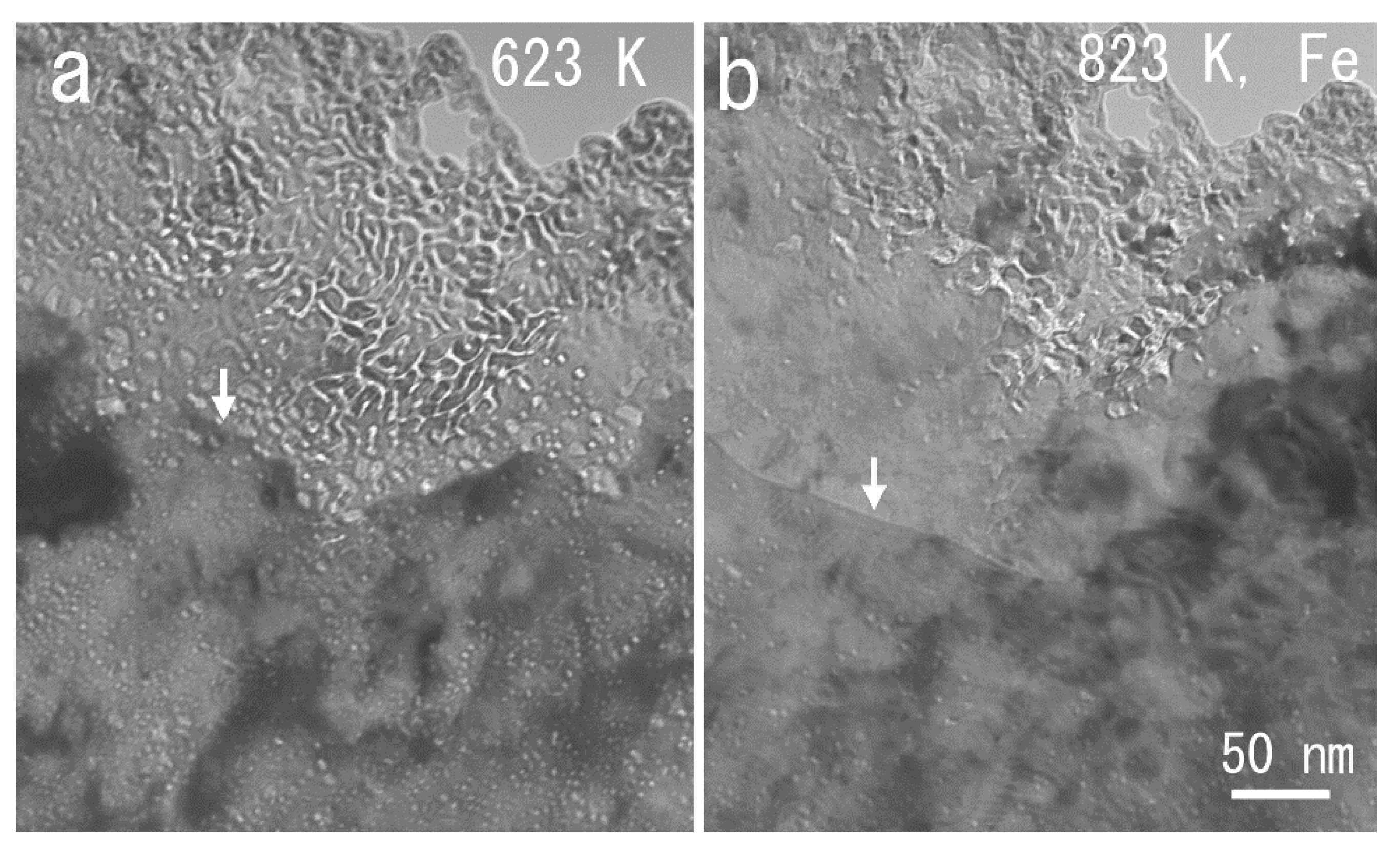

3.4. Iron

4. Discussion

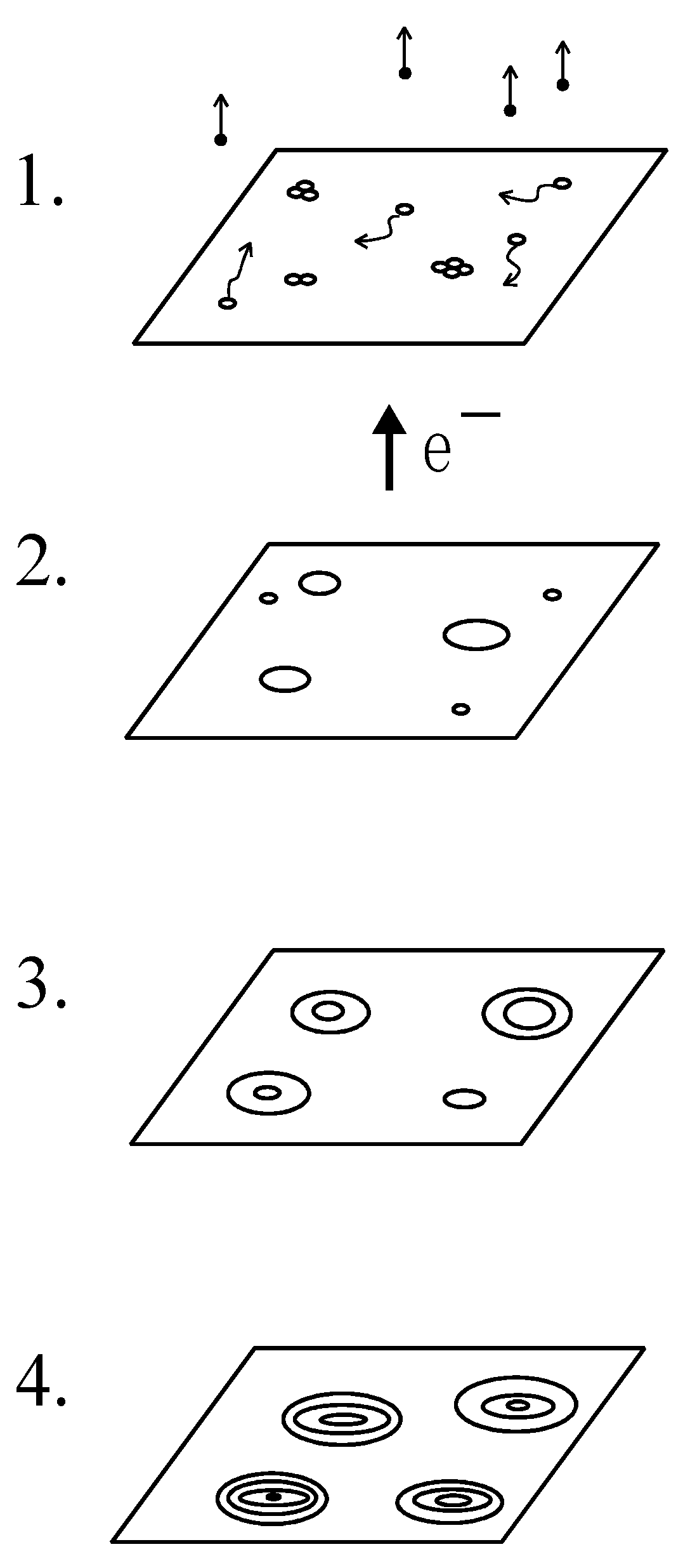

4.1. Formation Process of Deep Nanoholes

= Pw/N0 + Pw2/2N0Rp,

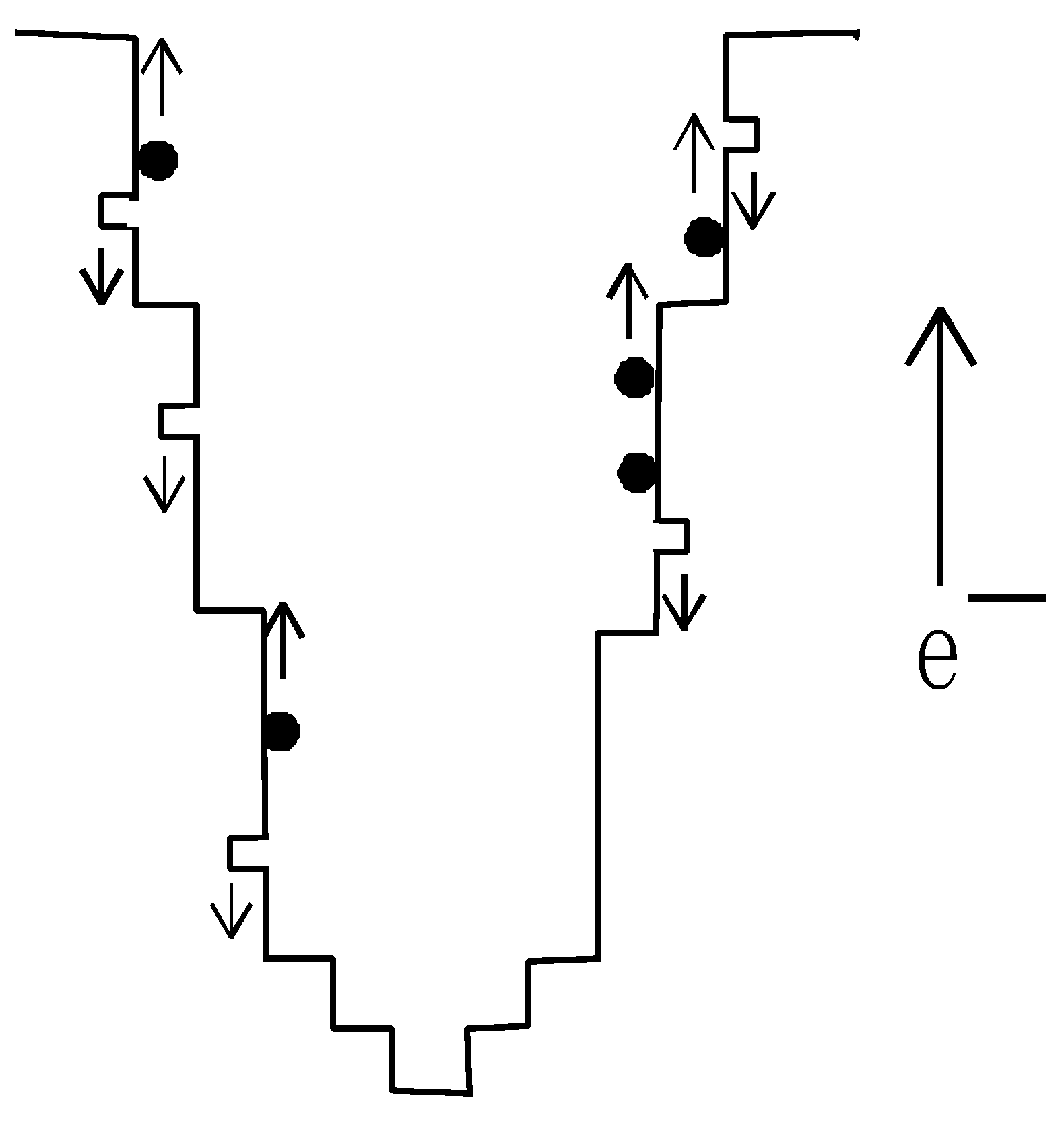

4.2. Self-Organization of Nanogrooves

- (1)

- The groove patterns are generated far from thermal equilibrium in an open, highly dissipative system.

- (2)

- Only a small fraction of the total energy input is stored (e.g., as surface energy at the grooves).

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Wua, T.; Lin, Y.-W. Surface-enhanced Raman scattering active gold nanoparticle/nanohole arrays fabricated through electron beam lithography. Appl. Surf. Sci. 2018, 435, 1143. [Google Scholar] [CrossRef]

- Tavakoli, M.; Jalili, Y.S.; Elahi, S.M. Rayleigh-Wood anomaly approximation with FDTD simulation of plasmonic gold nanohole array for determination of optimum extraordinary optical transmission characteristics. Superlattices Microstruct. 2019, 130, 454. [Google Scholar] [CrossRef]

- Chen, X.; Wang, H.; Xu, N.-S.; Chen, H.; Deng, S. Resonance coupling in hybrid gold nanohole–monolayer WS2 nanostructures. Appl. Mater. Today 2019, 15, 145. [Google Scholar] [CrossRef]

- Becker, R.S.; Golovchenko, J.A.; Swartzentruber, B.S. Atomic-scale surface modifications using a tunnelling microscope. Nature 1987, 325, 419. [Google Scholar] [CrossRef]

- Eiger, D.M.; Schweizer, E.K. Positioning single atoms with a scanning tunnelling microscope. Nature 1990, 344, 524. [Google Scholar] [CrossRef]

- Kobayashi, A.; Grey, F.; Williams, R.S.; Aono, M. Formation of nanometer-scale grooves in silicon with a scanning tunneling microscope. Science 1993, 259, 1724. [Google Scholar] [CrossRef] [PubMed]

- Saif, M.J.; Naveed, M.; Asif, H.M.; Akhtar, R. Irradiation applications for polymer nano-composites: A state-of-the-art review. J. Ind. Eng. Chem. 2018, 60, 218. [Google Scholar] [CrossRef]

- Córdoba, R.; Orús, P.; Strohauer, S.; Torres, T.E.; Teresa, J.M.D. Ultra-fast direct growth of metallic micro- and nano-structures by focused ion beam irradiation. Sci. Rep. 2019, 9, 14076. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Turner, P.S.; Bullogh, T.J.; Devenish, R.W.; Maher, D.M.; Humphereys, C.J. Nanometre hole formation in MgO using electron beams. Philos. Mag. Lett. 1990, 61, 181. [Google Scholar] [CrossRef]

- Kizuka, T.; Tanaka, N. Nanometre scale electron beam processing and in situ atomic observation of vacuum-deposited MgO films in high-resolution transmission electron microscopy. Philos. Mag. A 1995, 71, 631. [Google Scholar] [CrossRef]

- Cherns, D. The surface structure of (111) gold films sputtered in the high voltage electron microscope a theoretical model. Philos. Mag. 1977, 36, 1429. [Google Scholar] [CrossRef]

- Jin, N.Y.; Phillipp, F.; Seeger, A. Investigation of defect ordering in heavily irradiated metals by high-voltage electron microscopy. Phys. Stat. Sol. 1989, 116, 91. [Google Scholar] [CrossRef]

- Seeger, A.; Jin, N.Y.; Phillipp, F.; Zaiser, M. The study of self-organization processes in crystals by high-voltage electron microscopy. Ultramicroscopy 1991, 39, 342. [Google Scholar] [CrossRef]

- Ghoniem, N.M.; Walgraef, D.; Zinkle, S.J. Theory and experiment of nanostructure self-organization in irradiated materials. J. Comput. Aided Mater. Des. 2001, 8, 1. [Google Scholar] [CrossRef]

- Kharchenko, D.O.; Kharchenko, V.O.; Bashtova, A.I. Modeling self-organization of nano-size vacancy clusters in stochastic systems subjected to irradiation. Radiat. Eff. Defects Solids 2014, 169, 418. [Google Scholar] [CrossRef] [Green Version]

- Gao, Y.; Zhang, Y.; Schwen, D.; Jiang, C.; Sun, C.; Gan, J.; Bai, X.-M. Theoretical prediction and atomic kinetic Monte Carlo simulations of void superlattice self-organization under irradiation. Sci. Rep. 2018, 8, 6629. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vitral, E.; Walgraef, D.; Pontes, J.; Anjos, G.R.; Mangiavacchi, N. Nano-patterning of surfaces by ion sputtering: Numerical study of the anisotropic damped Kuramoto-Sivashinsky equation. Comput. Mater. Sci. 2018, 146, 193. [Google Scholar] [CrossRef]

- Niwase, K.; Sigle, W.; Phillipp, F.; Seeger, A. Generation of nanosized grooves and holes on metal surfaces by low-temperature electron irradiation. Philos. Mag. Lett. 1996, 74, 167. [Google Scholar] [CrossRef]

- Niwase, K.; Sigle, W.; Phillipp, F.; Seeger, A. Nanogrooves generated on Au surfaces by low-temperature electron irradiation. J. Surf. Anal. 1997, 3, 440. [Google Scholar]

- Niwase, K.; Sigle, W.; Phillipp, F.; Seeger, A. Novel phenomena of irradiation damage in FCC metals irradiated with high-energy electrons at low temperatures. J. Electron. Microsc. 1999, 48, 495. [Google Scholar] [CrossRef]

- Niwase, K.; Phillipp, F.; Seeger, A. Self-organized nanostructures generated on Au, Ag and Cu surfaces by low-temperature electron irradiation. Jpn. J. Appl. Phys. 2000, 39, 4624. [Google Scholar] [CrossRef]

- Niwase, K.; Abe, H. Generation of nanosized structures on Ni and Fe surfaces by electron irradiation. Mater. Trans. 2002, 43, 646. [Google Scholar] [CrossRef] [Green Version]

- Cherns, D. Sputtering of gold foils in a high voltage electron microscope a comparison of theory and experiment. Philos. Mag. 1977, 35, 693. [Google Scholar] [CrossRef]

- Hohenstein, M.; Seeger, A.; Sigle, W. The anisotropy and temperature dependence of the threshold for radiation damage in gold—comparison with other FCC metals. J. Nucl. Mater. 1989, 169, 33. [Google Scholar] [CrossRef]

- Kondo, Y.; Takayanagi, K. Gold nanobridge stabilized by surface structure. Phys. Rev. Lett. 1997, 79, 3455. [Google Scholar] [CrossRef] [Green Version]

- Kondo, Y.; Takayanagi, K. Synthesis and characterization of helical multi-shell gold nanowires. Science 2000, 289, 606. [Google Scholar] [CrossRef] [PubMed]

- Takeda, S.; Koto, K.; Iijima, S.; Ichihashi, T. Nanoholes on silicon surface created by electron irradiation under ultrahigh vacuum environment. Phys. Rev. Lett. 1997, 20, 2994. [Google Scholar] [CrossRef]

- Michely, T.; Land, T.; Littmark, U.; Comsa, G. Morphological effects induced by the formation of a Pt-adatom lattice gas on Pt (111). Surf. Sci. 1992, 272, 204. [Google Scholar] [CrossRef]

- Urban, K.; Seeger, A. Radiation-induced diffusion of point-defects during low-temperature electron irradiation. Philos. Mag. 1974, 30, 1395. [Google Scholar] [CrossRef]

- Sigle, W. The anisotropy of the threshold energy for atom displacements in silver. J. Phys Condens. Matter. 1991, 3, 3921. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niwase, K. Self-Organized Nanostructures Generated on Metal Surfaces under Electron Irradiation. Quantum Beam Sci. 2021, 5, 4. https://0-doi-org.brum.beds.ac.uk/10.3390/qubs5010004

Niwase K. Self-Organized Nanostructures Generated on Metal Surfaces under Electron Irradiation. Quantum Beam Science. 2021; 5(1):4. https://0-doi-org.brum.beds.ac.uk/10.3390/qubs5010004

Chicago/Turabian StyleNiwase, Keisuke. 2021. "Self-Organized Nanostructures Generated on Metal Surfaces under Electron Irradiation" Quantum Beam Science 5, no. 1: 4. https://0-doi-org.brum.beds.ac.uk/10.3390/qubs5010004