Grain-Size Effects on Multi-Wire Slurry Sawing of Translucent Alumina Ceramics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Characterization Methods

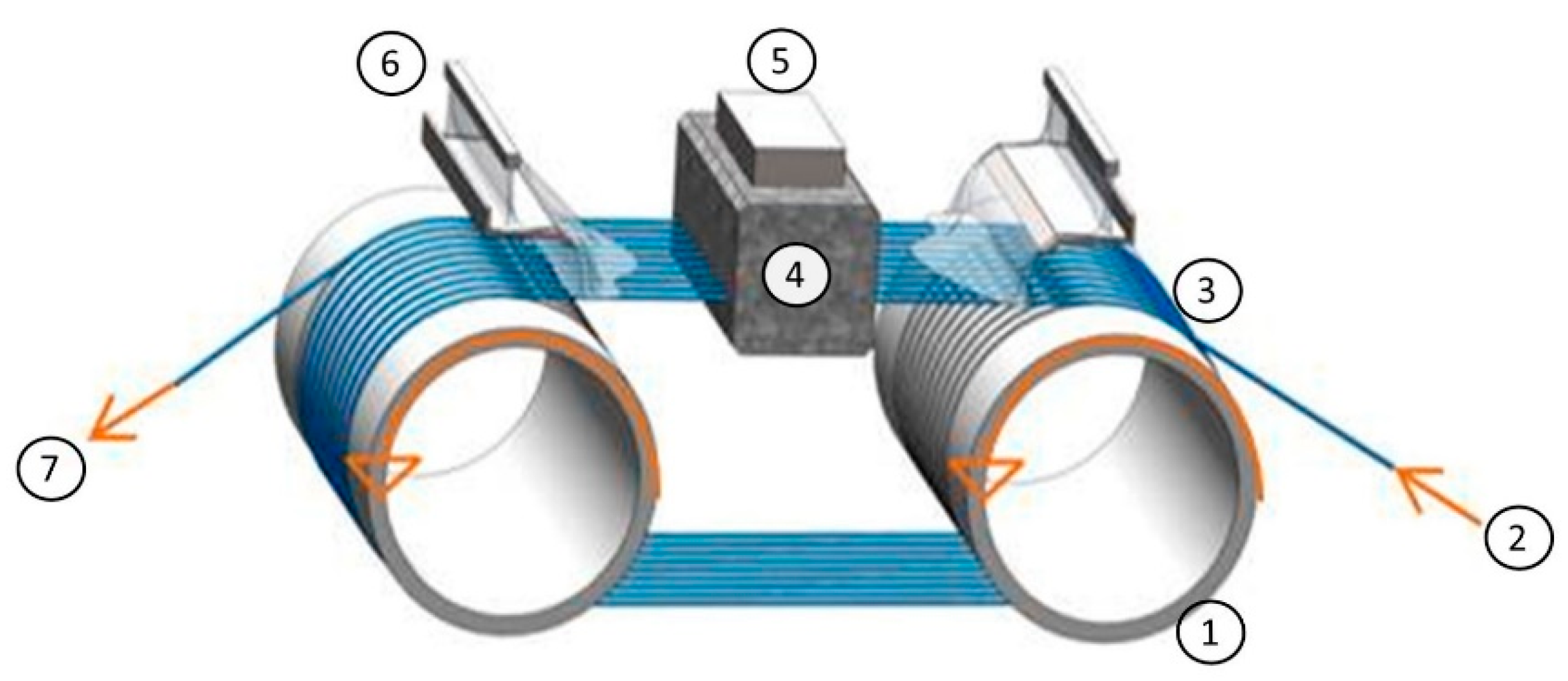

2.2. Experimental Multi-Wire Sawing Procedure

3. Results

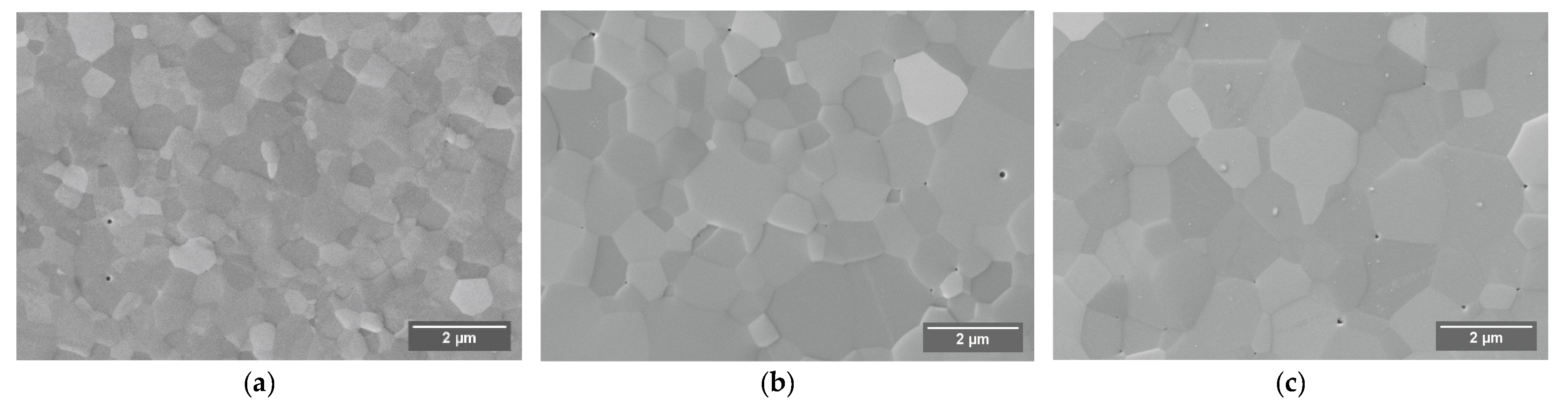

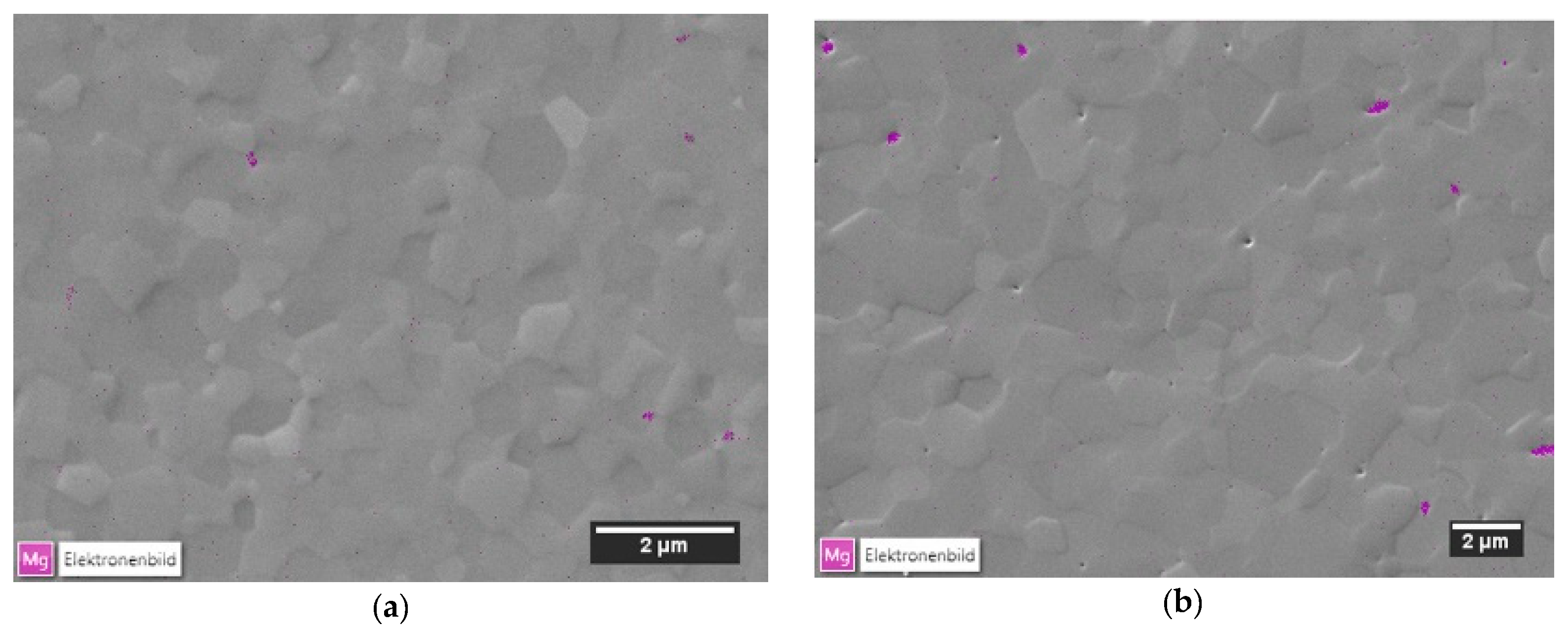

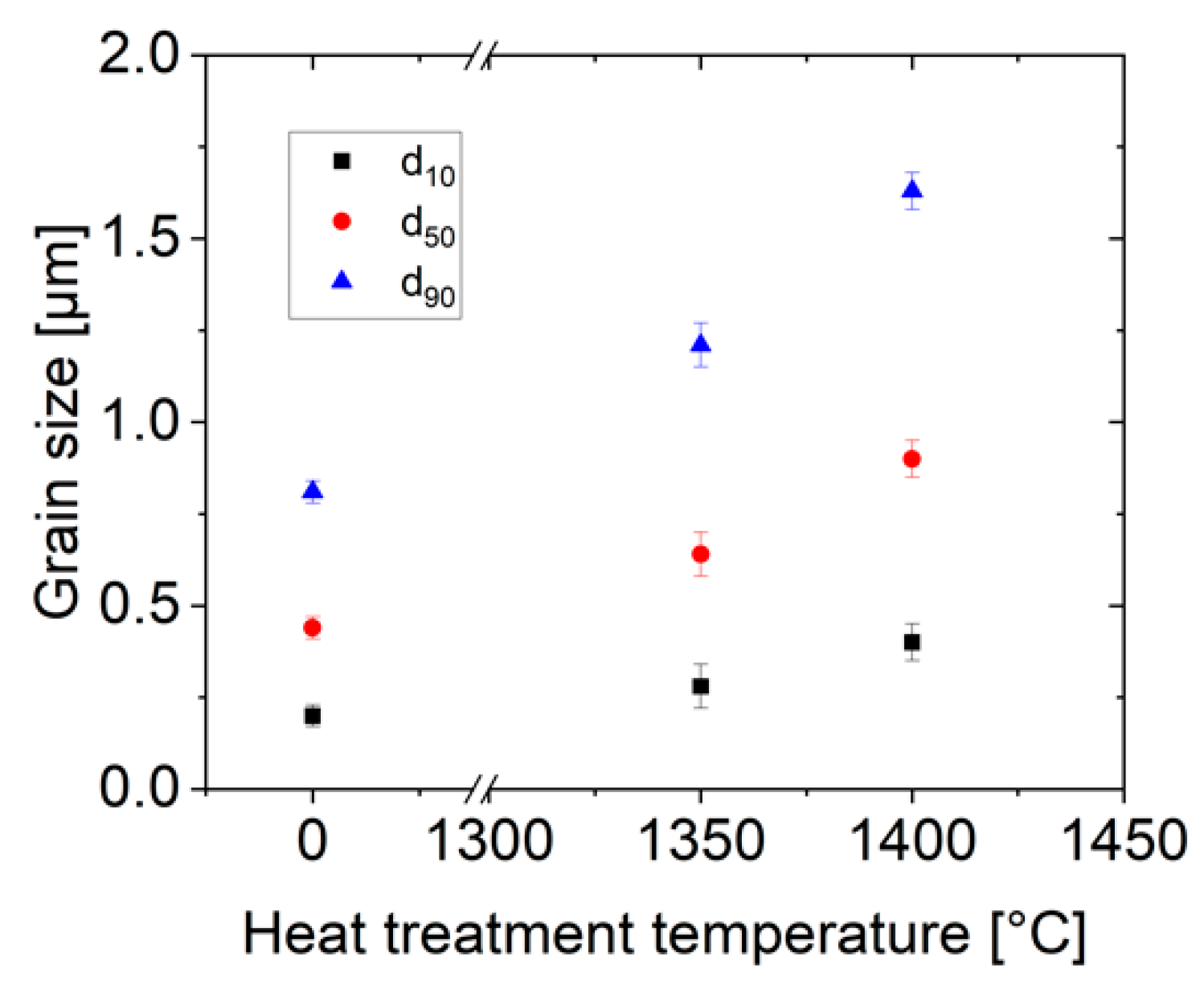

3.1. Microstructure and Properties of the Alumina Ceramic

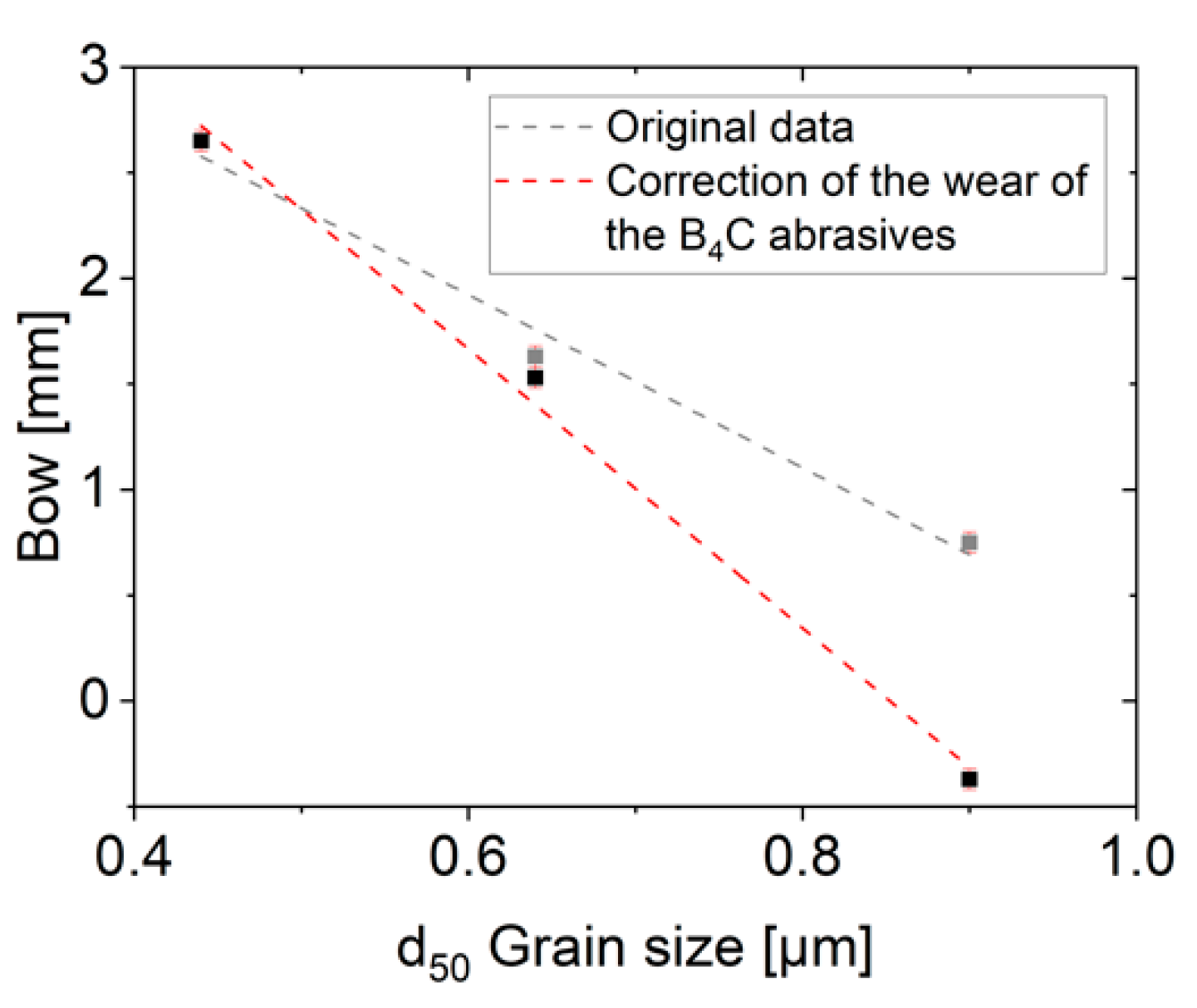

3.2. Influence of the Ceramic Grain Size on the Size of the Wire Bow

- d50 = 21.3 µm for cut #1 (O1, d50 alumina grain size: 0.44 µm)

- d50 = 15.7 µm for cut #2 (HT1400, d50 alumina grain size: 0.90 µm) and

- d50 = 20.8 µm for cut #3 (HT1350, d50 alumina grain size: 0.64 µm).

3.3. Characterization of the Alumina Ceramic Substrates

4. Discussion

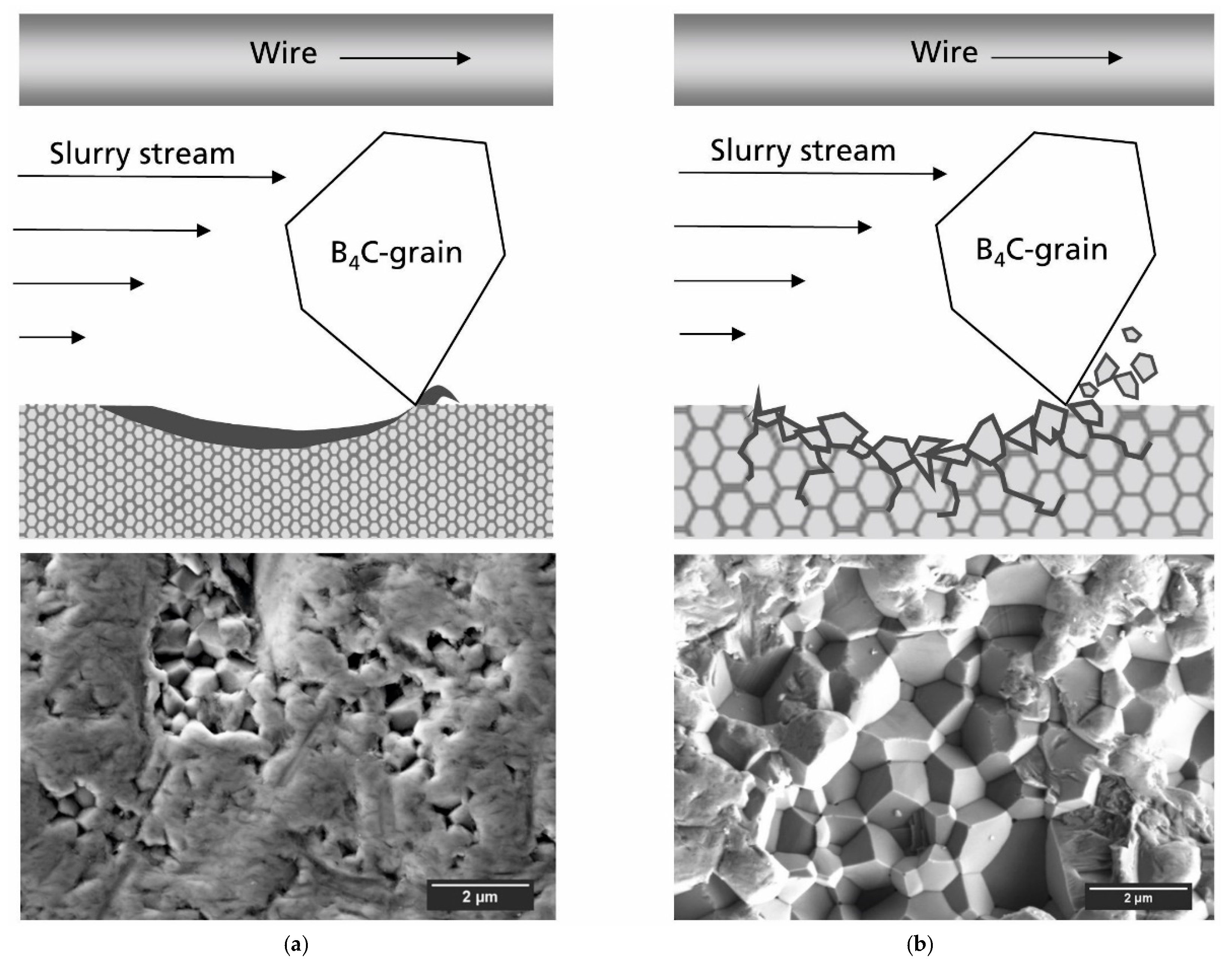

4.1. Relationship of Grain Coarsening and Efficiency of the Multi-Wire Sawing Process

4.2. Quality of the Ceramic Substrates

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Miric, A.; Dietric, P. Inorganic substrates for power electronics applications. Dvs-Ber. 2015, 310, 63–73. [Google Scholar]

- Kita, J.; Schubert, F.; Rettig, F.; Engelbrecht, A.; Groß, A.; Moos, R. Ceramic Alumina Substrates for High-temperature Gas Sensors—Implications for Applicability. Procedia Eng. 2014, 87, 1505–1508. [Google Scholar] [CrossRef] [Green Version]

- Hsu, Y.; Chen, S.; Tsao, C. Free abrasive wire saw machining of ceramics. Int. J. Adv. Manuf. Technol. 2009, 40, 503–511. [Google Scholar] [CrossRef]

- Theophil, L. Anpassung der Diamantdrahtsägeprozesse für eine Bessere Texturierfähigkeit von Multikristallinen Siliziumwafern. Master’s Thesis, TU Freiberg, Freiberg, Saxony, Germany, 2019. [Google Scholar]

- Gehl, E. Untersuchung der Topografie und Oberflächenschädigung an Siliziumwafern, die mit Unterschiedlichen Kühlschmierstoffen und Prozessparametern Hergestellt Wurden. Bachelor’s Thesis, TU Freiberg, Freiberg, Saxony, Germany, 2014. [Google Scholar]

- Schmidtner, L.; Heinrich, H.; Fuchs, M.; Pötzsch, A.; Janz, S.; Herrmann, M.; Aneziris, C.; Kaden, T. Multi-Wire Sawing of Translucent Alumina Ceramics. J. Manuf. Mater. Process. 2020, 4, 2. [Google Scholar] [CrossRef] [Green Version]

- Bidiville, A.; Wasmer, K.; Michler, J.; Nasch, P.M.; Van der Meer, M.; Ballif, C. Mechanisms of wafer sawing and impact on wafer properties. Prog. Photovolt. Res. Appl. 2010, 18, 563–572. [Google Scholar] [CrossRef]

- Munz, D.; Fett, T. Mechanical Properties, Failure Behaviour, Materials Selection; Springer: Berlin/Heidelberg, Germany, 1999; p. 36. [Google Scholar]

- Börger, A.; Supancic, P.; Danzer, R. The ball on three balls test for strength testing of brittle discs: Stress distribution in the disc. J. Eur. Ceram. Soc. 2002, 22, 1425–1436. [Google Scholar] [CrossRef]

- Danzer, R.; Harrer, W.; Supancic, P. Ein einfacher Festigkeitsversuch für Scheiben aus spröden Werkstoffen. Mater. Und Werkst. 2003, 34, 490–498. [Google Scholar] [CrossRef]

- Franken, P.; Gehring, A. Grain boundary analysis of MgO-doped Al2O3. J. Mater. Sci. 1981, 16, 384–388. [Google Scholar] [CrossRef]

- Krell, A. The effects of load, grain size, and grain boundaries on the hardness of alumina. Ceram. Eng. Sci. Proc. 1998, 19, 159–168. [Google Scholar]

- Yip, S. The strongest size. Nature 1998, 391, 532–533. [Google Scholar] [CrossRef]

- Möller, H.J. Basic Mechanisms and Models of Multi-Wire Sawing. Adv. Eng. Mater. 2004, 6, 501–513. [Google Scholar] [CrossRef]

- Yang, F.; Kao, I. Free Abrasive Machining in Slicing Brittle Materials with Wiresaw. J. Electron. Packag. 2001, 123, 254–259. [Google Scholar] [CrossRef]

- Zum Gahr, K.; Telle, R.; Zimmerlin, B.; Park, S. Einfluß der Korngröße auf mechanische Eigenschaften und den ungeschmierten reversierenden Gleitverschleiß von Al2O3-Keramik. Mater. Sci. Eng. Technol. 1992, 23, 329–338. [Google Scholar]

- Mukhopadhyay, A.; Chakraborty, D.; Swain, M.; Mai, Y. Scratch deformation behaviour of alumina under a sharp indenter. J. Eur. Ceram. Soc. 1997, 17, 91–100. [Google Scholar] [CrossRef]

- Cho, S.; Moon, H.; Hockey, B.J.; Hsu, S.M. The transition from mild to severe wear in alumina during sliding. Acta Metall. Mater. 1992, 40, 185–192. [Google Scholar] [CrossRef]

- Cho, S.; Hockey, B.; Lawn, B.; Bennison, S. Grain-Size and R-Curve Effects in the Abrasive Wear of Alumina. J. Am. Ceram. Soc. 1989, 72, 1249–1252. [Google Scholar] [CrossRef]

- Li, J.; Kao, I.; Prasad, V. Modeling Stresses of Contacts in Wire Saw Slicing of polycrystalline and crystalline ingots—Application to Silicon Wafer Production. J. Electron. Packag. 1998, 120, 123–128. [Google Scholar] [CrossRef]

- Michalowsky, L. Neue keramische Werkstoffe; Deutscher Verlag für Grundstoffindustrie Leipzig: Stuttgart, Germany, 1994; pp. 317–319. [Google Scholar]

- Evans, A. Microfracture from thermal expansion anisotrpy-I. Single phase systems. Acta Metall. 1978, 26, 1845–1853. [Google Scholar] [CrossRef]

- Teomete, E. Roughness damage evolution due to wire saw process. Int. J. Precis. Eng. Manuf. 2011, 66, 941–947. [Google Scholar] [CrossRef]

- Liedke, T.; Kuna, M. A macroscopic mechanical model of the wire sawing process. Int. J. Mach. Tools Manuf. 2011, 9, 711–720. [Google Scholar] [CrossRef]

| Sawing Parameters | |

|---|---|

| Wire condition | New |

| Wire speed (m/s) | 14 |

| Wire tension (N) | 25 |

| Pitch (mm) | 0.425 |

| Number of substrates cut in one process | 17 |

| Wire nominal diameter (mm) | 0.115 |

| Nominal B4C abrasive size (µm) | 8–32 |

| Table feed rate (mm/min) | 0.02 |

| B/F ratio | 0.64 |

| Original | Heat Treatment 1 | Heat Treatment 2 | |

|---|---|---|---|

| Process | HIP Al2O3 | HIP Al2O3 | HIP Al2O3 |

| Sample name | O1 | HT1350 | HT1400 |

| Additional heat treatment temperature (°C) | - | 1350 | 1400 |

| Density (g/cm3) | 3.98 ± 0.01 | 3.98 ± 0.01 | 3.98 ± 0.01 |

| Grain size d50-value (µm) | 0.44 ± 0.03 | 0.64 ± 0.06 | 0.90 ± 0.05 |

| Vicker’s hardness | |||

| HV0.5 | 2279 ± 1 | 2139 ± 23 | 2142 ± 23 |

| HV1 | 2220 ± 5 | 2060 ± 18 | 2027 ± 25 |

| HV2 | 2168 ± 13 | 2059 ± 23 | 1980 ± 15 |

| KIC (Niihara HP; HV1) (MPa*m0.5) | 3.5 ± 0.2 | 3.4 ± 0.1 | 2.8 ± 0.2 |

| Characteristic biaxial strength of the cut substrates (Mpa) | 1356 (1328‒1386) | 1144 (1116‒1173) | 1033 (1008–1059) |

| Weibull modulus | 16.3 ± 3.5 | 14.2 ± 4.0 | 14.0 ± 3.0 |

| Surface roughness of the cut substrates | |||

| Ra ⊥ (µm) | 0.23 ± 0.01 | 0.32 ± 0.03 | 0.33 ± 0.02 |

| Ra || (µm) | 0.23 ± 0.01 | 0.36 ± 0.08 | 0.33 ± 0.02 |

| Rz ⊥ (µm) | 1.70 ± 0.09 | 2.04 ± 0.53 | 3.00 ± 0.54 |

| Rz || (µm) | 1.62 ± 0.09 | 2.18 ± 0.50 | 2.84 ± 0.62 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schmidtner, L.; Herrmann, M.; Aneziris, C.G. Grain-Size Effects on Multi-Wire Slurry Sawing of Translucent Alumina Ceramics. Ceramics 2020, 3, 428-439. https://0-doi-org.brum.beds.ac.uk/10.3390/ceramics3040036

Schmidtner L, Herrmann M, Aneziris CG. Grain-Size Effects on Multi-Wire Slurry Sawing of Translucent Alumina Ceramics. Ceramics. 2020; 3(4):428-439. https://0-doi-org.brum.beds.ac.uk/10.3390/ceramics3040036

Chicago/Turabian StyleSchmidtner, Lea, Mathias Herrmann, and Christos G. Aneziris. 2020. "Grain-Size Effects on Multi-Wire Slurry Sawing of Translucent Alumina Ceramics" Ceramics 3, no. 4: 428-439. https://0-doi-org.brum.beds.ac.uk/10.3390/ceramics3040036