Mechanical Properties of 2Y-TZP Fabricated from Detonation Synthesized Powder

Abstract

:1. Introduction

2. Materials and Methods

3. Results

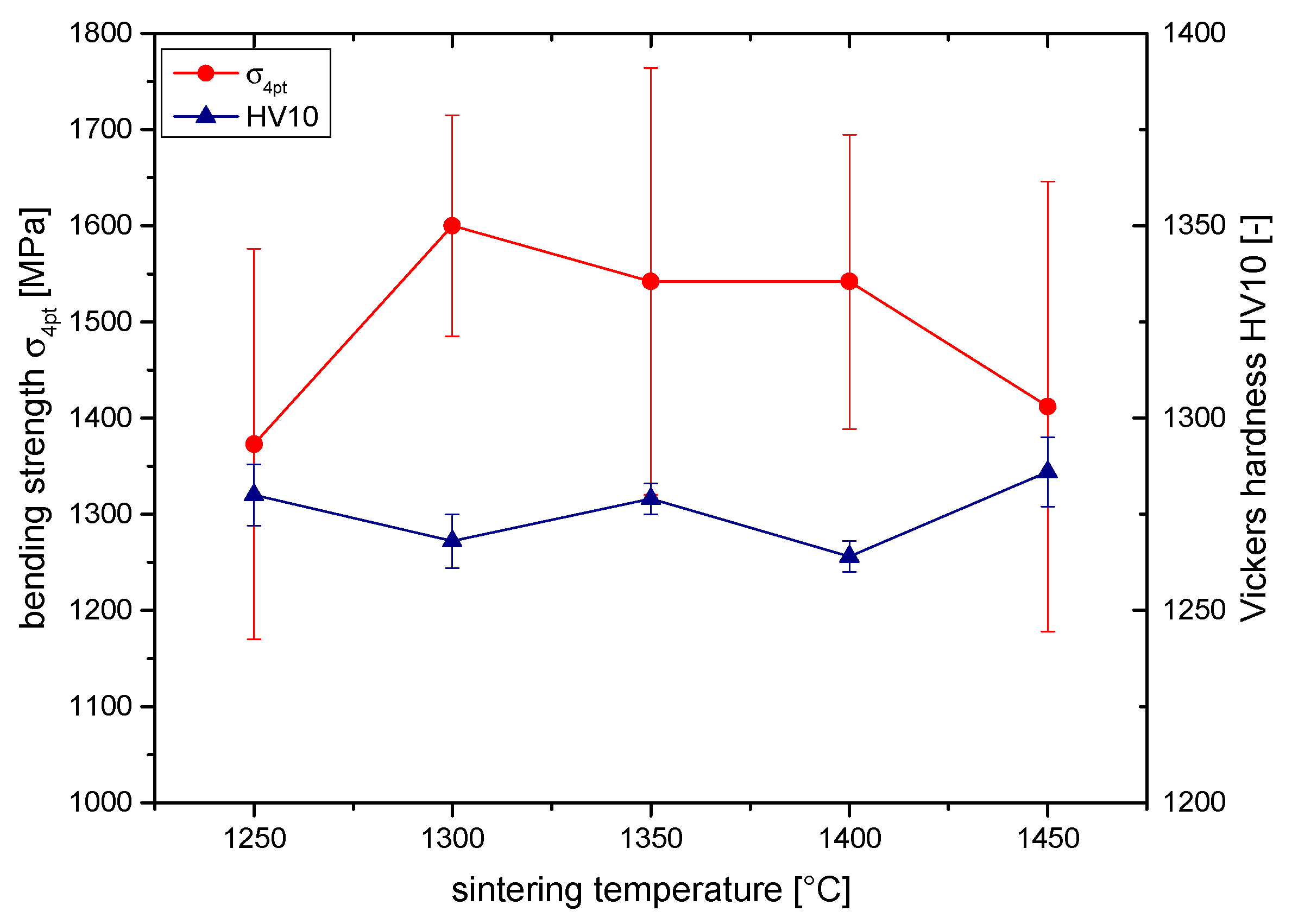

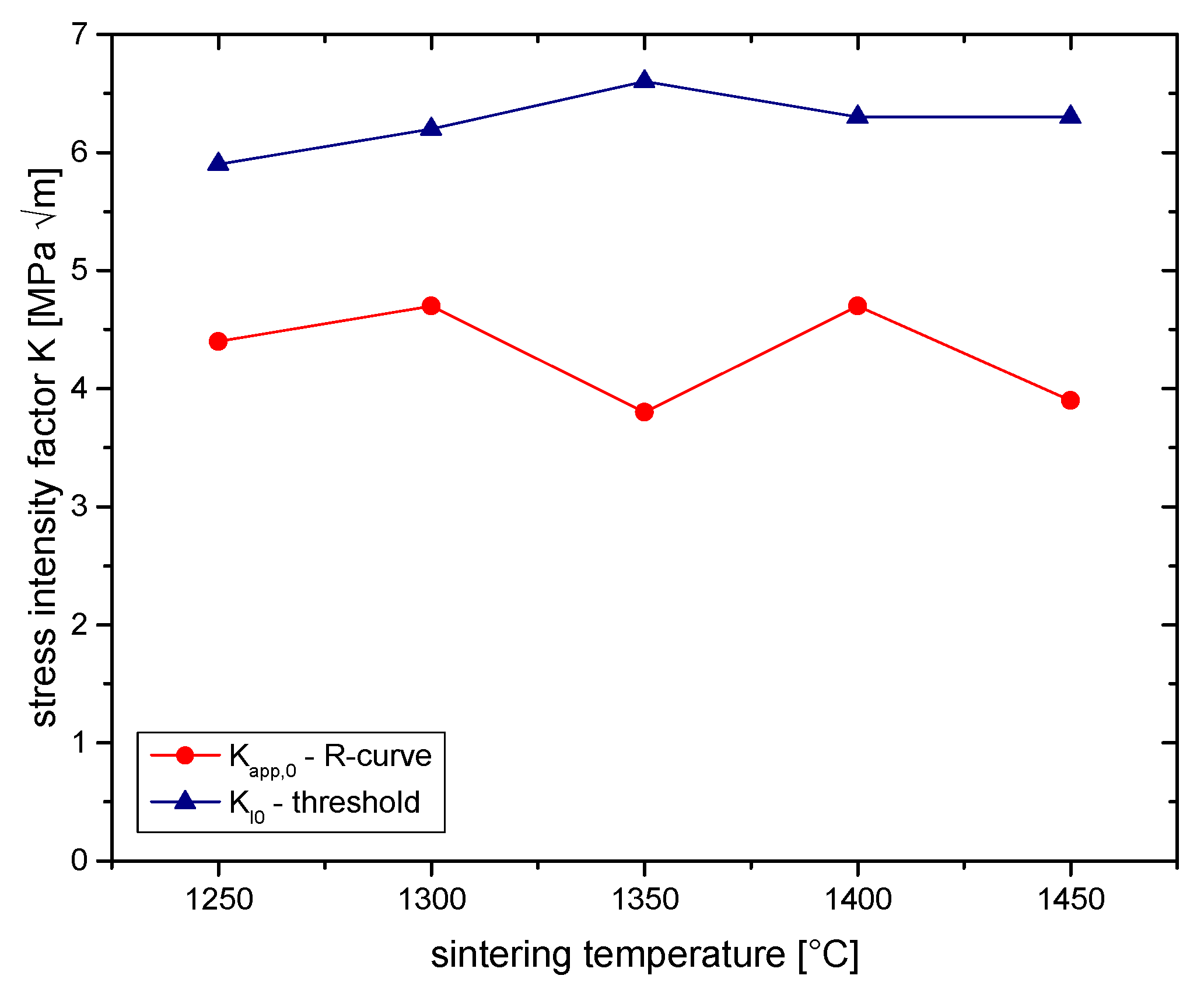

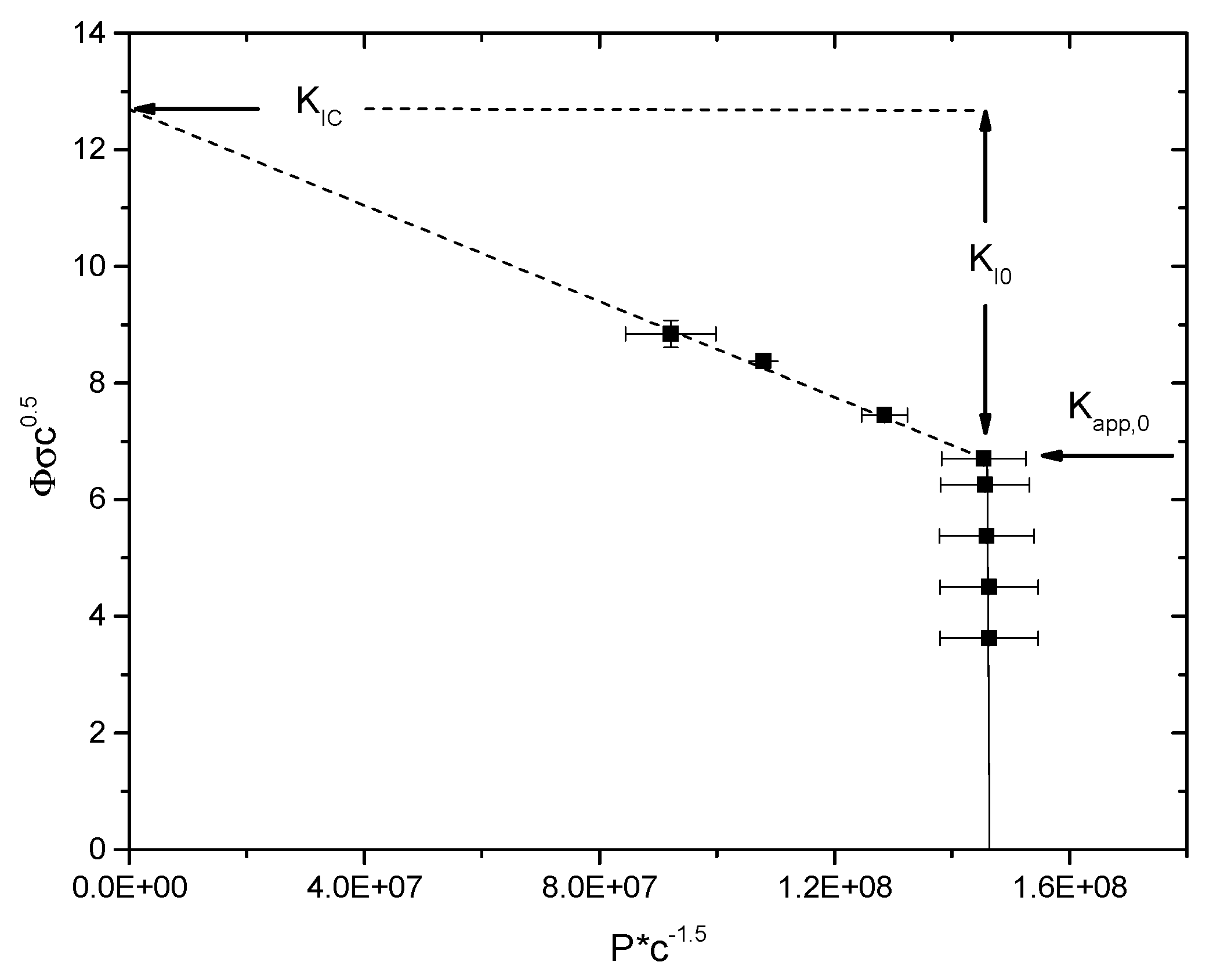

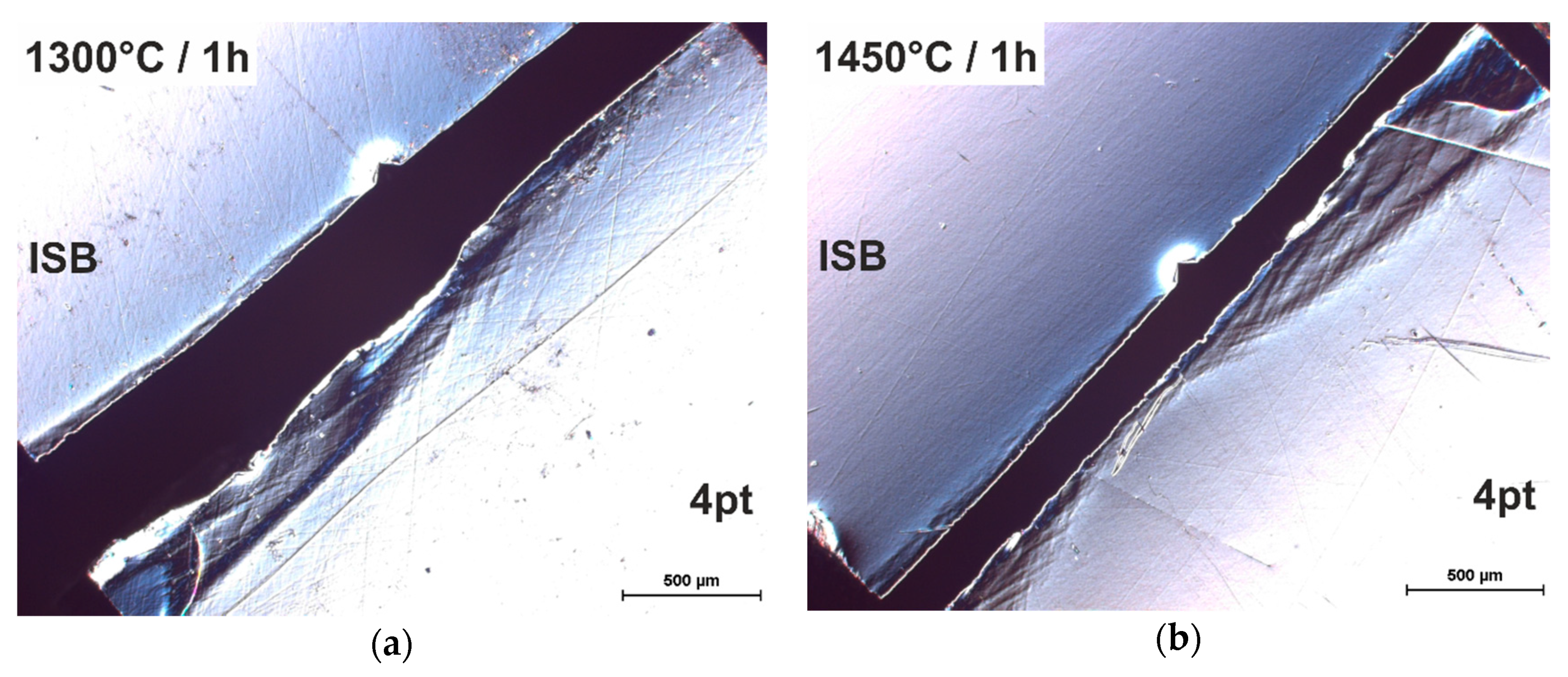

3.1. Mechanical Testing

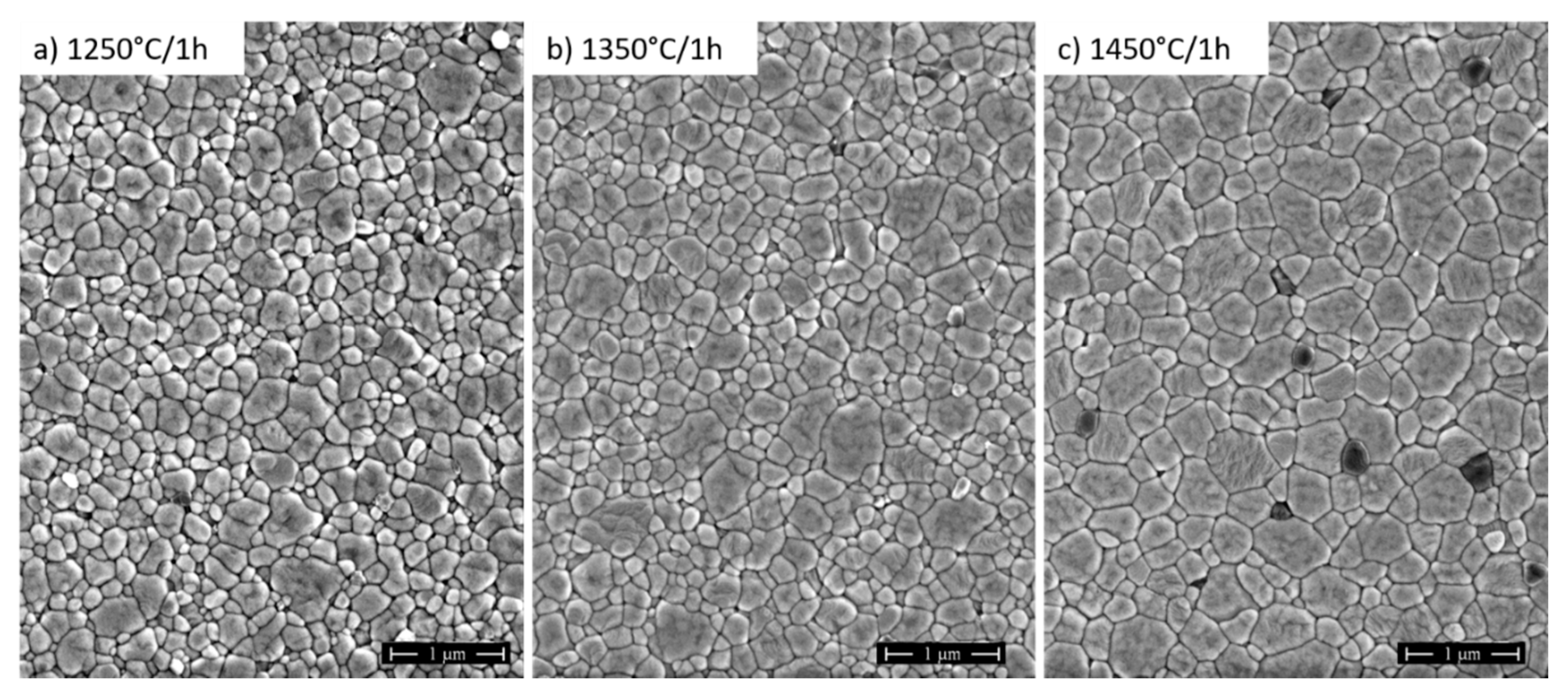

3.2. Microstructure

3.3. Phase Composition

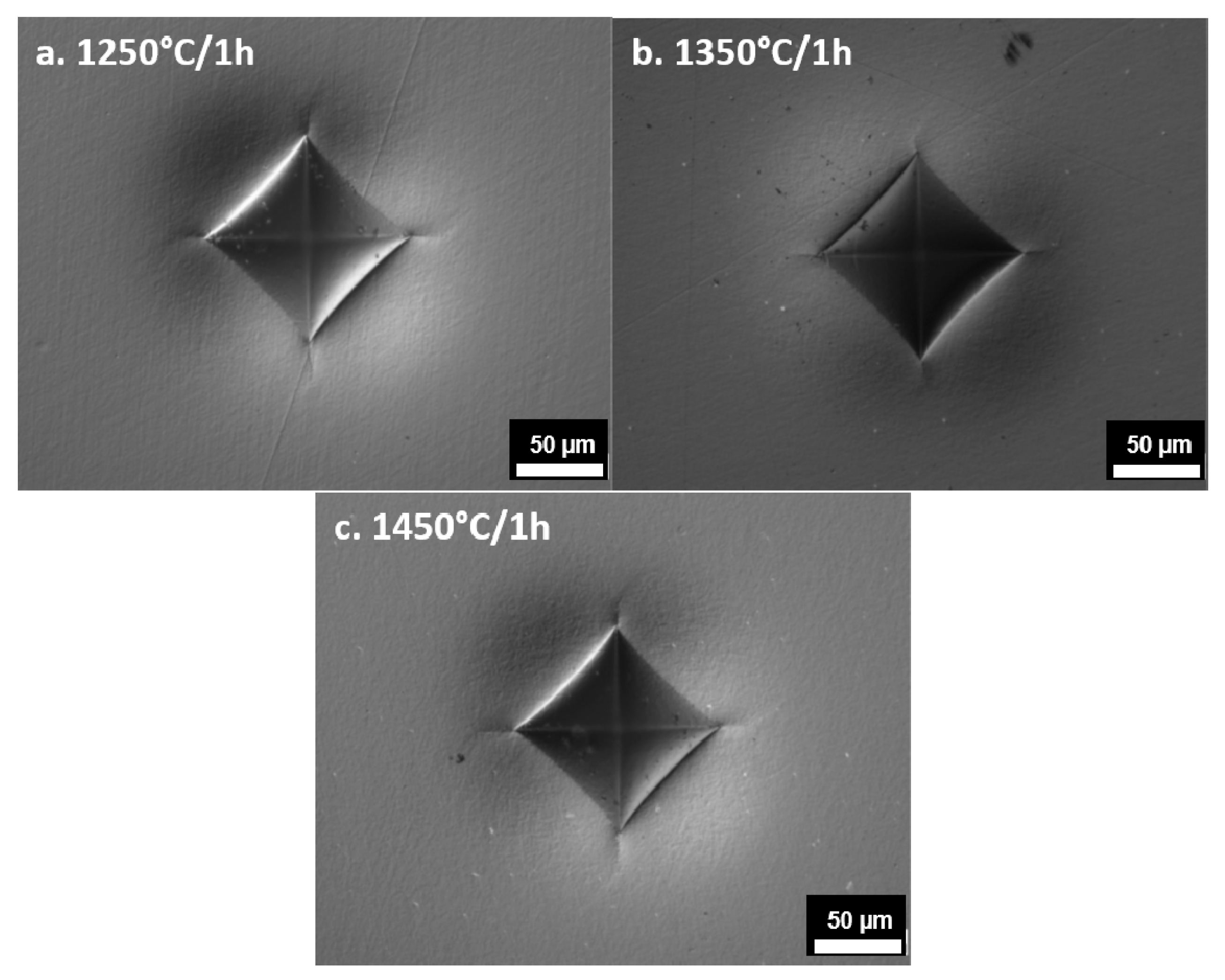

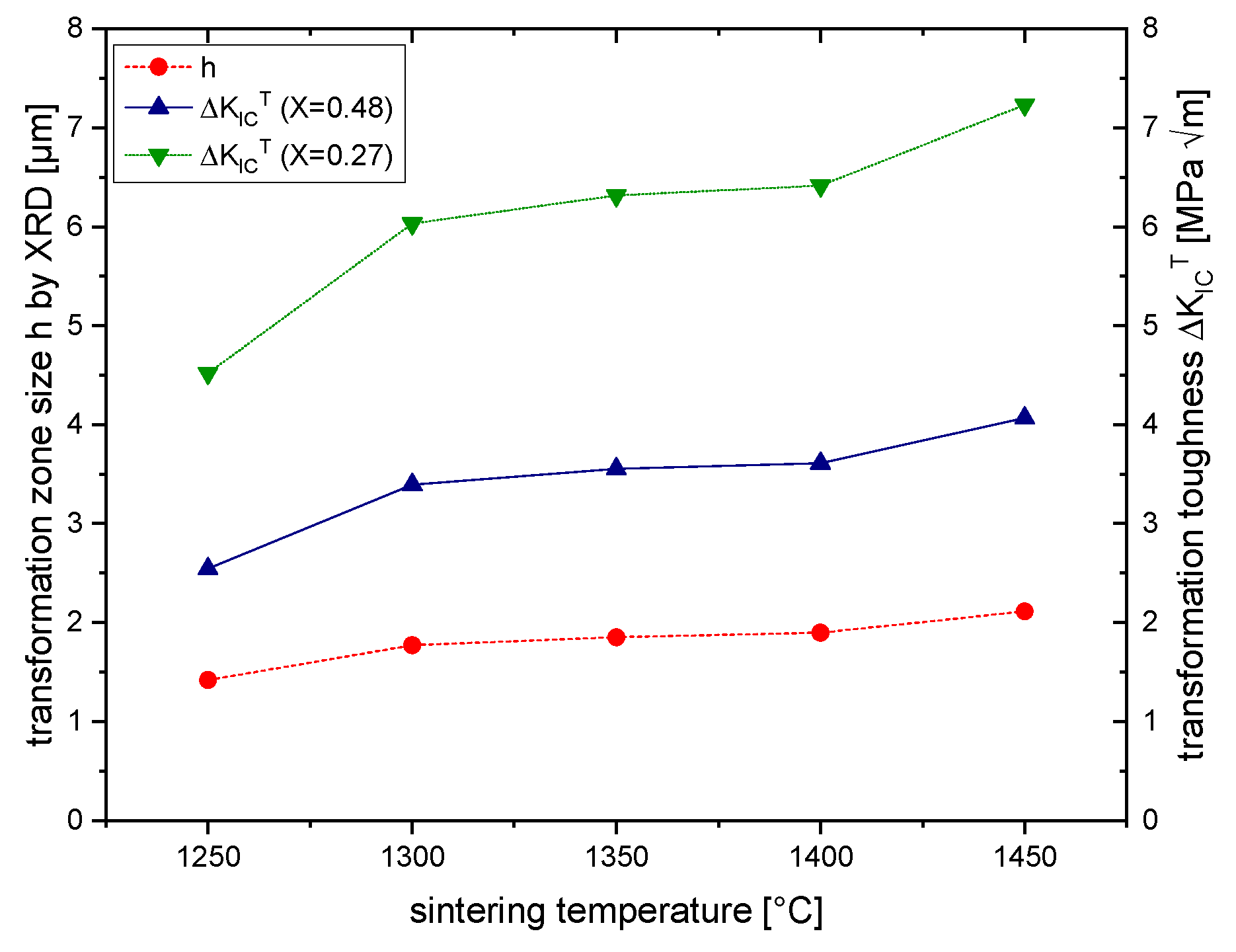

3.4. Transformation Zones

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hannink, R.H.J.; Kelly, P.M.; Muddle, B.C. Transformation Toughening in Zirconia-Containing Ceramics. J. Am. Ceram. Soc. 2000, 83, 461–487. [Google Scholar] [CrossRef]

- Chevalier, J.; Gremillard, L. Ceramics for medical applications: A picture for the next 20 years. J. Eur. Ceram. Soc. 2009, 29, 1245–1255. [Google Scholar] [CrossRef]

- Rahaman, M.N.; Yao, A.; Bal, B.S.; Garino, J.P.; Ries, M.D. Ceramics for Prosthetic Hip and Knee Joint Replacement. J Am. Ceram. Soc. 2007, 90, 1965–1988. [Google Scholar] [CrossRef]

- Sun, C.; Hui, R.; Roller, J. Cathode materials for solid oxide fuel cells: A review. J Solid State Electrochem. 2010, 14, 1125–1144. [Google Scholar] [CrossRef]

- Cao, X.Q.; Vassen, R.; Stoever, D. Ceramic materials for thermal barrier coatings. J. Eur. Ceram. Soc. 2004, 24, 1–10. [Google Scholar] [CrossRef]

- Kelly, P.M.; Rose, L.R.F. The martensitic transformation in ceramics—Its role in transformation toughening. Prog. Mater. Sci. 2002, 47, 463–557. [Google Scholar] [CrossRef]

- Kim, J.H.; Hwang, K.H.; Lee, J.K. Effect of calcination temperature on the properties of Y-TZP powders prepared by co-precipitation. J. Nanosci. Nanotechnol. 2017, 17, 4368–4371. [Google Scholar] [CrossRef]

- Chen, M.; Hallstedt, B.; Gauckler, L.J. Thermodynamic modeling of the ZrO2–YO1.5 system. Solid State Ion. 2004, 170, 255–274. [Google Scholar] [CrossRef]

- Matsui, K.; Horikoshi, H.; Ohmichi, N.; Ohgai, M.; Yoshida, H.; Ikuhara, Y. Cubic-Formation and Grain-Growth Mechanisms in Tetragonal Zirconia Polycrystal. J. Am. Ceram. Soc. 2003, 86, 1401–1408. [Google Scholar] [CrossRef]

- Swain, M.V. Grain-size dependence of toughness and transformability of 2mol % Y-TZP ceramics. J. Mater. Sci. Lett. 1986, 5, 1159–1162. [Google Scholar] [CrossRef]

- Basu, B.; Vleugels, J.; van der Biest, O. Toughness tailoring of yttria-doped zirconia ceramics. Mater. Sci. Eng. A 2004, 380, 215–221. [Google Scholar] [CrossRef]

- Binner, J.; Vaidhyanathan, B.; Paul, A.; Annaporani, K.; Raghupathy, B. Compositional Effects in Nanostructured Yttria Partially Stabilized Zirconia. Int. J. Appl. Ceram. Technol. 2011, 8, 766–782. [Google Scholar] [CrossRef] [Green Version]

- Lange, F.F. Transformation toughening: Part 3 Experimental observations in the ZrO2- Y203 system. J. Mater. Sci. 1982, 17, 240–246. [Google Scholar] [CrossRef]

- Singh, R.; Gill, C.; Lawson, S.; Dransfield, G.P. Sintering, microstructure and mechanical properties of commercial Y-TZPs. J. Mater. Sci. 1996, 31, 6055–6062. [Google Scholar] [CrossRef]

- Kern, F.; Strumberger, H.; Gadow, R. Effects of Stabilizer Content and Sintering Conditions on Y-TZP Ceramics made from Stabilizer-Coated Nanopowders. J. Ceram. Sci. Technol. 2017, 8, 7–18. [Google Scholar] [CrossRef]

- Kern, F. Evidence of Phase Transitions and Their Role in the Transient Behavior of Mechanical Properties and Low Temperature Degradation of 3Y-TZP Made from Stabilizer-Coated Powder. Ceram. 2019, 2, 271–285. [Google Scholar] [CrossRef] [Green Version]

- Bondioli, F.; Leonelli, C.; Manfredini, T.; Ferrari, A.M.; Caracoche, M.C.; Rivas, P.C.; Rodriguez, A.M. Microwave-Hydrothermal Synthesis and Hyperfine Characterization of Praseodymium-Doped Nanometric Zirconia Powders. J Am. Ceram. Soc. 2005, 88, 633–638. [Google Scholar] [CrossRef]

- Piticescu, R.R.; Monty, C.; Taloi, D.; Motoc, A.; Axinte, S. Hydrothermal synthesis of zirconia nanomaterials. J. Eur. Ceram. Soc. 2001, 21, 2057–2060. [Google Scholar] [CrossRef]

- Calado, J. Ceramic Powder Production with Emulsion Detonation Synthesis. CFI/Ber. DKG 2016, 93, E32–E34. [Google Scholar]

- Da Silva, J.M.C.; Antunes, E.M.D.S. Nanocrystalline Spherical Ceramic Oxides, Process for the Synthesis and Use Thereof. U.S. Patent 9,249,020, 2 February 2016. [Google Scholar]

- Kern, F.; Lindner, V.; Gadow, R. Low-Temperature Degradation Behaviour and Mechanical Properties of a 3Y-TZP Manufactured from Detonation-Synthesized Powder. J. Ceram. Sci. Technol. 2016, 07, 313–322. [Google Scholar] [CrossRef]

- Kern, F.; Reveron, H.; Chevalier, J.; Gadow, R. Mechanical behaviour of extremely tough TZP bioceramics. J. Mech. Behav. Biomed. Mater. 2019, 90, 395–403. [Google Scholar] [CrossRef]

- Niihara, K.; Morena, R.; Hasselman, D.P.H. Evaluation of KIc of brittle solids by the indentation method with low crack-to-indent ratios. J. Mater. Sci. Lett. 1982, 1, 13–16. [Google Scholar] [CrossRef]

- Chantikul, P.; Anstis, G.R.; Lawn, B.R.; Marshall, D.B. A Critical Evaluation of Indentation Techniques for Measuring Fracture Toughness: II, Strength Method. J. Am. Ceram. Soc. 1981, 64, 539–543. [Google Scholar] [CrossRef]

- Dransmann, G.W.; Steinbrech, R.W.; Pajares, A.; Guiberteau, F.; Dominguez-Rodriguez, A.; Heuer, A.H. Indentation Studies on Y2O3-Stabilized ZrO2: II, Toughness Determination from Stable Growth of Indentation-Induced Cracks. J Am. Ceram. Soc. 1994, 77, 1194–1201. [Google Scholar] [CrossRef]

- Newman, J.C.; Raju, I.S. Analyses of Surface Cracks in Finite Plates Unter Tension or Bending Loads. Nasa Tech. Pap. 1979, 1578, 1–43. [Google Scholar]

- Toraya, H.; Yoshimura, M.; Somiya, S. Calibration Curve for Quantitative Analysis of the Monoclinic-Tetragonal ZrO2 System by X-Ray Diffraction. J. Am. Ceram. Soc. 1984, 67, C119–C121. [Google Scholar] [CrossRef]

- Nakayama, S.; Maekawa, S.; Sato, T.; Masuda, Y.; Imai, S.; Sakamoto, M. Mechanical properties of ytterbia stabilized zirconia ceramics (Yb-TZP) fabricated from powders prepared by co-precipitation method. Ceram. Int. 2000, 26, 207–211. [Google Scholar] [CrossRef]

- Kosmać, T.; Wagner, R.; Claussen, N. X-Ray Determination of Transformation Depths in Ceramics Containing Tetragonal ZrO2. J. Am. Ceram. Soc. 1981, 64, C-72–C-73. [Google Scholar] [CrossRef]

- McMeeking, R.M.; Evans, A.G. Mechanics of Transformation-Toughening in Brittle Materials. J. Am. Ceram. Soc. 1982, 65, 242–246. [Google Scholar] [CrossRef]

- Patterson, A.L. The Scherrer Formula for X-Ray Particle Size Determination. Phys. Rev. 1939, 56, 978–982. [Google Scholar] [CrossRef]

- Mendelson, M.I. Average Grain Size in Polycrystalline Ceramics. J. Am. Ceram. Soc. 1969, 52, 443–446. [Google Scholar] [CrossRef]

- DIN. Dentistry—Ceramic Materials; The National Standards Authority of Ireland (NSAI): Dublin, Ireland, 2015. [Google Scholar]

- Quinn, G.D.; Bradt, R.C. On the Vickers Indentation Fracture Toughness Test. J. Am. Ceram. Soc. 2007, 90, 673–680. [Google Scholar] [CrossRef]

- Cook, R.F.; Braun, L.M.; Cannon, W.R. Trapped cracks at indentations: Part I: Experiments on yttria-tetragonal zirconia polycrystals. J. Mater. Sci. 1994, 29, 2133–2142. [Google Scholar] [CrossRef]

- Cook, R.F.; Braun, L.M. Trapped cracks at indentations: Part II: Fracture mechanics model. J. Mater. Sci. 1994, 29, 2192–2204. [Google Scholar] [CrossRef]

- Chevalier, J.; Saadaoui, M.; Olagnon, C.; Fantozzi, G. Double-torsion testing a 3Y-TZP ceramic. Ceram. Int. 1996, 22, 171–177. [Google Scholar] [CrossRef]

- Lube, T.; Fett, T. A threshold stress intensity factor at the onset of stable crack extension of Knoop indentation cracks. Eng. Fract. Mech. 2004, 71, 2263–2269. [Google Scholar] [CrossRef]

- Scott, H.G. Phase relationships in the zirconia-yttria system. J. Mater. Sci. 1975, 10, 1527–1535. [Google Scholar] [CrossRef]

- Swain, M.V.; Rose, L.R.F. Strength Limitations of Transformation-Toughened Zirconia Alloys. J. Am. Ceram. Soc. 1986, 69, 511–518. [Google Scholar] [CrossRef]

- Tsukuma, K. Thermal and Mechanical Properties of Y2O3-Stabilized Tetragonal Zirconia Polycrystals, Science and Technology of Zirconia II. Adv. Ceram. 1984, 12, 382–390. [Google Scholar]

- Chevalier, J.; Olagnon, C.; Fantozzi, G.; Cales, B. Subcritical Crack Growth and Thresholds in a 3Y-TZP Ceramic Under Static and Cyclic Loading Conditions. Ceram. Int. 1997, 23, 263–266. [Google Scholar] [CrossRef]

- Kern, F. 2.5Y-TZP from Yttria-Coated Pyrogenic Zirconia Nanopowder. J. Ceram. Sci. Technol. 2010, 01, 21–26. [Google Scholar] [CrossRef]

- Swain, M.V. Limitation of Maximum Strength of Zirconia-Toughened Ceramics by Transformation Toughening Increment. J. Am. Ceram. Soc. 1985, 68, C-97–C-99. [Google Scholar] [CrossRef]

- Sergo, V.; Clarke, D.R.; Pompe, W. Deformation Bands in Ceria-Stabilized Tetragonal Zirconia/Alumina: I, Measurement of Internal Stresses. J. Am. Ceram. Soc. 1995, 78, 633–640. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kern, F.; Gommeringer, A. Mechanical Properties of 2Y-TZP Fabricated from Detonation Synthesized Powder. Ceramics 2020, 3, 440-452. https://0-doi-org.brum.beds.ac.uk/10.3390/ceramics3040037

Kern F, Gommeringer A. Mechanical Properties of 2Y-TZP Fabricated from Detonation Synthesized Powder. Ceramics. 2020; 3(4):440-452. https://0-doi-org.brum.beds.ac.uk/10.3390/ceramics3040037

Chicago/Turabian StyleKern, Frank, and Andrea Gommeringer. 2020. "Mechanical Properties of 2Y-TZP Fabricated from Detonation Synthesized Powder" Ceramics 3, no. 4: 440-452. https://0-doi-org.brum.beds.ac.uk/10.3390/ceramics3040037