1. Introduction

Technical sports clothing with light-responsive features for outdoor sports practiced in low-light environments is of extreme importance to athlete’s safety, fundamentally regarding their visibility. Daily, multiple sportsmen practice their activity in obscured environments exposed to vehicle traffic under low-visibility conditions regarding the typology of responsive apparel detained. So far, several studies were carried out to analyze the relationship between the lack of visibility of pedestrians, cyclists and/or workers with the number of accidents occurring in conditions of low ambient light [

1,

2,

3,

4]. In fact, data published in 2002 suggest that the probability of a fatal collision between a vehicle and a pedestrian in obscured environments is 3 to 7 times higher than the probability of this occurring in bright environments [

5]. Furthermore, the study by Lahrmann et al. (2018) [

3] generated evidence that the use of fluorescent yellow jackets by cyclists can lead to a significant decrease in accidents with personal injuries in obscure environments. Recently, the interest in phosphorescent material has also increased, due to its imperceptibility in bright environments and the intensity of its “glow” in dark environments [

6].

Light-responsive solutions available on the market resort essentially to two different technologies to promote visibility: retroreflection and photoluminescence. In this study, research and development of new light-responsive materials will focus on photo luminescent technologies.

Photoluminescence refers to the emission of light radiation by a certain material after being subjected to an external excitation stimulus, in this case UV radiation or visible radiation. Depending on the duration of radiation emission, that is, on the persistence of luminescence, these processes can also be divided into fluorescence and phosphorescence [

7,

8].

Fluorescence is characterized by the fact that the emission of radiation lasts up to 10

−8 s after excitation, stopping almost as soon as excitation ends [

7,

8]. Molecules in a fluorescent body absorb radiation near the UV region of shorter wavelengths and high energy, converting it into visible radiation of longer wavelengths. Thus, fluorescent bodies produce a characteristic “brightness” of light, whereas those of conventional colors only reflect a small portion of energy from the visible spectrum [

9,

10,

11].

Some substances have the ability to maintain the emission of radiation after 10

−8 s of stimulus removal, being responsible for what is usually called “long-lasting glow in the dark”. Therefore, phosphorescence is the phenomenon responsible for the lasting emission mentioned [

6,

7,

8,

12].

Thus, the main distinction between fluorescent and phosphorescent substances resides in the persistence of luminescence once the excitation source is removed and can be characterized by the decay of emission intensity with time, compared to the initial emission intensity [

7]. In fluorescent bodies, the observed decay occurs almost instantaneously after the excitation source is removed, whereas in phosphorescence mechanisms, the decay occurs gradually over time.

The EU decided that the use of different standards regarding high-visibility clothing would not depend on the end-user activity but in the risk of the situation. Therefore, EN 20471 is to be used for high-risk situations, whereas EN 17353 is to be used for medium- risk situations. The new standard published in 2020, EN17353 supersedes two separate standards: EN 1150:1999: “Protective clothing. Visibility Clothing for non-professional use. Test methods and requirements” and EN 13356:2001: “Visibility accessories for non-professional use. Test methods and requirements”, which have been withdrawn from use. Since garments certified by EN 17353 are not intended for high-risk situations, this standard has been devised to allow manufactures more freedom in terms of product design. In addition, garments certified by EN17353 are permitted for use in daylight conditions (day), dark conditions only (night) or for both daylight and dark conditions. Concerning Type A equipment, which are worn by users where the risk of not being seen exists only in daylight conditions, the enhanced visibility component is a fluorescent material only. On the other hand, Type B equipment uses only retroreflective material as an enhanced visibility component, and are worn by users where the risk of not being seen exists only in dark conditions. Type AB equipment, worn by users where risk of not being seen is present in daylight, twilight and dark conditions, uses fluorescent as well as retroreflective material and/or combined performance materials as enhanced visibility components.

Regarding phosphorescent-coated knitted fabric, the standard used is DIN 67510-1: “Phosphorescent Pigments and Products”. According to this standard, samples are exposed during a time of 5 min at 1000 lux from a xenon lamp. The sample was kept under dark conditions for at least 48 h prior to excitation. In accordance with Section 4.5 in DIN 67510-1, a logarithmic extrapolation of the results was made to determine the time when the luminance is 0.3 mcd/m

2, the decay time. The minimum luminance required by DIN 67510-1 is 0.32 mcd/m

2 which according to literature is 100 times superior to human sight threshold [

13].

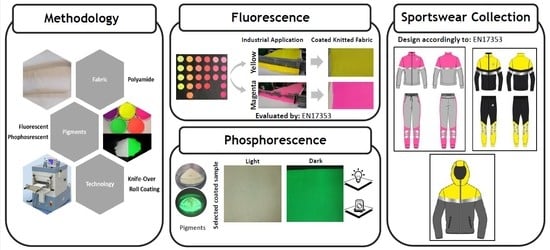

In this way, the aim of this study is to present the experimental work done and the results achieved within the development of new highly-resistant light-responsive structures, using two advanced technologies; fluorescence, and photoluminescence. This study also investigated their applications in sports clothing, considering the new EN 17353 standard requirements, which allow the user to be visually-signalized whenever the situation demands it, without neglecting the properties of comfort, ergonomics, and design. Exploring the use of fluorescent and phosphorescent pigments through knife over roll coating technology for textile knitted fabrics functionalization is of great significance to achieve light responsive structures suitable for application in sportswear, avoiding the use of dyeing technologies that consumes a huge amount of water being less environmentally friendly. Additionally, the application of the new EN 17353 standard to the innovative clothing design shows that is possible to develop aesthetically-appealing clothes with light-responsive materials. Therefore, this solution intends to respond to market needs in the area of light-responsive materials, through the development of a new clothing collection that is more flexible, more breathable and that provides a greater degree of signalization, protection and comfort, namely for long exposure times and without neglect the design.

2. Materials and Methods

To develop new light-responsive materials, different fluorescent and phosphorescent pigments were studied. Regarding the fluorescent materials, six different pigment colors (red, orange–red, orange–yellow, yellow, magenta and cerise) obtained from CESTISA were studied, with different additivation percentages (the amount of pigment (g) per 100 g of binder). Additivation percentages used are: 2, 5, 7, 10 and 25%.

On the other hand, three phosphorescent pigments (one from Brilliant and two from NEMOTO) were studied. These pigments present a yellow-green glow in dark conditions and differ from each other in relation to the diameter of the particles (P1: d = 65–75 µm; P2: d = 25 µm; P3: d = 2.5 µm).

After several experiments, it was possible to conclude that knife over roll coating is the most suitable technology for the pigments under study. Thus, it was the textile technology used in this study. Knife coating technology is one of the oldest coating methods in which a coating material is poured in front of the knife, with an adequate viscosity so that it does not permeate through the fabric. The coated fabric then passes through the drying oven. The coating thickness is mainly controlled by the gap between the knife and the fabric [

14]. In this study, the application was done using a coating device type SV Werner Mathis AG, followed by a drying phase performed using a drying oven LTE Werner Mathis AG during 5 min at 100 °C. The thermo-fixation was done in the same drying oven at 140 °C for 3 min. The thickness of the coated layer achieved was approximately 0.2 mm.

The base formulation of coating paste with fluorescent pigments,

Figure 1, is composed by: a binder—soft aqueous polyurethane dispersion—a thickening agent, and an emulsifier and dispersing agent. After the preliminary experiments, it was found that to improve fastness to wash a cross-linker should be added to the base formulation, and therefore, two cross-linkers were studied: CL1 which is an aliphatic polyisocyanate and CL2, which is a polyurethane-based formaldehyde-free crosslinking agent. On the other hand, the phosphorescent pigments were applied in a two-component transparent silicone paste since these pigments do not disperse entirely in the binder used for fluorescent pigments, as mentioned in

Figure 1.

The components used in the fluorescent and phosphorescent formulations are characterized in

Table 1.

For the application of the mentioned formulations by knife over roll coating, the knitted fabric utilized was an interlock 100% polyamide with 80 g/m2, which is suitable for the final application, sportswear clothing.

Regarding fluorescent functional finishing’s, in the screening phase, the developed materials were evaluated regarding color performance: chromaticity coordinates and luminance factor according to European Standard of Protective clothing: Enhanced visibility equipment for medium risk situations—Test methods and requirements (EN 17353). The color performance was tested using Macbeth 2145 equipment with the following conditions: 45/0 illumination geometry, observer 2° and illuminant D65.

Additionally, in the initial stage, samples were submitted to abrasion-resistance tests according to NP EN ISO 12947–2:2016, method 2—Determination of abrasion resistance of textile materials by the Martindale method. The abrasive fabric used was wool and the specimens were subjected to a constant pressure of 9 kPa and evaluated after 5000 cycles.

The final samples, knitted fabric coated with the optimized and selected formulations, were submitted to the test battery required by EN 17353, presented in

Table 2.

The color performance was tested using Macbeth 2145 equipment with the following conditions: 45/0 illumination geometry, observer 2° and illuminant D65. The color after the xenon test was tested using the equipment used in the color performance assay, after the samples had been submitted to xenon light. The exposure of the test sample was performed in accordance with ISO 105-B02:2014, method 3. For red and orange–red materials the exposure continued until the blue scale control standard number 5 changed to grade 3 of the grey-scale. For all other colors, the blue scale control standard number 4 changed to grade 4 of the grey-scale according to EN 20105-A02:2014.

Regarding color fastness to rubbing, the test was conducted in accordance with ISO 105-X12:2016. This test consisted of rubbing the textile specimens with a dry rubbing cloth, with a rubbing round finger and a downward force of 9N.

The color fastness to perspiration (acid and alkaline) refers to the ability not to fade and not to stain when the dyed fabric is perspired. The test was conducted in accordance with ISO 105-E04:2013 which consisted in placing a sample of textile in contact with a specified supporting fabric (polyester and cotton) that was soaked in two different solutions containing synthetic human sweat (histidine). Two tests were carried out, one with alkaline sweat solution and one with acidic sweat solution. The sample was then kept under pressure at 37 °C for four hours and then dried.

Color fastness to laundry tests were carried out in accordance with ISO 105-C06, test number A2S (40 °C, domestic laundry with sodium perborate in the washing water).

Concerning color fastness to hot pressing, tests were performed in agreement with ISO 105-X11 at 150 °C using a hot-pressing equipment.

Since the final purpose of this study is to integrate the developed light-responsive materials into a sportswear collection, water-vapor resistance tests were also carried out to evaluate materials breathability, according to ISO 11092. The water-vapor resistance test, in principle, consists in placing the specimen over a porous test plate, electrically heated, covered with a water-vapor permeable but liquid-water impermeable cellophane membrane. Water is then fed through the water metering to the heated plate which then evaporates and passes through the membrane as steam. The heat flux required to keep the temperature of the plate constant is proportional to the rate of transport of water-vapor through the textile, which is equal to the rate of evaporation of water, and, from this, the water-vapor resistance is then specified.

The developed phosphorescent materials were tested according to DIN 67510-1 to evaluate the luminance and decay time of the original samples and after several washing cycles. The luminance was measured using a Photometer LMT Lichmesstechnik GmbH and the samples were tested after exposure to a Xenon lamp (1000 lx) for 5 min. To evaluate the resistance of the phosphorescent coated samples, these samples were submitted to several washing cycles (1, 5, 10, 20, 30 and 40) at 40 °C for 40 min.

3. Results

3.1. Fluorescent Pigments

The obtained samples were evaluated regarding color performance: chromaticity coordinates and luminance factor. To comply with the high visibility standards, the color coordinates of the material developed must be comprised within a set of coordinates defined in the standards for each color, which are graphically represented by polygons as can be seen in

Figure 2. The results obtained allow us to conclude that for RD 513 and OR 514 pigments the increase of additivation percentage leads to a better color performance. Only the samples with 10 and 15% pigment meet the standard requirements for fluorescent red color (being inside the polygon). Concerning YE 517 pigment, all the samples obtained accomplished the normative requirements regarding chromaticity coordinates and luminance factor. The samples prepared with 5–15% of the OY 516 pigment obtained chromaticity coordinates in the fluorescent-orange polygon area, however, the results obtained with 25%, presented in

Figure 2, reveal that by increasing the pigment percentage, to 25%, the chromaticity coordinates approached orange-red fluorescent area, showing that there is a possibility, with increased percentage of pigment to accomplish also this polygon area. Regarding MG 521 pigment, samples coated with 5% to 15% fulfill normative requirements regarding to chromaticity coordinates of the pink fluorescent area, however, the luminance factor obtained by these samples is lower than the minimum required by the EN 17353 standard. Samples with 2% of MG 521 pigment meet the two requirements regarding color performance (chromaticity coordinates and luminance factor). Lastly, samples coated with 2%, 5% and 7% of CE 512 pigment obtained chromaticity coordinates in the fluorescent-pink polygon area but only the samples with 2% and 5% of pigment accomplished the minimum luminance factor required.

In the following part, the samples coated with 15% YE 517 pigment and with 2% MG 521 pigment were selected to further analysis, being submitted to the following tests: fastness to washing, fastness to light exposure and abrasion resistance. To assess fastness to light exposure, the samples were exposed to sunlight, being that, after 10 days the color performance was maintained. Regarding Martindale abrasion resistance, sample coated with YE 517 pigment (15%) presented an abrasion resistance superior to 30,000 cycles with a pressure of 9 kPa. On the other hand, sample coated with the MG 521 pigment (2%) obtained an abrasion resistance of 25,000 cycles with a pressure of 9 kPa. To evaluate fastness to washing, samples were submitted to several washing cycles (1, 5, 10 and 20 cycles) at 40 °C for 40 min. Concerning a sample coated with 15% of YE 517 pigment, after 10 washing cycles, a coating loss was observed near the edges of the sample, whereas after 20 cycles, the loss of coating and color intensity occurred in the entire sample. On the other hand, on the sample coated with 2% of MG 521 pigment, the loss of coating and color intensity was verified after 20 cycles.

The improved samples (regarding fastness to washing) of kitted fabric with 15% of YE 517 pigment, using two different cross-linkers (CL1—an aliphatic polyisocyanate—and CL2—a polyurethane-based formaldehyde-free crosslinking agent) are compared with the sample of kitted fabric with 15% of YE 517 pigment without cross-linker.

Figure 3 presents chromaticity coordinate results, obtained for samples coated with 15% of YE 517 pigment, without cross-linker and with CL1 and CL2 cross-linkers.

Comparing the performance obtained by a sample without a cross-linker agent with the samples with CL1 and CL2, it is possible to conclude that cross-linker agents improve fastness to washing. However, when comparing a sample coated with the formulation containing CL1 to the one coated with a CL2 formulation, it is possible to observe that the CL1 cross-linker obtains better results regarding improving fastness to washing. Concerning the luminance factor, the samples with and without a cross-linker agent obtained values superior to the minimum required by EN17353 (βmin = 0.70, even after 40 washing cycles).

Regarding the samples of knitted fabric with 2% MG 521 pigment, with and without a cross-linker agent,

Figure 4 shows chromaticity coordinate results obtained for both samples. The presence of the cross-linker agent CL1 slightly improves fastness to washing.

Concerning the luminance factor the samples with and without cross-linker agent obtained values superior to the minimum required by EN17353 (βmin = 0.30), even after 40 washing cycles.

In the following part, the testing results, according to EN17353, obtained from the knitted fabric industrial samples coated with 2% of MG 521 pigment and 15% of YE 517 pigment with CL1 fixer are presented.

Regarding the industrial sample coated with 15% YE 517, it meets the normative requirements for color performance, both in the original sample and in the samples after washing (40 washing cycles at 40 °C) and after exposure to light,

Figure 5. The luminance factor value obtained in the original sample was higher than the 0.70 required by standard EN 17353 (0.81). After exposure to light and after the washing cycles mentioned, the luminance factor value decreased to 0.75, but continues to fulfill the normative requirement.

Concerning color fastness of fluorescent material the developed coated knitted fabric accomplishes color change requirements according to EN17353 in the original stage and after the different test exposure (xenon light and 40 washing cycles). On the other hand, this standard requires at least grade 4 of the grey-scale with respect to staining. The results obtained, presented in

Table 3, show that the developed material has grade 3–4 of the grey-scale regarding to staining in cotton after exposure to laundry and grade 3 of the grey-scale concerning staining in cotton after exposure to perspiration, which are below the requirements.

Concerning water-vapor resistance, the coated sample with 15% YE 517 pigment obtained 4.60 m2·Pa/W accomplishing the normative requirements (Ret < 5 m2·Pa/W).

Regarding the industrial sample coated with 2% MG 521, the original sample meets the normative requirements for color performance. The chromaticity coordinates are inside the fluorescent pink polygon area, and the luminance factor value obtained is higher than the 0.30 required by standard EN 17353 (0.35).

Nevertheless, the results regarding chromaticity coordinates obtained for the industrial coated sample with 2% MG pigment are very close to the limit of the polygon area,

Figure 6, and considering the behavior obtained in the screening stage regarding color fastness to washing tests the remaining trials were not continued.

3.2. Phosphorescent Pigments

The results obtained with the initial samples developed with 5% and 20% of pigment P1 tested, according to DIN 67510-1, to evaluate the luminance and decay time, are presented in

Table 4.

Results obtained, presented in

Table 4, allow us to conclude that increasing the additivation percentage from 5 to 20% leads to a significant increase of luminance and decay time, approximately 4 times.

Regarding the samples developed with 20% of P2 pigment, results obtained, presented at

Table 5, show that P2 pigment provides better results concerning the parameters under study, since luminance and decay time results doubled, when comparing its performance, regarding luminance and decay time, to P1 pigment results.

As for the samples with 25% of P2 pigment, and with 20% and 25% of P3 pigment developed and submitted to washing tests (40 °C, 40 min), with the purpose of evaluate the phosphorescent character of the samples after submitted to several washing cycles, the luminance and decay time results are presented in

Table 6. The table presents results after 120 min, since the final purpose of the project is to integrate the developed materials in a sportswear collection, thus, considering that sports practice lasts from one to two hours.

The knitted fabric with 25% of P2 phosphorescent pigment translates into results far superior when compared with the knitted fabrics with 20% and 25% of P3 phosphorescent pigment. In addition is also possible to conclude that comparing P2 and P3 pigments with 25% of additivation, P2 pigment obtained better results regarding luminance and decay time. Analyzing the behavior of the samples with different washing cycles, presented in

Table 6, in a general way, the luminance and decay time decrease with the increase of washing cycles.

In the following part, the results obtained by samples coated with 20% and 25% of P2 pigment treated to increase resistance to washing cycles are presented in

Table 7.

Comparing the results obtained by samples coated with 25% of P2 pigment with and without treatment is possible to conclude that in fact, the treatment given to P2 pigment does not improve fastness to washing, once luminance and decay time results are inferior to those obtained previously.

3.3. Integration Innovative Materials with Light Responsive Properties in Sportswear Collection

A sportswear collection with the fluorescent and phosphorescent materials developed was designed, fulfilling area and design required by EN17353 for type AB equipment which includes protections for daylight, twilight, and dark conditions,

Figure 7. On the left side, an ensemble for women is presented using MG 521 fluorescent pigment and on the right side is an ensemble for man using YE 517 fluorescent pigment. Both ensembles present details with a P2 phosphorescent pigment.

In the following part, the results obtained from the integration process of the high-visibility materials developed with the shape and design defined previously are presented (big areas for fluorescent pigments and small details like collection logo for phosphorescent pigment). Both prototypes, for woman and man, were achieved using innovative technologies of garment manufacturing, namely laser cutting, ultrasound and fusing (carousel press). The prototypes were tested by voluntary potential end-users to evaluate important parameters regarding sports practice as ergonomics, lightness, comfort, freedom of movement and easiness to dress/undress,

Figure 8.

Potential end-users considered the developed clothing pieces, comfortable, ergonomic, and suitable for the final application.

4. Discussion

The coated 100% polyamide interlock knitted fabric with six different fluorescent pigments, using several additivation percentages, showed that only for two fluorescent pigments (RD 513 and OR 514) the increase in the additivation percentages led to a better color performance. The other fluorescent pigments presented a different behavior, in a general way: YE 517 fluorescent pigment presented positive performance for the different additivation percentages studied; OY 516 fluorescent pigment reveal that increasing the pigment percentage to 25% the chromaticity coordinates approached orange-red fluorescent area; MG 521 fluorescent pigment as well as CE 512 fluorescent pigment presented positive performance for lower percentages (2% and below 7% respectively) failing the luminance factor for higher percentages.

Considering the improved performance to washing cycles, it was achieved for the knitted fabric samples coated with MG 521 fluorescent pigment and YE 517 fluorescent pigment using cross-linkers agents, specially CL1. Formulation with CL1 cross-link agent presented greater impact in knitted fabric sample with YE 517 fluorescent pigment and only improved slightly fastness to washing for knitted fabric sample with MG 521 fluorescent pigment. This occurrence can probably be attributed to the difference existent in the chemical structure of the pigments.

Regarding the EN17353 requirements, industrial knitted fabric sample with YE 517 fluorescent pigment achieved good results for color performance (chromaticity coordinates and luminance factor) both in the original sample and in the samples after washing (40 washing cycles at 40 °C) and after exposure to xenon light. With respect to color fastness and in concrete to staining, the samples presented results below the required for staining in cotton: after exposure to laundry (grade 3–4 instead of grade 4 of grey-scale) and after exposure to perspiration (grade 3 instead of grade 4 of grey-scale). In this way, the color fastness to staining in cotton must be improved to achieve the requirements of EN 17353. The comparison of industrial knitted fabric samples coated with YE 517 fluorescent pigment and with MG 521 fluorescent pigment is only possible regarding color performance (chromaticity coordinates and luminance factor) in the original sample, accomplishing both the standard requirements. To notice that the knitted fabric sample coated with YE 517 fluorescent pigment accomplished the normative requirements for water-vapor resistance (Ret < 5 m2·Pa/W), that is an important parameter for sportwear clothing.

Concerning knitted fabric samples coated with the three different phosphorescent pigments under study, regarding P1 phosphorescent pigment, the results showed that increasing the percentage of pigment leads to an increase of luminance and decay time but when compared to P2 phosphorescent pigment the later presents luminance and decay results doubled. Comparing samples with P2 phosphorescent pigment with samples with P3 phosphorescent pigment after 40 washing cycles and 120 min, samples with P2 phosphorescent pigment presented much better performance. Additionally, the comparison of samples with P2 phosphorescent pigment with 25% additivation, with and without treatment for fastness to washing improvement, showed that the treatment didn’t present relevant results. A sample coated with P2 phosphorescent pigment with 25% additivation achieved excellent results regarding luminance, decay time and fastness to washing. This new material presents a decay time of 1351 min after 40 washing cycles (40 °C), meaning that after 5 min of exposure to a 1000 lux xenon lamp, for 22 h is possible to obtain the minimum luminance required by DIN 6510-1 (0.32 mcd/m2) which is according to literature is 100 times superior to human sight threshold.

The developed materials were integrated in a sportswear collection designed accordingly to EN17353, and afterwards the prototypes were tested by voluntary potential end-users who considered them comfortable, ergonomic, and suitable for the final application.

5. Conclusions

Considering the six fluorescent pigments under study and the results obtained with the functionalized knitted fabric used (interlock of 100% polyamide coated by knife over roll technology) for the tests performed according to EN 17353 (European Standard of Protective clothing: Enhanced visibility equipment for medium risk situations—Test methods and requirements), the YE 517 fluorescent pigment seems to be the most promising. The best performance was achieved for the knitted fabric coated with 15% YE 517 fluorescent pigment and using a cross-linker. Nevertheless, the developed material needs optimization to improve color fastness after exposure to laundry and perspiration, and therefore, accomplish the requirements of EN17353 standard.

Regarding the three phosphorescent pigments, the knitted fabric coated with a two-component silicone paste with 25% of P2 fluorescent pigment, in the original stage and after 40 washing cycles (40 °C, 40 min), achieved the best results regarding luminance and decay time, tested according to DIN 6510-1.

Two sportwear ensembles, one for men and other for women were designed considering the design requirements of EN17353 for type AB equipment. In both prototypes, the fluorescent and phosphorescent materials developed were applied.