A Review on Thermal Energy Modelling for Optimal Microgrids Management

Abstract

:1. Introduction

- Reviewed the existing thermal energy modeling for microgrids, including the application of combined cooling, heating and power (CCHP) and thermal comfort model to form virtual energy storage systems.

- Reviewed the most recent literature related to energy storage technology, materials for Thermal Energy Storage (TES) applications, and the contribution of electrical energy storage for grid applications.

- From the TES technology perspective, the key characteristics, parameters and models of the TES system to be considered when used in microgrids and multi-energy networks, and other emerging applications are discussed.

- From the energy system perspective, the opportunities and challenges of deploying thermal energy modeling applications on the optimal energy management of microgrids are discussed.

2. Thermal Energy Storage Systems and Performance Parameters

2.1. Thermal Energy Storage System Characteristics

- (1)

- Low cost: The thermal energy storage technology converts solar energy (or absorbs other thermal energy generated in industrial production), stores and releases it again, using inexhaustible solar energy or underutilized thermal energy generated in industrial production [24].

- (2)

- Long storage time: The storage time ranges to several months, which far exceeds the current solar energy storage time limit developed at home and abroad. As the storage is not affected by the weather, users can choose different storage periods and different storage methods according to their needs [24].

- (3)

- Wide application: Thermal energy storage technology stores and uses solar thermal energy and other thermal energy generated in industrial production, which is a substitute for all existing underground energy sources. Wherever existing thermal energy is used, whether for power generation, heating, or modern agricultural heating, and other fields that require thermal energy, thermal energy storage technology can replace all existing fossil energy sources which can generate electricity, heat, and meet any demand for thermal energy [24].

- (4)

- Conducive to environmental protection: In addition to the catalyst, there is no consumption of materials and none of the environmental cost attached to fossil energy, which truly realizes the win-win goal of energy use and environmental protection.

2.2. Thermal Energy Storage Technology Types

2.2.1. Technical Characteristics Comparison

2.2.2. Economic Analysis of Heat Storage Technology

2.2.3. Application Status of Heat Storage Technology

2.2.4. Development Trend of Heat Storage Technology

3. Modelling of Thermal Energy System in Microgrids

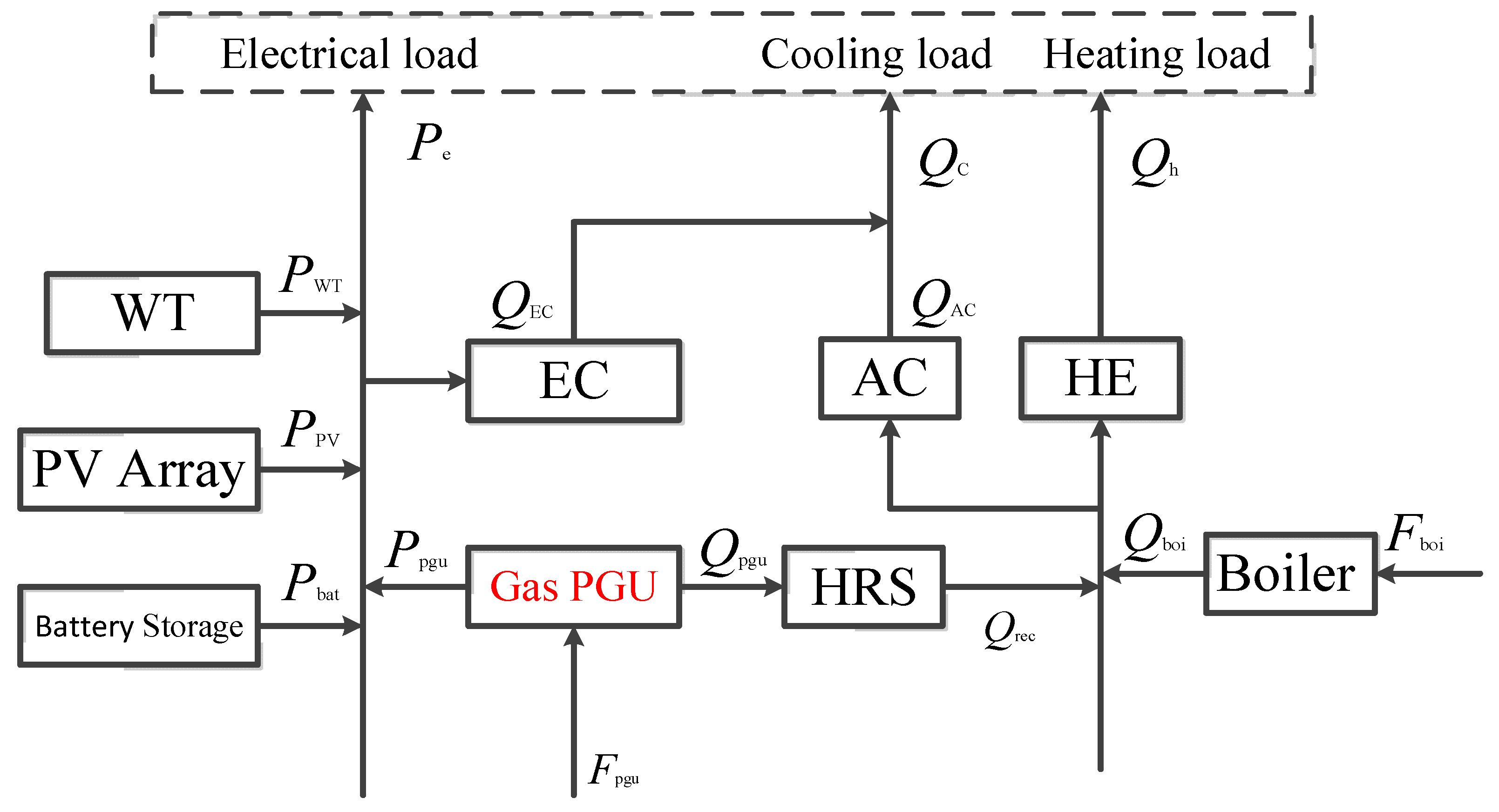

3.1. CCHP Systems Current Research and Development

3.2. Virtual Energy Storage System Current Research and Development

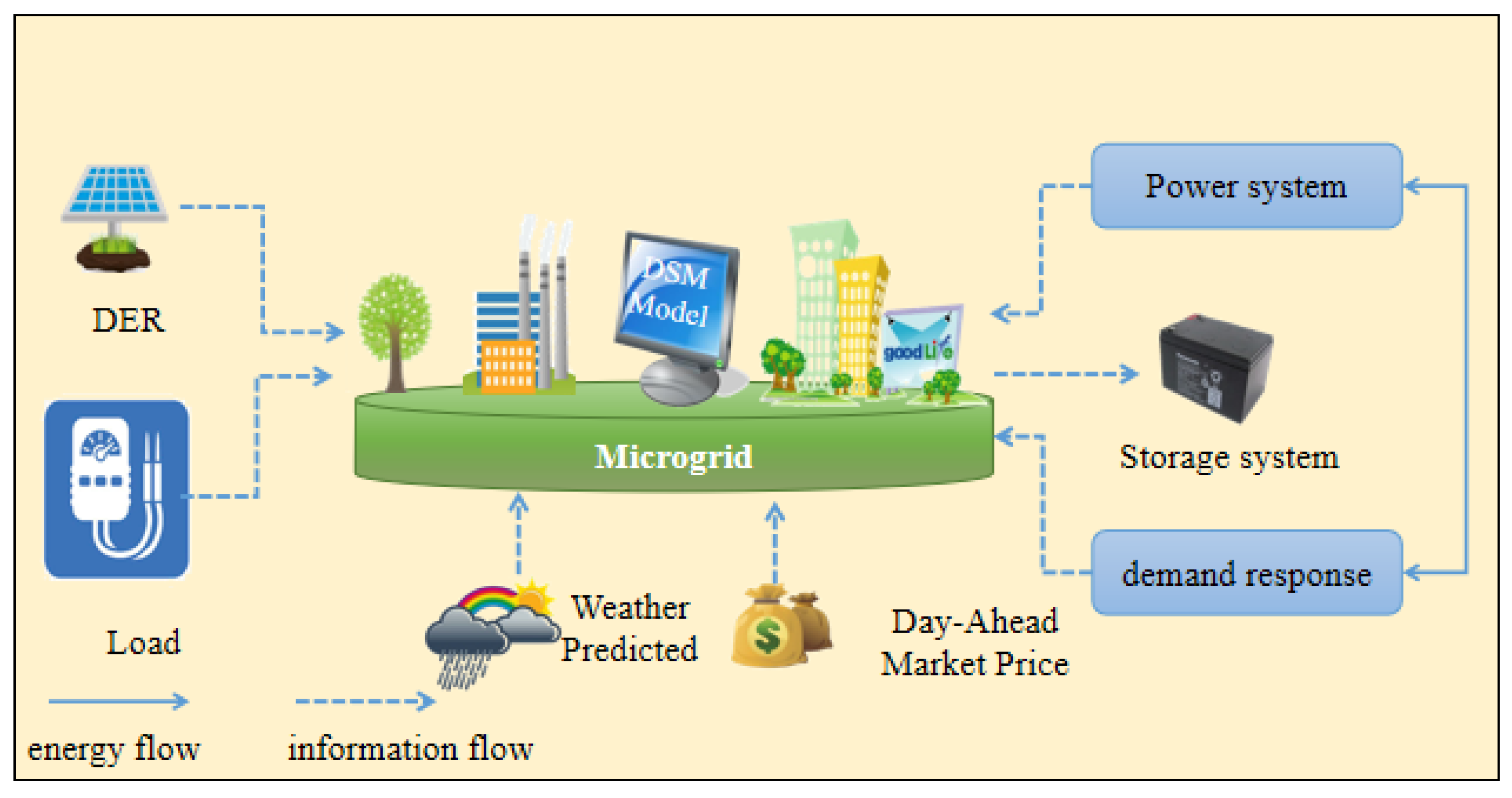

4. Energy Management of the TES Microgrid

4.1. TES Microgrid Energy Management Model

4.2. Optimization of TES Microgrid Energy Management

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- García Vera, Y.E.; Dufo-López, R.; Bernal-Agustín, J.L. Energy management in microgrids with renewable energy sources: A literature review. Appl. Sci. 2019, 9, 3854. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.; Wu, R.; Li, X.; Lai, C.S.; Wu, X.; Wei, J.; Xu, Y.; Wu, W.; Lai, L.L. Two-stage optimal scheduling of air conditioning resources with high photovoltaic penetrations. J. Clean. Prod. 2019, 241, 118407. [Google Scholar] [CrossRef]

- Xu, Y.; Lai, L.L.; Zhao, F.; Wang, Y.; Li, X.; Lai, C.S.; Xu, F.Y. Coordination operation of gas and electricity networks. In Proceedings of the International Conference on Applied Energy, Västerås, Sweden, 12–15 August 2019. [Google Scholar]

- Xu, Y.; Zhao, F.; Lai, L.L.; Wang, Y. Integrated electricity and natural gas system for day-ahead scheduling. In Proceedings of the 2019 IEEE International Conference on Systems, Man and Cybernetics (SMC), Bari, Italy, 6–9 October 2019. [Google Scholar]

- Li, Y.; Zhang, F.; Li, Y.; Wang, Y. An improved two-stage robust optimization model for CCHP-P2G microgrid system considering multi-energy operation under wind power outputs uncertainties. Energy 2021, 223, 120048. [Google Scholar] [CrossRef]

- Jiang, Y.; Guo, L. Research on wind power accommodation for an electricity-heat-gas integrated microgrid system with power-to-gas. IEEE Access 2019, 7, 87118–87126. [Google Scholar] [CrossRef]

- Tostado-Véliz, M.; Arevalo, W.P.; Jurado, F. A comprehensive electrical-gas-hydrogen microgrid model for energy management applications. Energy Convers. Manag. 2020, 228, 113726. [Google Scholar] [CrossRef]

- Boudoudouh, S.; Mohammed, M. Renewable energy sources integration and control in railway microgrid. IEEE Trans. Ind. Appl. 2018, 55, 2045–2052. [Google Scholar] [CrossRef]

- Alsaidan, I.; Khodaei, A.; Gao, W. A comprehensive battery energy storage optimal sizing model for microgrid applications. IEEE Trans. Power Syst. 2018, 33, 3968–3980. [Google Scholar] [CrossRef]

- Adefarati, T.; Bansal, R.C. Reliability, economic and environmental analysis of a microgrid system in the presence of renewable energy resources. Appl. Energy 2019, 236, 1089–1114. [Google Scholar] [CrossRef]

- Lai, C.S.; Jia, Y.; Dong, Z.; Wang, D.; Tao, Y.; Lai, Q.H.; Wong, R.T.K.; Zobaa, A.F.; Wu, R.; Lai, L.L. A review of technical standards for smart cities. Clean Technol. 2020, 2, 290–310. [Google Scholar] [CrossRef]

- Lai, C.S.; Locatelli, G.; Pimm, A.; Wu, X.; Lai, L.L. A review on long-term electrical power system modeling with energy storage. J. Clean. Prod. 2021, 280, 124298. [Google Scholar] [CrossRef]

- Yang, L.; Zhang, Z.; Li, G.; Zhao, D.; Tian, W. Optimal scheduling of an isolated microgrid with battery storage considering load and renewable generation uncertainties. IEEE Trans. Ind. Electron. 2019, 66, 1565–1575. [Google Scholar]

- Jacob, A.S.; Banerjee, R.; Ghosh, P.C. Sizing of hybrid energy storage system for a PV based microgrid through design space approach. Appl. Energy 2018, 212, 640–653. [Google Scholar] [CrossRef]

- Wang, J.; Zhong, H.; Xia, Q.; Kang, C.; Du, E. Optimal joint-dispatch of energy and reserve for CCHP-based microgrids. IET Gener. Transm. Distrib. 2017, 11, 785–794. [Google Scholar] [CrossRef]

- Thale, S.S.; Wandhare, R.G.; Agarwal, V. A novel reconfigurable microgrid architecture with renewable energy sources and storage. IEEE Trans. Ind. Appl. 2015, 51, 1805–1816. [Google Scholar] [CrossRef]

- Varasteh, F.; Nazar, M.S.; Heidari, A.; Shafie-Khah, M.; Catalão, J.P. Distributed energy resource and network expansion planning of a CCHP based active microgrid considering demand response programs. Energy 2019, 172, 79–105. [Google Scholar] [CrossRef]

- Fang, F.; Wang, Q.H.; Shi, Y. A novel optimal operational strategy for the CCHP system based on two operating modes. IEEE Trans. Power Syst. 2012, 27, 1032–1041. [Google Scholar] [CrossRef]

- Talari, S.; Yazdaninejad, M.; Haghifam, M.R. Stochastic-based scheduling of the microgrid operation including wind turbines, photovoltaic cells, energy storages and responsive loads. IET Gener. Transm. Distrib. 2015, 9, 1498–1509. [Google Scholar] [CrossRef]

- Nami, H.; Anvari-Moghaddam, A. Small-scale CCHP systems for waste heat recovery from cement plants: Thermodynamic, sustainability and economic implications. Energy 2020, 192, 116634. [Google Scholar] [CrossRef]

- Wu, X.; Wu, R.; Wang, D.; Wei, J.; Li, X.; Lai, L.L.; Lai, C.S. Coordinated air conditioning resources scheduling with high photovoltaic penetrations. In Proceedings of the 2018 International Conference on Power System Technology (POWERCON), Guangzhou, China, 6–8 November 2018; pp. 2242–2248. [Google Scholar]

- Kamel, M.A.; Elbanhawy, A.Y.; El-Nasr, M.A. A novel methodology to compare between side-by-side photovoltaics and thermal collectors against hybrid photovoltaic thermal collectors. Energy Convers. Manag. 2019, 202, 112196. [Google Scholar] [CrossRef]

- Wang, X.; Shu, G.; Tian, H.; Wang, R.; Cai, J. Operation performance comparison of CCHP systems with cascade waste heat recovery systems by simulation and operation optimization. Energy 2020, 206, 118123. [Google Scholar] [CrossRef]

- Enescu, D.; Chicco, G.; Porumb, R.; Seritan, G. Thermal energy storage for grid applications: Current status and emerging trends. Energies 2020, 13, 340. [Google Scholar] [CrossRef] [Green Version]

- Lai, C.S.; Locatelli, G.; Pimm, A.; Tao, Y.; Li, X.; Lai, L.L. A financial model for lithium-ion storage in a photovoltaic and biogas energy system. Appl. Energy 2019, 251, 113179. [Google Scholar] [CrossRef]

- Alva, G.; Lin, Y.; Fang, G. An overview of thermal energy storage systems. Energy 2018, 144, 341–378. [Google Scholar] [CrossRef]

- Abedin, A.H.; Rosen, M.A. A critical review of thermochemical energy storage systems. Open Renew. Energy 2011, 4, 42–46. [Google Scholar] [CrossRef] [Green Version]

- Sarbu, I.; Sebarchievici, C. A comprehensive review of thermal energy storage. Sustainability 2018, 10, 191. [Google Scholar] [CrossRef] [Green Version]

- Dincer, I.; Dost, S.; Li, X. Performance analyses of sensible heat storage systems for thermal applications. Int. J. Energy Res. 1997, 21, 1157–1171. [Google Scholar] [CrossRef]

- Jegadheeswaran, S.; Pohekar, S.D. Performance enhancement in latent heat thermal storage system: A review. Renew. Sustain. Energy Rev. 2009, 13, 2225–2244. [Google Scholar] [CrossRef]

- Pardo, P.; Deydier, A.; Anxionnaz-Minvielle, Z.; Rougé, S.; Cabassud, M.; Cognet, P. A review on high temperature thermochemical heat energy storage. Renew. Sustain. Energy Rev. 2014, 32, 591–610. [Google Scholar] [CrossRef] [Green Version]

- Agyenim, F.; Hewitt, N.; Eames, P.; Smyth, M. A review of materials, heat transfer and phase change problem formulation for latent heat thermal energy storage systems (LHTESS). Renew. Sustain. Energy Rev. 2010, 14, 615–628. [Google Scholar] [CrossRef]

- Kenisarin, M.M. High-temperature phase change materials for thermal energy storage. Renew. Sustain. Energy Rev. 2010, 14, 955–970. [Google Scholar] [CrossRef]

- Pielichowski, K.P.K. Phase change materials for thermal energy storage. Prog. Mater. Sci. 2014, 65, 67–123. [Google Scholar] [CrossRef]

- Fan, L.; Khodadadi, J. Thermal conductivity enhancement of phase change materials for thermal energy storage: A review. Renew. Sustain. Energy Rev. 2011, 15, 24–46. [Google Scholar] [CrossRef]

- Gunasekara, S.N.; Martin, V.; Chiu, J.N. Phase equilibrium in the design of phase change materials for thermal energy storage: State-of-the-art. Renew. Sustain. Energy Rev. 2017, 73, 558–581. [Google Scholar] [CrossRef]

- Abhat, A. Low temperature latent heat thermal energy storage: Heat storage materials. Sol. Energy 1983, 30, 313–332. [Google Scholar] [CrossRef]

- Xu, H.; Romagnoli, A.; Sze, J.Y.; Py, X. Application of material assessment methodology in latent heat thermal energy storage for waste heat recovery. Appl. Energy 2017, 187, 281–290. [Google Scholar] [CrossRef]

- Yang, X.; Lu, Z.; Bai, Q.; Zhang, Q.; Jin, L.; Yan, J. Thermal performance of a shell-and-tube latent heat thermal energy storage unit: Role of annular fins. Appl. Energy 2017, 202, 558–570. [Google Scholar] [CrossRef]

- Li, G. Energy and exergy performance assessments for latent heat thermal energy storage systems. Renew. Sustain. Energy Rev. 2015, 51, 926–954. [Google Scholar] [CrossRef]

- Gonzalez-Portillo, L.F.; Muñoz-Antón, J.; Martínez-Val, J.M. An analytical optimization of thermal energy storage for electricity cost reduction in solar thermal electric plants. Appl. Energy 2017, 185, 531–546. [Google Scholar] [CrossRef]

- Gao, L.; Hwang, Y.; Cao, T. An overview of optimization technologies applied in combined cooling, heating and power systems. Renew. Sustain. Energy Rev. 2019, 114, 109344. [Google Scholar] [CrossRef]

- Ren, F.; Wang, J.; Zhu, S.; Chen, Y. Multi-objective optimization of combined cooling, heating and power system integrated with solar and geothermal energies. Energy Convers. Manag. 2019, 197, 111866. [Google Scholar] [CrossRef]

- Feng, L.; Dai, X.; Mo, J.; Shi, L. Performance assessment of CCHP systems with different cooling supply modes and operation strategies. Energy Convers. Manag. 2019, 192, 188–201. [Google Scholar] [CrossRef]

- Wan, J.; Zhou, J.; Gui, X. Sustainability Analysis of Green Data Centers with CCHP and Waste Heat Reuse Systems. IEEE Trans. Sustain. Comput. 2021, 6, 155–167. [Google Scholar] [CrossRef]

- Cho, H.; Smith, A.D.; Mago, P. Combined cooling, heating and power: A review of performance improvement and optimization. Appl. Energy 2014, 136, 168–185. [Google Scholar] [CrossRef]

- Wu, D.; Han, Z.; Liu, Z.; Zhang, H. Study on configuration optimization and economic feasibility analysis for combined cooling, heating and power system. Energy Convers. Manag. 2019, 190, 91–104. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, J.; Hu, Y.; Zhang, X. Optimal operation strategy of multi-energy complementary distributed CCHP system and its application on commercial building. IEEE Access 2019, 7, 127839–127849. [Google Scholar] [CrossRef]

- Cheng, M.; Sami, S.S.; Wu, J. Benefits of using virtual energy storage system for power system frequency response. Appl. Energy 2017, 194, 376–385. [Google Scholar] [CrossRef] [Green Version]

- Jin, X.; Mu, Y.; Jia, H.; Wu, J.; Jiang, T.; Yu, X. Dynamic economic dispatch of a hybrid energy microgrid considering building based virtual energy storage system. Appl. Energy 2017, 194, 386–398. [Google Scholar] [CrossRef]

- Xie, C.; Wang, D.; Lai, C.S.; Wu, R.; Wu, X.; Lai, L.L. Optimal sizing of battery energy storage system in smart microgrid considering virtual energy storage system and high photovoltaic penetration. J. Clean. Prod. 2021, 281, 125308. [Google Scholar] [CrossRef]

- Wang, D.; Meng, K.; Gao, X.; Qiu, J.; Lai, L.L.; Dong, Z.Y. Coordinated dispatch of virtual energy storage systems in LV grids for voltage regulation. IEEE Trans. Ind. Inform. 2018, 14, 2452–2462. [Google Scholar] [CrossRef]

- Cheng, M.; Sami, S.S.; Wu, J. Virtual energy storage system for smart grids. Energy Procedia 2016, 88, 436–442. [Google Scholar] [CrossRef] [Green Version]

- Xie, K.; Hui, H.; Ding, Y. Review of modeling and control strategy of thermostatically controlled loads for virtual energy storage system. Prot. Control Mod. Power Syst. 2019, 4, 1–13. [Google Scholar] [CrossRef]

- Meng, K.; Dong, Z.Y.; Xu, Z.; Zheng, Y.; Hill, D.J. Coordinated dispatch of virtual energy storage systems in smart distribution networks for loading management. IEEE Trans. Syst. Man Cybern. Syst. 2017, 49, 1–11. [Google Scholar] [CrossRef]

- Liu, W.; Liu, C.; Lin, Y.; Ma, L.; Bai, K.; Wu, Y. Optimal scheduling of residential microgrids considering virtual energy storage system. Energies 2018, 11, 942. [Google Scholar] [CrossRef] [Green Version]

- Nandha, K.K.; Krishnasamy, V.; Chaudhari, K. Virtual energy storage capacity estimation using ANN-based kWh modelling of refrigerators. IET Smart Grid 2018, 1, 31–39. [Google Scholar]

- Fambri, G.; Badami, M.; Tsagkrasoulis, D.; Katsiki, V.; Giannakis, G.; Papanikolaou, A. Demand flexibility enabled by virtual energy storage to improve renewable energy penetration. Energies 2020, 13, 5128. [Google Scholar] [CrossRef]

- Cheng, Z.; Li, X.; Li, Z.; Si, J.; Xu, S.; Nie, R. Optimal scheduling strategy of building integrated photovoltaic microgrid considering virtual energy storage. Appl. Sci. 2020, 10, 6176. [Google Scholar] [CrossRef]

- Youwei, J.; Lyu, X.; Lai, C.S.; Xu, Z.; Chen, M. A retroactive approach to microgrid real-time scheduling in quest of perfect dispatch solution. J. Mod. Power Syst. Clean Energy 2019, 7, 246–256. [Google Scholar]

- Wang, D.; Qiu, J.; Reedman, L.; Meng, K.; Lai, L.L. Two-stage energy management for networked microgrids with high renewable penetration. Appl. Energy 2018, 226, 39–48. [Google Scholar] [CrossRef]

- Rovira, A.; Montes, M.J.; Valdes, M.; Martínez-Val, J.M. Energy management in solar thermal power plants with double thermal storage system and subdivided solar field. Appl. Energy 2011, 88, 4055–4066. [Google Scholar] [CrossRef]

- Rao, Z.; Wang, S. A review of power battery thermal energy management. Renew. Sustain. Energy Rev. 2011, 15, 4554–4571. [Google Scholar] [CrossRef]

- Comodi, G.; Giantomassi, A.; Severini, M.; Squartini, S.; Ferracuti, F.; Fonti, A.; Cesarini, D.N.; Morodo, M.; Polonara, F. Multi-apartment residential microgrid with electrical and thermal storage devices: Experimental analysis and simulation of energy management strategies. Appl. Energy 2015, 137, 854–866. [Google Scholar] [CrossRef]

- Pan, K.; Xie, C.; Lai, C.S.; Wang, D.; Lai, L.L. Photovoltaic output power estimation and baseline prediction approach for a residential distribution network with behind-the-meter systems. Forecast 2020, 2, 470–487. [Google Scholar] [CrossRef]

- Li, Z.; Wu, W.; Shahidehpour, M.; Wang, J.; Zhang, B. Combined heat and power dispatch considering pipeline energy storage of district heating network. IEEE Trans. Sustain. Energy 2015, 7, 12–22. [Google Scholar] [CrossRef]

- Tokarev, V.V.; Shalaginova, Z.I. Technique of multilevel adjustment calculation of the heat-hydraulic mode of the major heat supply systems with the intermediate control stages. Therm. Eng. 2016, 63, 68–77. [Google Scholar] [CrossRef]

- Parameshwaran, R.; Kalaiselvam, S.; Harikrishnan, S.; Elayaperumal, A. Sustainable thermal energy storage technologies for buildings: A review. Renew. Sustain. Energy Rev. 2012, 16, 2394–2433. [Google Scholar] [CrossRef]

- Bentley, W.G.; Evelyn, J.C. Customer thermal energy storage a marketing opportunity for cooling off electric peak demand. IEEE Trans. Power Syst. 2007, 1, 57–61. [Google Scholar] [CrossRef]

- Lee, X.; Yan, M.; Xu, F.Y.; Wang, Y.; Fan, Y.; Lee, Z.; Wen, Y.; Shahidehpour, M.; Lai, L.L. Virtual storage-based DSM with error-driven prediction modulation for microgrids. IEEE Access 2019, 7, 71109–71118. [Google Scholar] [CrossRef]

- Violante, W.; Canizares, C.A.; Trovato, M.A.; Forte, G. An energy management system for isolated microgrids with thermal energy resources. IEEE Trans. Smart Grid 2020, 11, 2880–2891. [Google Scholar] [CrossRef]

- Mohammadkhani, N.; Sedighizadeh, M.; Esmaili, M. Energy and emission management of CCHPs with electric and thermal energy storage and electric vehicle. Therm. Sci. Eng. Prog. 2018, 8, 494–508. [Google Scholar] [CrossRef]

- Shams, M.H.; Shahabi, M.; Kia, M.; Heidari, A.; Lotfi, M.; Shafie-khah, M.; Catalão, J.P.S. Optimal operation of electrical and thermal resources in microgrids with energy hubs considering uncertainties. Energy 2019, 187, 115949. [Google Scholar] [CrossRef]

- Liu, N.; He, L.; Yu, X.; Ma, L. Multi-party energy management for grid-connected microgrids with heat and electricity coupled demand response. IEEE Trans. Ind. Inform. 2017, 14, 1887–1897. [Google Scholar] [CrossRef]

- Arteconi, A.; Ciarrocchi, E.; Pan, Q.; Carducci, F.; Comodi, G.; Polonara, F.; Wang, R. Thermal energy storage coupled with PV panels for demand side management of industrial building cooling loads. Appl. Energy 2017, 185, 1984–1993. [Google Scholar] [CrossRef]

- Bracco, S.; Brignone, M.; Delfino, F.; Pampararo, F.; Rossi, M.; Ferro, G.; Robba, M. An optimization model for polygeneration microgrids with renewables, electrical and thermal storage: Application to the Savona campus. In Proceedings of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Palermo, Italy, 12–15 June 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Karki, R.; Hu, P.; Billinton, R. A simplified wind power generation model for reliability evaluation. IEEE Trans. Energy Convers. 2006, 21, 533–540. [Google Scholar] [CrossRef]

- Singh, R.; Pal, B.C.; Jabr, R.A. Statistical representation of distribution system loads using Gaussian Mixture model. IEEE Trans. Power Syst. 2010, 25, 29–37. [Google Scholar] [CrossRef] [Green Version]

- Homayoun, R.; Bahmani-Firouzi, B.; Niknam, T. Multi-objective operation of distributed generations and thermal blocks in microgrids based on energy management system. IET Gener. Transm. Distrib. 2021, 15, 1451–1462. [Google Scholar] [CrossRef]

- Dorahaki, S.; Dashti, R.; Shaker, H.R. Optimal energy management in the smart microgrid considering the electrical energy storage system and the demand-side energy efficiency program. J. Energy Storage 2020, 28, 101229. [Google Scholar] [CrossRef]

| Technologies | Sensible Heat Storage [29] | Latent Heat Storage [30] | Thermochemical Energy Storage [31] |

|---|---|---|---|

| Energy capacity per tonne (kWh/t) | 10–50 | 50–150 | 120–250 |

| Power (MW) | 0.001–10.0 | 0.001–1.0 | 0.01–1.0 |

| Storage period | Days/months | Hours/months | Hours/days |

| Cost (€/kWh) | 0.1–10 | 10–50 | 8–100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, M.; Wang, D.; Lai, C.S.; Lai, L.L. A Review on Thermal Energy Modelling for Optimal Microgrids Management. Thermo 2021, 1, 63-76. https://0-doi-org.brum.beds.ac.uk/10.3390/thermo1010006

Yan M, Wang D, Lai CS, Lai LL. A Review on Thermal Energy Modelling for Optimal Microgrids Management. Thermo. 2021; 1(1):63-76. https://0-doi-org.brum.beds.ac.uk/10.3390/thermo1010006

Chicago/Turabian StyleYan, Mengxuan, Dongxiao Wang, Chun Sing Lai, and Loi Lei Lai. 2021. "A Review on Thermal Energy Modelling for Optimal Microgrids Management" Thermo 1, no. 1: 63-76. https://0-doi-org.brum.beds.ac.uk/10.3390/thermo1010006