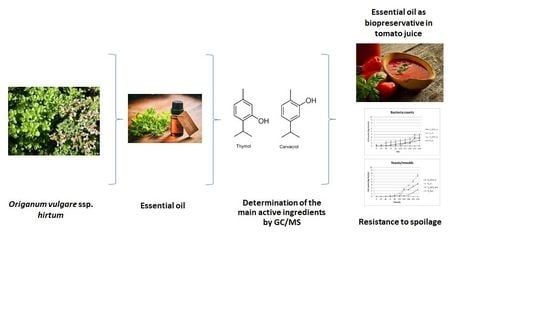

Origanum vulgare ssp. hirtum Essential Oil as a Natural Intrinsic Hurdle against Common Spoilage and Pathogenic Microbes of Concern in Tomato Juice

Abstract

:1. Introduction

2. Materials and Methods

2.1. Extraction of OEO by Hydrodistillation

2.2. Microbial Strains

2.3. OEO Emulsion Preparation

2.4. Tomato Juice Supplementation with OEO

2.5. Analytical Procedures

2.5.1. GC/MS Analysis

2.5.2. Antimicrobial Assays

Screening of OEO Antimicrobial Activity by the Disc Diffusion Assay

Determination of Minimum Inhibitory Concentration (MIC), Non-Inhibitory Concentration (NIC), and Minimum Lethal Concentration (MLC)

Antimicrobial Activity of OEO in Tomato Juice

2.6. Preliminary Sensory Evaluation and Spoilage Determination

2.7. Statistical Analysis

3. Results and Discussion

3.1. GC/MS Analysis of OEO

3.2. Antimicrobial Assays

3.3. Antimicrobial Activity in Tomato Juice Supplemented with OEO

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bakkali, F.; Averbeck, S.; Idaomar, M. Biological effects of essential oils—A review. Food Chem. Toxicol. 2008, 46, 446–475. [Google Scholar] [CrossRef] [PubMed]

- Swamy, M.K.; Akhtar, M.S.; Sinniah, U.R. Antimicrobial Properties of Plant Essential Oils against Human Pathogens and Their Mode of Action: An Updated Review. Evid. Based Complement. Altern. Med. 2016, 2016, 1–21. [Google Scholar] [CrossRef]

- Burt, S. Essential oils: Their antibacterial properties and potential applications in foods—A review. Int. J. Food Microbiol. 2004, 94, 223–253. [Google Scholar] [CrossRef] [PubMed]

- Chorianopoulos, N.G.; Evergetis, E.T.; Aligiannis, N.; Mitakou, S.; Nychas, G.-J.E.; Haroutounian, S.A. Correlation between Chemical Composition of Greek Essential Oils and their Antibacterial Activity against Food-borne Pathogens. Nat. Prod. Commun. 2007, 2, 419–426. [Google Scholar] [CrossRef]

- Nychas, G.J.E.; Skandamis, P.N.; Tassou, C. Antimicrobials from herbs and spices. In Natural Antimicrobials for the Minimal Processing of Foods; Elsevier BV: Amsterdam, The Netherlands, 2003; pp. 176–200. [Google Scholar]

- Chorianopoulos, N.; Kalpoutzakis, E.; Aligiannis, N.; Mitaku, S.; Nychas, G.-J.; Haroutounian, S.A. Essential Oils of Satureja, Origanum, and Thymus Species: Chemical Composition and Antibacterial Activities Against Foodborne Pathogens. J. Agric. Food Chem. 2004, 52, 8261–8267. [Google Scholar] [CrossRef]

- Şahin, F.; Güllüce, M.; Daferera, D.; Sökmen, A.; Sökmen, M.; Polissiou, M.; Agar, G.; Özer, H. Biological activities of the essential oils and methanol extract of Origanum vulgare ssp. vulgare in the Eastern Anatolia region of Turkey. Food Control. 2004, 15, 549–557. [Google Scholar] [CrossRef]

- Baranauskienė, R.; Venskutonis, P.R.; Dambrauskienė, E.; Viškelis, P. Harvesting time influences the yield and oil composition of Origanum vulgare L. ssp. vulgare and ssp. hirtum. Ind. Crop. Prod. 2013, 49, 43–51. [Google Scholar] [CrossRef]

- De Martino, L.; De Feo, V.; Formisano, C.; Mignola, E.; Senatore, F. Chemical Composition and Antimicrobial Activity of the Essential Oils from Three Chemotypes of Origanum vulgare L. ssp. hirtum (Link) Ietswaart Growing Wild in Campania (Southern Italy). Molecules 2009, 14, 2735–2746. [Google Scholar] [CrossRef] [Green Version]

- Chorianopoulos, N.G.; Skandamis, P.N.; Nychas, G.-J.E.; Haroutounian, S.A. Agricultural University of Athens Iera odos Athens Greece Use of essential oil treatments to control the Listeria monocytogenes growth in various food commodities. Planta Med. 2008, 74, PI31. [Google Scholar] [CrossRef]

- Tsimogiannis, D.; Choulitoudi, E.; Bimpilas, A.; Mitropoulou, G.; Kourkoutas, Y.; Oreopoulou, V. Exploitation of the biological potential of Satureja thymbra essential oil and distillation by-products. J. Appl. Res. Med. Aromat. Plants 2017, 4, 12–20. [Google Scholar] [CrossRef]

- Hyldgaard, M.; Mygind, T.; Meyer, R.L. Essential Oils in Food Preservation: Mode of Action, Synergies, and Interactions with Food Matrix Components. Front. Microbiol. 2012, 3, 12. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Oviasogie, F.E.; Ogofure, A.G.; Obatusin, S.V.; Beshiru, A.; Onwuaduegbo, J. Microbial spoilage of canned tomato sold in Benin city. J. Adv. Sci. Res. 2015, 6, 6–9. [Google Scholar]

- Oladunjoye, A.O.; Singh, S.; Ijabadeniyi, O.A. Inactivation of Listeria monocytogenes ATCC 7644 on fresh-cut tomato using nisin in combinations with organic salts. Braz. J. Microbiol. 2016, 47, 757–763. [Google Scholar] [CrossRef] [Green Version]

- Turtoi, M. Inactivation of Saccharomyces cerevisiae using nonconventional treatments. A review. Rom. Biotechnol. Lett. 2014, 19, 8901–8909. [Google Scholar]

- Samuel, O.; Orji, M.U. Fungi Associated with the Spoilage of Post-harvest Tomato Fruits Sold in Major Markets in Awka, Nigeria. Univers. J. Microbiol. Res. 2015, 3, 11–16. [Google Scholar] [CrossRef]

- Metcalf, D.; Costa, M.C.; Dew, W.; Weese, J. Clostridium difficile in vegetables, Canada. Lett. Appl. Microbiol. 2010, 51, 600–602. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bakri, M.M.; Brown, D.; Butcher, J.P.; Sutherland, A. Clostridium difficilein Ready-to-Eat Salads, Scotland. Emerg. Infect. Dis. 2009, 15, 817–818. [Google Scholar] [CrossRef]

- Mitropoulou, G.; Fitsiou, E.; Spyridopoulou, K.; Tiptiri-Kourpeti, A.; Bardouki, H.; Vamvakias, M.; Panas, P.; Chlichlia, K.; Pappa, A.; Kourkoutas, Y. Citrus medica essential oil exhibits significant antimicrobial and antiproliferative activity. LWT 2017, 84, 344–352. [Google Scholar] [CrossRef]

- Mitropoulou, G.; Sidira, M.; Skitsa, M.; Tsochantaridis, I.; Pappa, A.; Dimtsoudis, C.; Proestos, C.; Kourkoutas, Y. Assessment of the Antimicrobial, Antioxidant, and Antiproliferative Potential of Sideritis raeseri subps raeseri Essential Oil. Foods 2020, 9, 860. [Google Scholar] [CrossRef] [PubMed]

- Chorianopoulos, N.; Lambert, R.; Skandamis, P.; Evergetis, E.; Haroutounian, S.; Nychas, G.-J.E. A newly developed assay to study the minimum inhibitory concentration of Satureja spinosa essential oil. J. Appl. Microbiol. 2006, 100, 778–786. [Google Scholar] [CrossRef]

- Lambert, R. A model for the efficacy of combined inhibitors. J. Appl. Microbiol. 2003, 95, 734–743. [Google Scholar] [CrossRef] [PubMed]

- Arendrup, M.C.; Meletiadis, J.; Mouton, J.W.; Lagrou, K.; Hamal, P.; Guinea, J. Subcommittee on Antifungal Susceptibility Testing (AFST) of the ESCMID European Committee for Antimicrobial Susceptibility Testing. EUCAST Definitive Document EDEF 9.3.2 Method for the Determination of Broth Dilution Minimum Inhibitory Concentrations of Anti-fungal Agents for Conidia Forming Moulds. 2020. Available online: https://www.eucast.org/fileadmin/src/media/PDFs/EUCAST_files/AFST/Files/EUCAST_E_Def_9.3.2_Mould_testing_definitive_revised_2020 (accessed on 7 April 2020).

- Arendrup, M.C.; Meletiadis, J.; Mouton, J.W.; Lagrou, K.; Hamal, P.; Guinea, J. Subcommittee on Antifungal Susceptibil-ity Testing (AFST) of the ESCMID European Committee for Antimicrobial Susceptibility Testing. EUCAST Definitive Document EDEF 7.3.2 Method for the Determination of Broth Dilution Minimum Inhibitory Concentrations of Anti-fungal Agents for Yeasts. 2020. Available online: https://www.eucast.org/fileadmin/src/media/PDFs/EUCAST_files/AFST/Files/EUCAST_E_Def_7.3.2_Yeast_testing_definitive_revised_2020 (accessed on 8 April 2020).

- Balkan, C.; Ercan, I.; Isik, E.; Akdeniz, E.S.; Balcioglu, O.; Kodedová, M.; Zimmermannová, O.; Dundar, M.; Sychrová, H.; Koc, A. Genomewide Elucidation of Drug Resistance Mechanisms for Systemically Used Antifungal Drugs Amphotericin B, Caspofungin, and Voriconazole in the Budding Yeast. Antimicrob. Agents Chemother. 2019, 63. [Google Scholar] [CrossRef] [Green Version]

- Mandras, N.; Roana, J.; Scalas, D.; Fucale, G.; Allizond, V.; Banche, G.; Barbui, A.; Vigni, N.L.; A Newell, V.; Cuffini, A.M.; et al. In vitro antifungal activity of fluconazole and voriconazole against non-Candida yeasts and yeast-like fungi clinical isolates. New Microbiol. 2015, 38, 583–587. [Google Scholar]

- Aboukhalid, K.; Al Faiz, C.; Douaik, A.; Bakha, M.; Kursa, K.; Agacka-Mołdoch, M.; Machon, N.; Tomi, F.; Lamiri, A. Influence of Environmental Factors on Essential Oil Variability in Origanum compactum Benth. Growing Wild in Morocco. Chem. Biodivers. 2017, 14, e1700158. [Google Scholar] [CrossRef]

- Shams, M.; Esfahan, S.Z.; Esfahan, E.Z.; Dashtaki, H.N.; Dursun, A.; Yildirim, E. Effects of Climatic Factors on the Quantity of Essential Oil and Dry Matter Yield of Coriander (Coriandrum sativum L.). Indian J. Sci. Technol. 2016, 9, 6. [Google Scholar] [CrossRef]

- Code of Federal Regulations (Annual Edition) AE 2.106/3:9/ Title 9—Animals and Animal Products. Chapter I—Animal and Plant Health Inspection Service, Department of Agriculture Subchapter E—Viruses, Serums, Toxins, and Analogous Products; Organisms and Vectors Part 114–Production Requirements for Biological Products. Section 114.10–Antibiotics as Preservatives. 9 CFR § 114.10. 1 January 2011, 39 FR 16869, May 10, 1974, as Amended at 56 FR 66784; U.S. Government Publishing Office: Washington, DC, USA, 1991.

- Barbosa, L.N.; Rall, V.L.M.; Fernandes, A.A.H.; Ushimaru, P.I.; Probst, I.D.S.; Júnior, A.F. Essential Oils Against Foodborne Pathogens and Spoilage Bacteria in Minced Meat. Foodborne Pathog. Dis. 2009, 6, 725–728. [Google Scholar] [CrossRef] [PubMed]

- Chami, F.; Chami, N.; Bennis, S.; Bouchikhi, T.; Remmal, A. Oregano and clove essential oils induce surface alteration of Saccharomyces cerevisiae. Phytother. Res. 2005, 19, 405–408. [Google Scholar] [CrossRef]

- Pawar, V.C.; Thaker, V.S. In vitro efficacy of 75 essential oils against Aspergillus niger. Mycoses 2006, 49, 316–323. [Google Scholar] [CrossRef]

- Klingenberg, A. Emulsion. US Patent 20130089644, 2013. Available online: https://patents.justia.com/inventor/andreas-klingenber (accessed on 16 April 2020).

- Yang, Y.; Leser, M.E.; Sher, A.A.; McClements, D.J. Formation and stability of emulsions using a natural small molecule surfactant: Quillaja saponin (Q-Naturale®). Food Hydrocoll. 2013, 30, 589–596. [Google Scholar] [CrossRef]

- Hawkins, S.G. Antimicrobial Activity of Cinnamic Acid, Citric Acid, Cinnamaldehyde, and Levulinic Acid against Foodborne Pathogens. Chancellor’s Honors Program Projects. University of Tennessee, Knoxville Trace: Tennessee Research and Creative, Knoxville, TN, USA, 2014. Available online: http://trace.tennessee.edu/utk_chanhonoproj (accessed on 1 May 2014).

- Leistner, L.; Gorris, L.G. Food preservation by hurdle technology. Trends Food Sci. Technol. 1995, 6, 41–46. [Google Scholar] [CrossRef]

- Skandamis, P.N.; Nychas, G.-J.E. Development and Evaluation of a Model Predicting the Survival of Escherichia coli O157:H7 NCTC 12900 in Homemade Eggplant Salad at Various Temperatures, pHs, and Oregano Essential Oil Concentrations. Appl. Environ. Microbiol. 2000, 66, 1646–1653. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ayala-Zavala, J.F.; Oms-Oliu, G.; Odriozola-Serrano, I.; González-Aguilar, G.A.; Alvarez-Parrilla, E.; Martín-Belloso, O. Bio-preservation of fresh-cut tomatoes using natural antimicrobials. Eur. Food Res. Technol. 2007, 226, 1047–1055. [Google Scholar] [CrossRef]

- Giner, M.J.; Vegara, S.; Funes, L.; Martí, N.; Saura, D.; Micol, V.; Valero, M. Antimicrobial activity of food-compatible plant extracts and chitosan against naturally occurring micro-organisms in tomato juice. J. Sci. Food Agric. 2012, 92, 1917–1923. [Google Scholar] [CrossRef] [PubMed]

- Antunes, M.D.; Rodrigues, D.; Pantazis, V.; Cavaco, A.M.; Siomos, A.S.; Miguel, M.G. Nutritional quality changes of fresh-cut tomato during shelf life. Food Sci. Biotechnol. 2013, 22, 1–8. [Google Scholar] [CrossRef]

- Patanè, C.; Malvuccio, A.; Saita, A.; Rizzarelli, P.; Rapisarda, M.; Rizzo, V.; Muratore, G. Quality aspects of fresh-cut ‘long-storage tomato’ as affected by package, calcium chloride and storage time. Int. J. Food Sci. Technol. 2017, 53, 819–827. [Google Scholar] [CrossRef]

| LRI 1 | Compounds | % Area 2 |

|---|---|---|

| 595 | ethyl acetate | 0.010 |

| 741 | methyl isovalerate | 0.047 |

| 743 | methyl-2-methyl-butyrate | Tr |

| 820 | methyl tiglate | 0.022 |

| 821 | cis-3-hexenol | Tr |

| 852 | ethyl isobutylketone | 0.015 |

| 919 | thujene | 0.250 |

| 926 | α-pinene | 0.263 |

| 937 | camphene | 0.058 |

| 959 | oct-1-en-3-ol | 0.607 |

| 975 | myrcene | 1.026 |

| 988 | a-phellandrene | 0.125 |

| 994 | unknown alkane (CnH2n+2) | 0.026 |

| 996 | δ-3-carene | 0.053 |

| 1001 | a-terpinene | 1.103 |

| 1005 | p-cymene | 6.502 |

| 1012 | β-phellandrene | 0.132 |

| 1013 | limonene | 0.172 |

| 1020 | cis-ocimene | 0.022 |

| 1032 | trans-ocimene | 0.053 |

| 1045 | γ-terpinene | 9.014 |

| 1048 | cis-sabinene hydrate | 0.065 |

| 1059 | unknown | 0.120 |

| 1075 | terpinolene | 0.079 |

| 1082 | linalol | 0.129 |

| 1097 | unknown alkane (CnH2n+2) | 0.024 |

| 1115 | unknown | 0.130 |

| 1147 | borneol | 0.260 |

| 1158 | terpin-4-ol | 0.316 |

| 1169 | α-terpineol | 0.100 |

| 1194 | unknown alkane (CnH2n+2) | 0.087 |

| 1212 | citronellol | 0.101 |

| 1213 | thymyl methyl ether | 0.033 |

| 1256 | citronellyl formiate | 0.027 |

| 1262 | indol | 0.020 |

| 1283 | thymol | 48.120 |

| 1294 | carvacrol | 27.190 |

| 1315 | unknown | 0.150 |

| 1388 | unknown alkane (CnH2n+2) | 0.032 |

| 1398 | unknown alkane (CnH2n+2) | 0.059 |

| 1413 | caryophellene | 1.060 |

| 1423 | unknown | 0.100 |

| 1433 | unknown sesquiterpene | 0.050 |

| 1446 | humulene | 0.120 |

| 1488 | υnknown sesquiterpene | 0.070 |

| 1500 | β-bisabolene | 1.720 |

| Microbial Species | Essential Oil | Metronidazole | Gentamycin | Voriconazole | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MIC | NIC | MLC a | MIC | NIC | MLC a | MIC | NIC | MLC a | MIC a | NIC | MLC a | |

| L. monocytogenes | 1148 ± 27 | 528 ± 37 | 5738 | − | − | − | 3.121 ± 0.002 | 3.001 ± 0.002 | 16.0 | − | − | − |

| C. difficile | 1314 ± 27 | 204 ± 27 | 7404 | 0.064 ± 0.001 | 0.032 ± 0.001 | 4.0 | − | − | − | − | − | − |

| S. cerevisiae | 1647 a | - | 6590 | − | − | − | − | − | − | 0.25 | − | 1.00 |

| A. niger | 2197 a | - | 8786 | − | − | − | − | − | − | 0.50 | 2.00 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mitropoulou, G.; Oreopoulou, A.; Papavassilopoulou, E.; Vamvakias, M.; Panas, P.; Fragias, S.; Kourkoutas, Y. Origanum vulgare ssp. hirtum Essential Oil as a Natural Intrinsic Hurdle against Common Spoilage and Pathogenic Microbes of Concern in Tomato Juice. Appl. Microbiol. 2021, 1, 1-10. https://0-doi-org.brum.beds.ac.uk/10.3390/applmicrobiol1010001

Mitropoulou G, Oreopoulou A, Papavassilopoulou E, Vamvakias M, Panas P, Fragias S, Kourkoutas Y. Origanum vulgare ssp. hirtum Essential Oil as a Natural Intrinsic Hurdle against Common Spoilage and Pathogenic Microbes of Concern in Tomato Juice. Applied Microbiology. 2021; 1(1):1-10. https://0-doi-org.brum.beds.ac.uk/10.3390/applmicrobiol1010001

Chicago/Turabian StyleMitropoulou, Gregoria, Antigoni Oreopoulou, Eleni Papavassilopoulou, Manolis Vamvakias, Panayiotis Panas, Stavros Fragias, and Yiannis Kourkoutas. 2021. "Origanum vulgare ssp. hirtum Essential Oil as a Natural Intrinsic Hurdle against Common Spoilage and Pathogenic Microbes of Concern in Tomato Juice" Applied Microbiology 1, no. 1: 1-10. https://0-doi-org.brum.beds.ac.uk/10.3390/applmicrobiol1010001